Patents

Literature

103results about How to "Achieve preload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

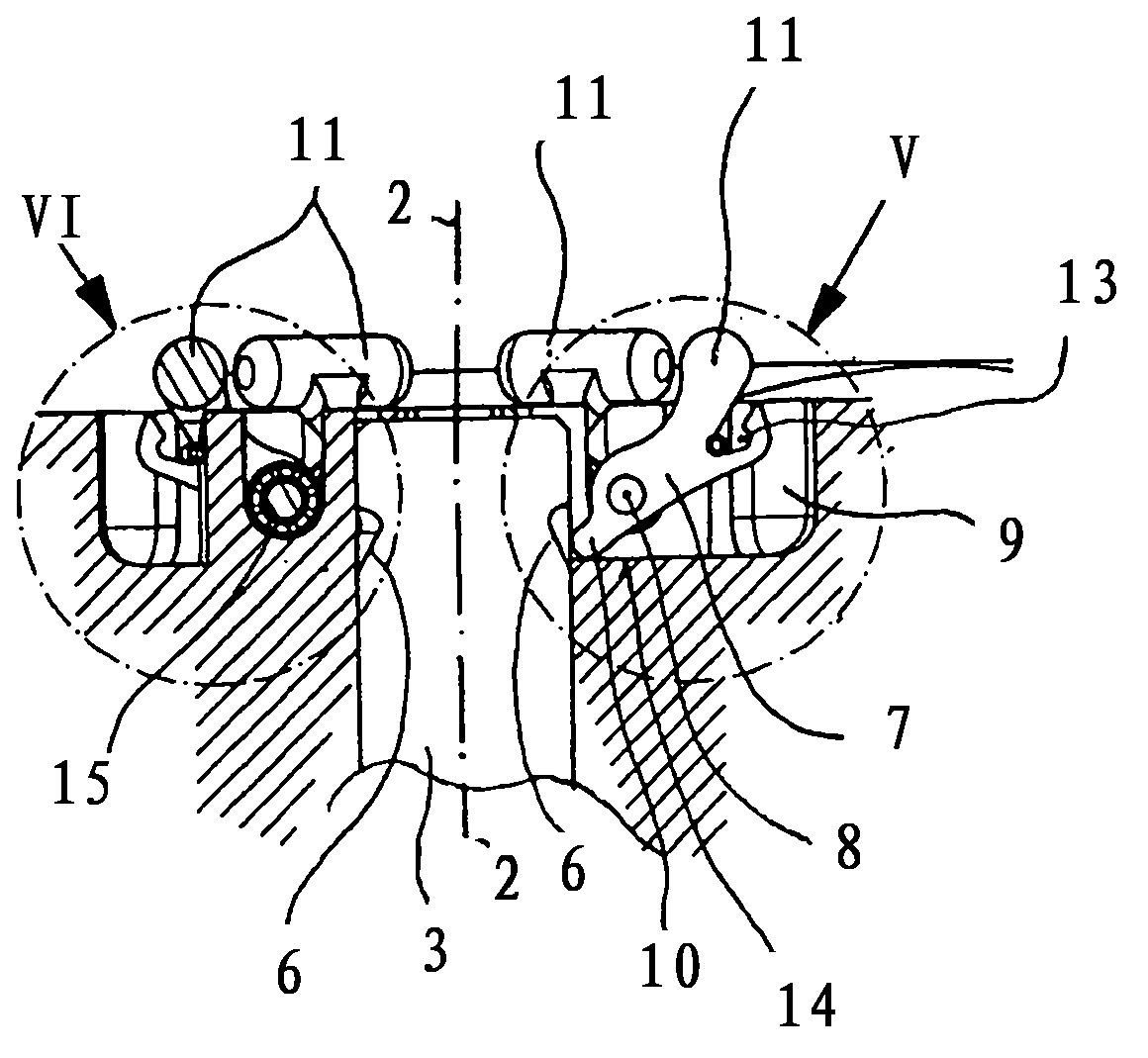

Three-point high-precision large-aperture electric reflector frame

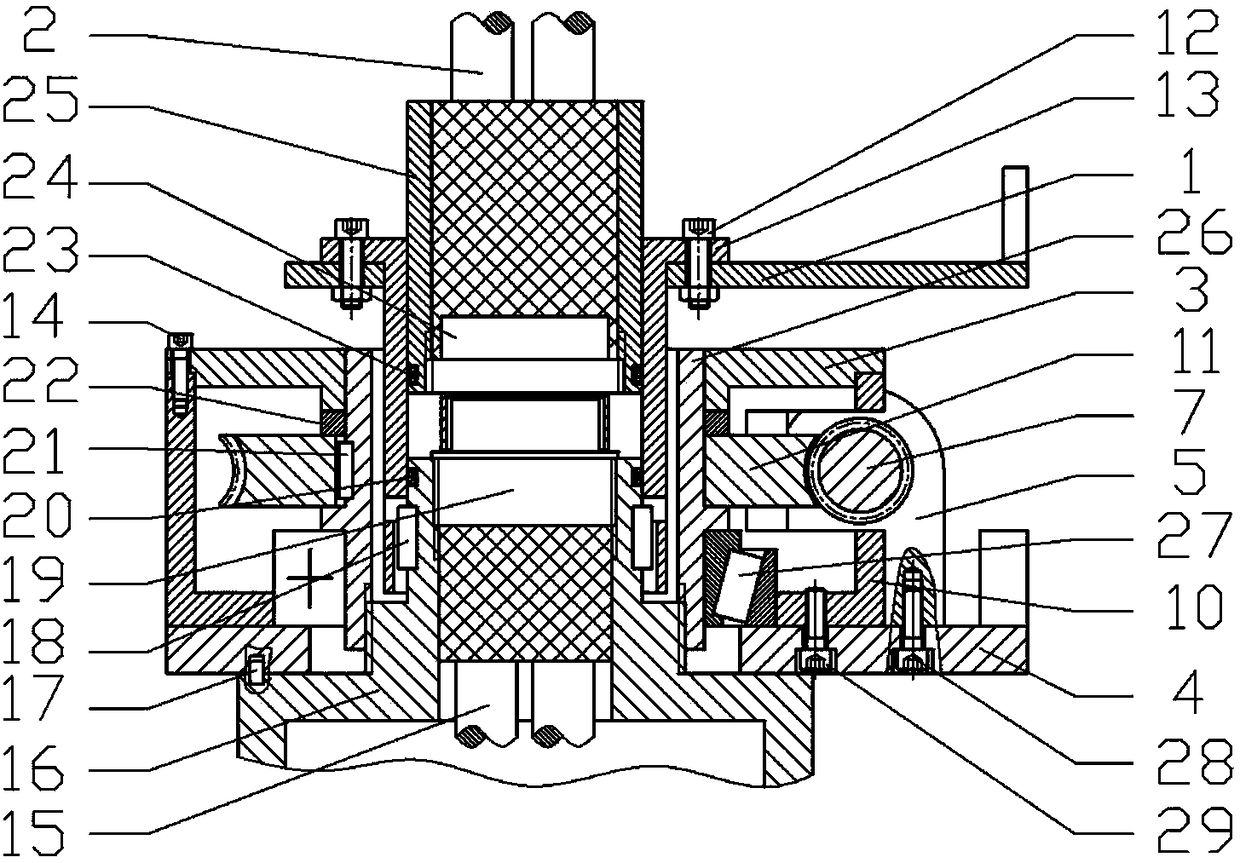

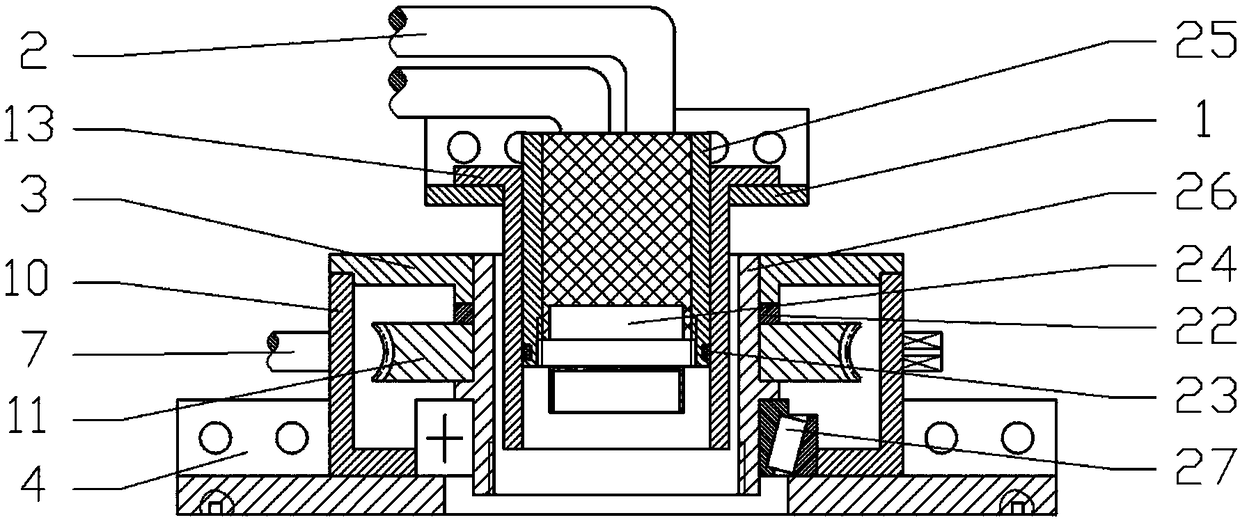

The invention provides a three-point high-precision large-aperture electric reflector frame, relating to an electric reflector frame. According to the three-point high-precision large-aperture electric reflector frame, the transmission direction of large-aperture laser beams is precisely guided and controlled, and the problems of the alignment and guidance of the laser beams in an inertial confinement laser nuclear fusion device and the near-field adjustment of light beams are solved. The reflector frame component is arranged at the front end of a machine frame component; the reflector frame component is connected with the machine frame component in a rotating manner; two micro driver components pass through the reflector frame component and the machine frame component sequentially from front to back; a drive control system is connected with the two micro driver components through conducting wires and is used for controlling the two micro driver components; the reflector frame component is suspended on a machine frame through a spherical support; and the left spherical tip is contacted with a plane support block, and the right spherical tip is contacted with a V-shaped support block. The three-point high-precision large-aperture electric reflector frame is applicable to inertial confinement laser nuclear fusion equipment.

