A method for recycling waste mineral oil

A technology for waste mineral oil and heavy recovery, which is applied in the treatment of hydrocarbon oil, petroleum industry, and multi-stage series refining process treatment, etc. Avoid pickling process, high product quality, reduce acidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

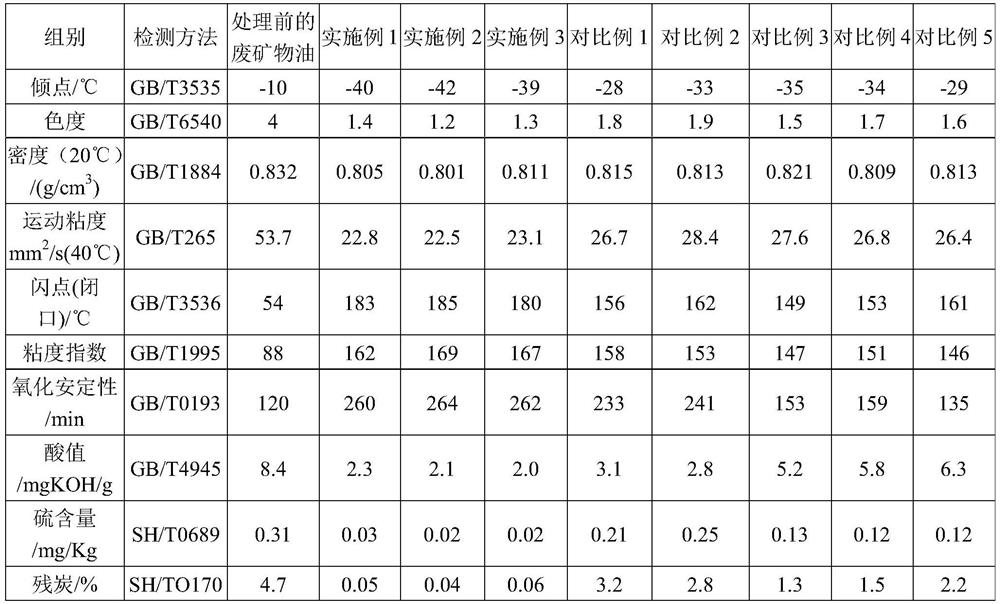

Embodiment 1

[0031] Embodiment 1 A kind of method of heavy recycling of waste mineral oil

[0032] The method for the heavy recycling of described waste mineral oil, described steps are as follows:

[0033] S1. Settling: the waste mineral oil is transported to the settling tank, and after filtering out the solid impurities with large particle size in the waste mineral oil, a flocculant is added for sedimentation and separation to form upper waste oil, middle liquid and bottom slag; the flocculant It is polyacrylamide; the added amount of the flocculant is 1% of the waste mineral oil weight;

[0034] S2. Distillation under reduced pressure: pump the waste oil in the upper layer obtained in step S1 into the reaction kettle, add extractant and catalyst, stir evenly, and directly heat the furnace under the kettle for 1 hour, the heating temperature is 85 ° C, and the pressure is 5Kpa, separate light component and water; The consumption ratio of described extraction agent and upper strata wast...

Embodiment 2

[0038] Embodiment 2 A kind of method of heavy recycling of waste mineral oil

[0039] The method for the heavy recycling of described waste mineral oil, described steps are as follows:

[0040] S1. Settling: the waste mineral oil is transported to the settling tank, and after filtering out the solid impurities with large particle size in the waste mineral oil, a flocculant is added for sedimentation and separation to form upper waste oil, middle liquid and bottom slag; the flocculant It is zinc chloride; the addition of the flocculant is 3% of the waste mineral oil weight;

[0041]S2. Distillation under reduced pressure: pump the waste oil in the upper layer obtained in step S1 into the reaction kettle, add extractant and catalyst, stir evenly, and directly heat the heating furnace under the kettle for 1.5 hours, the heating temperature is 105 ° C, and the pressure is 8Kpa, separate light component and water; The consumption ratio of described extraction agent and upper strat...

Embodiment 3

[0045] Embodiment 3 A kind of method of heavy recycling of waste mineral oil

[0046] The method for the heavy recycling of described waste mineral oil, described steps are as follows:

[0047] S1. Settling: the waste mineral oil is transported to the settling tank, and after filtering out the solid impurities with large particle size in the waste mineral oil, a flocculant is added for sedimentation and separation to form upper waste oil, middle liquid and bottom slag; the flocculant Be aluminum chloride; The addition amount of described flocculant is 5% of waste mineral oil weight;

[0048] S2, vacuum distillation: pump the upper waste oil obtained in step S1 into the reaction kettle, add extractant and catalyst, stir evenly, and directly heat the bottom of the kettle with a heating furnace for 2 hours at a heating temperature of 85-120°C. The pressure is 10Kpa to separate light components and water; the amount ratio of the extractant to the upper waste oil is 60mL:100mL; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com