Patents

Literature

43results about How to "Achieve continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

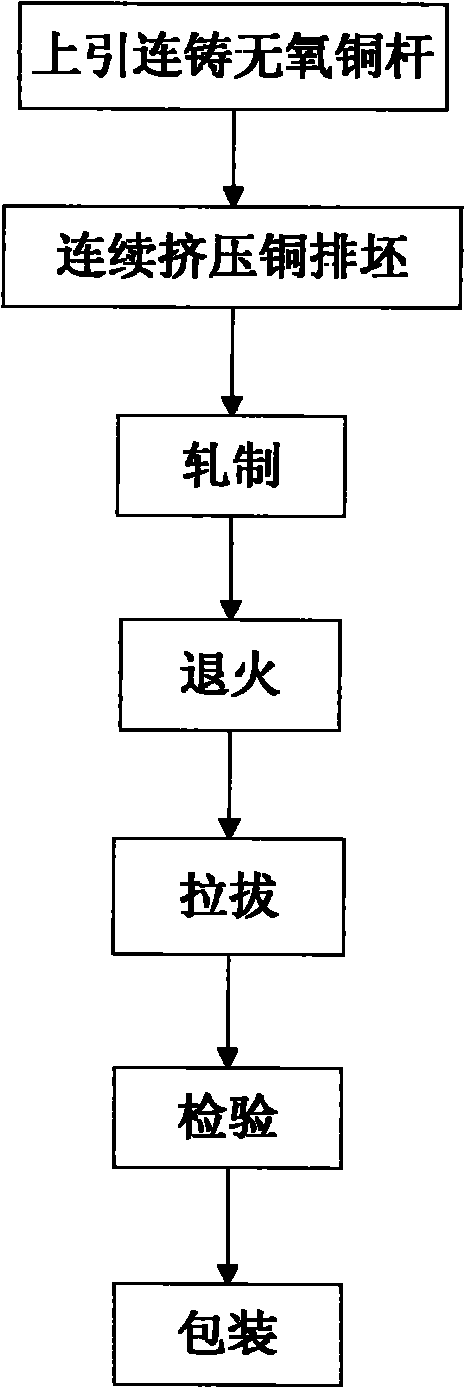

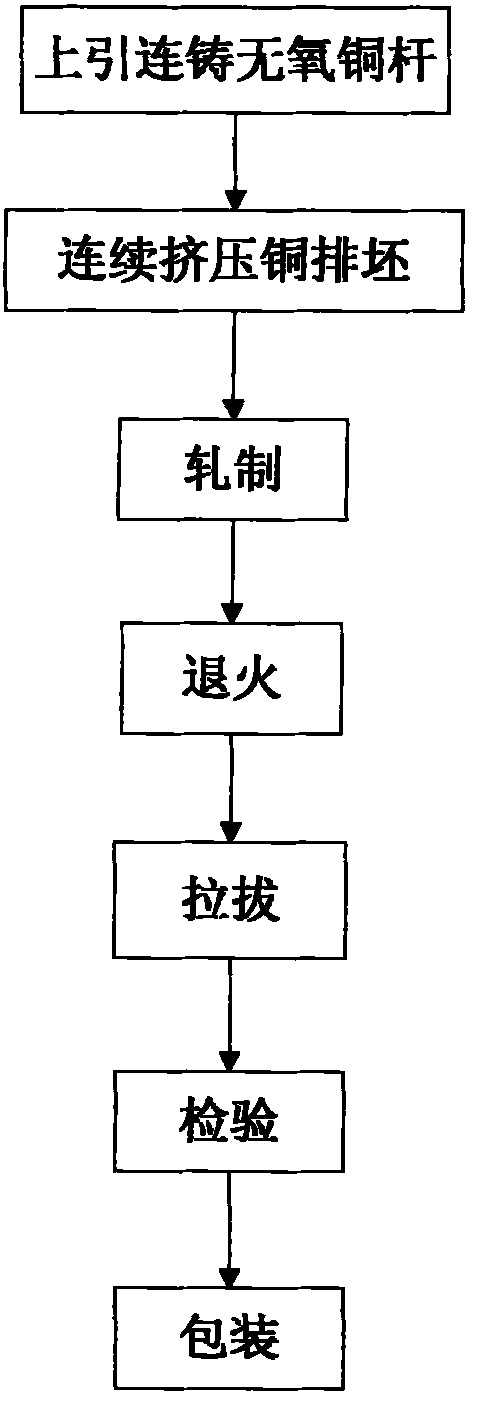

Production method of conducting copper bars for bus duct with large flakiness ratio

InactiveCN101916624AAvoid picklingImprove working environmentOpen bus-bar installationsCable/conductor manufactureLow oxygenHigh conductivity

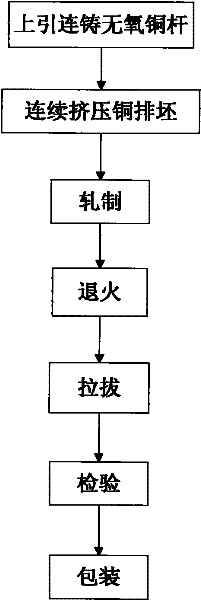

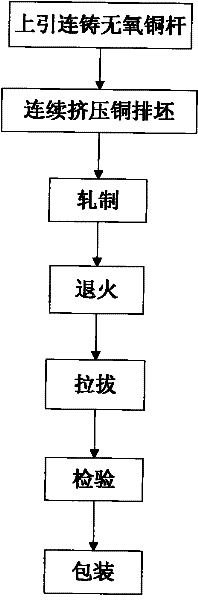

The invention discloses a production method of conducting copper bars for a bus duct with a large flakiness ratio, belonging to the technical field of processing of non-ferrous metals. The production method is characterized by comprising the following steps of: upward continuously casting oxygen-free copper bars, continuously extruding copper bar billets, rolling, annealing, drawing, checking and packaging. By adopting the continuous extrusion technology to produce the copper bar billets, the continuous production can be realized, and the weight of each roll of copper bar billets can reach more than 3 tons. Moreover, because the copper bar billets are produced in a roll shape, the defect of cutting the head and the tail of each copper bar in the traditional production process is avoided, and the yield of the product reaches more than 90%. Meanwhile, by reasonably setting continuous extrusion process parameters, rolling rate and the like, the invention effectively improves the quality of the product and has the advantages of high purity, low oxygen content, high conductivity, excellent surface quality and the like. The product is detected to show that the content of Cu and Ag is greater than or equal to 99.97%, the content of O is less than or equal to 10ppm, and the conductivity is 98-101% according to the IACS.

Owner:浙江力博实业股份有限公司

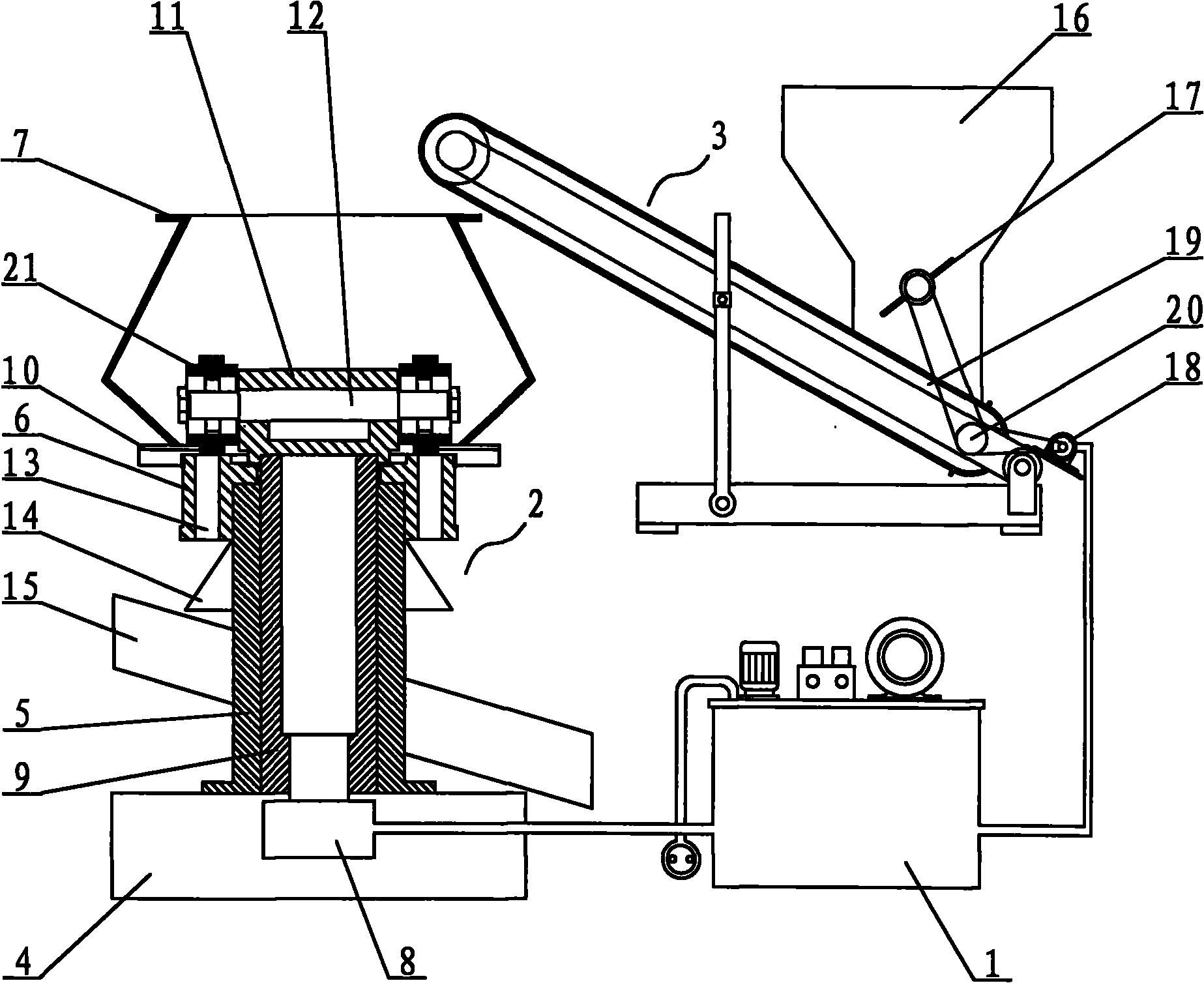

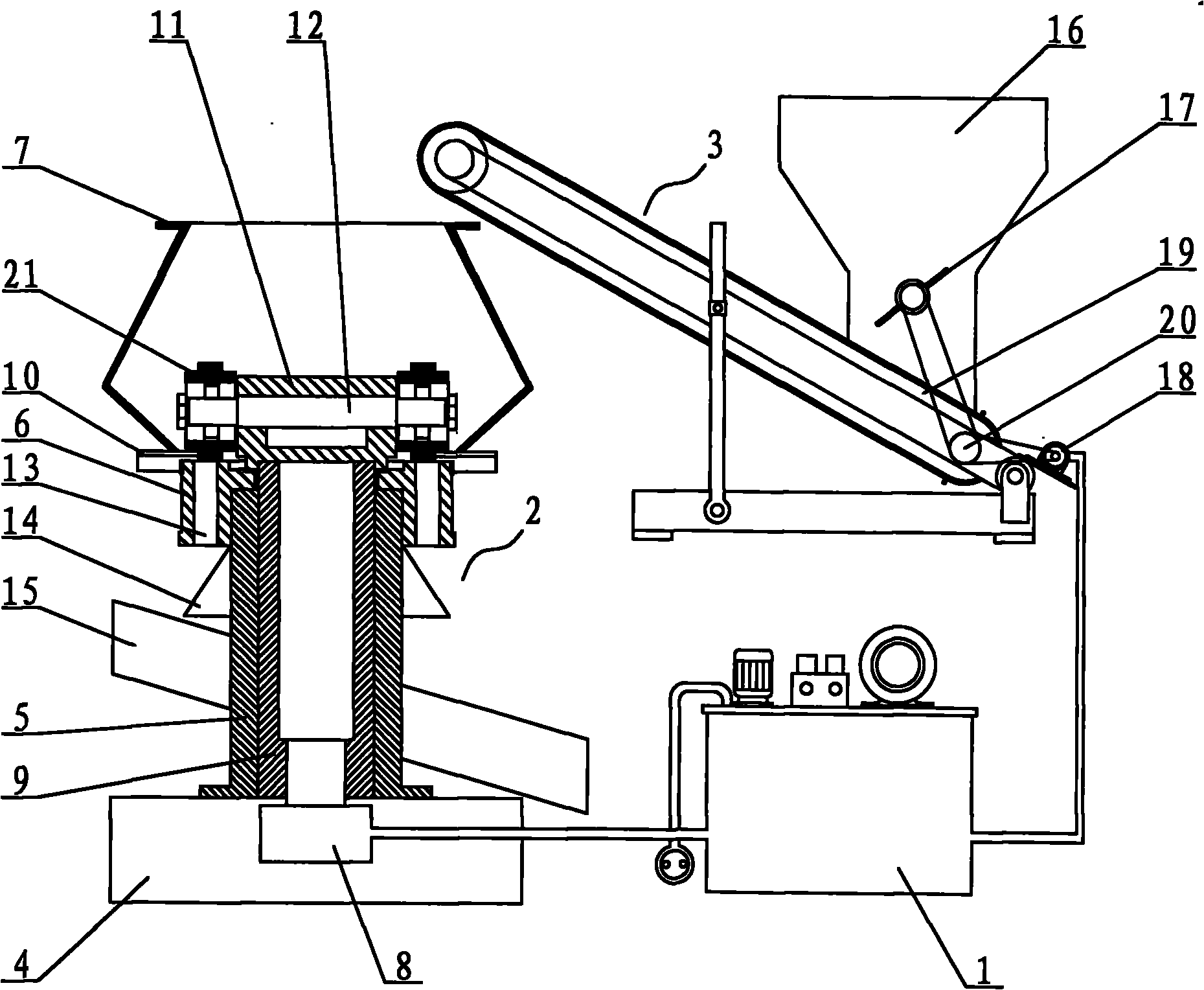

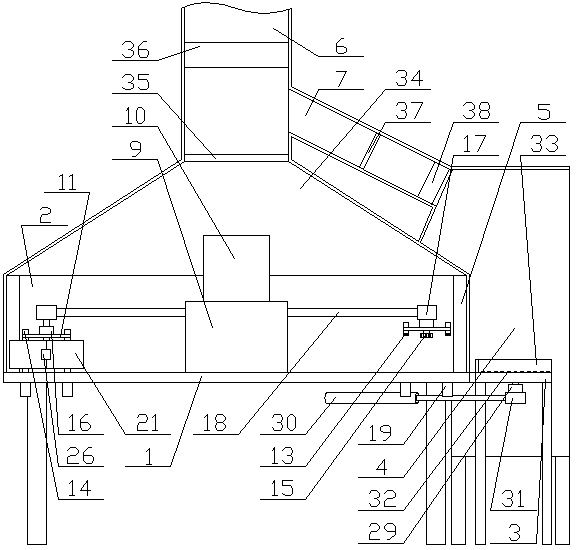

Hydraulic forming machine set for moulding and solidifying biomass

InactiveCN101774284AHigh calorific valueImprove rolling effectShaping pressHigh densityMechanical engineering

The invention relates to a hydraulic forming machine set for moulding and solidifying biomass, which comprises a hydraulic station, a feeder, a forming machine and a control cabinet, wherein the feeder comprises a hopper and a conveyer belt; the forming machine is formed by connecting a base, a support cylinder and a die pressing device sequentially; a main shaft is arranged in the support cylinder; the die pressing device comprises a die pressing plate, a connecting plate, a pinch roller shaft and two pinch rollers; the die pressing plate is sleeved at the top end of the support cylinder; a circle of circular discharging die holes are formed on the die pressing plate; the top end of the main shaft is connected with the connecting plate; the pinch roller shaft runs through the connecting plate horizontally; the pinch rollers are respectively sleeved at both ends of the pinch roller shaft; and a track formed by rotating the pinch rollers around the main shaft is positioned above the discharging die holes of the die pressing plate and is in clearance fit with the upper surface of the die pressing plate. The hydraulic mould forming machine set is driven by full hydraulic power, and the pinch rollers perform rotation while performing revolution, so that the biomass is formed by rolling compaction through the discharging die holes, and the hydraulic forming machine set has the advantages of simple integral structure, high hydraulic power, low energy consumption, long service life, good effect of rolling compaction, high density of formed blocks and good burning effect, and is suitable for forming various biomass straws.

Owner:江苏鼎绿科技有限公司

Method for smelting low-phosphorus steel through converter under condition of ultrahigh scrap ratio

ActiveCN113215347AImprove smelting scrap ratioReduce manufacturing costManufacturing convertersProcess efficiency improvementSmelting processControl system

The invention relates to a method for smelting low-phosphorus steel through a converter under the condition of ultrahigh scrap steel ratio. According to the method, the 130t top-bottom combined blown converter is adopted for smelting, a molten iron turnover mode of one tank to the bottom is adopted, 7-8 tons of scrap steel is added to the tank bottom, the total quantity of molten iron is 112-115t, the temperature of the desulfurized molten iron is 1310-1360 DEG C, the mass percentage of silicon is 0.3-0.6%, the quantity of the added scrap steel is 38-48t, and the specific smelting process comprises the following steps of implementing (1) a slag remaining operation system, (2) a waste steel loading system, (3)a slag adding and oxygen supplying system, (4) a bottom blowing system, and (5) an end point control system so as to realize smelting of the low-phosphorus steel under the condition of ultrahigh waste steel ratio. The method has the advantages that a complete and effective control method is formed through optimization of converter smelting operation, a large penetration depth ratio oxygen lance, a combined blowing technology and the like on the basis of practice of an existing high scrap steel ratio technology, and the purposes of stable smelting process, cost reduction, terminal point controllability and low-phosphorus tapping can be achieved in the charging process of the 130t converter at high scrap ratio.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

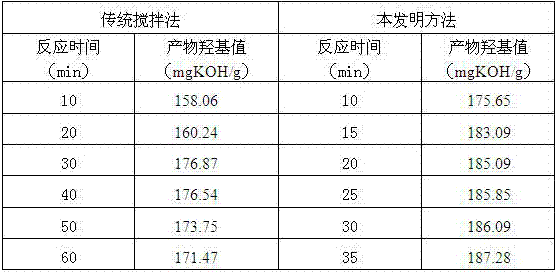

New method for preparation of plant oil fatty acid ethyl ester

The invention relates to a new method for preparation of plant oil fatty acid ethyl ester, wherein the method comprises the following steps: (1) taking plant oil, and preheating the plant oil to 65-75 DEG C; (2) taking KOH, putting the KOH into absolute ethyl alcohol, and making the KOH completely dissolved in the absolute ethyl alcohol by ultrasonic treatment, to obtain a KOH ethyl alcohol solution; (3) mixing the preheated plant oil with the KOH ethyl alcohol solution, then connecting to a hydrodynamic cavitation device, and carrying out a circular reaction for 10-30 min under a condition of the temperature of 65-75 DEG C; and (4) after the end of the reaction, adjusting the pH value of the product to neutral, and carrying out rotary evaporation for 25-35 min under a condition of the temperature of 65-75 DEG C, to obtain the plant oil fatty acid ethyl ester. With the plant oil as the main raw material, and with use of the hydrodynamic cavitation technology, the fatty acid ethyl ester is prepared, the preparation effect is good, and the method has the advantages of convenience in use, low cost and less investment, and can effectively improve the reaction rate, shorten the reaction time and reduce energy consumption.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Biological method for expelling flies in cage-culture chicken house

InactiveCN106857408AEliminate odorAvoid secondary pollutionClimate change adaptationExcrement fertilisersCage cultureHermetia illucens

The invention discloses a biological method for expelling flies in a cage-culture chicken house. The method comprises the following steps: cleaning a hencoop excrement-falling area, and then uniformly scattering 1-20mm thick hermetia illucens excrement, 1 day later, uniformly scattering 4-6 days old hermetia illucens larvae to the excrement-falling area in the density of 1-3 ten thousand pieces / square meter, and cleaning the chicken manure after the hermetia illucens larvae grow to be prepupa. According to the method provided by the invention, the hermetia illucens excrement is put into a chicken manure pit in advance, and meanwhile, the hermetia illucens larvae at the optimal utilization stage (4-6 days old) are directly utilized, so that the continuous production of fly-expelling matters and efficient fly expelling can be realized and the fly-expelling efficiency is greatly increased. The method provided by the invention is an ecology-friendly fly-expelling technique, is capable of extremely avoiding the application and residue of the harmful substances, such as antibiotics and pesticides, to human food chain and is capable of protecting human health.