Owner:HARBIN INST OF TECH

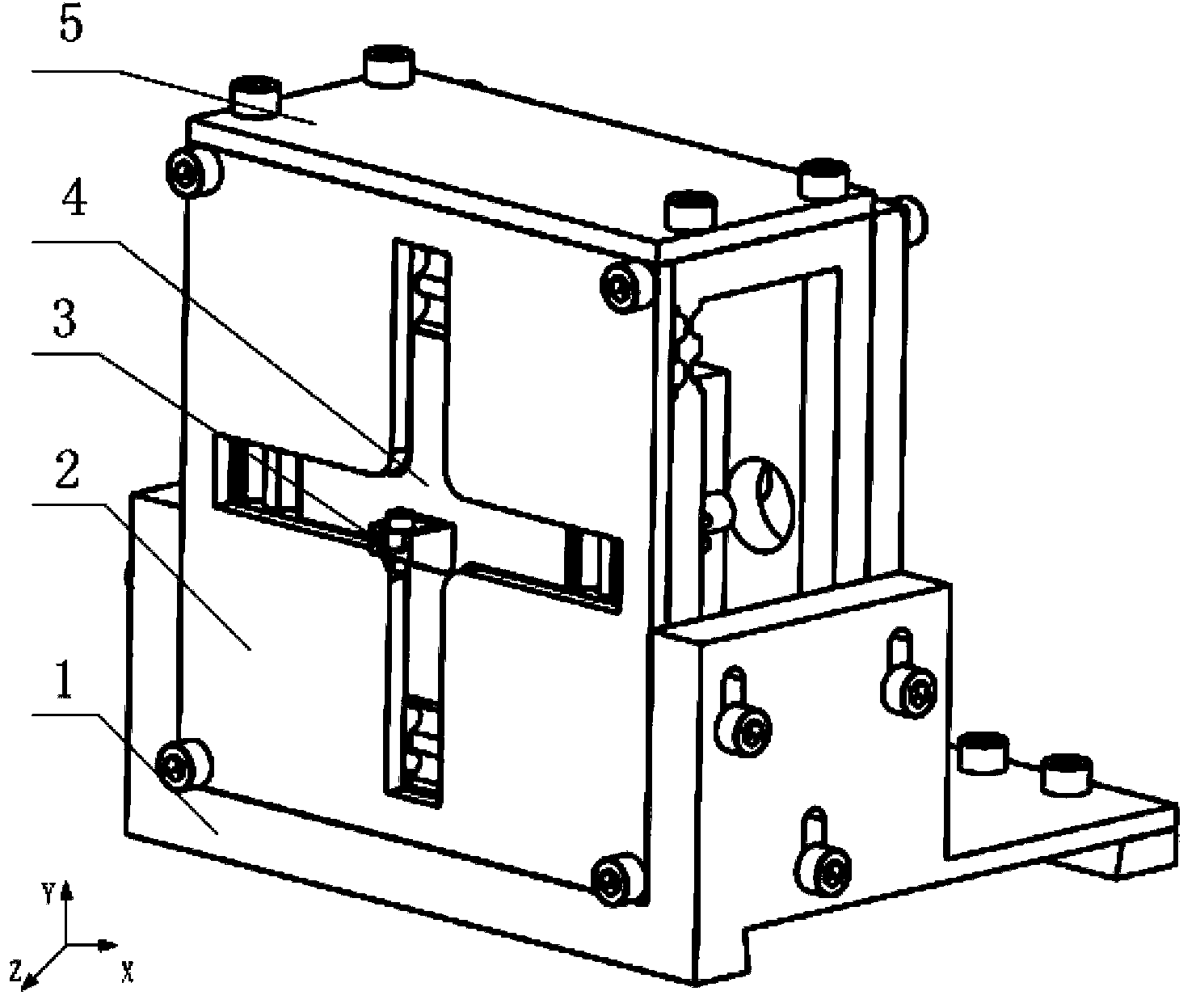

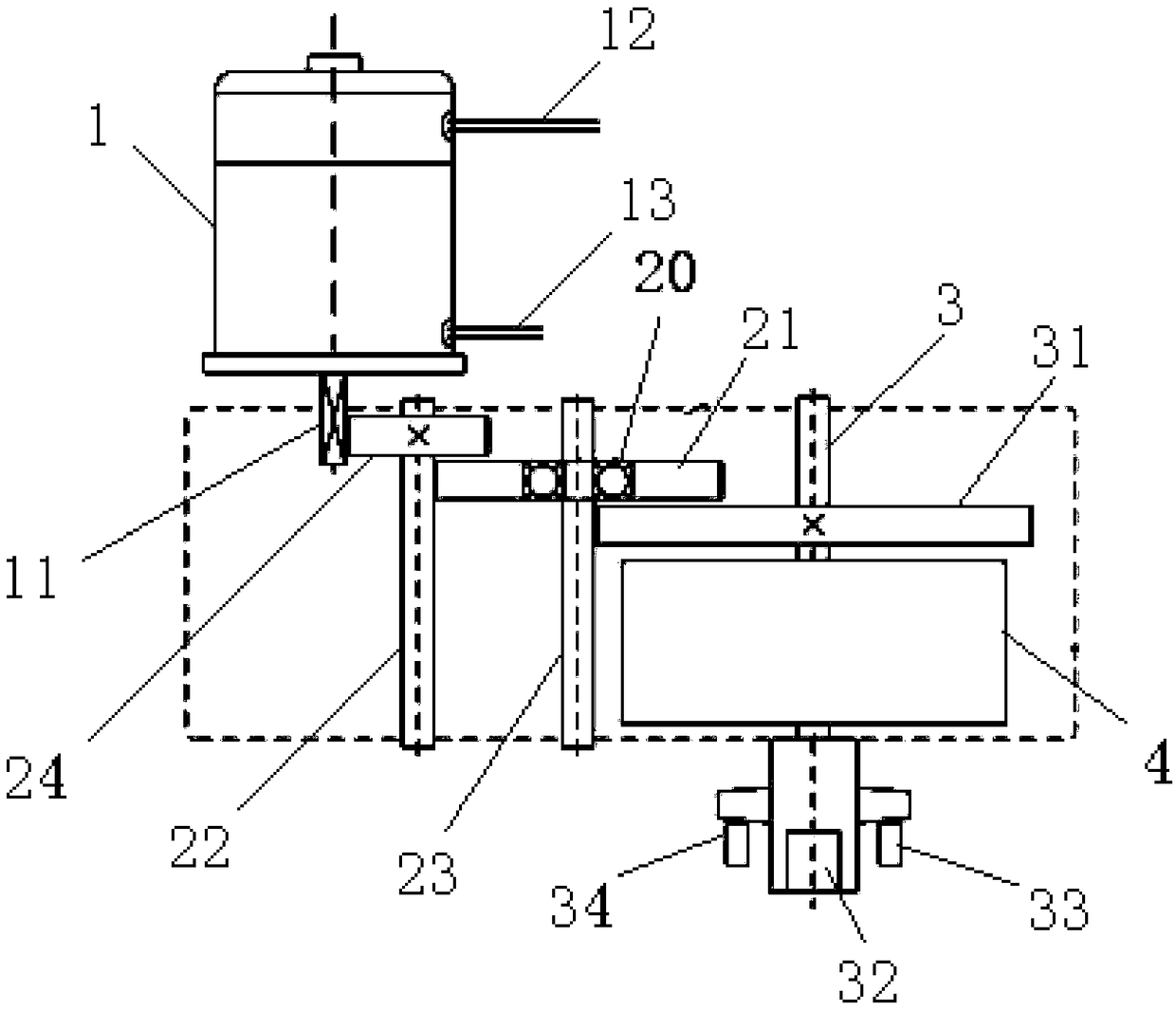

Off-resonance three-dimensional elliptical diamond vibration cutting method and device

ActiveCN103394705AActive adjustment to achieveAdapt to the requirements of processing complex curved surfacesAutomatic control devicesAuxillary equipmentDiamond cuttingOff resonance

