Method for reducing content of volatile organic compounds in polyether polyol

A technology of volatile organic compounds and polyether polyols, which is applied in the field of chemical synthesis, can solve problems such as increasing production costs, and achieve the effects of saving production costs, reducing concentrations, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

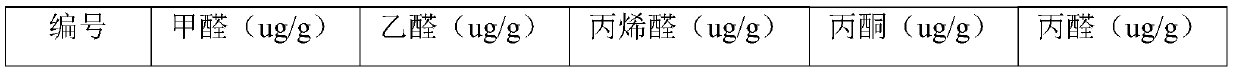

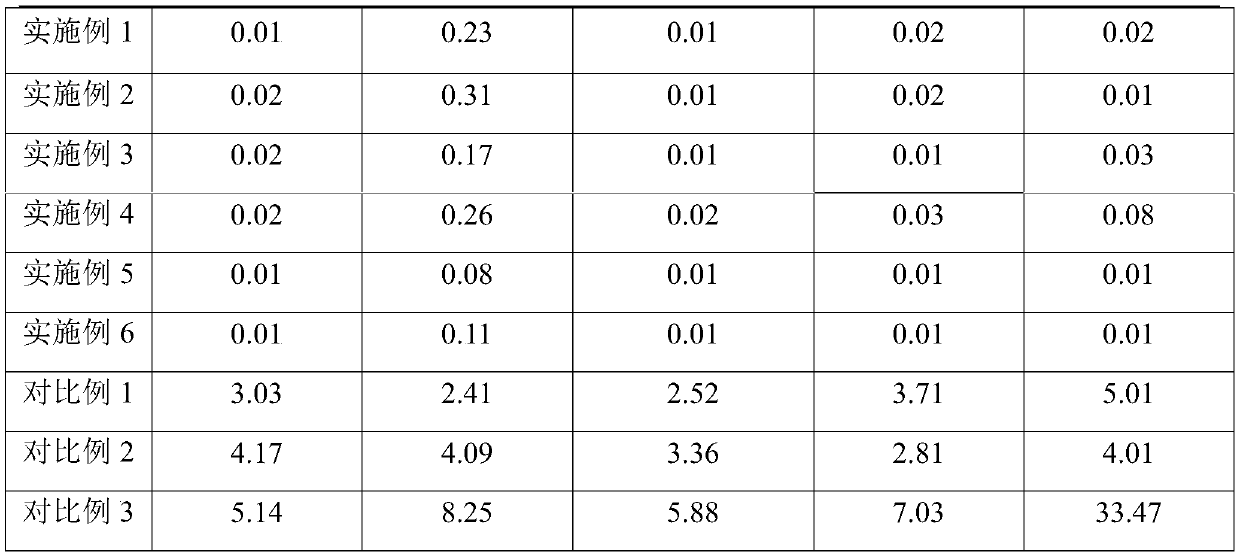

Examples

Embodiment 1

[0025] Add 1000g of polyether polyol to be treated into a 5-liter stainless steel reactor, nitrogen replacement 3 times (oxygen content in the reactor ≤ 100ppm), start the reactor to stir, heat the material in the reactor to 50°C, and pour it under the protection of nitrogen Add 0.01g aldehyde remover (propylene glycol: phosphoric acid: 2 functionalities, 400 molecular weight polyether polyol = 1:1:1) into the reactor, during which the reactor stirrer keeps rotating), and nitrogen replacement is carried out on the reactor (reaction Oxygen content in the kettle ≤ 100ppm), and stirred for 10 minutes, then added 10g of pure water and 1g of magnesium silicate adsorbent to the reaction kettle, stirred for 10 minutes respectively, and then nitrogen bubbled the above materials, and dried under reduced pressure , Filtration, the polyether polyol finished product is obtained.

Embodiment 2

[0027] Add 1000g of polyether polyol to be treated in a 5-liter stainless steel reactor, nitrogen replacement 3 times (oxygen content in the reactor ≤ 100ppm), start the reactor to stir, heat the material in the reactor to 130°C, and pour it under the protection of nitrogen Add 0.5g aldehyde remover to the reaction kettle (a mixture of ethylene glycol and tert-butanol with a mass ratio of 1:1: a mixture of sulfuric acid and nitric acid with a mass ratio of 1:1: a 2-functionality, 4000 molecular weight with a mass ratio of 1:1 Polyether polyol and polyether polyol mixture with 3 functionalities of 3000 molecular weight = 1:5:50), during which the stirrer of the reactor kept rotating, the reactor was replaced with nitrogen (oxygen content in the reactor ≤ 100ppm), and the timing was stirred After 120 minutes, 100g of pure water and 10g of aluminum silicate adsorbent were successively added to the reaction kettle, stirred for 120 minutes respectively, and then the above materials ...

Embodiment 3

[0029] Add 1000g of polyether polyol to be treated in a 5-liter stainless steel reactor, nitrogen replacement 3 times (oxygen content in the reactor ≤ 100ppm), start the reactor to stir, heat the material in the reactor to 110°C, and pour it under the protection of nitrogen Add 0.05g of aldehyde remover (ethylene glycol: sulfuric acid: 3 functionalities, 3000 molecular weight polyether polyol = 1:5:20) into the reactor, during which the reactor stirrer keeps rotating, and the reactor is replaced with nitrogen ( Oxygen content in the reaction kettle ≤ 100ppm), and stirred for 20 minutes, then added 20g of pure water and 8g of magnesium aluminum silicate adsorbent to the reaction kettle, stirred for 20 minutes respectively, and then carried out nitrogen bubbling to the above materials, reduced Drying under pressure and filtering to obtain the finished polyether polyol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com