Owner:广州翘楚昆虫繁育中心有限公司

A waste heat recovery evaporative crystallization device

ActiveCN105597363BAchieve instant evaporationAchieve continuous productionEvaporator accessoriesSolution crystallizationHeat fluxHigh energy

Owner:安徽国孚环境科技股份有限公司

Production method of conducting copper bars for bus duct with large flakiness ratio

InactiveCN101916624BIncrease productivityAchieve continuous productionOpen bus-bar installationsCable/conductor manufactureLow oxygenHigh conductivity

The invention discloses a production method of conducting copper bars for a bus duct with a large flakiness ratio, belonging to the technical field of processing of non-ferrous metals. The production method is characterized by comprising the following steps of: upward continuously casting oxygen-free copper bars, continuously extruding copper bar billets, rolling, annealing, drawing, checking andpackaging. By adopting the continuous extrusion technology to produce the copper bar billets, the continuous production can be realized, and the weight of each roll of copper bar billets can reach more than 3 tons. Moreover, because the copper bar billets are produced in a roll shape, the defect of cutting the head and the tail of each copper bar in the traditional production process is avoided, and the yield of the product reaches more than 90%. Meanwhile, by reasonably setting continuous extrusion process parameters, rolling rate and the like, the invention effectively improves the quality of the product and has the advantages of high purity, low oxygen content, high conductivity, excellent surface quality and the like. The product is detected to show that the content of Cu and Ag is greater than or equal to 99.97%, the content of O is less than or equal to 10ppm, and the conductivity is 98-101% according to the IACS.