The invention relates to an off-resonance three-dimensional elliptical diamond vibration cutting method and device and belongs to a cutting method and device. Four piezoelectric stacks which are placed in parallel are driven according to input signals, and phase angles of the input signals are different in a two-to-two mode. The piezoelectric stacks push a pushing face on a tool apron hinge base body to enable various hinges to produce micrometric displacement, therefore a diamond cutter point three-dimensional elliptical movement track capable of being adjusted can be obtained, the track can be adjusted initiatively through frequency, amplitudes and phase differences of driving signals of the piezoelectric stacks and installation positions of the piezoelectric stacks. The off-resonance three-dimensional elliptical diamond vibration cutting method and device can meet requirements for various difficult-to-machine materials and different face types through diamond cutting, and obtains the best cutting machining performance.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

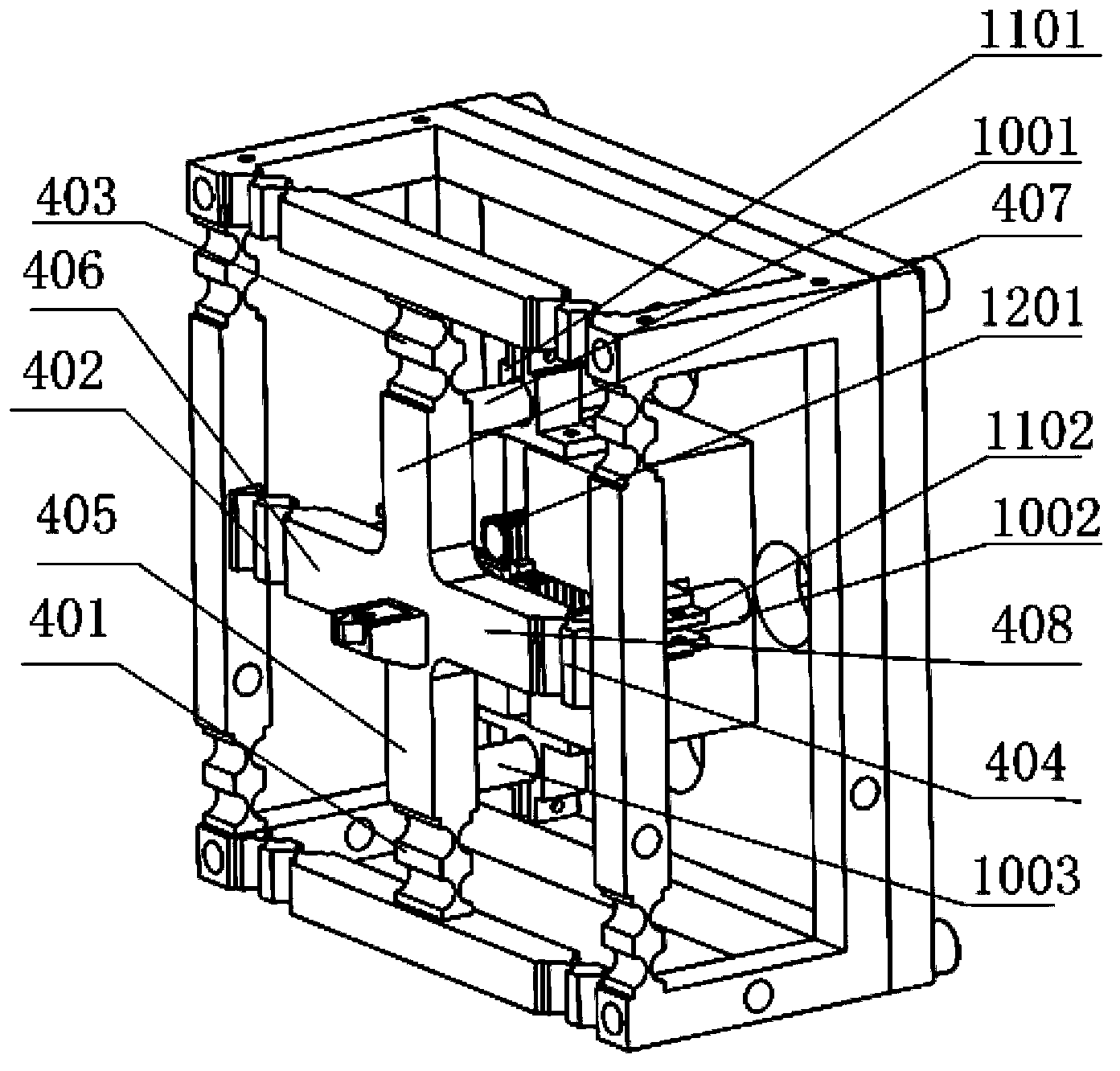

Wearable exoskeleton upper-limb rehabilitation robot

InactiveCN106691778ASimple structureSolve the phenomenon of chain drive or belt drive tooth skippingChiropractic devicesWrist jointsSacroiliac joint

The invention discloses a wearable exoskeleton upper-limb rehabilitation robot. The wearable exoskeleton upper-limb rehabilitation robot comprises an arm adjustment component, a shoulder joint flexion and extension component, a shoulder joint folding and unfolding component, an upper-limb rotational motion component, an elbow joint flexion and extension component,, a front-arm rotational motion component, a wrist joint flexion and extension component and a frame motor component. The arm adjustment component is fixed to the frame motor component. The arm adjustment component, the shoulder joint flexion and extension component, the shoulder joint folding and unfolding component, the upper-arm rotational motion component, the elbow joint flexion and extension component, the front-arm rotational motion component and the wrist joint flexion and extension component are connected in sequence. The wearable exoskeleton upper-limb rehabilitation robot has the advantages that six-freedom-degree motion of flexion and extension as well as inward folding and outward unfolding of shoulder joints, internal and external rotation of upper arms, flexion and extension of elbow joints, internal and external rotation of front arms and flexion and extension of wrist joints can be achieved, and one-freedom-degree motion of arm adjustment can be also achieved; all the joints of the upper-limb rehabilitation robot are driven indirectly, the weight of robot arms is reduced, weight loading capability of the robot arms is improved, mechanical structure is simplified, and flexibility of the robot is improved.

