A kind of continuous production process for preparing glufosinate-ammonium

A production process and glufosinate-ammonium technology are applied in the production process field of continuous preparation of glufosinate-ammonium, which can solve the problem of not involving glufosinate-ammonium synthesis process operation flow and process equipment, difficult recycling of by-products, and inconcentration of recovered hydrochloric acid. and other problems, to achieve the effect of continuous production of by-products, saving equipment investment, and small one-time investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

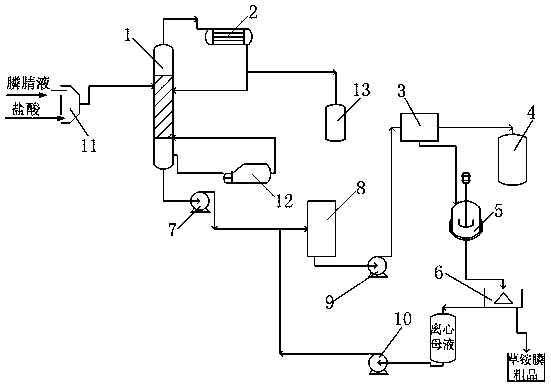

[0028] A production process for continuously preparing glufosinate-ammonium, comprising the following steps:

[0029] A. After mixing the phosphazene liquid with hydrochloric acid, send it to the hydrolysis tower 1, the low boiler obtained by hydrolysis completes step B, and the kettle liquid obtained by hydrolysis completes step C;

[0030] B, low boilers obtain recovery ethanol through condenser 2;

[0031] C, still liquid is sent into hydrochloric acid flasher 3, and the hydrochloric acid that removes is sent into hydrochloric acid absorber 4, and concentrated solution is sent into crystallization kettle 5;

[0032] D. The crystallization material in the crystallization tank 5 is sent into the centrifuge 6 to obtain the crude product of glufosinate-ammonium, and the centrifuged mother liquor is returned to the hydrochloric acid flasher 3.

Embodiment 2

[0034] In this embodiment, on the basis of Example 1, the temperature in the hydrolysis tower 1 in step A is limited, the temperature should be controlled at 100° C., and the pressure should be controlled at 0.02 MPa.

Embodiment 3

[0036] In this example, on the basis of Example 1, the temperature of the condenser 2 in step B is limited, and the temperature should be controlled at 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com