Owner:浙江力博实业股份有限公司

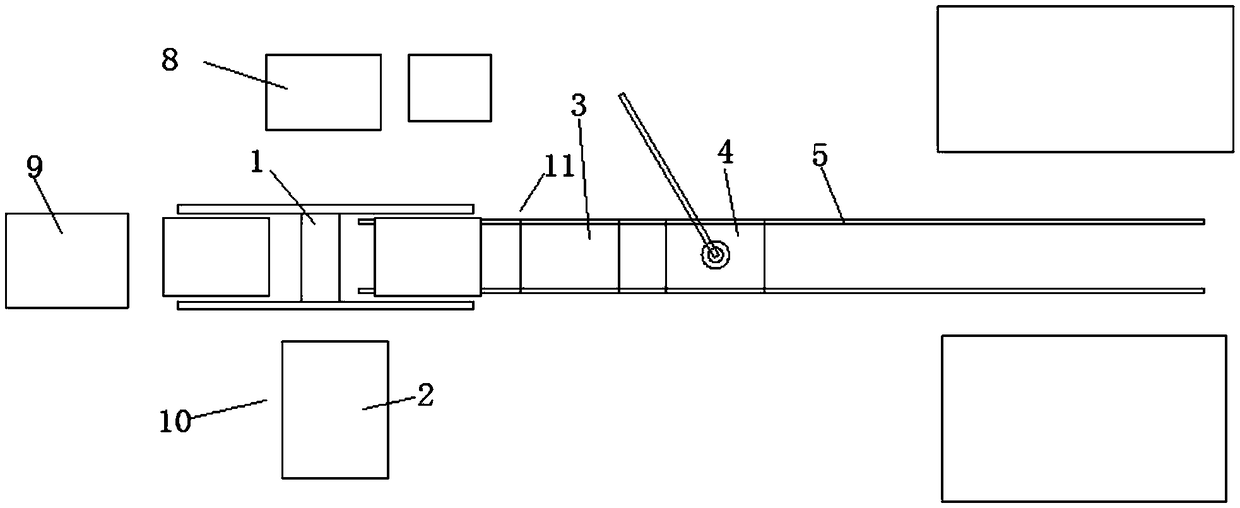

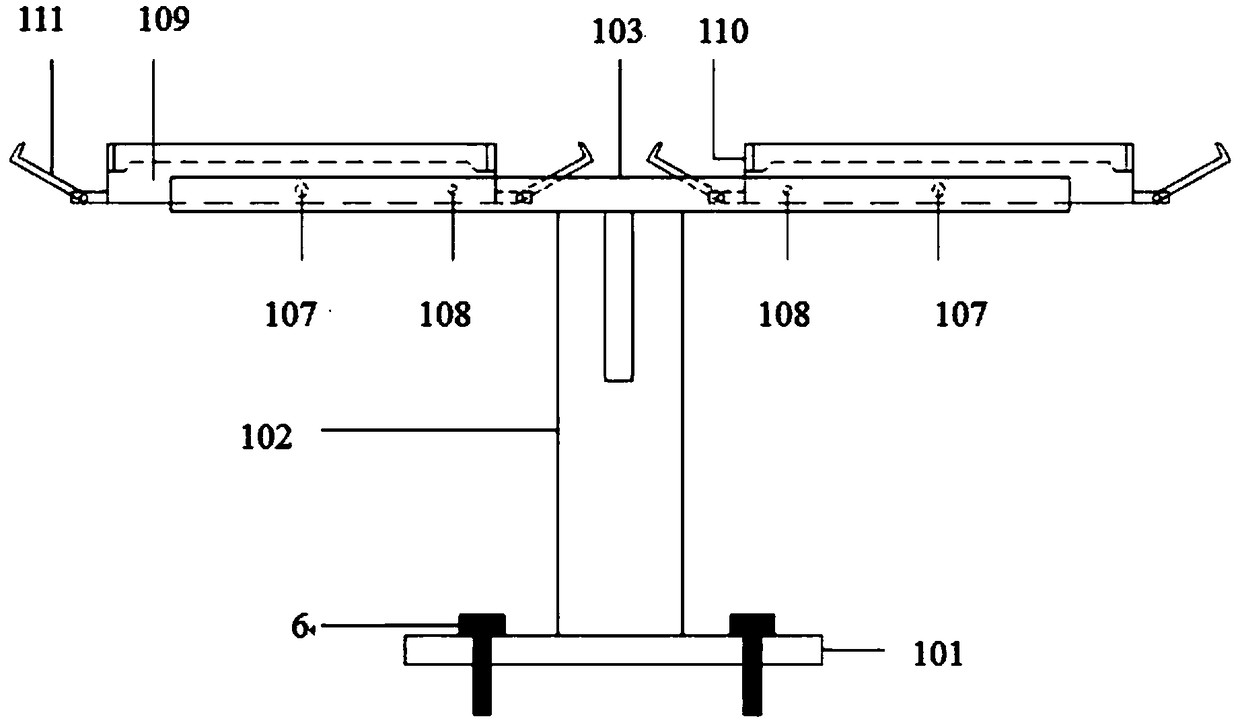

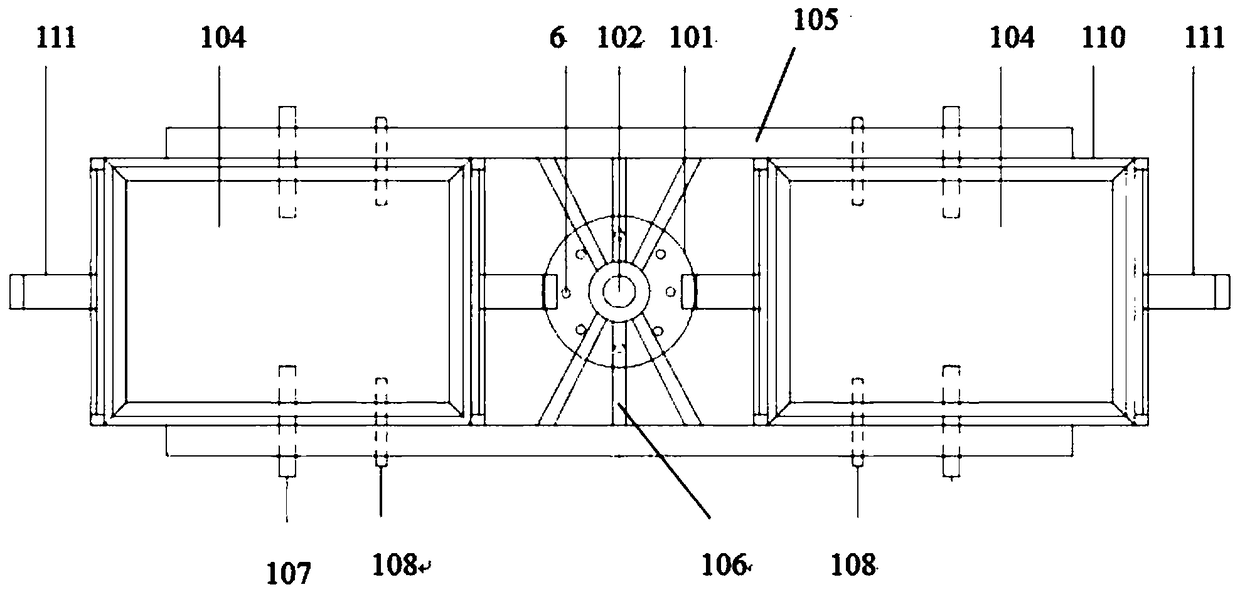

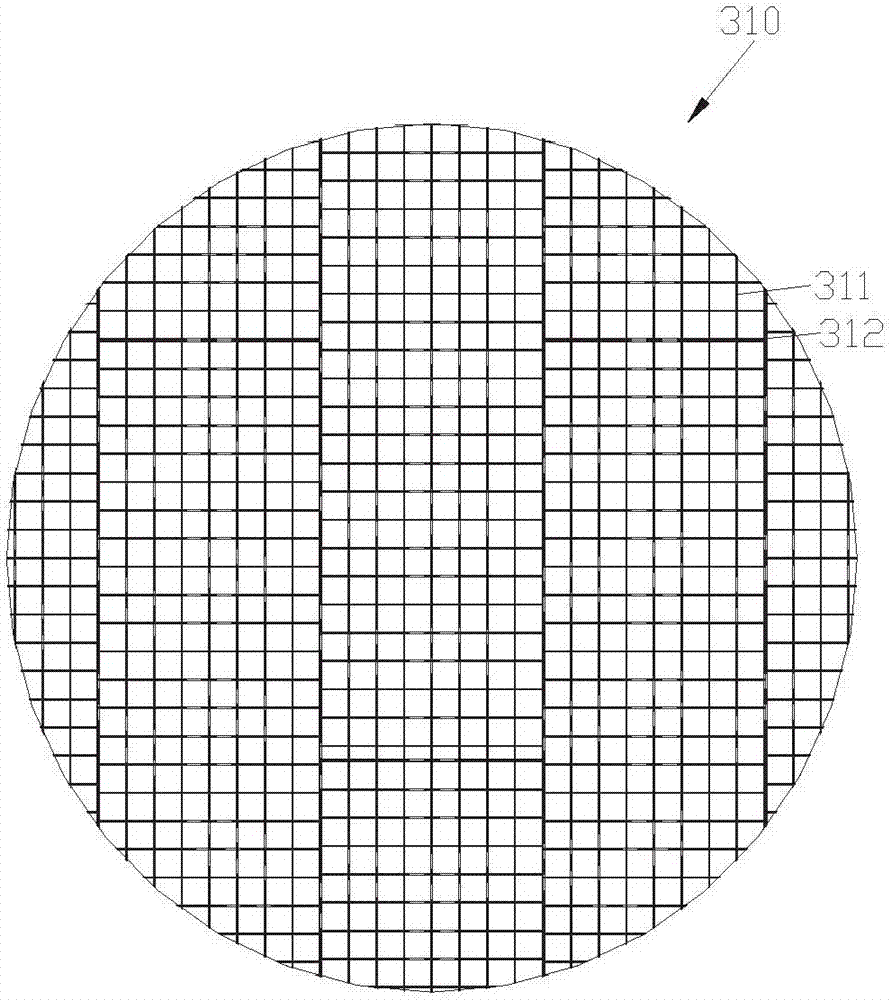

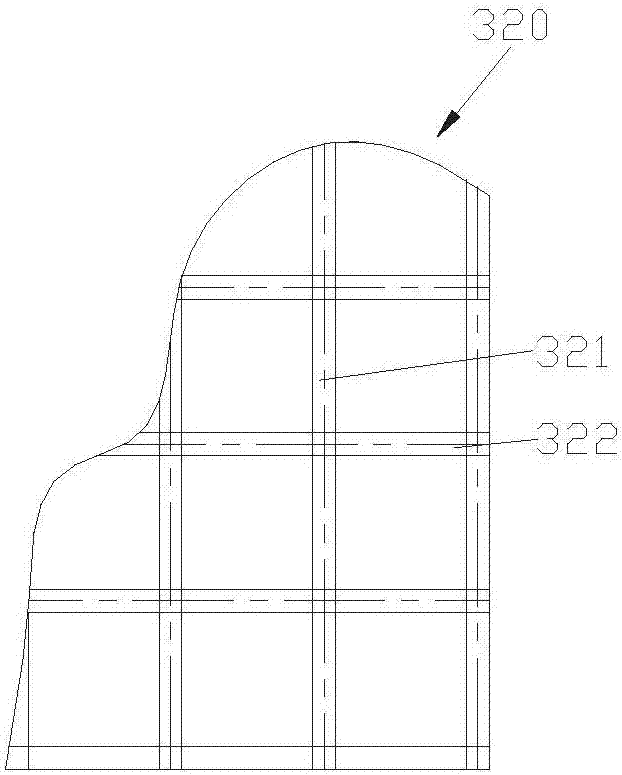

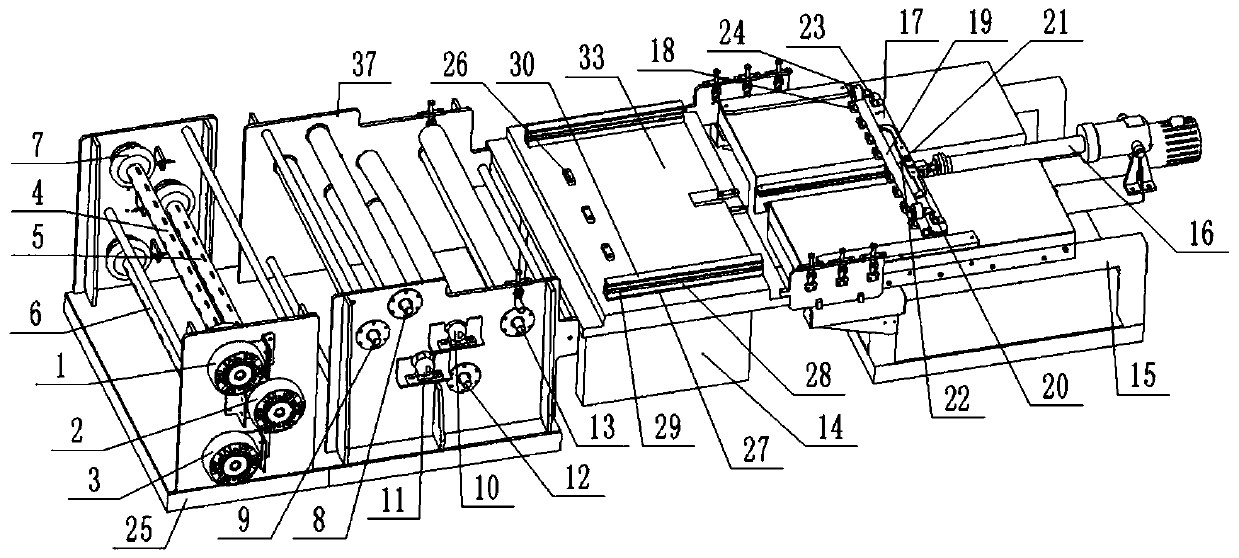

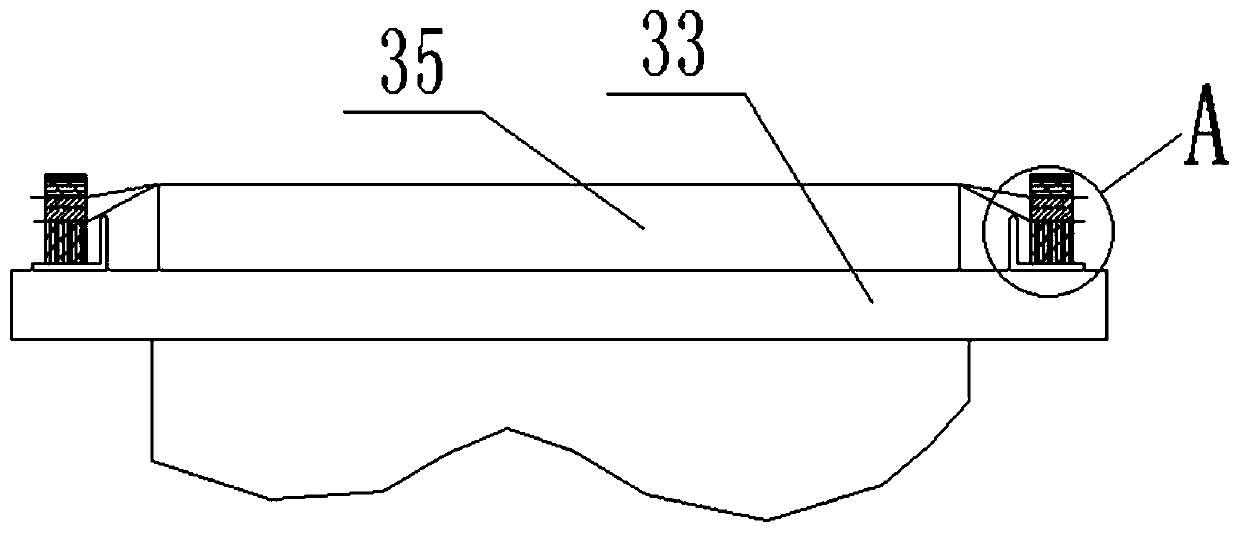

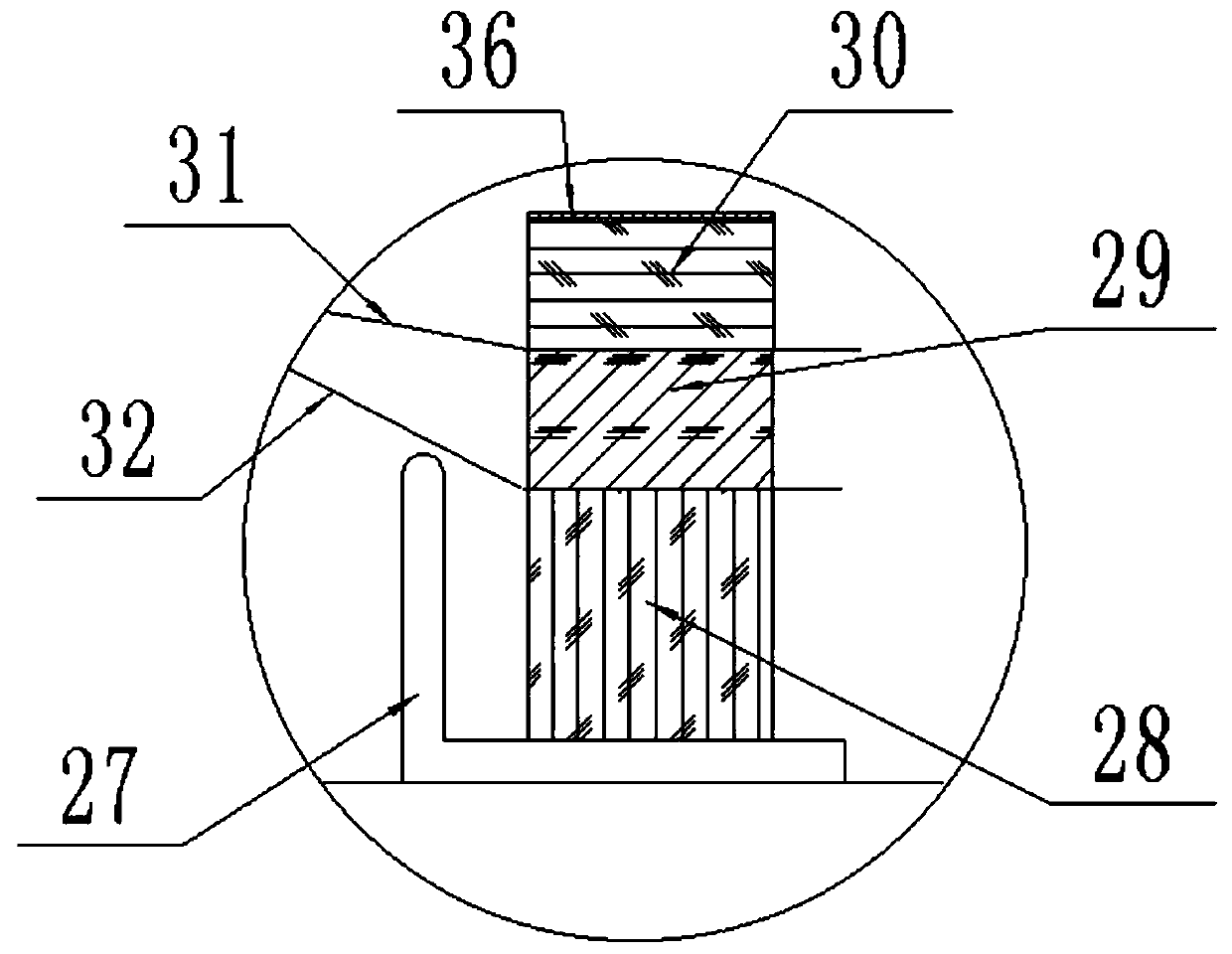

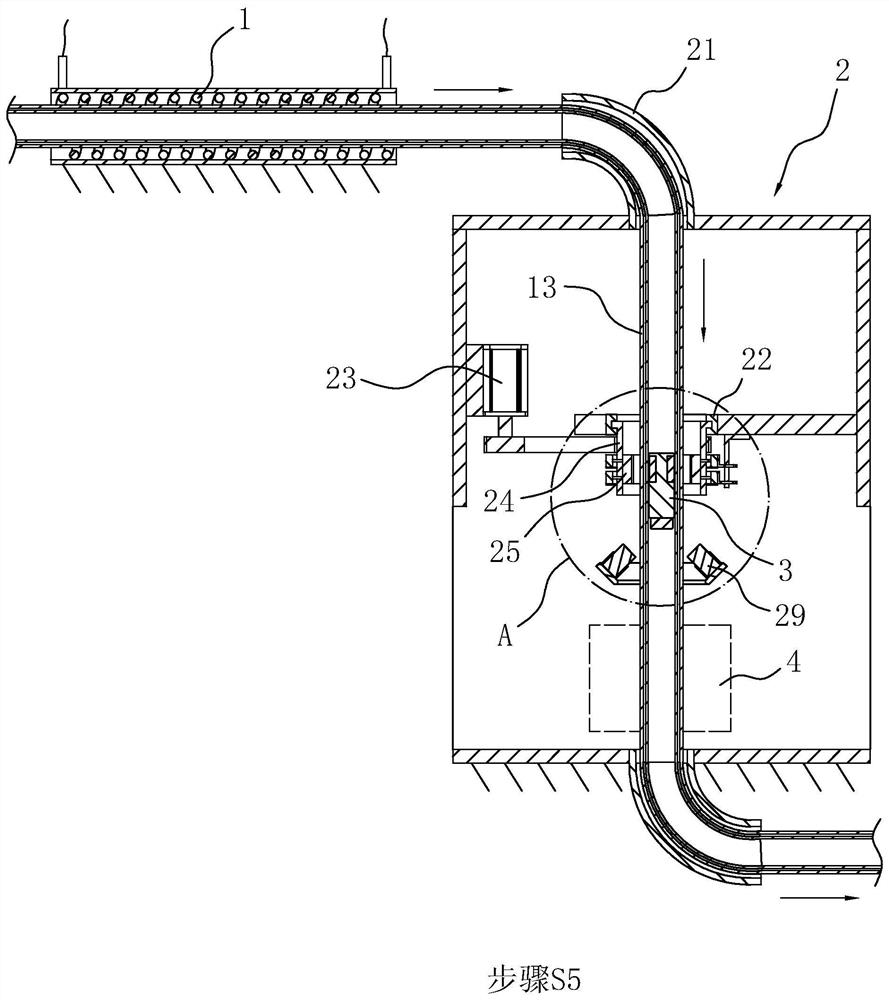

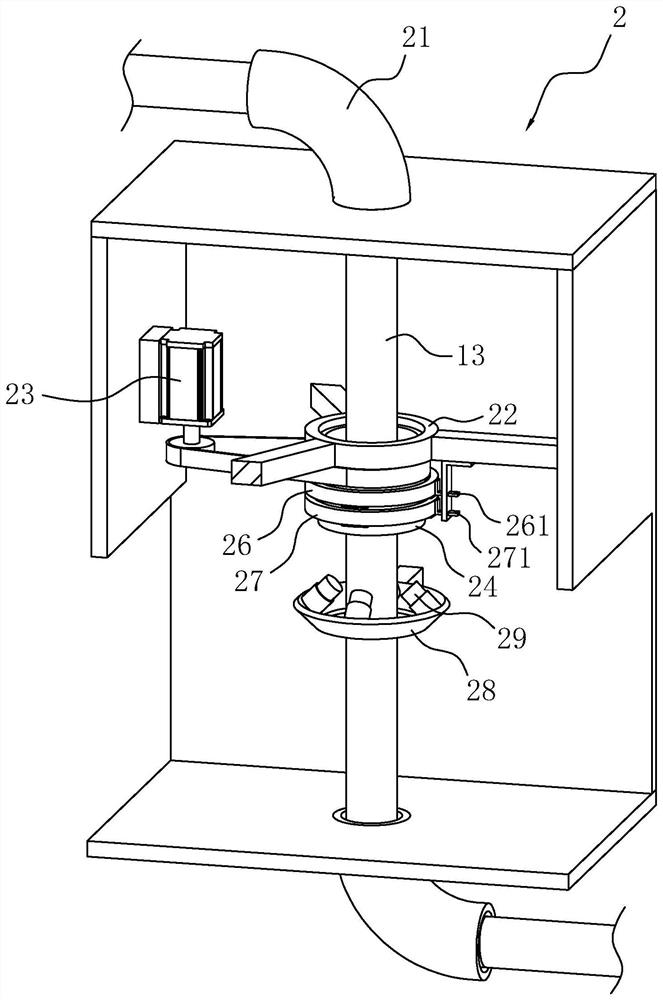

Production line of precast concrete members

ActiveCN109382905AReduce areaIncrease productivityDischarging arrangementCeramic shaping plantsContinuous productionPrecast concrete

The invention provides a production line of precast concrete members. The production line greatly reduces the area of a production site, reduces the construction of the production line and greatly improves the production efficiency. A turnover template can achieve continuous production of a pouring mold table, and a vibration table makes concrete more compact and controllable in quality. Large-scale arrangement of a fixing mold table is avoided, the demolding process is simplified, the area of a pouring site is reduced, the pouring quality is ensured, and meanwhile the situation is avoided that a large crane beam or tower crane is used for hoisting transportation; the process is simplified through turnover demolding, the occupied area of the production line is reduced, the labor use of theproduction line is reduced, equipment of the production line is simple, the miniaturization of the production line of the precast concrete members can be achieved, the turntable pouring die table canensure efficient operation of the production line, and the pouring quality of the members is ensured by arranging the liftable vibration table on the production line. The equipment input of the wholeproduction line is small, the labor use is low, and the occupied site is small while the operation is efficient.