Owner:HEBEI UNIV OF TECH

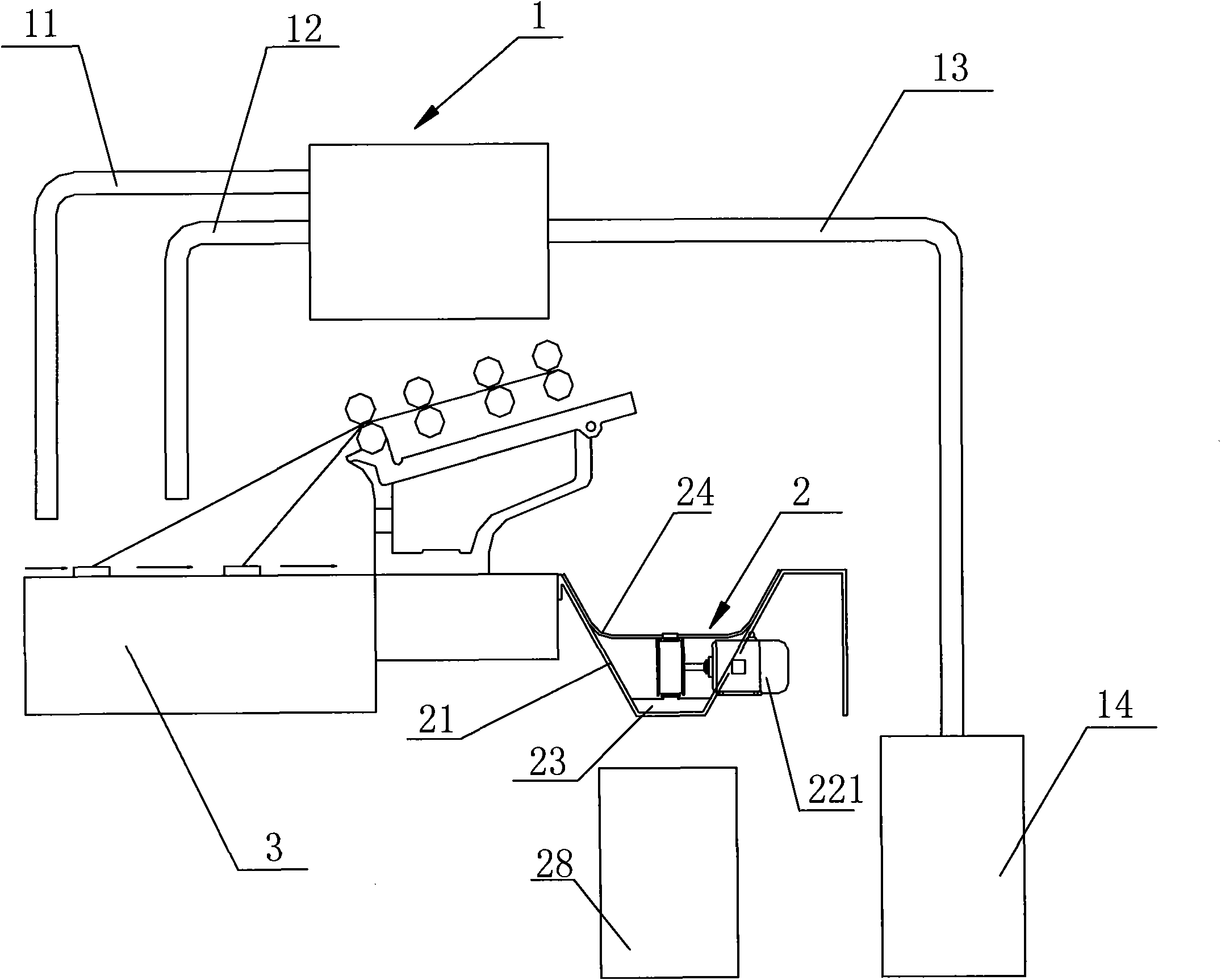

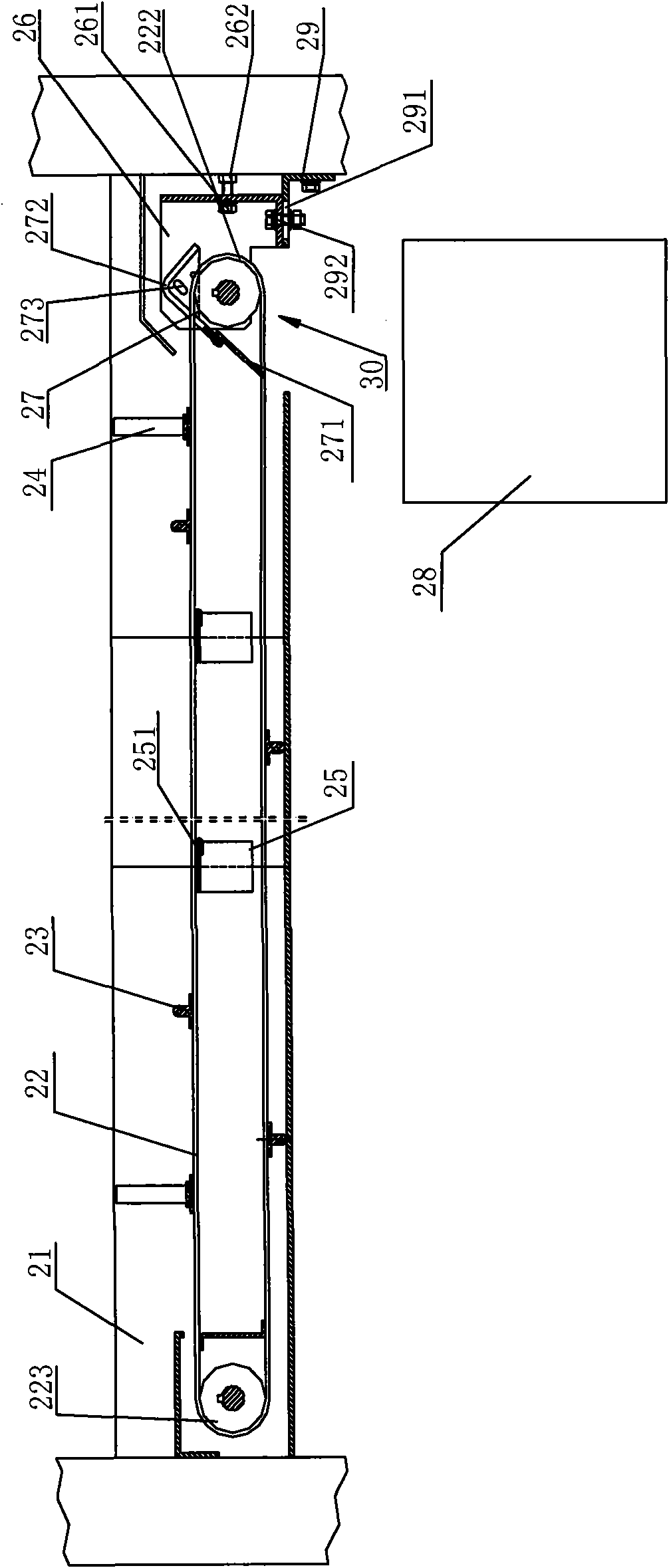

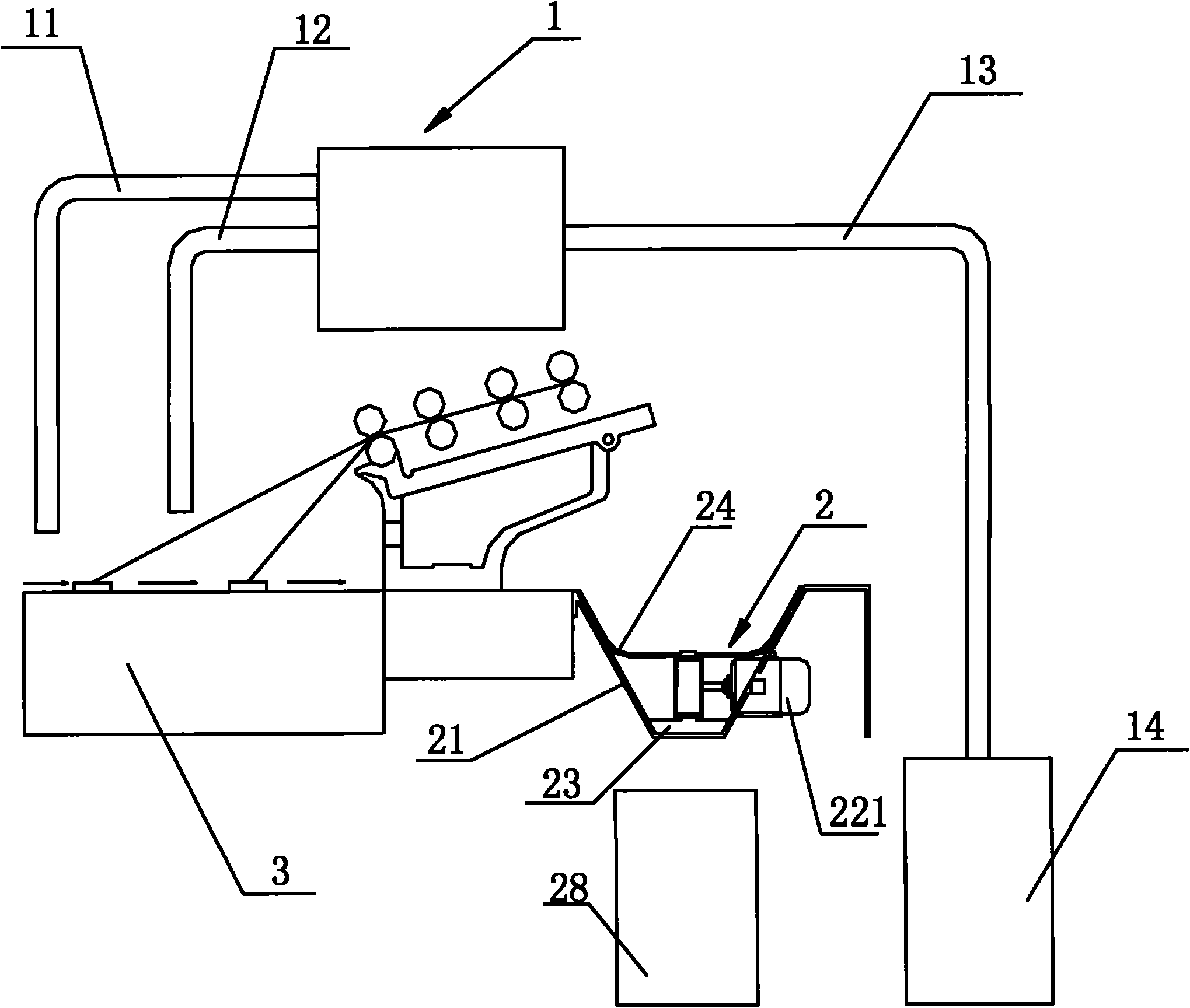

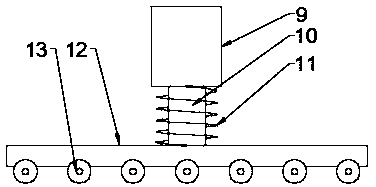

Cotton collecting device of roving machine

ActiveCN101845694AEasy to scrape synchronouslyGood cotton collection effectTextiles and paperEngineeringMechanical engineering

The invention discloses a cotton collecting device of a roving machine, comprising a blowing and suction cleaner and a cotton collector, wherein the blowing and suction cleaner is positioned above a machine body; the cotton collector is positioned at the rear side of the machine body; the blowing and suction cleaner is provided with an air blowing pipe, an air suction pipe and a dust discharging pipe, wherein pipe orifices of the air blowing pipe and the air suction pipe face toward the machine body of the roving machine; the cotton collector is provided with a cotton collecting groove which is opened upwards and a rotary type annular belt which stretches along the length direction of the cotton collecting groove; and the body of the rotary type annular belt is provided with a clean scraping plate which is appropriate to the bottom inside the cotton collecting groove. The cotton collecting device is characterized in that the body of the rotary type annular belt is also provided with flexible elastic scraping strips which can scrape cotton wastes attached to the inner walls of both sides of the cotton collecting groove; the belt body carrying with the flexible elastic scraping strips can repeatedly continuously scrape from one end of the cotton collecting groove to the other end of the cotton collecting groove simultaneously along the inner walls of both sides of the cotton collecting groove in the rotary process of the rotary type annular belt, and the cotton wastes attached to the inner walls of both sides of the cotton collecting groove are scraped to drop into the bottom inside the cotton collecting groove. The invention is convenient for the synchronous scrape of the clean scraping plate and beneficial to keeping better cotton collecting effect.

