A method for producing hot-rolled pickled plates and a pickling system for hot-rolled pickled plates

A hot-rolled pickling and pickling technology, applied in the field of iron and steel smelting, can solve problems such as energy consumption and heating, and achieve the effects of avoiding bubbles, reducing acid consumption, and avoiding surface over-pickling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

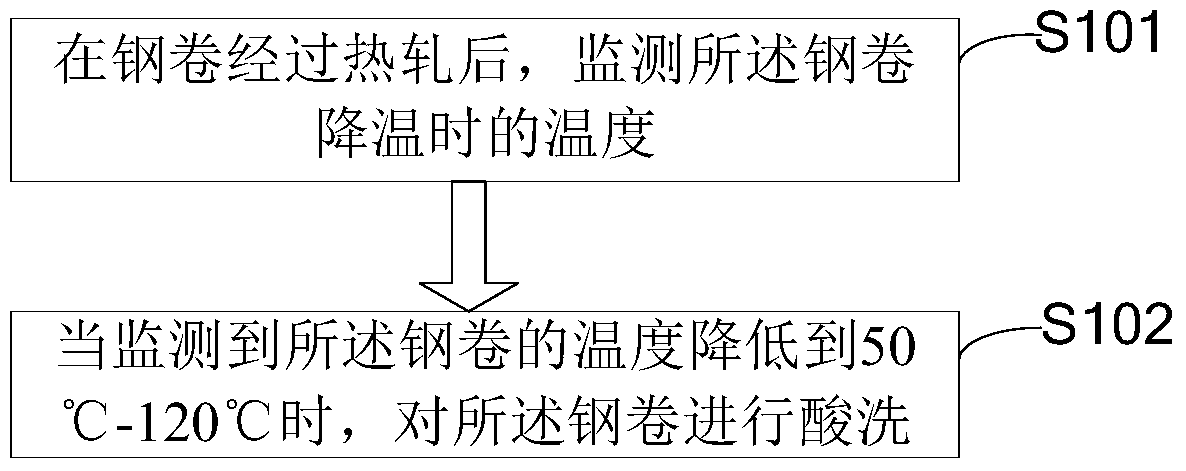

[0033] This embodiment provides a method for producing hot-rolled pickled plates, please refer to figure 1 , figure 1 It is a flow chart of the method for producing hot-rolled pickled plate in this embodiment, the method comprising:

[0034] Step S101, after the steel coil is hot-rolled, monitor the temperature of the steel coil when it cools down;

[0035] Step S102, when it is detected that the temperature of the steel coil drops to 50°C-120°C, start to pickle the steel coil.

[0036] The method for producing hot-rolled pickled plate provided by the application is described in detail below:

[0037] First, after steelmaking, the resulting coils are hot-rolled.

[0038] Specifically, in order to make the waste heat of the steel coil meet the requirement of heating the acid solution, the off-line temperature of the steel coil after hot rolling can be set at 500°C-800°C.

[0039] Next, step S101 is executed to monitor the temperature of the steel coil when it is cooled down...

Embodiment 2

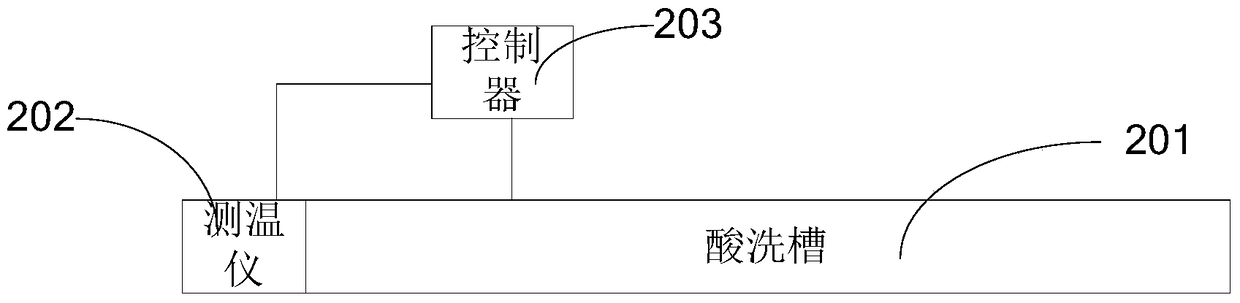

[0072] In embodiment two, a pickling system for hot-rolled pickling plates is provided, please refer to figure 2 , figure 2 It is a schematic diagram of the system in this embodiment, and the system includes:

[0073] Pickling tank 201;

[0074] A thermometer 202, located at one end of the pickling tank 201, is used to monitor the temperature of the steel coil when it is cooled down after the steel coil is hot-rolled;

[0075] The controller 203 is connected with the temperature measuring instrument 202, and is used to control the steel coil when receiving the prompt signal sent by the temperature measuring instrument 202 indicating that the temperature of the steel coil has dropped to 50°C-120°C Move in the pickling tank 201 and pickle.

[0076] In a specific implementation process, the thermometer 202 may be an infrared thermometer or an electronic thermometer, which is not limited in this embodiment.

[0077] In the embodiment of the present application, the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com