Water treatment agent raw material high-pressure mixing device

A high-pressure mixing and water treatment agent technology, applied in the field of water treatment, can solve the problems of long time and low mixing efficiency, and achieve the effects of increased production efficiency, high mixing efficiency and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

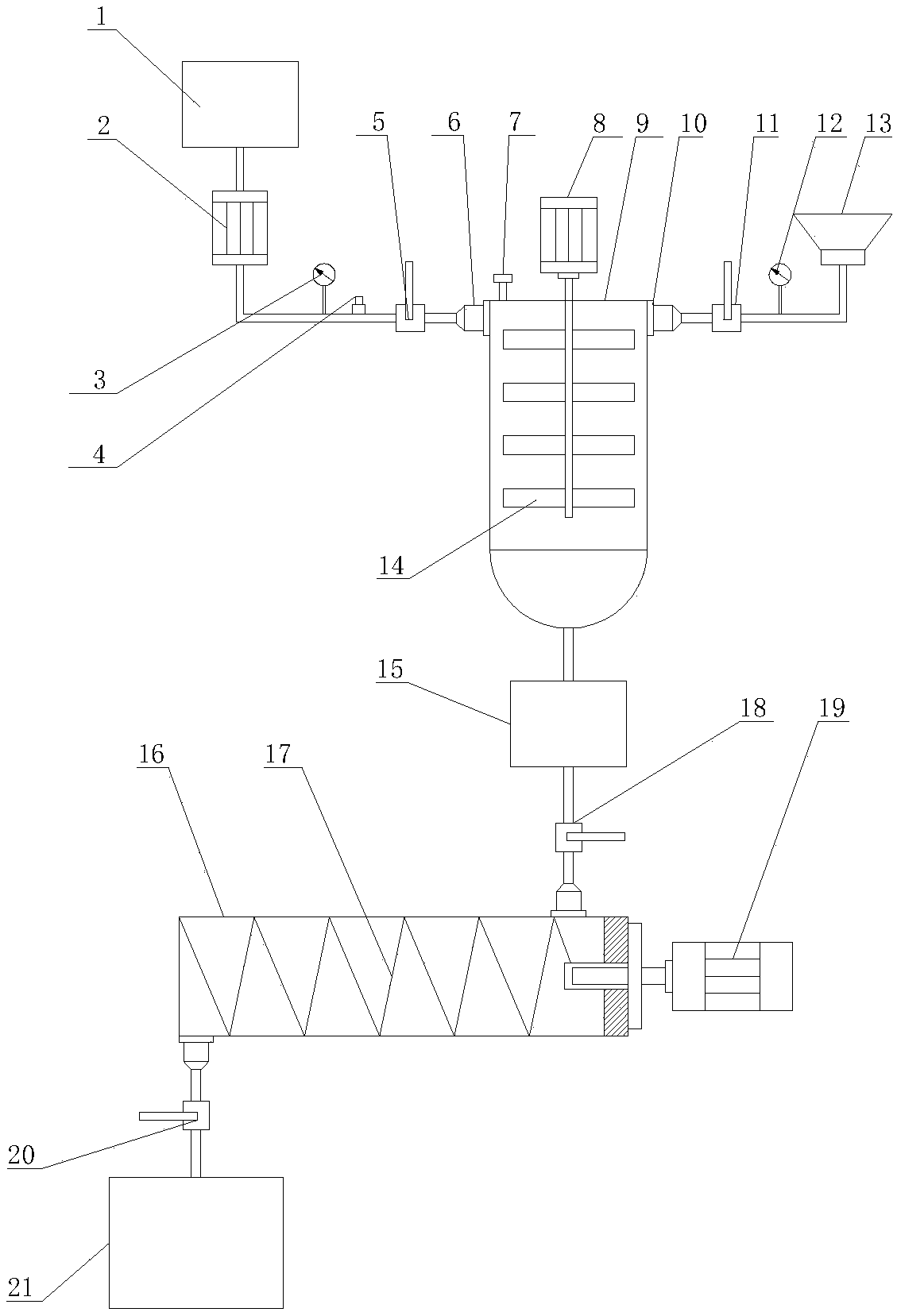

[0023] The water treatment agent material high-pressure mixing device of the present embodiment, such as figure 1 Shown, comprise vertical stirring tank 9, surge tank 15, horizontal stirring tank 16 and collecting barrel 21, the lower end of vertical stirring tank 9 is communicated with surge tank 15 by pipeline, the lower end of surge tank 15 is connected with horizontal stirring tank 16 One end of the horizontal stirring tank 16 is communicated with the collecting bucket 21 through a pipeline, and the vertical stirring tank 9 is vertically provided with a stirring paddle 14, and the side wall of the vertical stirring tank 9 is provided with a first The feed port 6 and the second feed port 10, the first feed port 6 is connected with the liquid material tank 1 through the pipeline, and the booster pump 2 is arranged on the pipeline between the first feed port 6 and the liquid material tank 1 , the top of the vertical stirring tank 9 is equipped with a first motor 8 for driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com