Owner:CMT HICORP MACHINERY QINGDAO

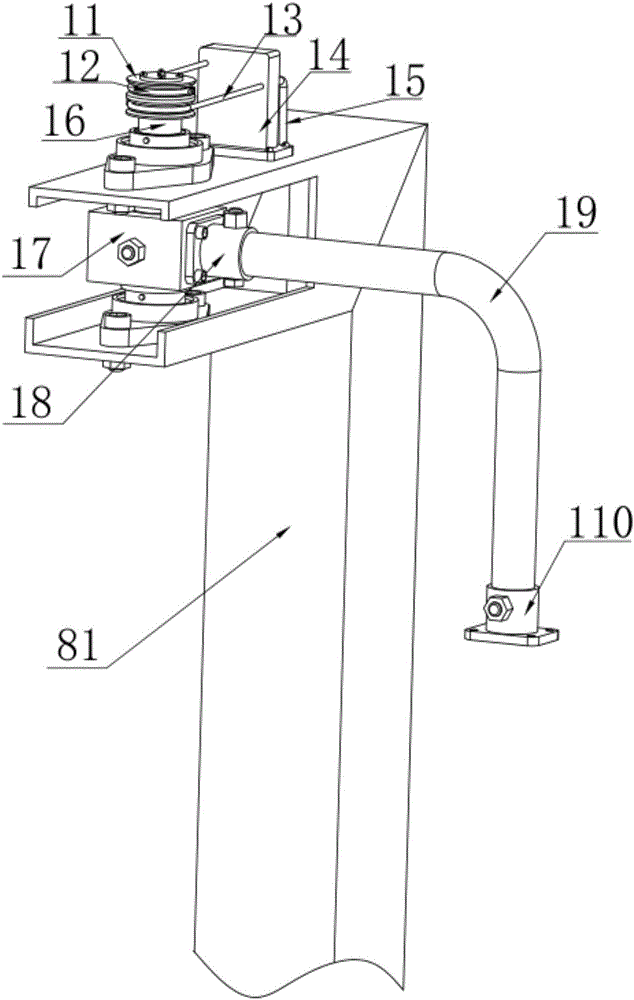

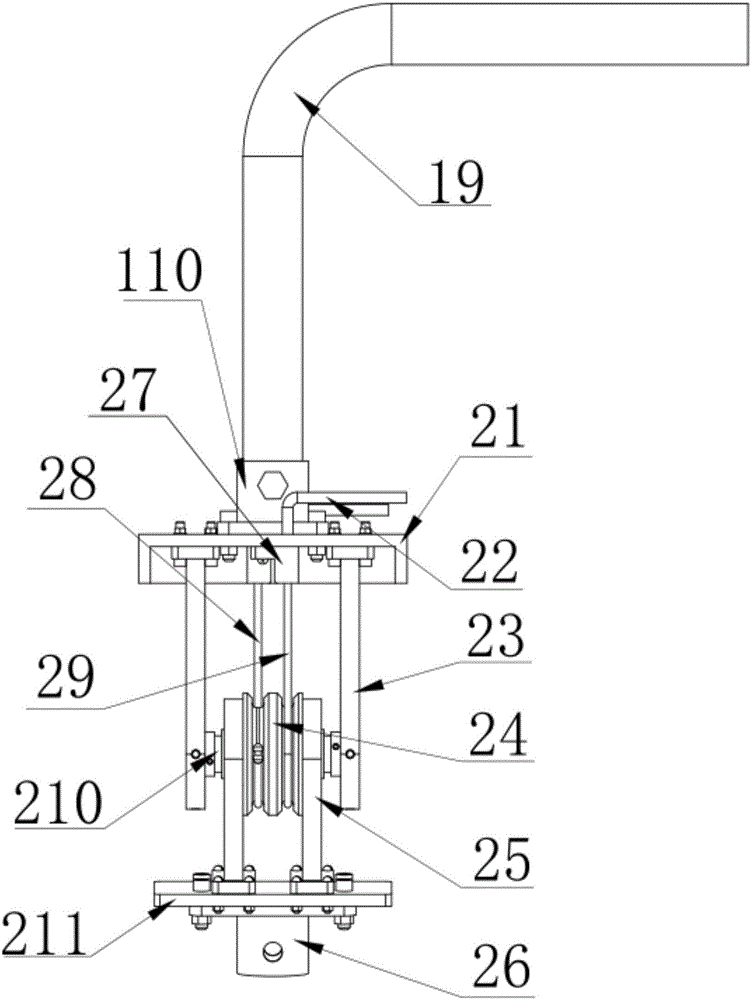

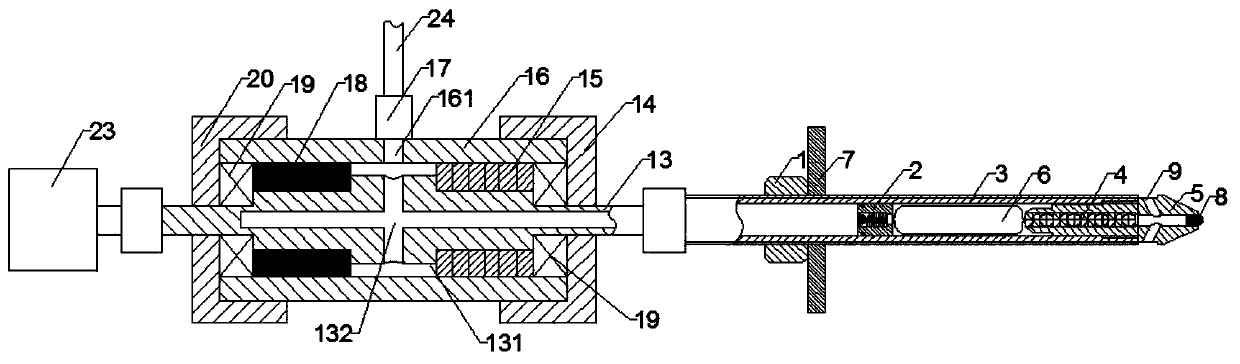

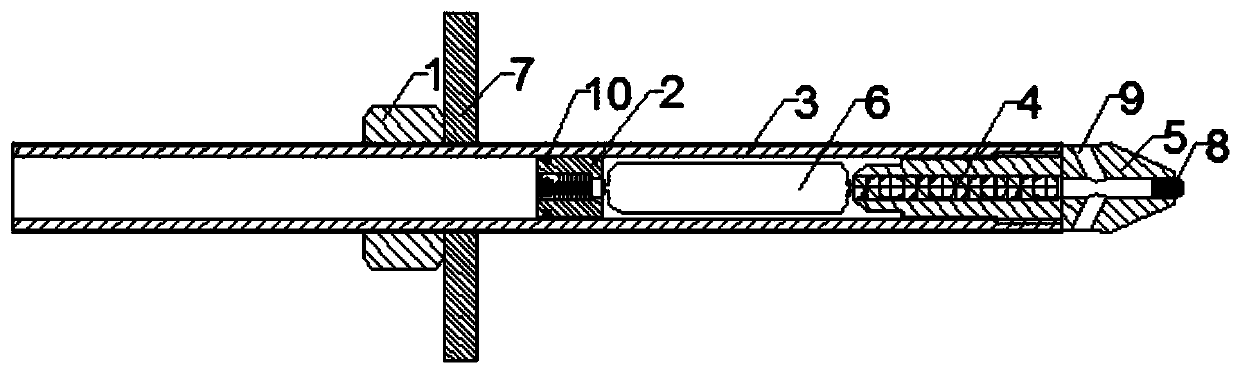

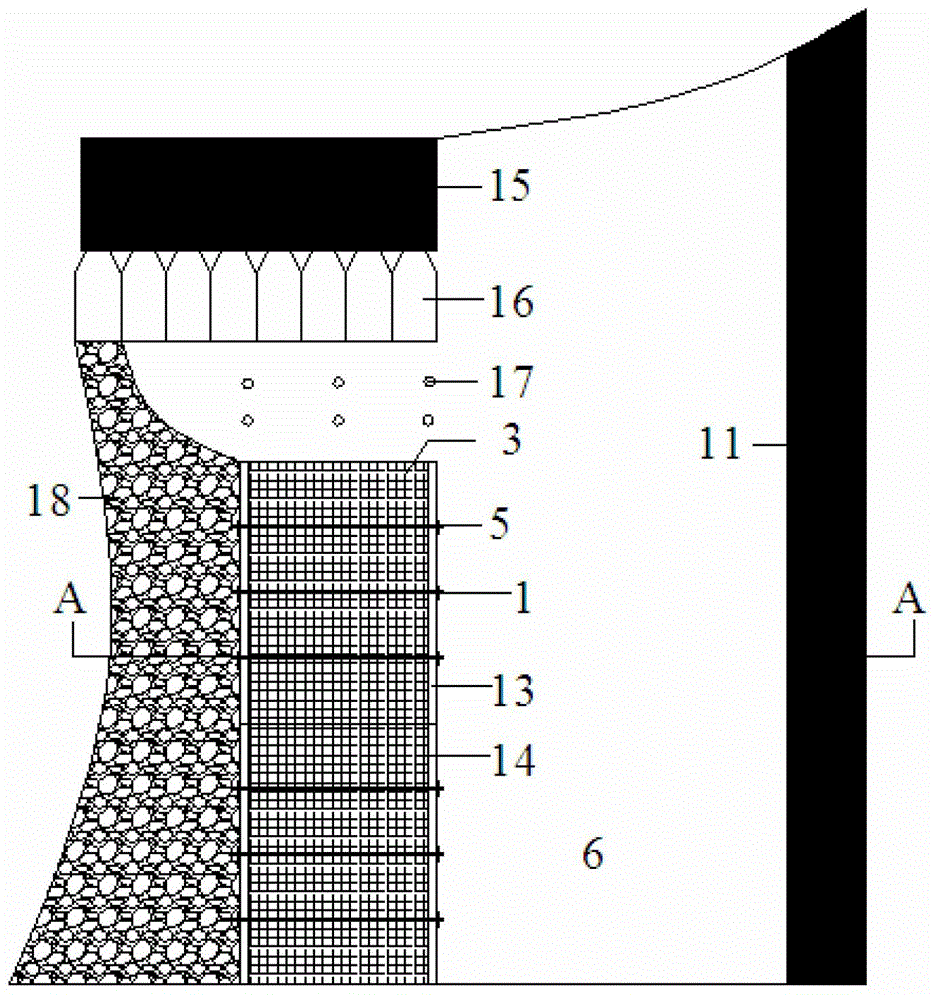

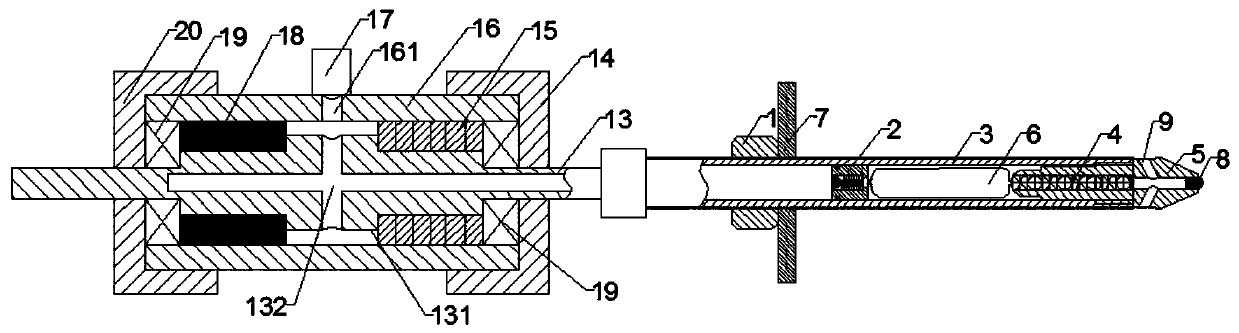

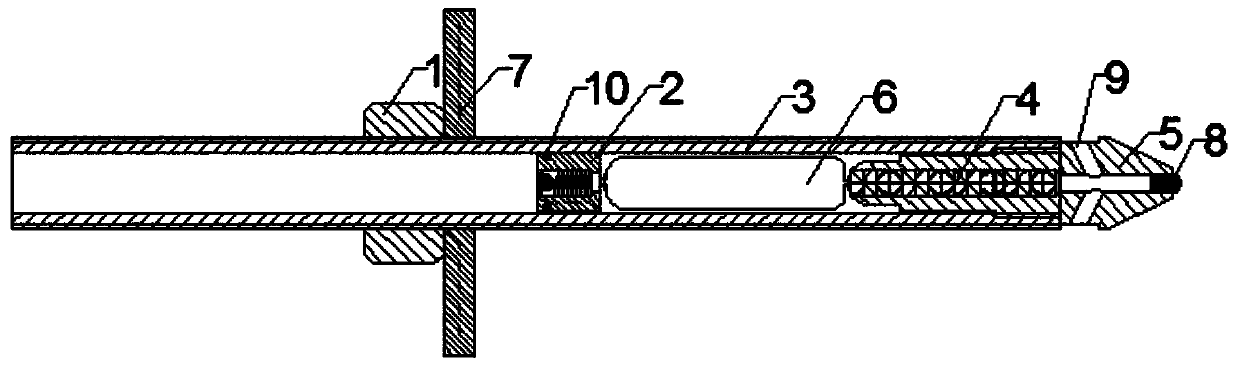

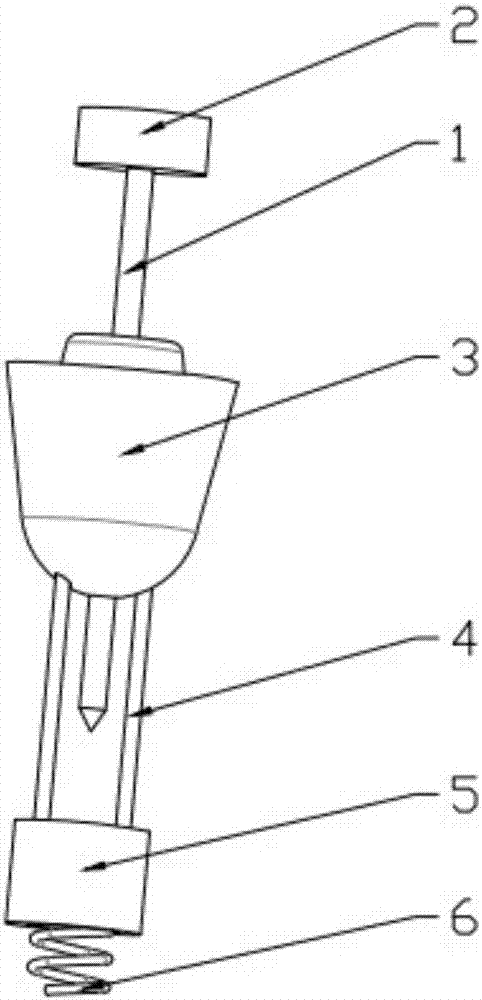

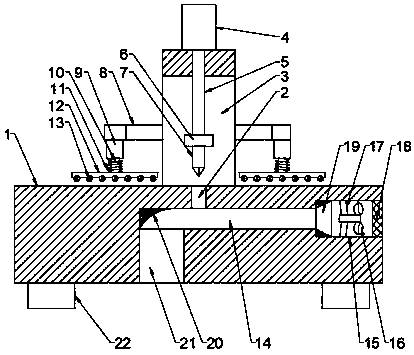

Mounting process of novel drilling, anchoring and injecting integrated resin anchor rod

The invention discloses a mounting process of a novel drilling, anchoring and grouting integrated resin anchor rod. The mounting process comprises the following procedures: a, selecting a rotary jointand an anchor rod; b, drilling an anchor rod hole to enable the anchor rod hole to meet the requirement; c, placing an anchoring agent bag (6) in an anchor rod body (3), and inserting the anchor rodinto the anchor rod hole; d, detachably connecting one end part of a rotating shaft (13) of the rotating joint with one end of the anchor rod body (3), then connecting a high-pressure water pipe (24)with an injection hole (161) formed in a sleeve (16) of the rotating joint, and opening a valve of the high-pressure water pipe (24) until anchoring is completed; e, connecting the other end of the rotating shaft (13) of the rotating joint with the output end of drilling equipment (23); and f, starting the drilling equipment to pre-tighten the anchor rod. According to the process, uniform mixing of the anchoring agent, anchoring, pre-tightening and high-pressure grouting can be integrated, and the problems that an existing resin anchor rod is complex in mounting process, high in technical requirement for the mounting personnel, high in failure rate and the like are solved.