Owner:江苏智信达建筑科技有限公司

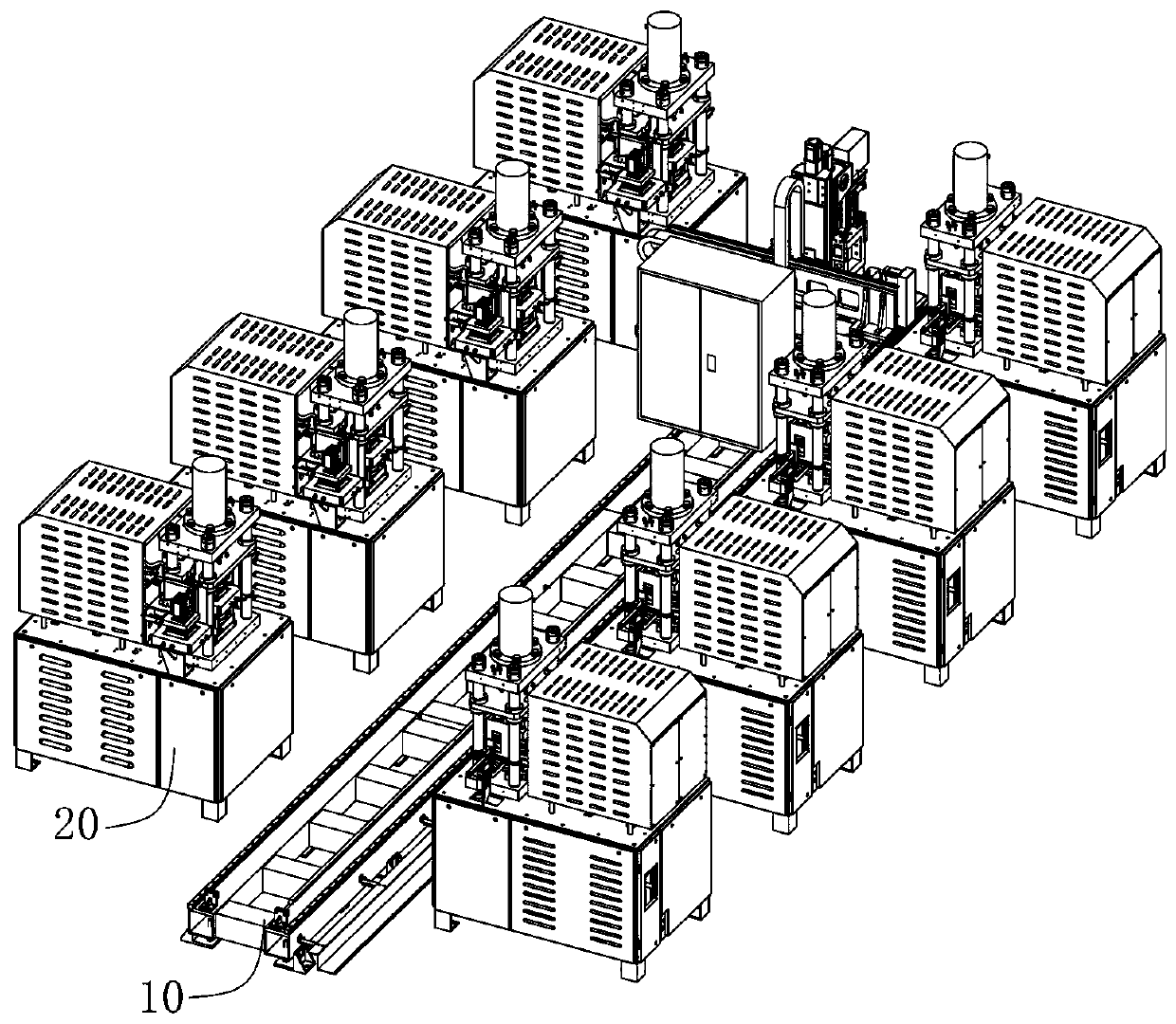

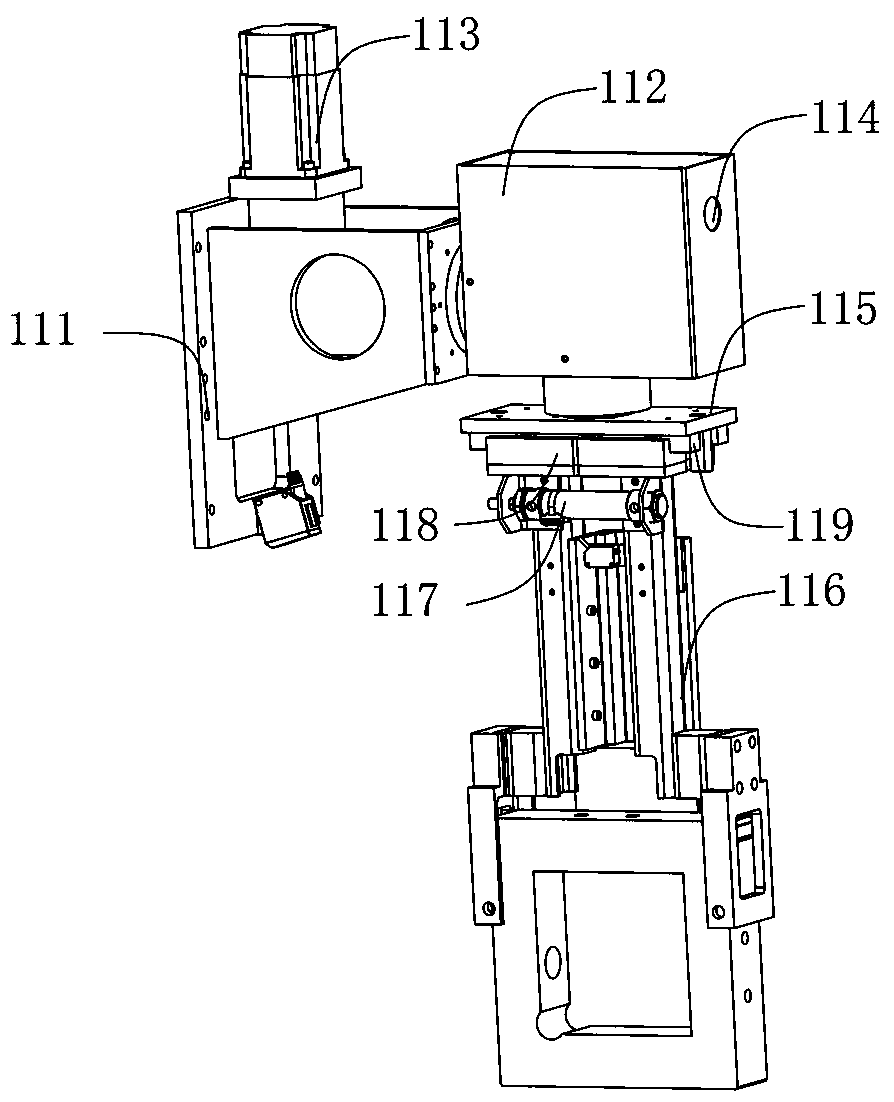

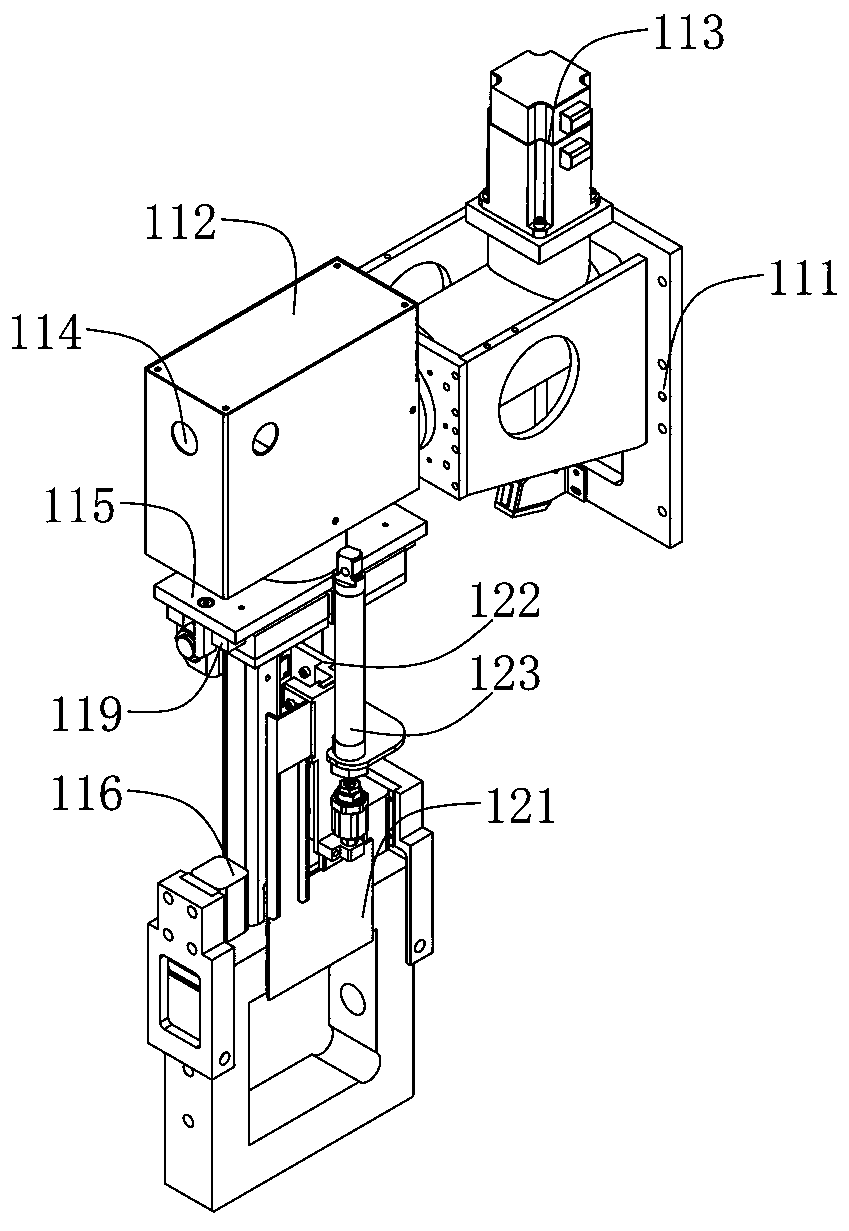

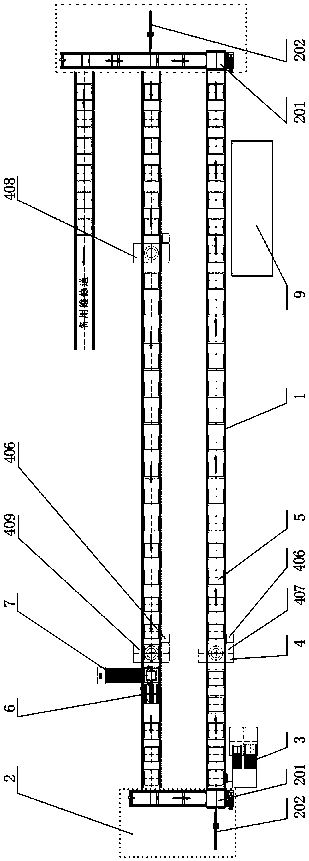

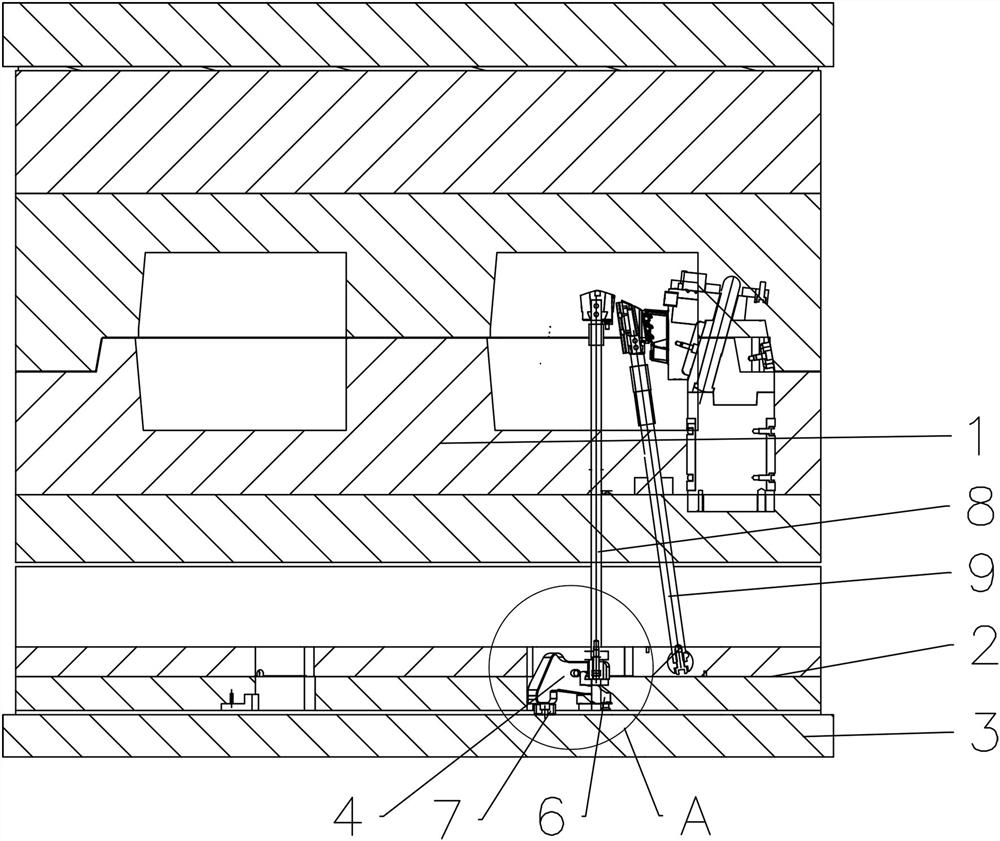

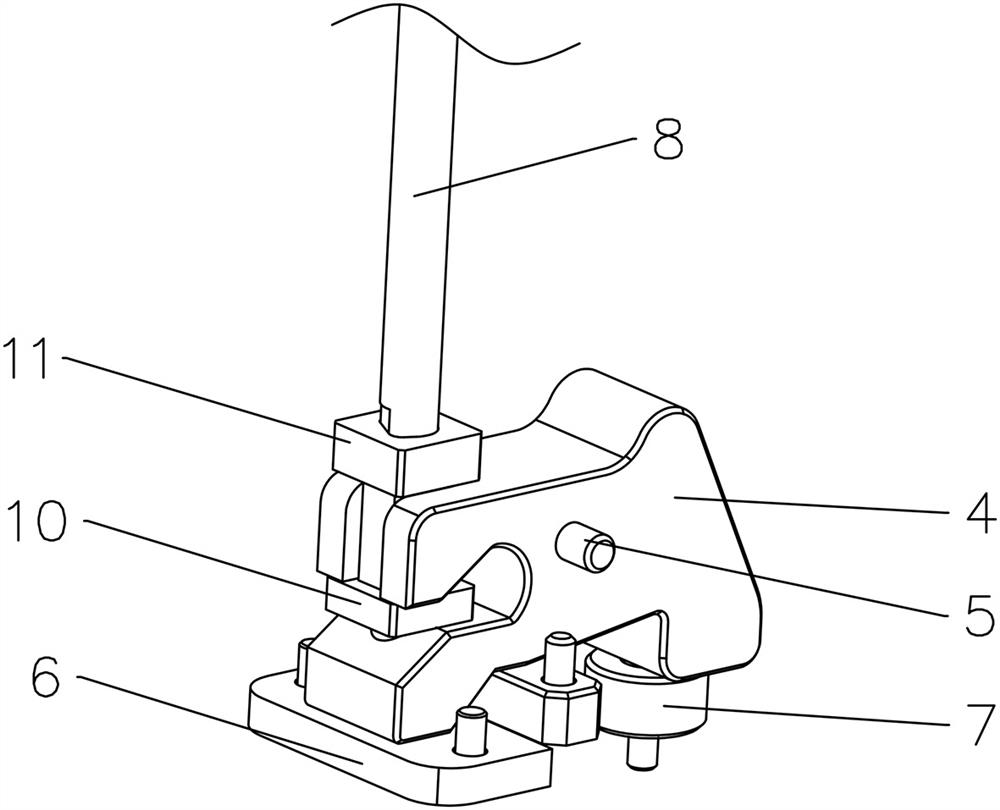

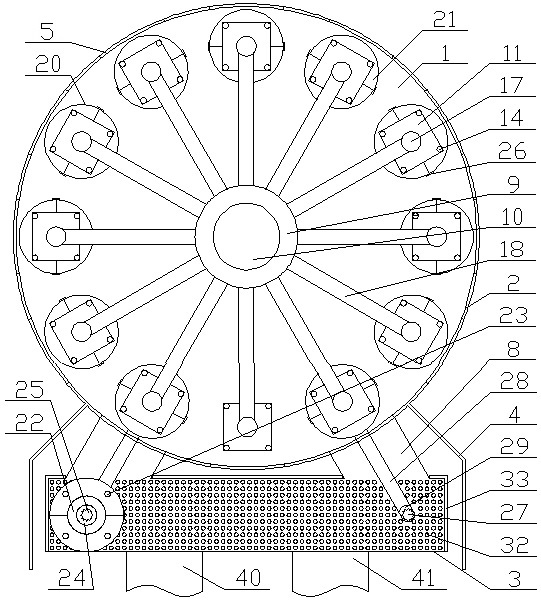

Automatic hot press sintering system and method for diamond tool bits

PendingCN108673360ARealize unified operationAvoid problems with work step interferenceGrinding devicesControl systemManipulator

The invention belongs to the technical field of hot press sintering machines, and discloses an automatic hot press sintering system and method for diamond tool bits. The system comprises a model framecapture manipulator, a plurality of hot press sintering machines and a control system, wherein the hot press sintering machines are respectively arranged at one side or two sides of the model frame capture manipulator; the model frame capture manipulator comprises a walking ground rack, a base, a transmission truss, a model frame capture device and a model frame tray; and the model frame capturedevice comprises a mounting seat, a suspension frame and a capture component. The method is an automatic diamond tool bit sintering process carried out by the automatic hot press sintering system. Thesystem and the method are reasonable in structural design, and are capable of realizing automatic operation, realizing collaborative adjustment operation in allusion to different process requirementsand greatly improving the production efficiency and sustainability of the whole hot press sintering process.

Owner:郑州金海威科技实业有限公司 +1

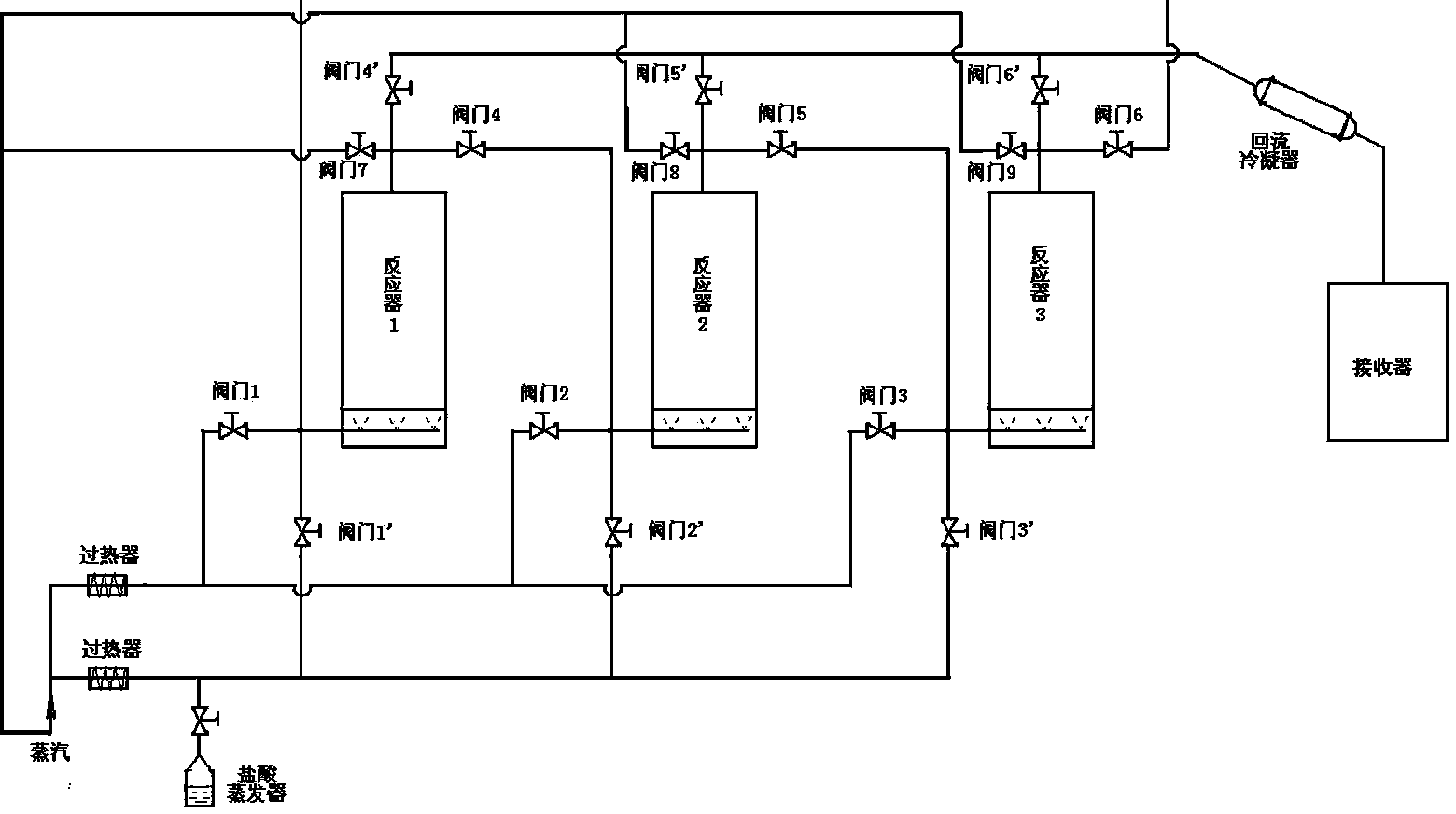

Gas phase acid catalytic biomass hydrolysis continuous production method of furfural

ActiveCN102766120BIncrease concentrationReduce material requirementsOrganic chemistryChemical industryGas phase

The invention discloses a gas phase acid catalytic biomass hydrolysis continuous production method of furfural and belongs to the field of chemical industry. The method includes that straw is used as a raw material, superheated steam and gas-phase acid are led in, a multi-kettle series connection gas phase acid catalyzed hydrolysis method is adopted, the straw performs hydrolysis reaction in the gas phase acid, the furfural is prepared, concentration of acid in the superheated steam is 1-30%, and hydrolysis reaction temperature is 110-180 DEG C. The gas phase acid catalytic biomass hydrolysis continuous production method of the furfural has the advantages of being wide in raw material sources, small in side reaction, high in furfural yield, low in energy consumption, simple in waste water and waste residue treatment, small in waste gas, waste water and waste residue emission and the like and is convenient for industrial production.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

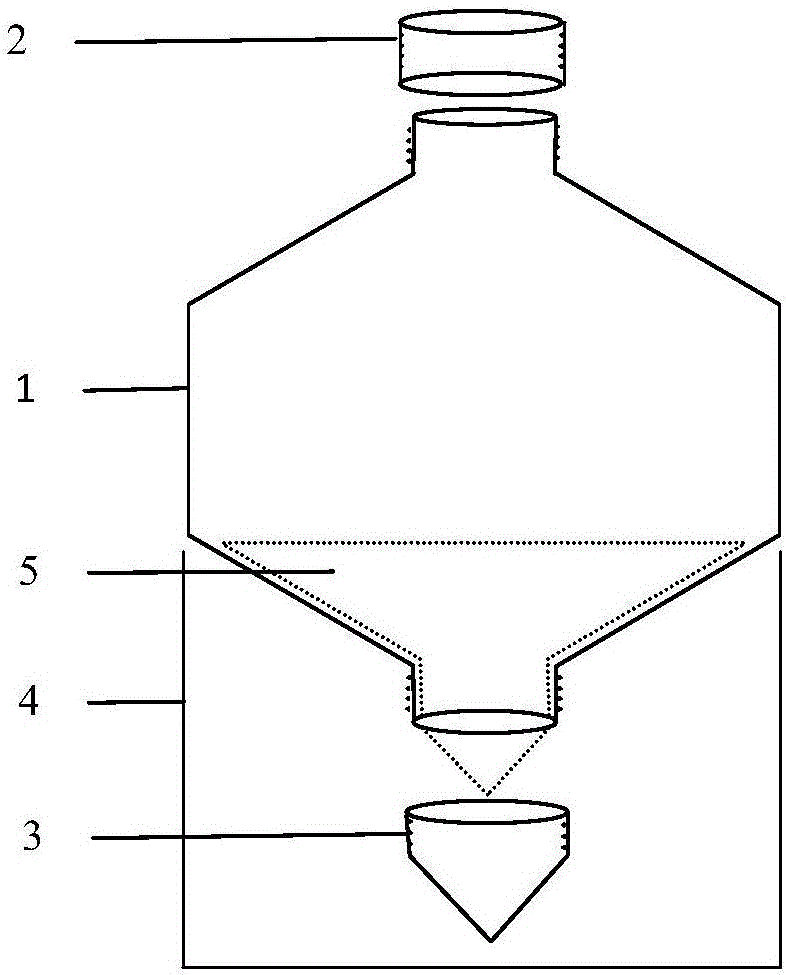

Continuous fermentation device for slime producing bacteria

InactiveCN106367323AEasy to inoculateReduce wasteBioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationBottle

The invention discloses a continuous fermentation device for slime producing bacteria. The continuous fermentation device comprises a hanging bottle, an upper cap, a lower cap and a collection bottle, openings are formed in the upper portion and the lower portion of the hanging bottle, the lower cap is provided with a conical top, the bacteria and a liquid culture medium are separated by the aid of bottleneck barrier action and properties of gel in a solid culture medium, continuous stable nutrient substances are provided for the bacteria by the aid of gravity action, bacterial agents are automatically collected by the aid of slime producing characteristics of the bacteria, the conical bare solid culture medium is manufactured by the aid of the lower cap, so that bacterial strains are conveniently inoculated, the bacterial agents are conveniently collected, glass and resin materials are selected, high-pressure steam sterilization can be achieved, combination of shapes is designed, and sterilization and sterile operations are facilitated. The continuous fermentation device can be used for fermentation production of slime producing bacteria, continuous fermentation production of the bacterial agents is achieved, the culture media keeps fresh, and fermentation processes of the slime producing bacteria are saved, continuous and facilitated.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

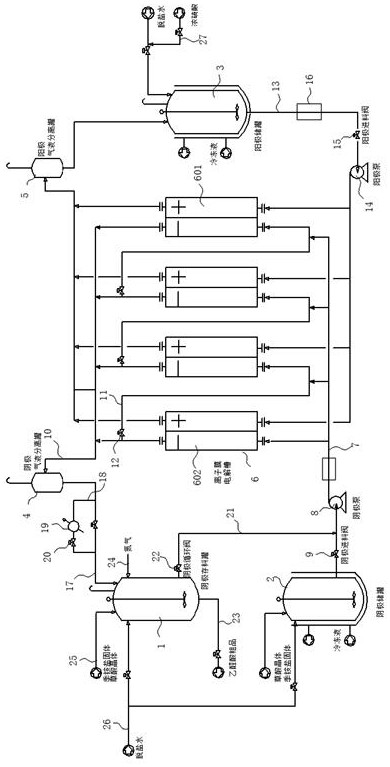

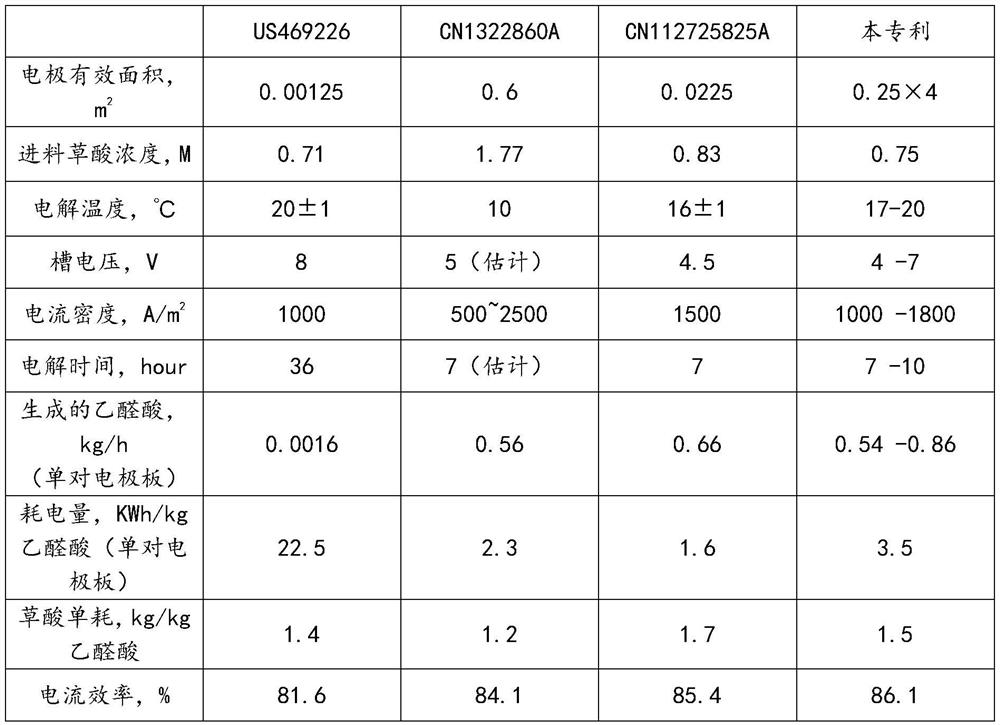

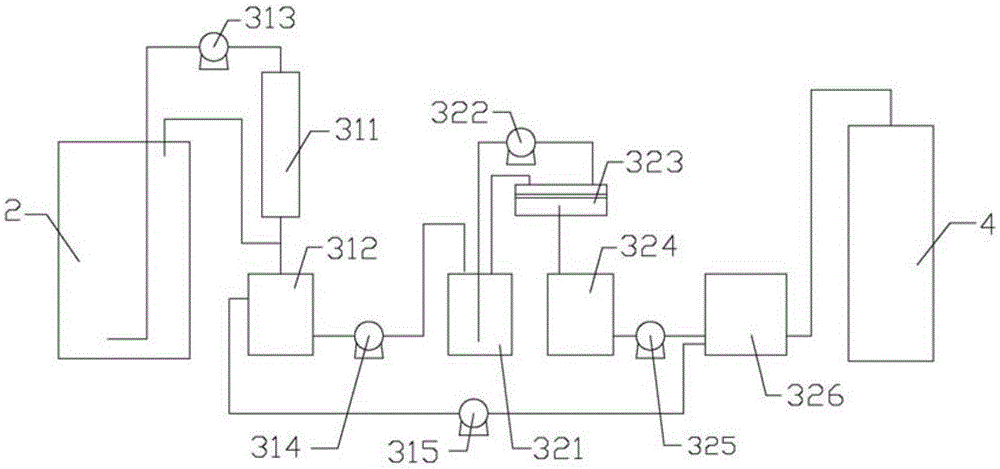

Method for continuously preparing glyoxylic acid through oxalic acid electrolysis

ActiveCN114016059ASimple processLow investment costElectrolysis componentsChemical industryOXALIC ACID DIHYDRATEContinuous operation

The invention discloses a method for continuously preparing glyoxylic acid through oxalic acid electrolysis, which comprises a cathode storage tank, a cathode storage tank, an anode storage tank, a cathode gas-liquid separation tank, an anode gas-liquid separation tank and a plurality of electrolytic cell modules,the electrolytic cell modules are equally divided into anode chambers and cathode chambers, one end of each cathode chamber and the output end of the cathode storage tank are connected with a cathode feeding header pipe, and a cathode pump and a cathode feeding valve are arranged between the two ends of the cathode feeding header pipe. According to the invention, free switching between intermittent operation and continuous operation is realized through switching of connection modes of the plurality of electrolytic cell modules, and the purpose of continuous production is finally achieved: the plurality of electrolytic cell modules are connected in parallel, so that the catholyte is subjected to a rapid circular reaction between the cathode storage tank and the electrolytic cell, and after the concentration of glyoxylic acid in the catholyte reaches a set value, and switching is carried out to a series connection mode, and the circulation is closed to carry out continuous production.

Owner:EAST CHINA ENG SCI & TECH +1

System and method for producing C5-C19 alkyl ketones

InactiveCN105567551AAchieve entryAchieve continuous productionBioreactor/fermenter combinationsBiological substance pretreatmentsEvaporation PurificationKetone

The invention relates to a system and method for producing C5-C19 alkyl ketones, belonging to the technical field of biochemical engineering. The system comprises a fermentation apparatus, a product separation and purification device and a chemical catalytic unit, wherein the fermentation apparatus is connected with the chemical catalytic unit through the product separation and purification device; and the product separation and purification device is composed of at least one of a gas stripping purification device, a pervaporation membrane purification device, an adsorptive purification device, a steam penetration purification device, a liquid-liquid extraction purification device, a centrifugal device, a multi-effect evaporation purification device and a rectification purification device. By using the system and method, industrial sugar-containing waste molasses or agricultural waste straws can be converted into C5-C19 long-chain alkyl ketones under the biological catalytic and chemical catalytic actions, and the C5-C19 long-chain alkyl ketones can be used as gasoline, diesel or aviation fuel directly or after being deoxidized.

