A mold opening auxiliary ejection structure

A mold and straight top technology, applied in the field of mold opening auxiliary ejection structure, can solve the problems of product damage, increased cost, time-consuming and labor-intensive processing, etc., and achieves the effect of high stability and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

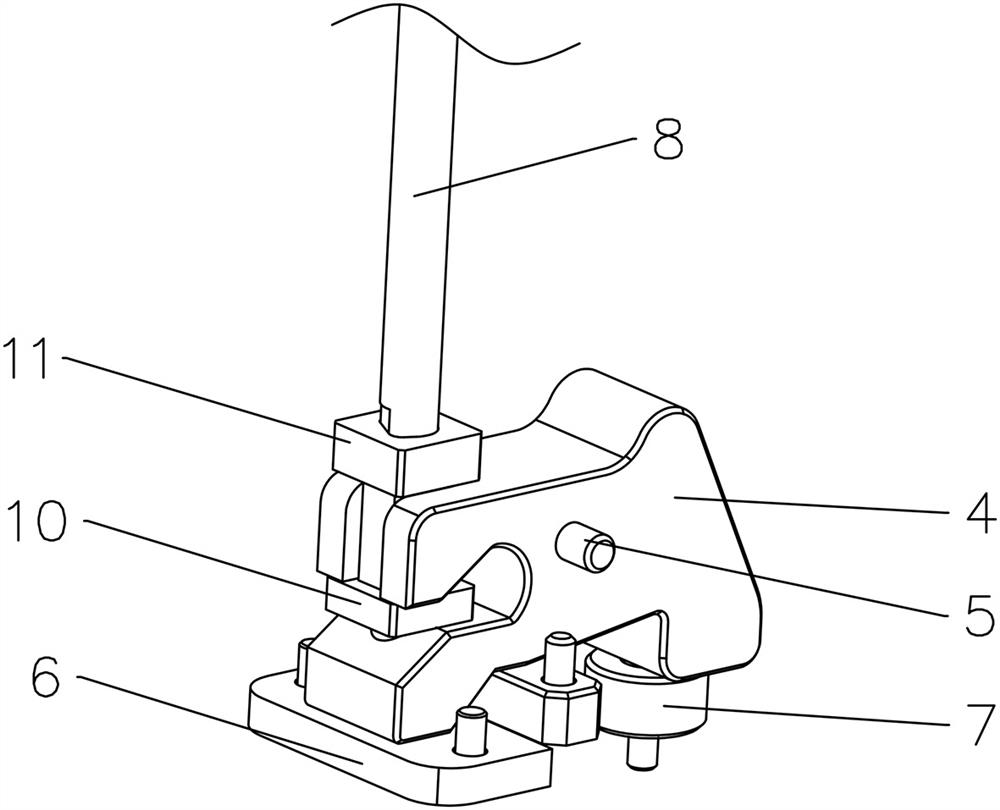

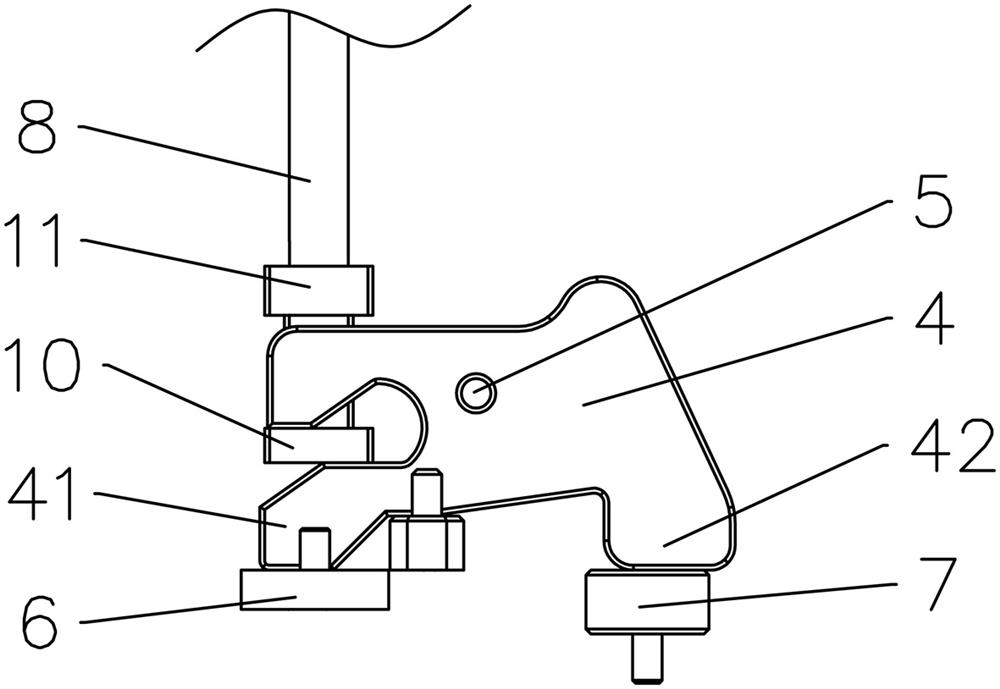

[0016] The present invention is further explained in conjunction with the accompanying drawings.

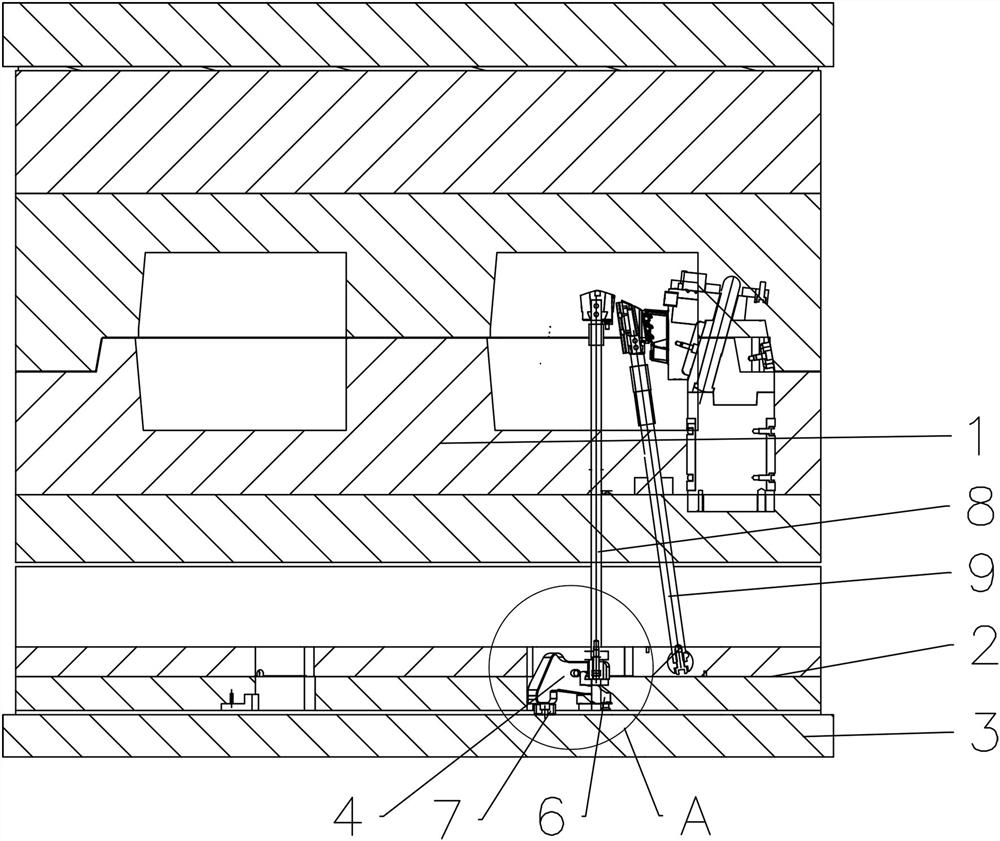

[0017] see Figure 1 to Figure 4 The mold opening auxiliary ejection structure shown includes a mold body 1 and an ejector plate 2 and a bottom plate 3 arranged on one side of the mold body 1 in sequence. The ejector plate 2 is provided with a through groove, and the through groove is provided with There is a pendulum block 4, one end of the bottom of the pendulum block 4 extends downward to form a first leg 41, and the other end of the bottom of the pendulum block 4 extends downward to form a second leg 42. The first pad 6 matched with the first leg 41, the bottom plate 3 is provided with a second pad 7 matched with the second leg 42, the pendulum block 4 is rotatably mounted on the ejector plate 2, And the pendulum block 4 has a tendency to turn over to the second cushion block 7, the pendulum block 4 is provided with a mounting hole, and a rotating shaft 5 is arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com