Owner:四川钛星工程科技有限责任公司

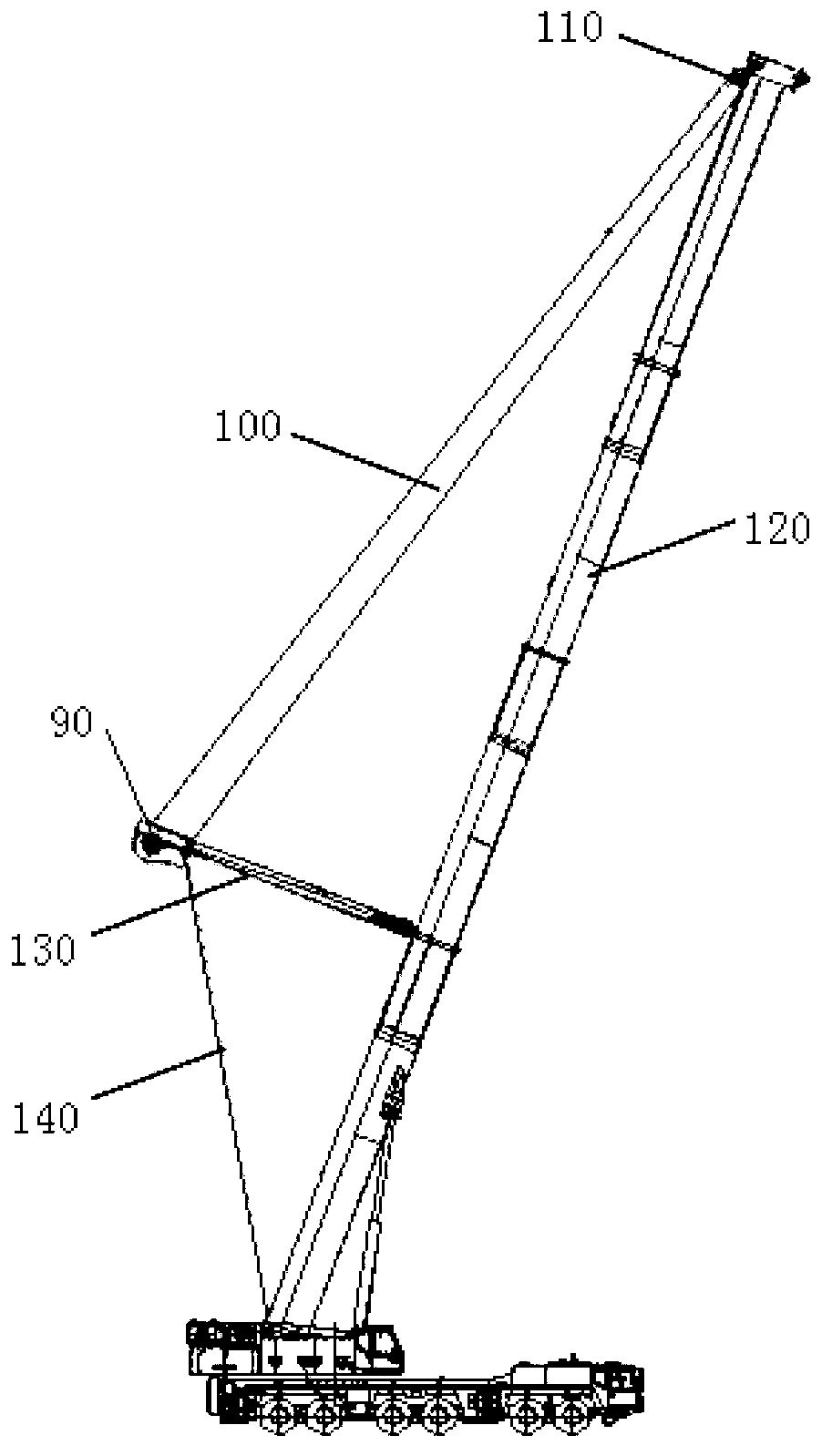

Crane, guying mast and pulling pre-tightening device of guying mast

The invention provides a crane, a guying mast and a pulling pre-tightening device of the guying mast. The pulling pre-tightening device comprises a first base, a second base, a movable lug, an elastic component and an adjustment cylinder, wherein the movable lug is located between the first and second bases; the first end of the elastic component is connected with the first base and the second end of the elastic component is connected with the first end of the movable lug; and the first end of the adjustment cylinder is connected with the second base, and the second end of the adjustment cylinder is connected with that of the movable lug. By telescopic movement of the adjustment cylinder, the pulling point position of a front tightening steel wire rope and the guying mast is changed, the effect of adjusting the pre-tightening force of the front tightening steel wire rope is achieved, and the structural rigidity of the whole boom can be adjusted.

Owner:ZOOMLION HEAVY IND CO LTD

Comprehensive measurement device and method for bearing rigidity and starting friction torque

ActiveCN106525424AAchieve stiffnessAchieve frictionMachine bearings testingForce sensorsFriction torqueMeasurement device

The invention discloses a comprehensive measurement device for bearing rigidity and starting friction torque, including a driving shaft, an inner axial pressure conduction block, an outer axial pressure conduction block, a pressure sensor and locking nuts. The driving shaft comprises a first step, a second step which is used for clamping a bearing, a testing end and a fastening end, and the testing end and the fastening end are provided with outer threads. The inner axial pressure conduction block is sleeved on the first step and is provided with a groove. The outer axial pressure conduction block is provided with a projection cooperated with the groove. The pressure sensor is sleeved on the driving shaft, and the end surface of the pressure sensor is adhered to the end surface of the inner axial pressure conduction block. The locking nuts are fixedly connected at two ends of the driving shaft respectively. The comprehensive measurement device for bearing rigidity and starting friction torque obtains the pretightening force, rigidity and starting friction torque of a single bearing or bearings in pair with one measurement device.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Roller-bearing preloading adjustment structure and method

InactiveCN107289030AEnsure clearanceEnsure preloadGearing detailsBearing unit rigid supportGear wheelDrive shaft

The invention discloses a roller bearing preload adjustment structure and method. The roller bearing preload adjustment structure includes: a roller bearing capable of being installed on a transmission shaft; a bearing seat supporting the roller bearing, and the bearing seat is installed in a box On the body, and the inner ring of the bearing seat is provided with an internal thread; the bearing lock nut is provided with an external thread that engages with the internal thread on the bearing seat, and the inner side of the bearing lock nut is in contact with the roller bearing the outer ring abutment. The roller bearing preload adjustment structure disclosed in the present invention adjusts the bearing lock nut when adjusting the axial positioning of the roller bearing. Since the bearing lock nut and the bearing seat are threaded, the bearing lock nut rotates One turn, forward or backward by one pitch, so as to ensure that the clearance and preload of the roller bearing meet the technical requirements, and realize the axial position adjustment of the transmission parts such as the gear on the transmission shaft. The use of grinding parts is reduced, and the adjustment can be realized only by rotating the bearing lock nut, which has high efficiency.