Owner:DALIAN UNIV OF TECH

Glove blow molding and film making forming linkage production method and glove blow molding and film making forming machine

The invention relates to a glove blow molding and film making forming linkage production method and a glove blow molding and film making forming machine. The method comprises the following specific steps of film making, wherein a film blow molding mechanism is utilized for making a continuous cylindrical film belt; tidying, wherein the cylindrical film belt is compressed into a double-layer film belt; and forming, wherein the double-layer film belt is introduced into the glove forming mechanism to be subjected to hot pressing to form gloves. The glove blow molding and film forming machine comprises a rack, a film blow molding mechanism, a glove forming mechanism and a traction mechanism. The film blow molding mechanism comprises a machine cylinder, a die head and a melt metering pump. Theglove forming mechanism comprises a hot pressing die and a drive mechanism. Double-layer films formed by the die head enter the corresponding glove forming mechanism through the traction mechanism tobe subjected to hot pressing to form the gloves. According to the method and the machine, the film making function and the glove hot pressing function can be combined, after the films are made, the films directly enter the glove forming machine to be subjected to hot pressing to form the gloves, the films do not need to be stored, the storage area and the storage cost are saved, and the productionefficiency is improved.

Owner:ZHANGJIAGANG BOLAIKE RUBBER & PLASTIC PROD

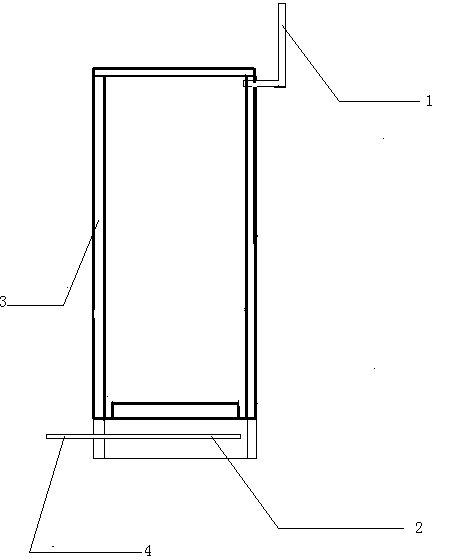

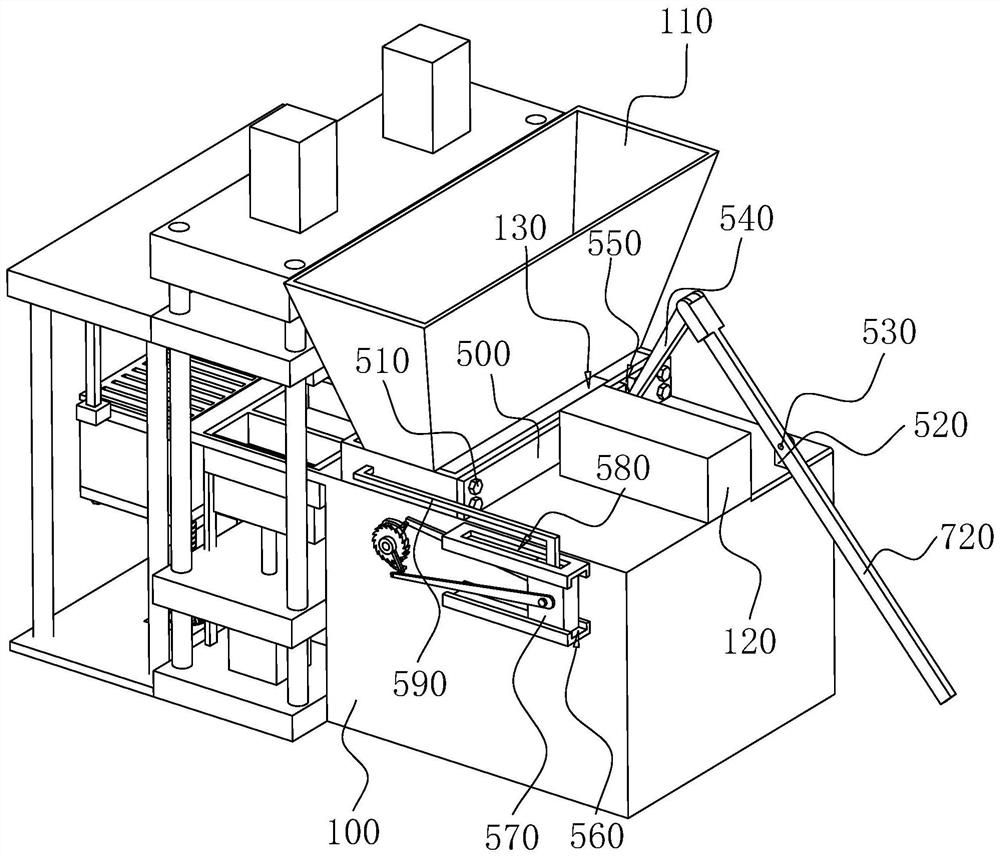

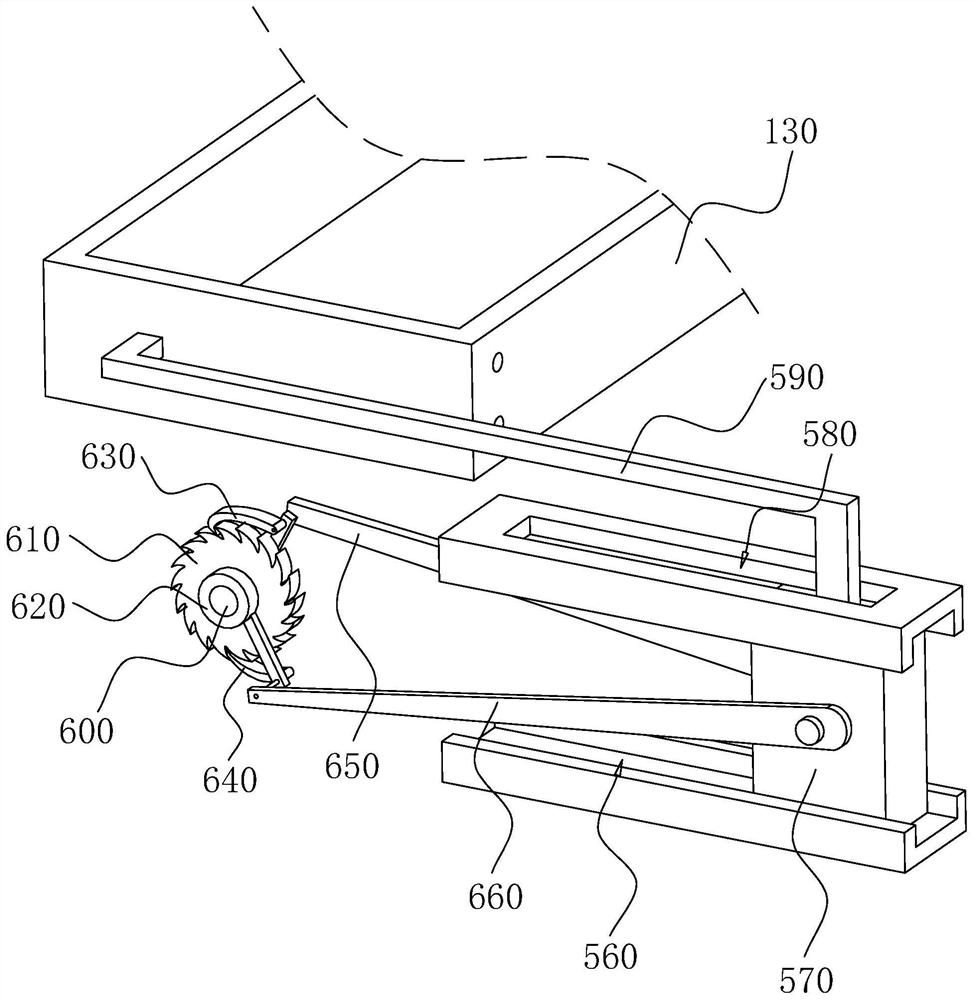

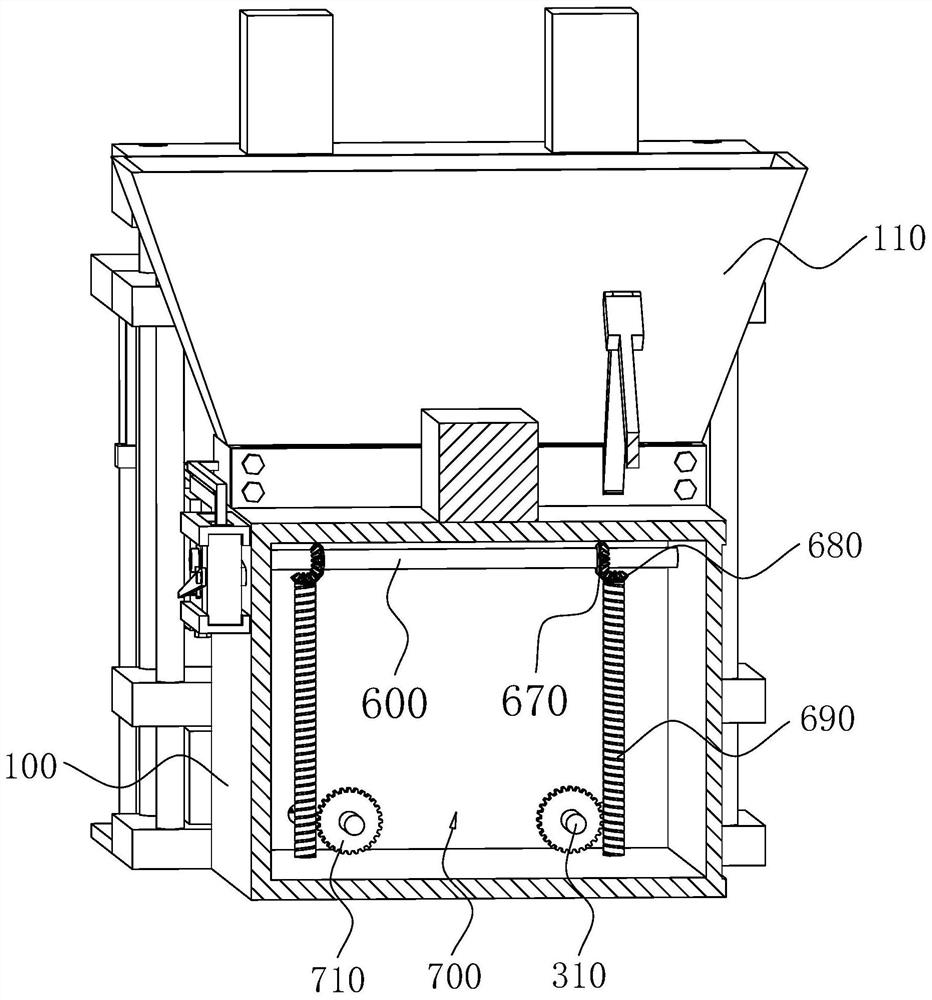

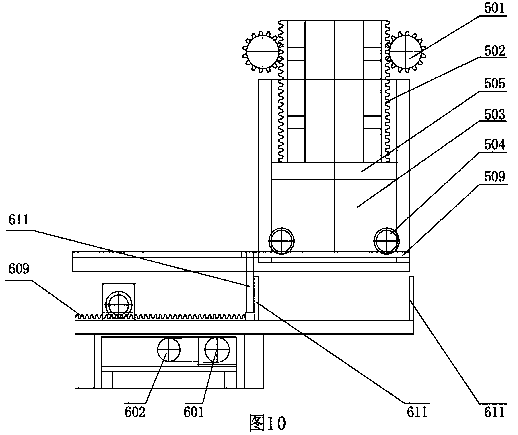

Perlite insulation board pressing machine

ActiveCN112318678AAchieve continuous productionIncrease productivityFeeding arrangmentsHydraulic cylinderMachining process

The invention relates to a perlite insulation board pressing machine, and relates to the technical field of insulation board production equipment. The perlite insulation board pressing machine comprises a workbench, a feeding device arranged on the workbench and a discharging device arranged on one side of the workbench, wherein the feeding device comprises a feeding frame connected to the workbench in a sliding mode, a pushing assembly arranged on the workbench, a third hydraulic cylinder arranged on the workbench and a first connecting piece arranged between the feeding frame and the third hydraulic cylinder; and the discharging device comprises a discharging frame arranged on one side of the workbench, a lifting assembly arranged on one side of the workbench and a mounting table arranged on the lifting assembly. Through the arrangement of the feeding device and the discharging device, a worker can conduct automatic production and machining processes on an insulation board and can also conduct feeding and discharging work on the insulation board in a manual mode when the hydraulic cylinder is in the maintenance stage, so that continuous production of the perlite insulation boardis achieved, and the production efficiency of the perlite insulation board is further improved.

Owner:绍兴易鑫新材料有限公司

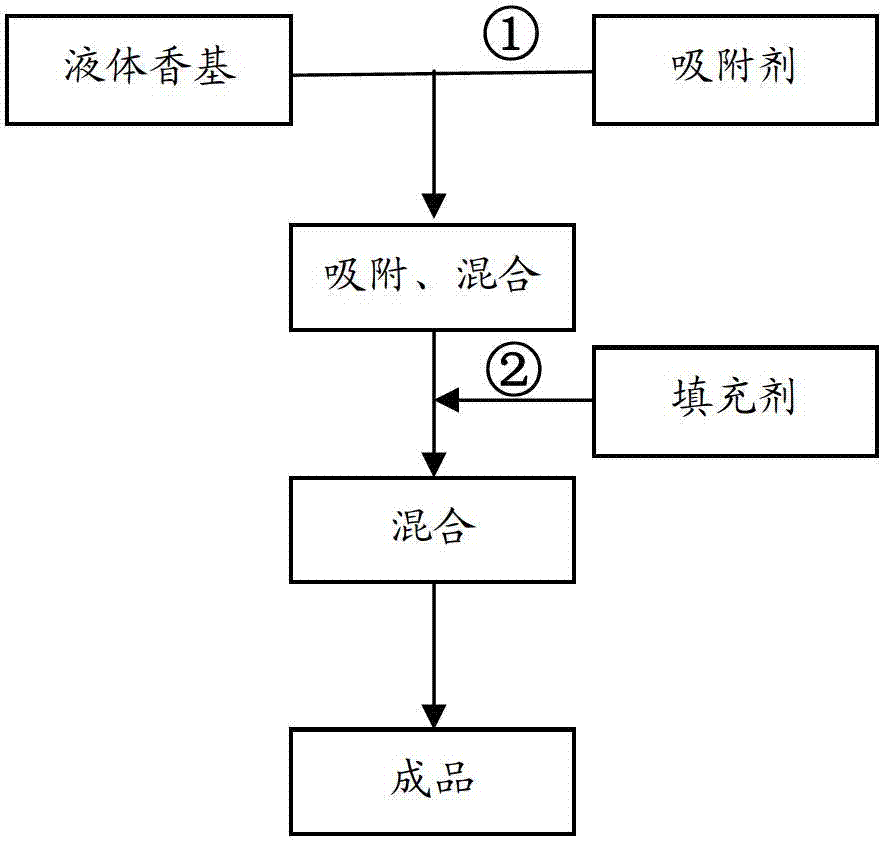

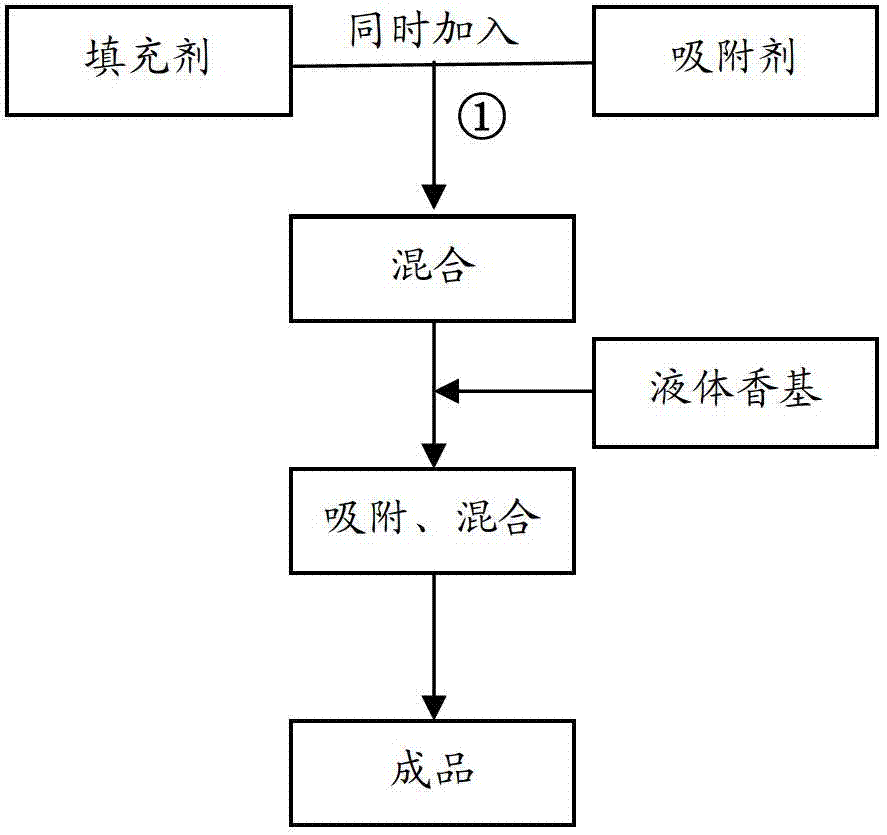

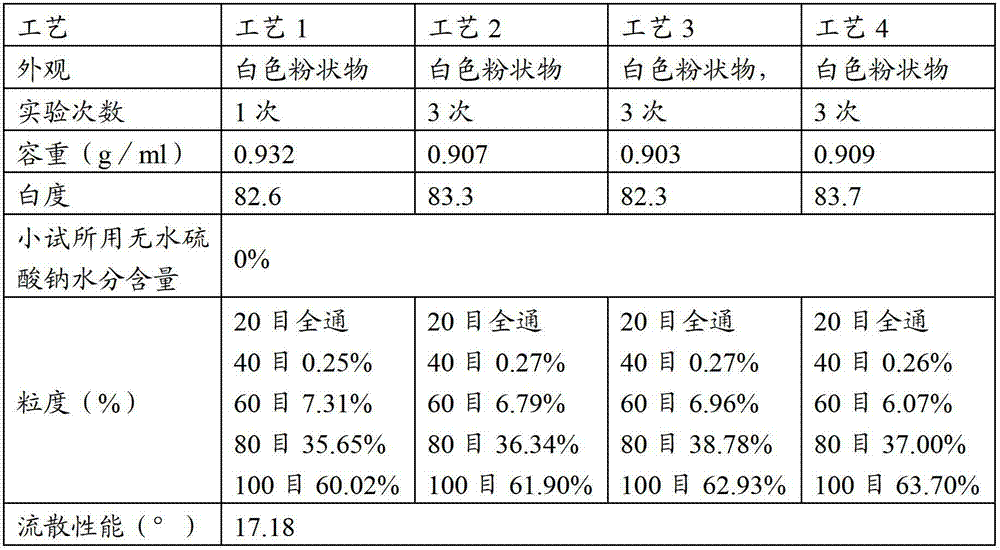

Powdered feed flavor and production method thereof

InactiveCN102860420AReduce feeding stepsAchieve continuous productionAnimal feeding stuffSorbentFiller Excipient

The invention relates to a production method of powdered feed flavor. The powdered feed flavor comprises carrier and liquid flavor base. The carrier comprises adsorbent and filler. The production method of the powdered feed flavor includes adding both the adsorbent and the filler into a mixing chamber for mixing; adding the liquid flavor base for mixing; preferably, mixing the adsorbent and the filler for 1-3 minutes; and adding the liquid flavor base for mixing for 3-5 minutes. By weight, the liquid flavor bases accounts for 150-250 parts, the carrier accounts for 600-900 parts, the adsorbent accounts for 100-300 parts, and the filler accounts for 500-800 parts. The invention further relates to the powdered feed flavor. The production method of the powdered feed flavor is ingenious in design, the carrier feeding steps can be decreased, and accordingly production efficiency is improved. The production cost is reduced greatly, products cake less easily, and the powdered feed flavor and the production thereof are applicable to large-scale popularization and application.

