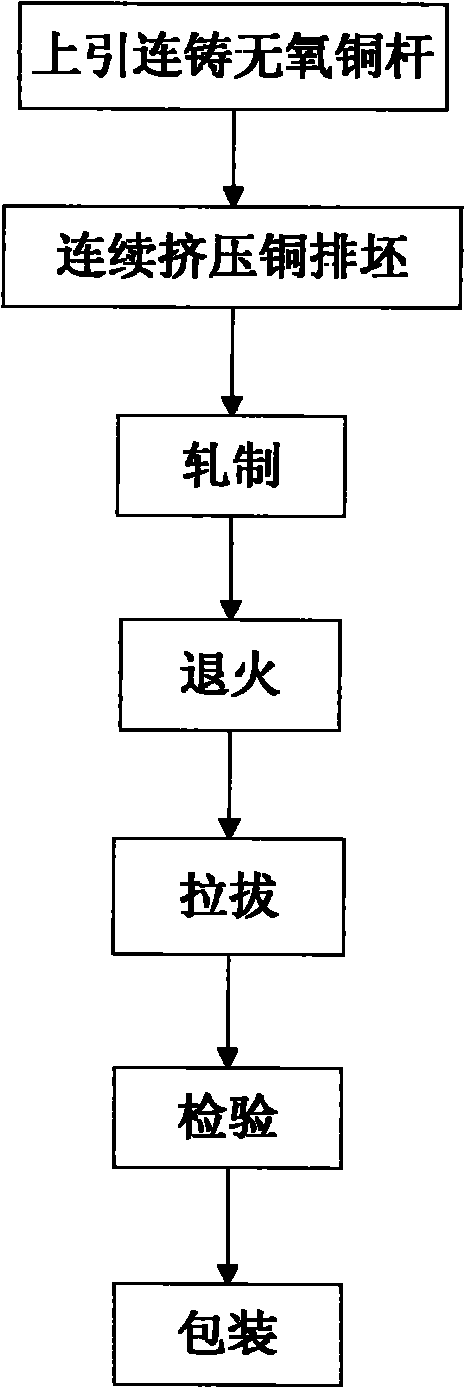

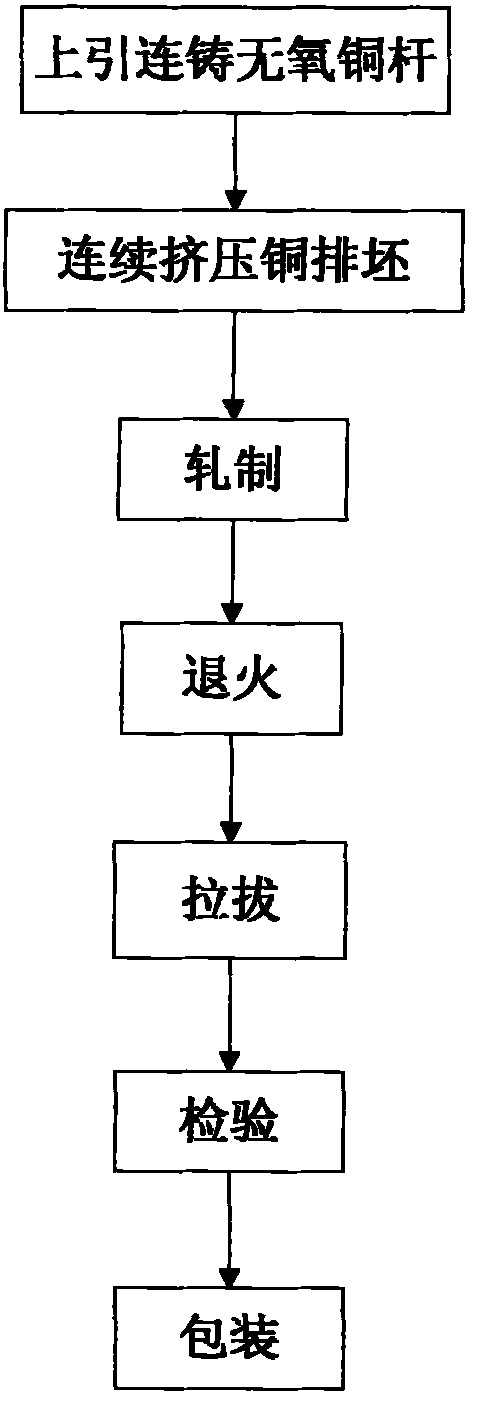

Production method of conducting copper bars for bus duct with large flakiness ratio

A production method and technology for bus ducts, which are applied to open busbar installation, circuits, electrical components, etc., can solve problems such as environmental pollution, long time, and poor product quality, and achieve the effect of improving the working environment and avoiding the pickling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] 1. Upward continuous casting oxygen-free copper rod

[0039] High-purity cathode copper is selected as raw material, which is preheated and dried before melting. The water pressure of the crystallizer is 2-4MPa, the temperature of the crystallizer outlet water is controlled at 35°C-50°C, and the temperature of the copper liquid is 1150°C±10°C. Using an online degassing and deoxidizing device, the copper liquid is filled with high-purity argon or nitrogen, and the metered amount of argon or nitrogen is pressed into the copper liquid through the controlled rotating graphite shaft and rotor and broken into tiny bubbles, so that It is evenly dispersed in the copper liquid. Air source outlet pressure 0.5~1MPa, flow rate 0.5~1.5Nm 3 / n. The surface of the copper liquid is covered with dried charcoal and graphite flakes. The oxygen-free copper rod is drawn up by the clutch type vacuum of the traction unit, and then the oxygen-free copper rod enters the take-up device. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com