Water-soluble fertilizer purification treatment method

A purification treatment and water-soluble technology, applied in liquid fertilizers, microbial treatment, fertilizer mixtures, etc., can solve the problems of few water-soluble fertilizer purification technologies, affecting the nutritional quality of water-soluble fertilizers, and high requirements for the degree of purification of water-soluble fertilizers, so as to improve soil. Nutritional status, good environmental protection, less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

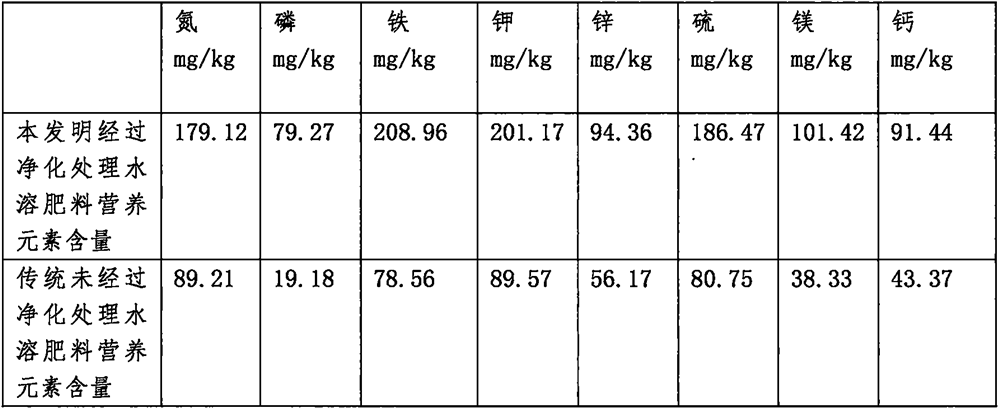

Embodiment 1

[0033] The composition ratio of the water-soluble fertilizer of the present invention includes 45 parts of pea pods, 35 parts of loofah vine, 30 parts of eucalyptus leaves, 50 parts of pig's trotter, 50 parts of ethanol solution, 30 parts of potassium dihydrogen phosphate, and 25 parts of magnesium aluminum silicate. 60 parts of Bacillus subtilis, 40 parts of Bacillus colloid, 30 parts of yeast, 52 parts of superphosphate, 48 parts of liquid ammonia, 25 parts of ammonium polyphosphate, 10 parts of diethyl aminoethyl hexanoate, 36 parts of liquid nitrogen fertilizer, liquid potash fertilizer 39 parts, 10 parts of sodium nitrophenolate, 9 parts of ethalicin, 11 parts of polyaspartic acid, 15 parts of polyglutamic acid, 12 parts of alkyl glycosides, 15 parts of iron sulfate, 11 parts of gibberellin, tetramethyl 27 parts of base glutaric acid, 20 parts of ferrous sulfate heptahydrate, 15 parts of mepion, 7 parts of potassium humate, 19 parts of polyacrylamide, 17 parts of boric aci...

Embodiment 2

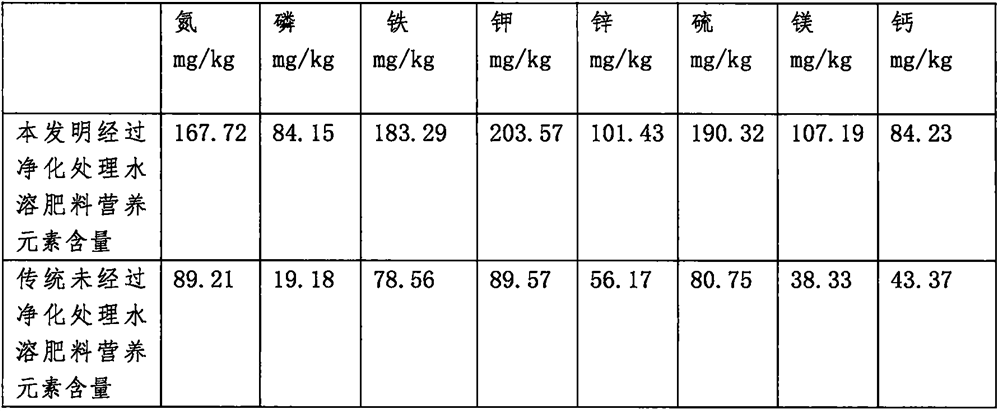

[0048] The composition ratio of the water-soluble fertilizer of the present invention includes: 31 parts of highland barley seedlings, 37 parts of lettuce seedlings, 29 parts of eucalyptus leaves, 60 parts of bovine hoof, 39 parts of ethanol solution, potassium dihydrogen phosphate 30 parts, 21 parts of magnesium aluminum silicate, 25 parts of ammonium polyphosphate, 25 parts of Bacillus subtilis, 41 parts of Bacillus colloid, 50 parts of yeast, 50 parts of superphosphate, 35 parts of liquid ammonia, 38 parts of phosphoric acid solution, 15 parts of diethyl aminoethyl hexanoate, 27 parts of liquid nitrogen fertilizer, 25 parts of liquid potash fertilizer, 27 parts of sodium nitrophenolate, 14 parts of acetonitrile, 8 parts of polyaspartic acid, 27 parts of alkyl glycosides, 20 parts of sodium a-naphthalene acetate , 16 parts of gibberellin, 8 parts of chlorfenuron, 19 parts of ferrous sulfate heptahydrate, 12 parts of methylphenidate, 17 parts of potassium humate, 26 parts of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com