Owner:上海美农生物科技股份有限公司

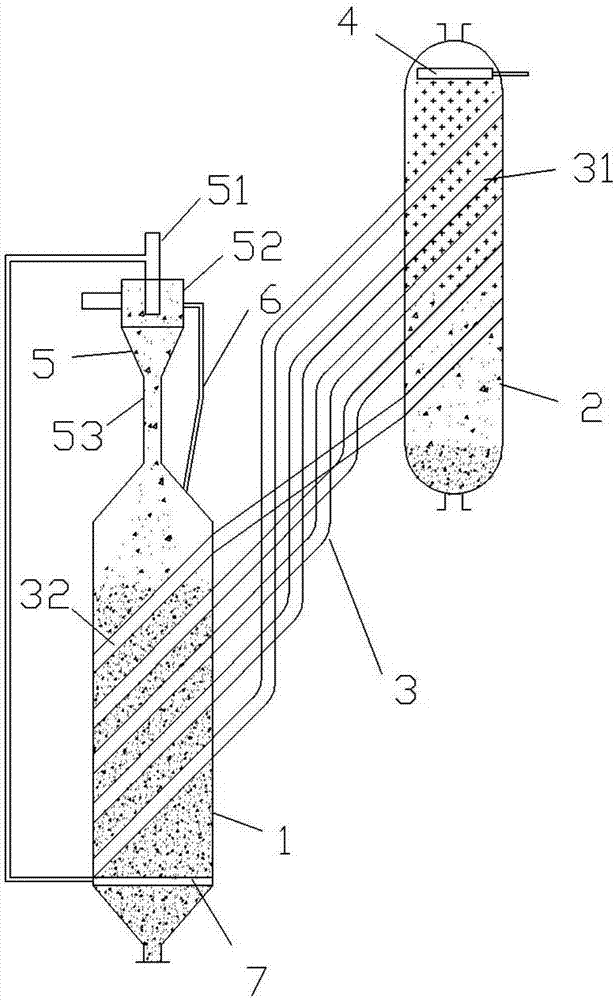

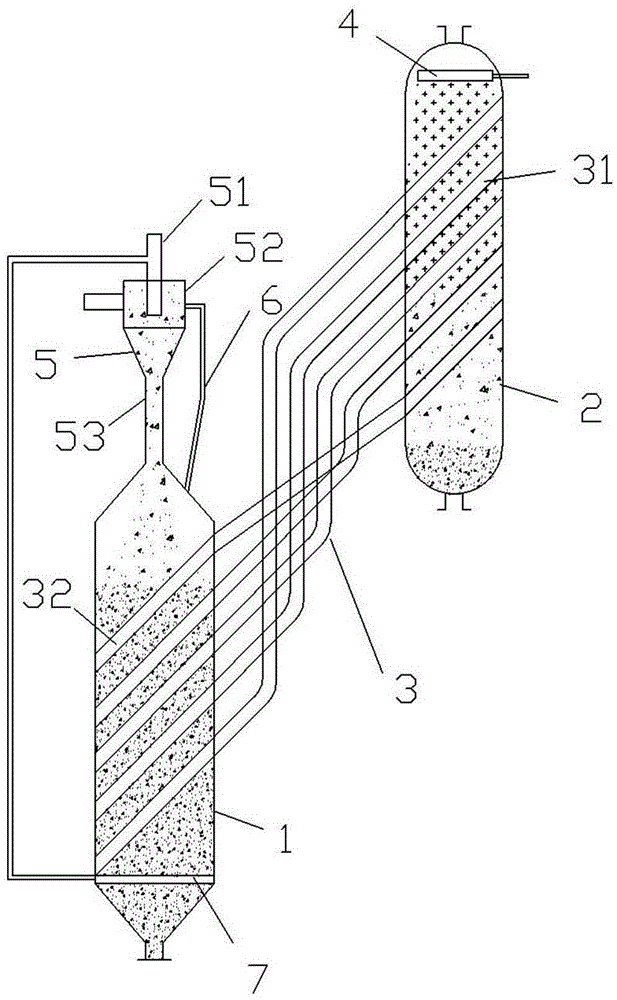

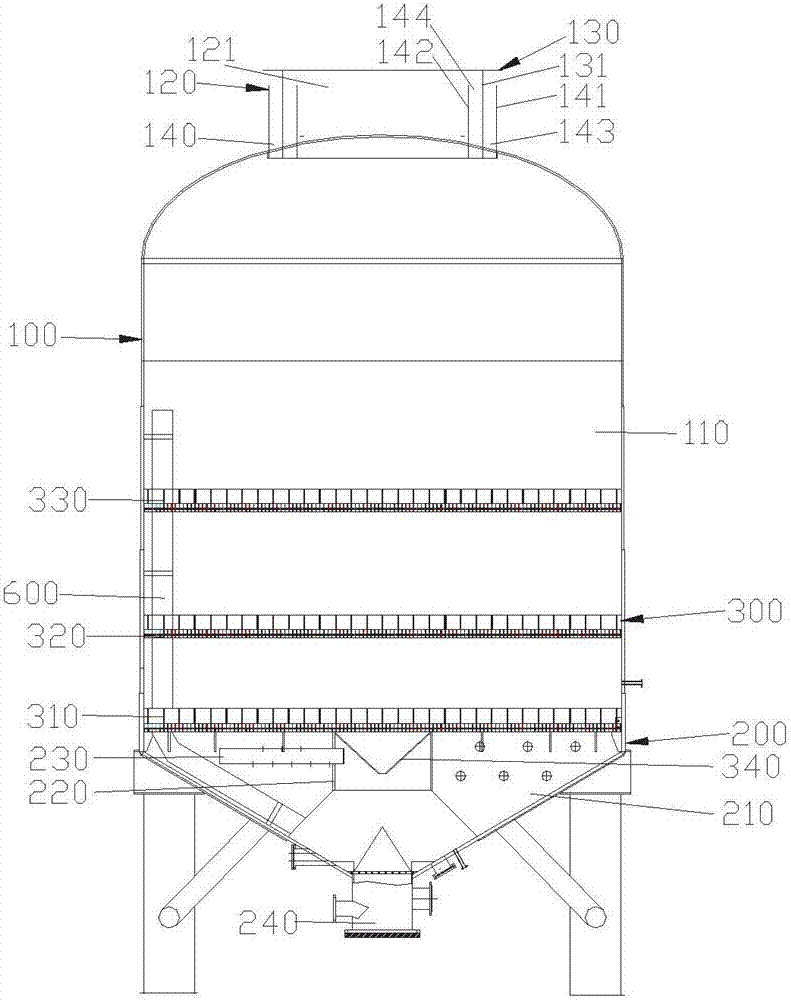

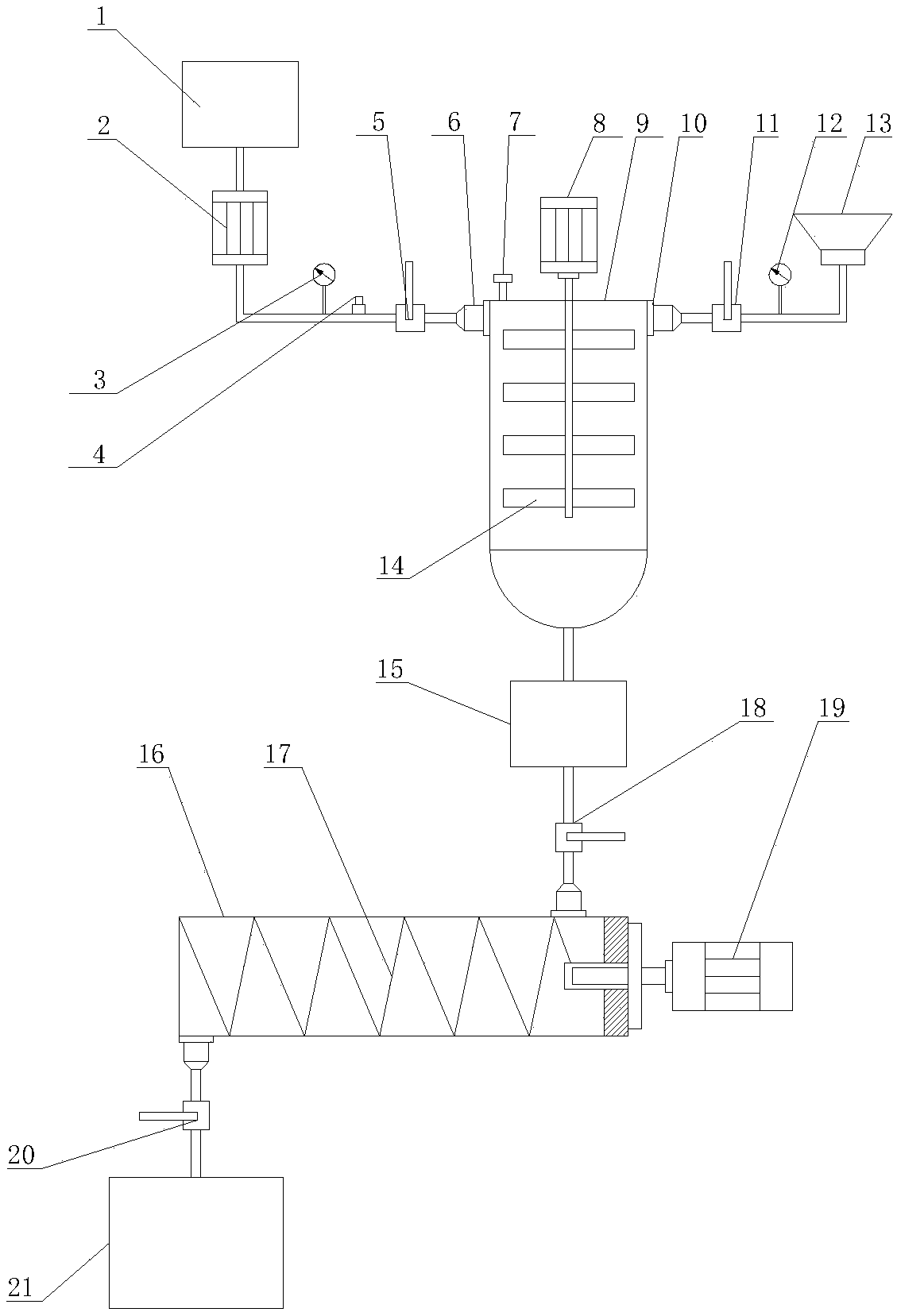

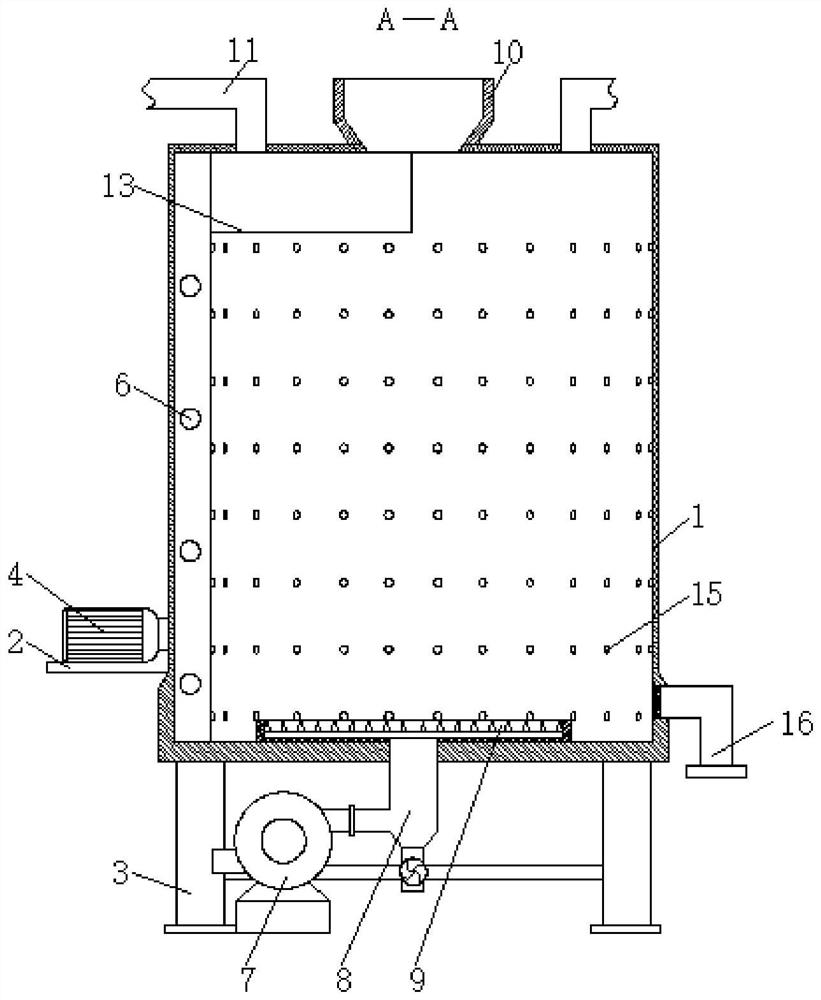

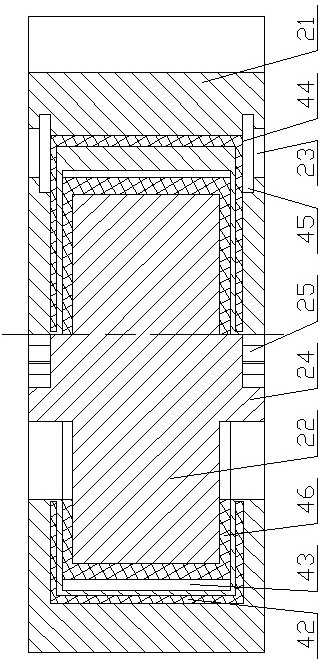

Waste heat recovery type evaporative crystallization device

ActiveCN105597363AAchieve instant evaporationAchieve continuous productionEvaporator accessoriesSolution crystallizationHeat fluxEvaporation

The invention discloses a waste heat recovery type evaporative crystallization device. The evaporative crystallization device is characterized by comprising an evaporation kettle and a waste heat recovery tower, wherein a heat tube is arranged in the waste heat recovery tower, the hot end of the heat tube is arranged in the waste heat recovery tower, the cold end of the heat tube is arranged in the evaporation kettle, a cyclone separator is arranged at the top of the waste heat recovery tower, an ash discharge hole of the cyclone separator is directly communicated with an inner cavity of the waste heat recovery tower, a distributor is arranged at the top of the evaporation kettle, and an air tube is arranged at the bottom of the waste heat recovery tower to introduce updrafts into the waste heat recovery tower. Compared with the prior art, the evaporative crystallization device has the advantages that via large heat flux of heat conduction of the heat tube, a solution can be evaporated instantly, so that a continuous production effect can be achieved, and a difficulty of traditional intermittent production with operation on evaporative crystals is broken; in addition, with such design, traditional 'waste heat' in a solid phase is efficiently recovered and utilized, and multiple heat transfer manners coexist, so that the heat transfer effect is excellent, the energy utilization rate is high, and effects of energy conservation and environment protection are achieved.

Owner:ANHUI GUOFU LUBRICANT IND

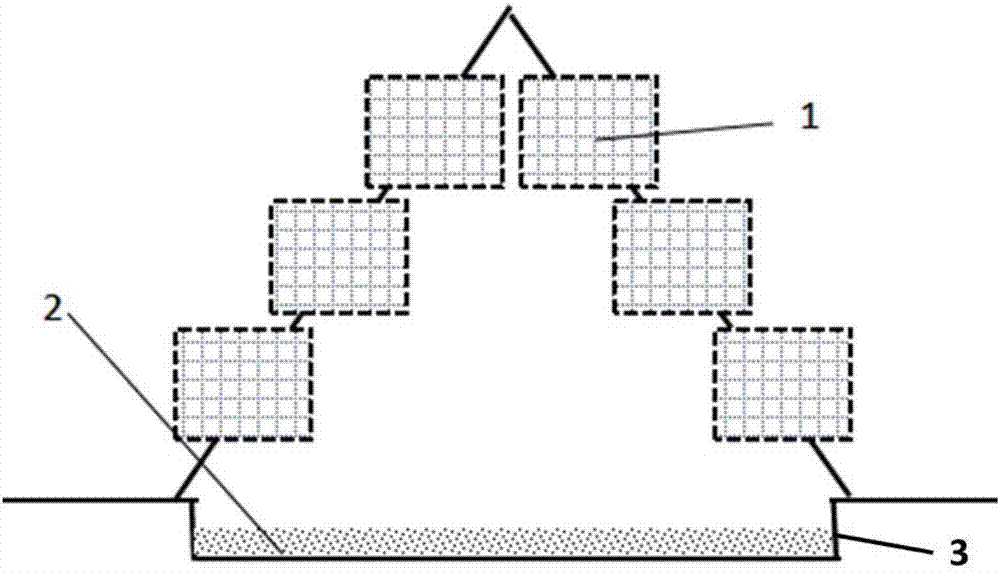

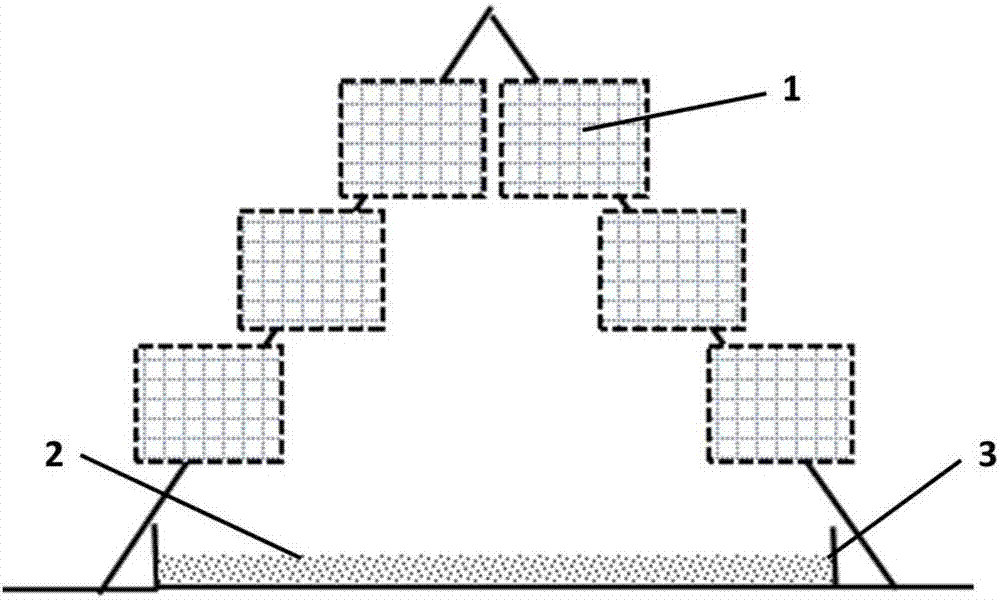

Cascaded oxidation reaction method and assembly, and application thereof

PendingCN107537409AIncrease the reaction contact areaIncrease productivityIron oxides/hydroxidesChemical/physical processesEngineeringReaction layer

The invention provides a cascaded oxidation reaction assembly. The cascaded oxidation reaction assembly comprises a plurality of members stacked together, wherein at least one layer of a member is arranged, each member is provided with through holes, and an aperture ratio of the through holes in the members is 2.5: 1 to 25: 1. The cascaded oxidation reaction assembly comprises more than one layerof a member, and the aperture of a lower member is less than the aperture of an upper member, so continuously consumed reaction raw materials continuously move to lower layers with decrease of the volume of the reaction raw materials; and thus, re-distribution of gas and liquid is driven in the process of movement, and the a reaction contact area of the materials is increased. Raw materials with different reaction rates undergo reactions on different reaction layers (i.e., raw materials with large volumes undergo reactions on upper-layer members and raw materials with small volumes undergo reactions on lower-layer members), so a stereo cascaded reaction system is formed, and production efficiency is improved.

Owner:SHANGHAI YIPIN PIGMENTS CO LTD

Water treatment agent raw material high-pressure mixing device

InactiveCN109012289AImprove mixing efficiencyImprove the mixing effectRotary stirring mixersTransportation and packagingEngineeringHigh pressure

The invention relates to a water treatment agent raw material high-pressure mixing device and belongs to the technical field of water treatment. The device includes a vertical stirring tank, a buffertank, a horizontal stirring tank, and a collection bucket. A stirring paddle is vertically arranged in the vertical stirring tank. A first feeding port and a second feeding port are formed on the sidewall of the upper end of the vertical stirring tank. A liquid material box is connected to the first feeding port through a pipeline, wherein a booster pump is arranged on the pipeline between the liquid material box and the first feeding port. A spiral shaft is horizontally arranged in the horizontal stirring tank. By means of the booster, the liquid material in the liquid material box is pressurized and then is fed into the vertical stirring tank at high speed, so that the liquid material, at high pressure and high speed, is quickly mixed with other materials. With assistance of the stirring paddle in the vertical stirring tank for mixing the materials, the device is good in mixing effect and high in mixing efficiency.

Owner:江苏天泽教育咨询有限公司

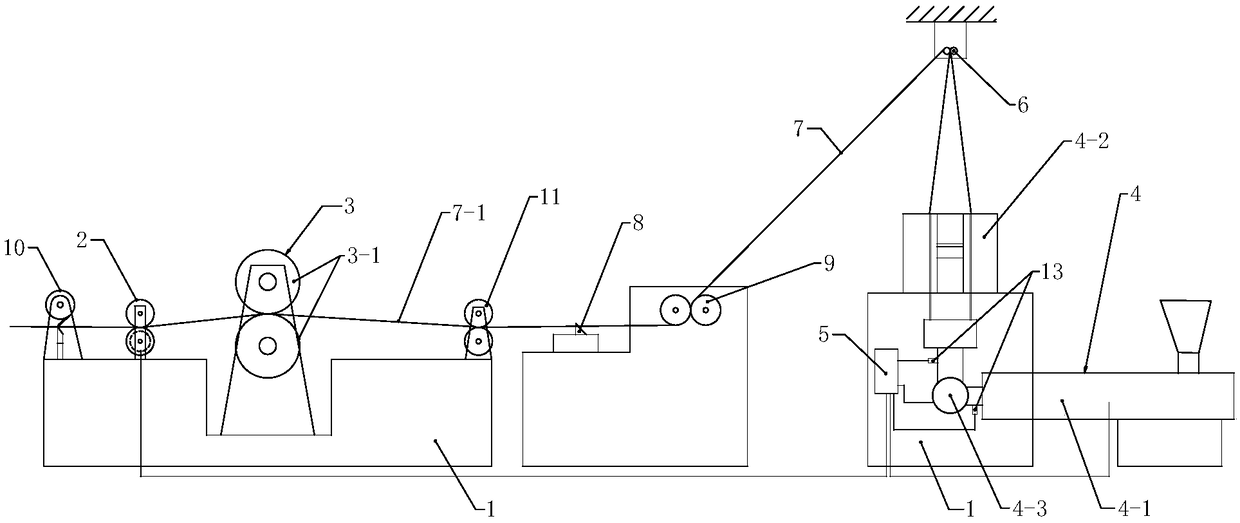

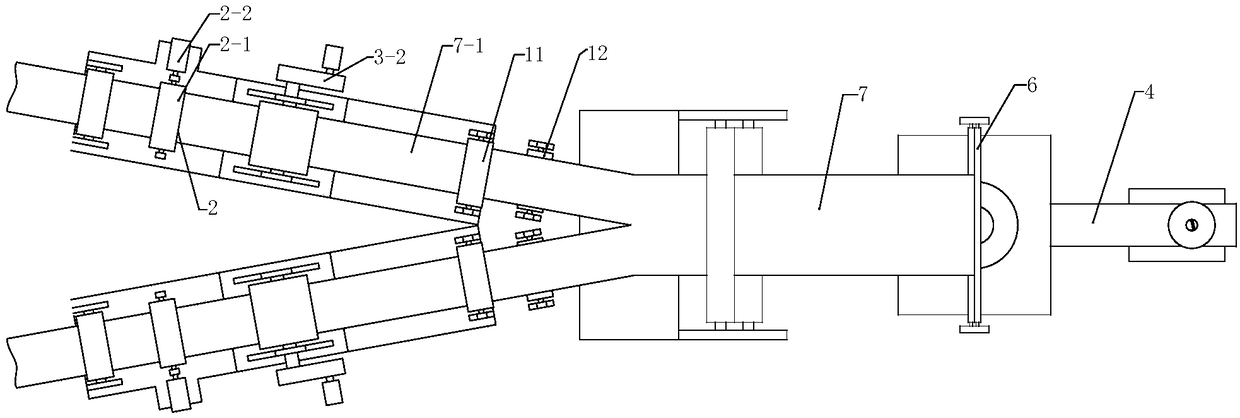

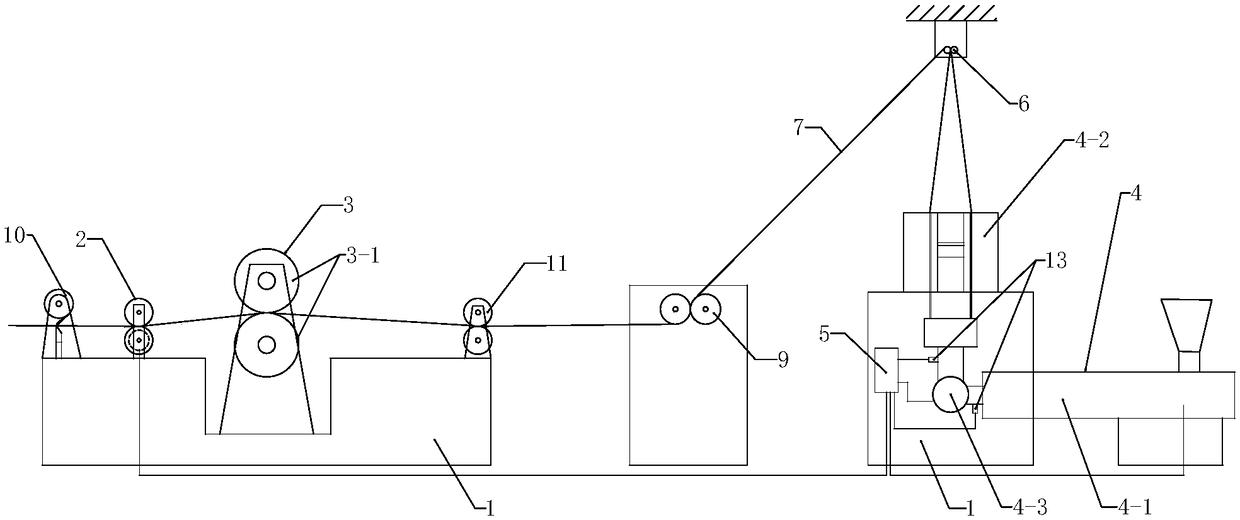

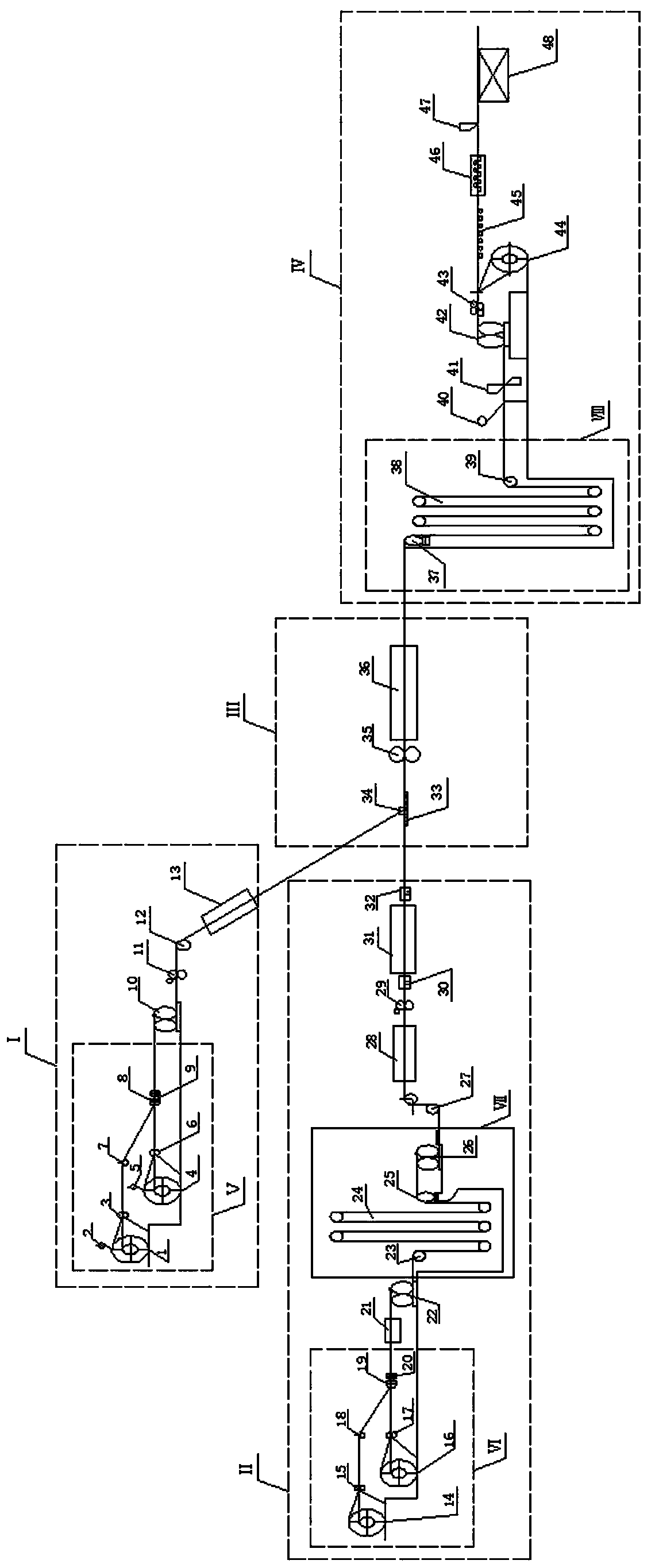

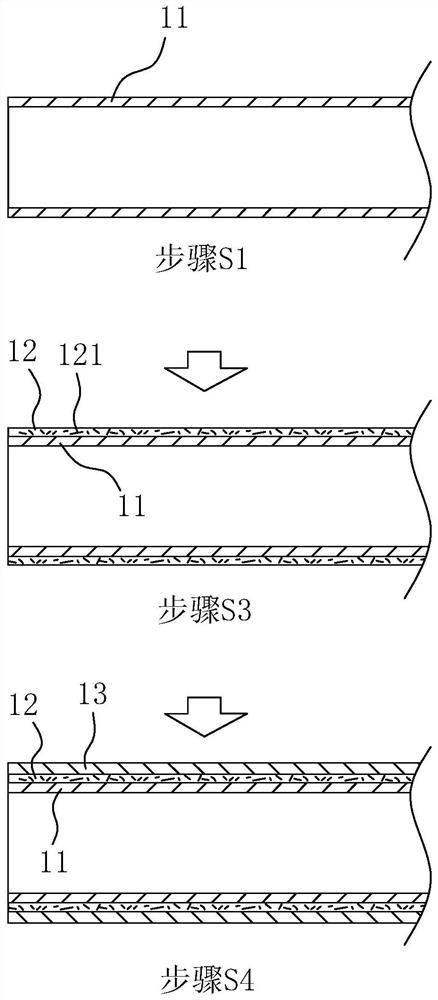

Continuous automatic production device and production method of metal thin film plate

ActiveCN107009714BTimely storageImprove performanceLaminationLamination apparatusSheet steelMetal thin film

The invention belongs to the field of building decoration materials and discloses a continuous automated production device and method of metal film plates to solve the problems that metal plates are high in price and limited in application range and producing metal film plates through a single-plate unit are high in manpower cost, incapable of realizing continuous production and low in yield. The device comprises an upper-layer steel plate treatment unit, a lower-layer steel plate treatment unit, a compositing unit and an aftertreatment unit. The method includes steps: treating upper-layer steel plates; treating lower-layer steel plates; compositing the two layers of the steel plates; treating after compositing. By adopting the full-automatic device, processes of the upper-layer and lower-layer steel plates are conducted at the same time, and a double decoiler is used for both the upper-layer steel plates and the lower-layer steel plates, so that the objective of automated and continuous production of the metal film plates is achieved. The continuous automated production device and method is high in yield, so that production cost is lowered greatly, using cost is lowered, and the metal film plates can be widely applied.

Owner:嘉峪关天源新材料有限责任公司

Negative pressure production process of additive-free animal oil for feedstuffs

InactiveCN110819431ALow acid valueReduce energy consumptionFatty-oils/fats refiningFatty-oils/fats productionFeed processingProcess engineering

The invention discloses a negative pressure production process of additive-free animal oil for feedstuffs, and relates to the technical field of feed processing. The process takes leftovers of live pigs as raw materials, and comprises the following steps of a. taking animal fat raw materials, and mincing the raw materials; b. preheating the minced raw materials until oil materials are separated out; c. putting the separated oil into a low-temperature negative-pressure environment for oil extraction; and d. adding argil into the extracted oil to filter and decolor the oil, then performing solid-liquid separation, taking the separated primary liquid oil as an extracted finished product of the raw material fat, and storing the extracted finished product. The negative pressure production process breaks through the traditional production mode and adopts a negative pressure low-temperature extraction mode, so that the produced oil product is low in acid value, clear in color and luster, easyto store, and free from peculiar smell in the production process; and the continuous product production can be realized simultaneously, thereby achieving the effects of environmental protection and low energy consumption.

Owner:南充市嘉瑞特饲料有限公司

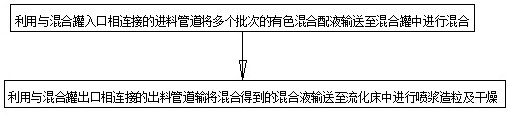

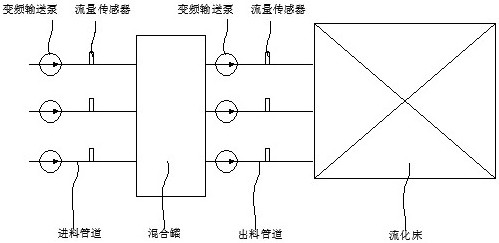

Method and system for spraying and granulating multiple batches of colored mixed liquid in fluidized bed

InactiveCN113398841ASolve chromatic aberrationImprove granulation efficiencyGranulation by powder suspensionSpray GranulationFluidized bed

The invention relates to a method and a system for spraying and granulating a plurality of batches of colored mixed liquid into a fluidized bed. The method comprises the following steps of: A, conveying the plurality of batches of colored mixed liquid into a mixing tank for mixing by using a feeding pipeline connected with an inlet of the mixing tank; and B, conveying the mixed liquid obtained by mixing into the fluidized bed by using a discharge pipeline connected with the outlet of the mixing tank, and carrying out spraying granulation and drying. According to the invention, the problems of chromatic aberration and content deviation of particle products are solved, the market competitiveness of the products is improved, the granulation efficiency is high, and the cost is low.

Owner:浙江拜克生物科技有限公司

A fully automatic production line for fruit core shaping and expelling gas in the core

ActiveCN105852179BGuaranteed continuityWork coordinationFood shapingProduction lineDistribution system

The invention discloses a full-automatic production line for shaping kernels and discharging gases in the kernels. The full-automatic production line comprises three pressure-maintaining tank car walking guide rails paved in parallel on the ground plane, an entrance-end steering device and an exit-end steering device arranged at the two ends of the guide rail respectively, a hydraulic propulsion device, an automatic loading, weighing, measuring and distribution system arranged on one side of the guide rail, a pressure-maintaining tank car, servo hydraulic machines arranged on three different stations of the guide rail, a pressure-maintaining tank car upper cover reset device, a discharge conveying device arranged on one side of the guide rail, a pressurizing self-locking device arranged on the pressure-maintaining tank car and a full-set production line centralized control room. The full-automatic production line disclosed by the invention has the advantages of compact structure, high automation degree, environmental friendliness and high efficiency, reduces the labor intensity, greatly lowers the energy consumption, improves the working efficiency, and realizes continuous automatic production for shaping kernels and discharging gases in the kernels in the whole processes of weighing and measuring, sustainable pressurizing, pressure maintaining and re-pressurizing.

Owner:郑州华隆机械制造有限公司 +2

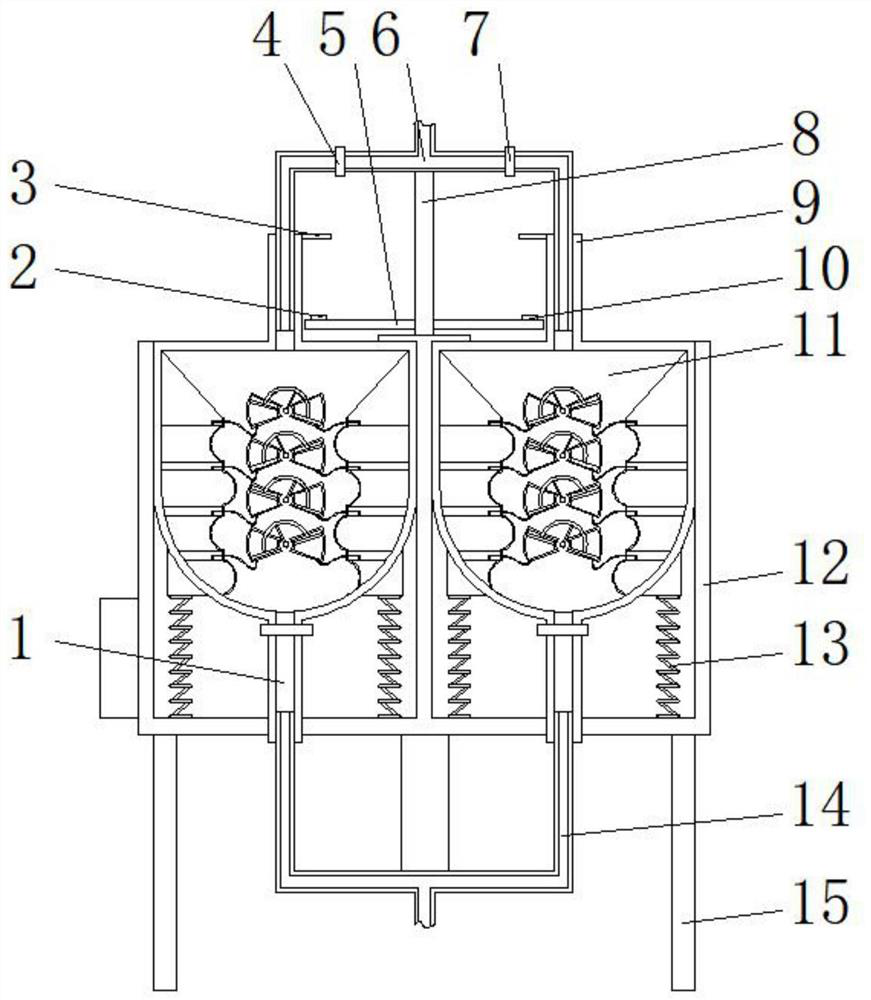

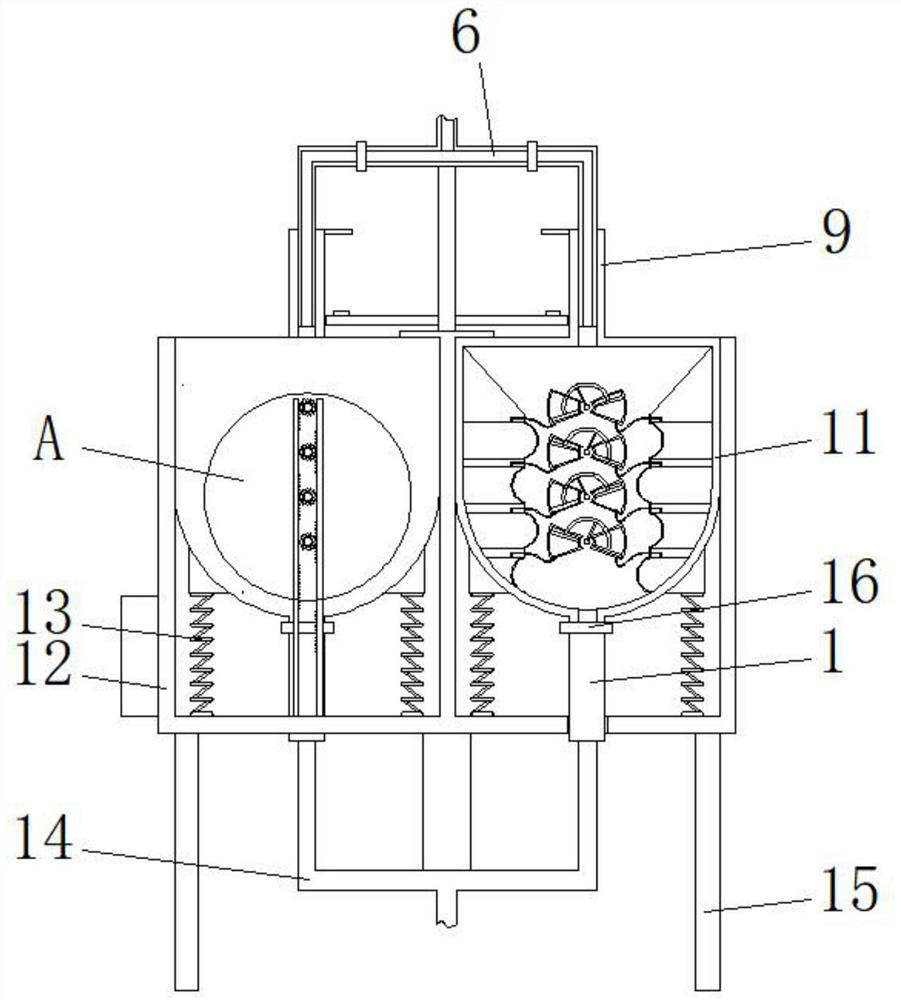

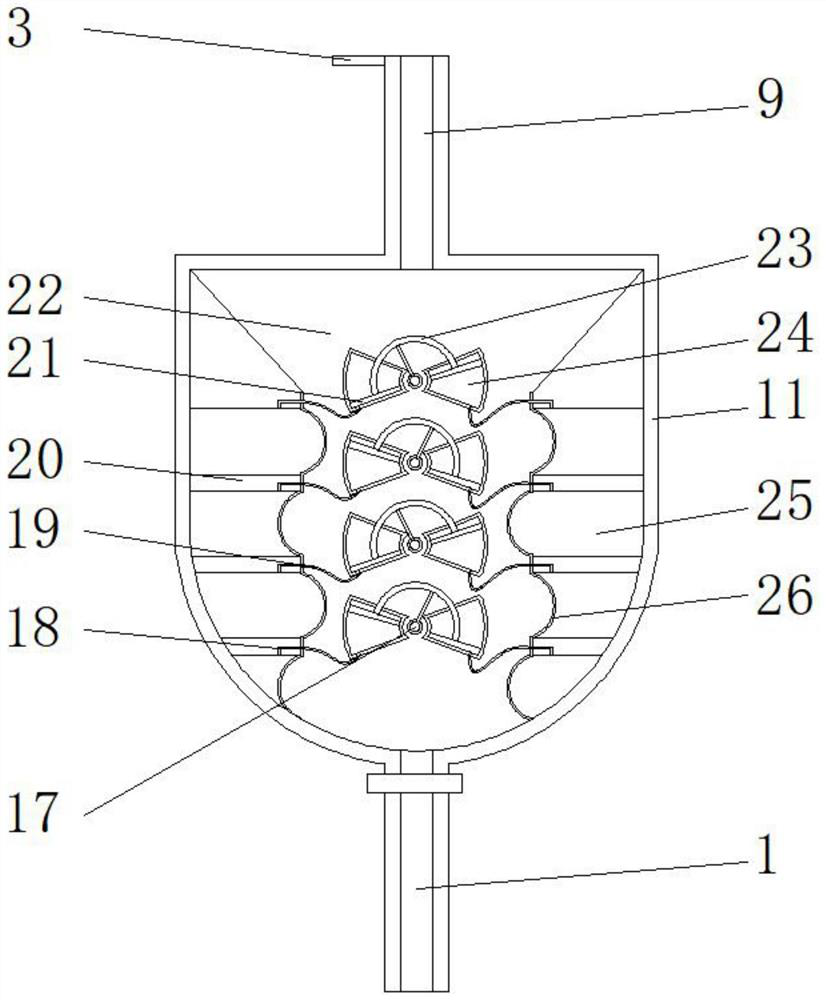

Biopharmaceutical stem cell reaction equipment for cell biological genetic engineering

ActiveCN112980688AQuality improvementAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyRubber membrane

The invention discloses biopharmaceutical stem cell reaction equipment for cell biological genetic engineering, and belongs to the technical field of genetic engineering. The biopharmaceutical stem cell reaction equipment comprises a device body, wherein two reaction tanks are symmetrically connected in the device body in a sliding mode, partition plates are transversely fixed to the two sides of the interior of each reaction tank at equal intervals, a rubber film is connected to the end between every two vertically adjacent partition plates, guide pipes are arranged in the partition plates at the top of the inflation cavity, one end of each guide pipe is connected with a hose, rotating shafts are vertically installed at the center line position of an emulsification channel at equal intervals, arc-shaped piston cylinders are fixed to the two sides of each rotating shaft, and a piston plate is slidably connected into the arc-shaped piston cylinder. In the descending process, soft rubber films on the two sides of the interior of the reaction tank are driven to creep, cell sap entering the reaction tank is stirred, hard stirring of the cell sap and damage to the interior of the cell sap are prevented, and the quality of the cell sap is improved.

Owner:HUZHOU COLLEGE

Adjustable constant-force screen manufacturing device and application method thereof

PendingCN110126284AAchieving lateral preloadAchieve preloadDomestic netsMechanical engineeringEngineering

The invention relates to the technical field of screen manufacturing devices, in particular to an adjustable constant-force screen manufacturing device and an application method thereof. The adjustable constant-force screen manufacturing device comprises a net rack; a guide frame is fixed to the right side of the net rack; a vulcanizing machine is fixed to the right side of the guide frame; a support plate of the vulcanizing machine is provided with a pulling device which is used for longitudinally pulling a wire screen which is connected to a PP frame in a melting way; a limiting block used for positioning the PP frame is fixed to the left side of the upper end of the support plate; and a pull-out device is fixed to the right side of the vulcanizing machine. The adjustable constant-forcescreen manufacturing device provided by the invention realizes constant-force dynamic continuous output of a coiled wire screen by virtue of a pneumatic expansion shaft, a safety chuck and a magneticpowder brake; the wire screen is horizontally pre-tightened when the wire screen is pulled; in a product manufacturing process, rubber is extruded in the longitudinal direction so that the wire screenbetween the rubber is longitudinally tensioned with deformation of the rubber and is afterwards hot-molten; pre-tightening and continuous production of the wire screen are realized in the overall manufacturing process; the production efficiency is improved; and meanwhile the pre-tensioning of the wire screen is realized as well.

Owner:PUYANG ZHONGYUAN RUISHIDA PETROLEUM EQUIP CO LTD

A kind of production process of fiber-reinforced pvc hose

ActiveCN111546676BIncrease elasticityImprove structural strengthTubular articlesMetal fiberMagnetic poles

The invention discloses a production process of a fiber-reinforced PVC hose, and relates to the technical field of hose production and manufacturing. Through the adjustment equipment; the adjustment equipment is provided with a magnet, and the same magnetic pole of the magnet is directed toward the center of the outer layer tube along the radial direction of the outer layer tube; the core body is passed through the inner layer tube, and the core body is provided with a magnet one along the circumference, and the same magnetic pole of the magnet one Along the radial direction of the outer tube towards the outer tube, the magnets and the magnets at the opposite ends of the magnet attract each other; the PVC hose is located between the magnet one and the magnet; step S6: make the PVC hose continue along its length Move through the adjustment device. This production process can adjust the position of the metal fiber, significantly improve the elasticity and structural strength of the metal fiber in the PVC hose, and can also realize the continuous production of the continuous hose; the inner tube and the outer tube can maintain a high The shaft degree, the quality of the produced PVC hose is better.

Owner:台州巨壹塑业有限公司

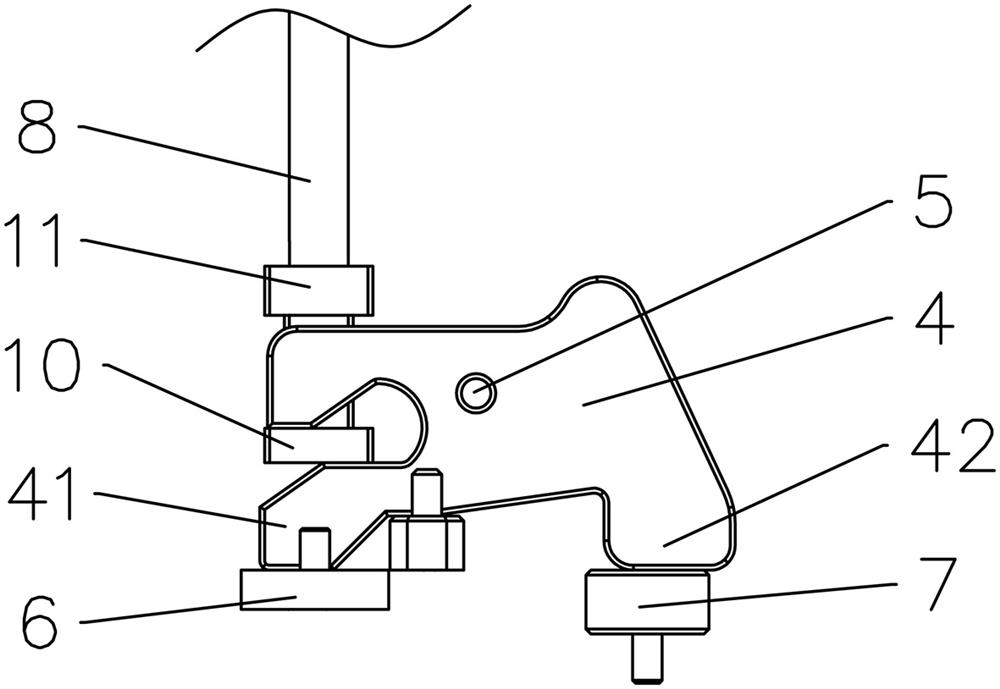

A mold opening auxiliary ejection structure

The invention discloses a mold opening auxiliary ejection structure which comprises a mold body, an ejector pin plate and a bottom plate. The ejector pin plate and the bottom plate are sequentially arranged on one side of the mold body, a through groove is formed in the ejector pin plate, a swing block is arranged in the through groove, one end of the bottom of the swing block extends downwards toform a first supporting foot, the other end of the bottom of the swing block extends downwards to form a second supporting foot, a first cushion block is arranged in the ejector pin plate, a second cushion block is arranged on the bottom plate, the swing block is rotationally installed on the ejector pin plate and tends to overturn towards the second cushion block, a straight ejector pin and an inclined ejector pin are arranged in the mold body, the bottom of the straight ejector pin is connected with the upper end of the swing block, the straight ejector pin and the first cushion block are located at the same end of the swing block, and the bottom of the inclined ejector pin is connected with the ejector pin plate. The mold opening auxiliary ejection structure provided by the invention is simple in structure, can eject out and demould a product and facilitates object taking by a manipulator.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

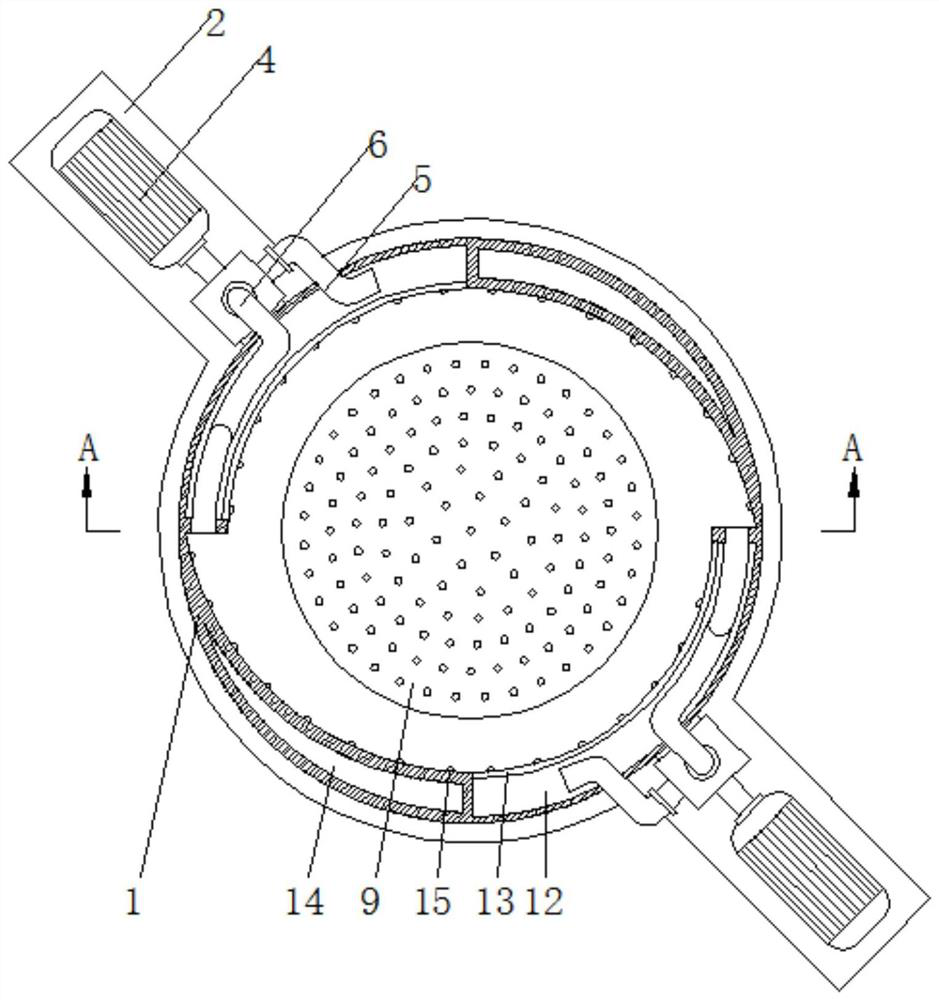

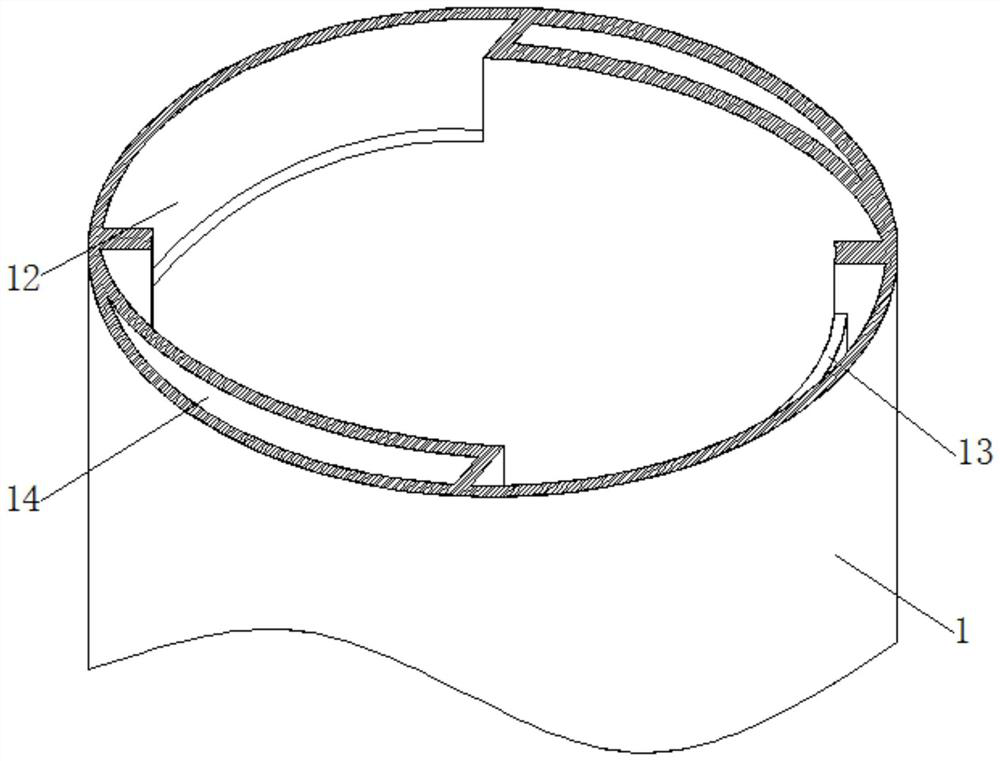

A continuous hydraulic pulper

InactiveCN110904707BQuality improvementImprove uniformityPaper recyclingRaw material divisionFiberEngineering

The invention relates to the technical field of pulping equipment, and discloses a continuous hydraulic pulper, which includes a tank body, a fixing seat and supporting legs, and the fixing seat is fixedly installed on the bottom of the outside of the tank body and is symmetrical to the center of the tank body , the supporting legs are fixedly installed on the top of the tank body and there are four and fixedly connected by connecting rods. The tank body and the impact water pipe are set so that after the slurry enters the slurry inlet cavity, it is driven by the high-pressure pump to impact the slurry in the inner cavity of the tank, and the slurry is driven to rotate and stir, so that the waste paper is decomposed, which is different from the existing one. Compared with the existing technology, the present invention removes the traditional mechanical drive, effectively reduces mechanical damage and improves the quality of fibers through pure hydraulic drive, and at the same time, through the tiny bubbles injected from the bubble disc, a part of the bubbles can lift the slurry from bottom to top, Improve the uniformity of the fiber and accelerate the decomposition efficiency, and another part of the air bubbles will expand or rupture after combining with the fiber, further accelerating the fiber decomposition efficiency.

Owner:山东沂南园区开发建设有限公司

Tire thermocuring flow production line

A station rotating motor is fixed to a vertical shaft in the center of a station table, an output shaft is fixed to a rotating shaft sleeve, a connecting rod is fixed to the rotating shaft sleeve, a lifting device A is fixed to the connecting rod, a turnover plate is arranged at the bottom of the lifting device A, and a grabbing device is arranged at the bottom of the turnover plate; the grabbing device moves downwards to the maximum stroke, fixes the tire thermocuring mold and is connected with the electric heating device, the grabbing device moves upwards to the maximum stroke, the grabbing device is separated from the tire thermocuring mold, each station is provided with a positioning device, a heat preservation cover is fixed to the upper portion of the station table, and an operation table is arranged on one side of the station table. The two ends, facing the station table, of the operation table are connected with the station table through connecting tables, and a tire feeding frame and a tire discharging frame are arranged on one side of the operation table. Known from the structure, the thermocuring flow production line of the tire realizes continuous production of one-time thermocuring molding of the tire using a composite fiber material as a belted layer, and the production efficiency is improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for smelting low-phosphorus steel in converter under the condition of ultra-high steel scrap ratio

ActiveCN113215347BImprove smelting scrap ratioReduce manufacturing costManufacturing convertersProcess efficiency improvementSmelting processControl system

The invention relates to a method for smelting low-phosphorus steel in a converter under the condition of an ultra-high ratio of steel scrap to steel. It adopts a 130t top-bottom double-blown converter for smelting, and the molten iron turnover mode is one tank to the bottom. 112-115t, the temperature of molten iron after desulfurization is 1310-1360°C, the mass percentage of silicon is 0.3-0.6%, and the amount of scrap steel is 38-48t. The specific smelting process includes: (1) Implementing the slag retention operation system, ( 2) scrap loading system, (3) slag adding and oxygen supply system, (4) bottom blowing system, (5) end point control system, to realize the smelting of low-phosphorus steel under the condition of ultra-high steel scrap ratio; the method of the present invention is On the basis of the existing high scrap steel ratio process practice, through the optimization of converter smelting operation, large penetration specific oxygen lance, reblowing process, etc., a complete and effective control method is formed to realize the high scrap steel ratio of 130t converter when entering the furnace, smelting The purpose of process stability, cost reduction, controllable end point and low phosphorus tapping.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com