Owner:CHONGQING GEARBOX

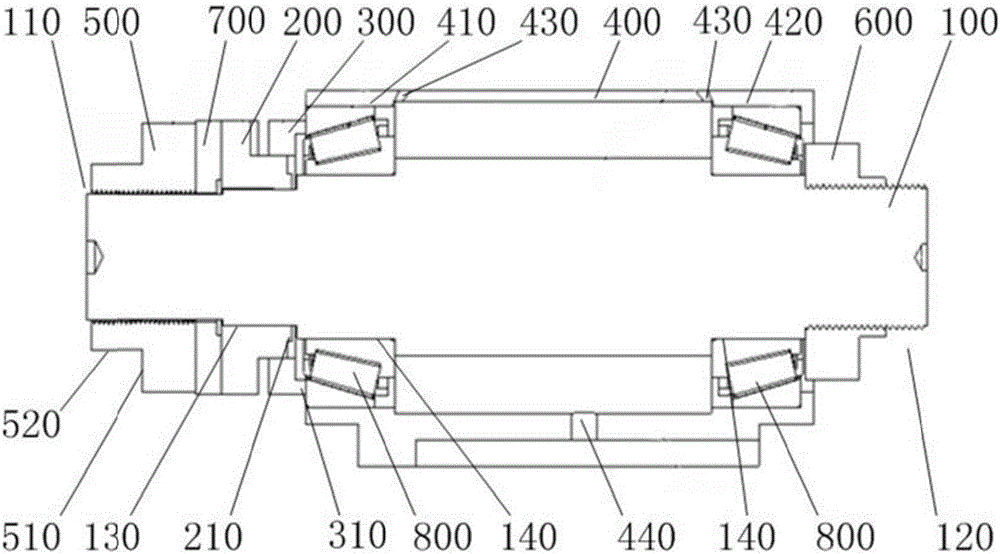

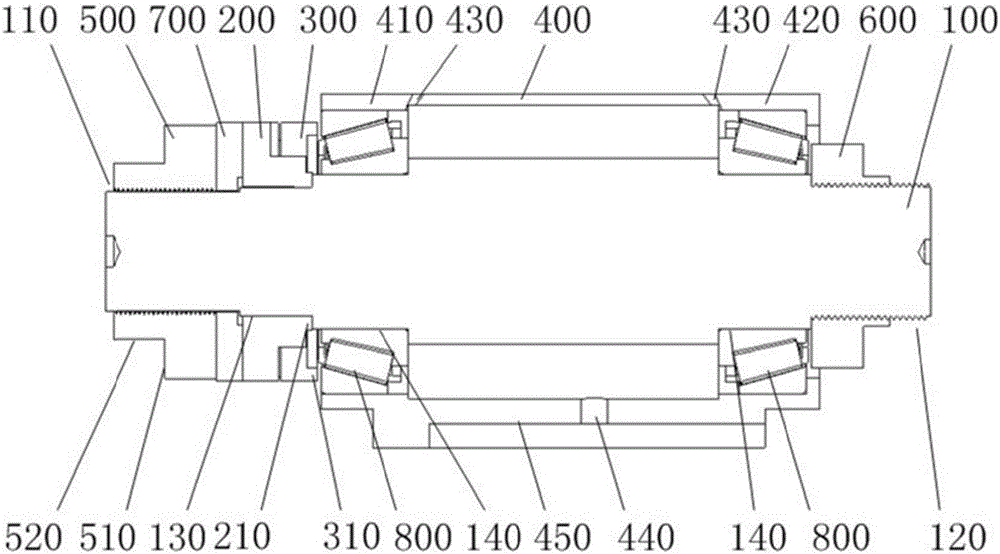

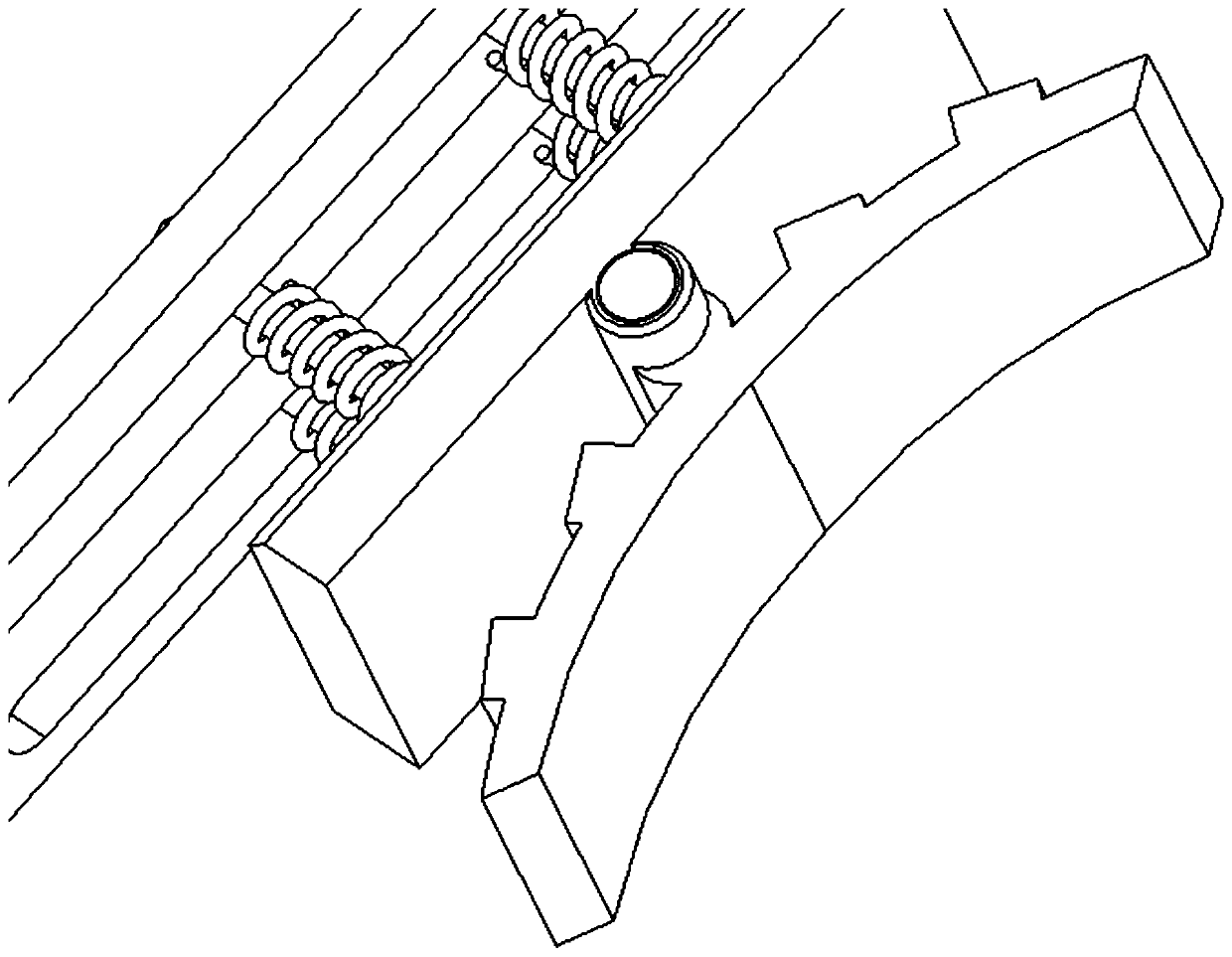

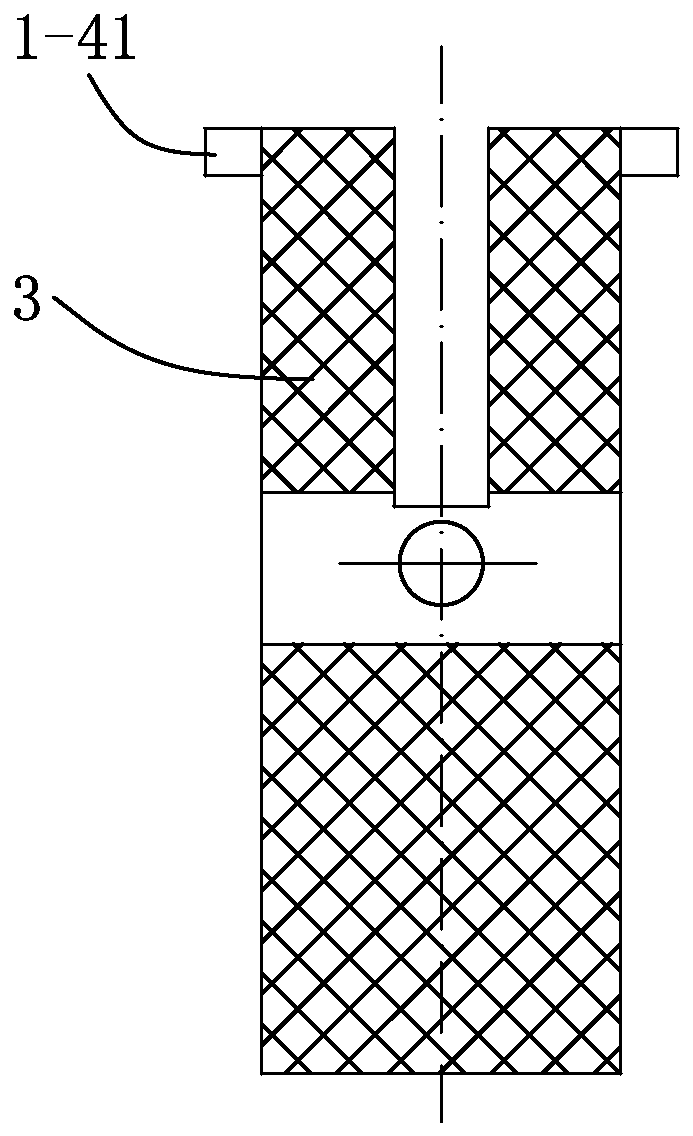

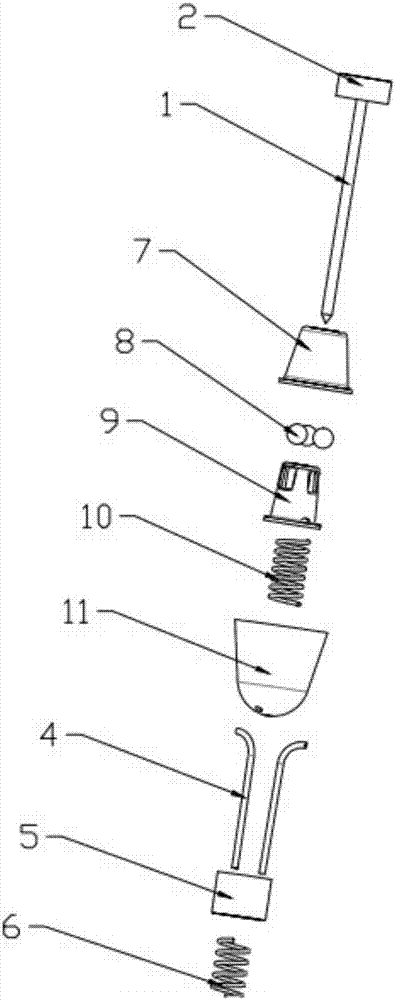

Passive clamping type piezoelectric actuator

ActiveCN102664554AReduce volumeIncrease flexibilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

The invention provides a passive clamping type piezoelectric actuator and relates to a piezoelectric actuator. The invention aims to solve the problems that the adjustment of the pretightening force of the existing passive clamping type piezoelectric actuator is controlled in cooperation with interference, so the control flexibility is poor, and the structural type of the clamping amplification structure is complex. The passive clamping type piezoelectric actuator provided by the invention comprises a first clamping mechanism, an actuating mechanism, a second clamping mechanism and a guide rail, wherein the first clamping mechanism and the second clamping mechanism are arranged in sequence from right to left, and the guide rail penetrates through the middle parts of the first clamping mechanism and the second clamping mechanism in sequence, and the actuating mechanism connects the first clamping mechanism and the second clamping mechanism. The passive clamping type piezoelectric actuator provided by the invention has small size and can realize self-locking when a power failure occurs, a clamping device is provided with a triangle amplifying mechanism, which can amplify the displacement of a clamping piezoelectric stack, thus reducing the difficulties of processing and assembling. The passive clamping type piezoelectric actuator is applied to the micro drive process.

Owner:HARBIN INST OF TECH

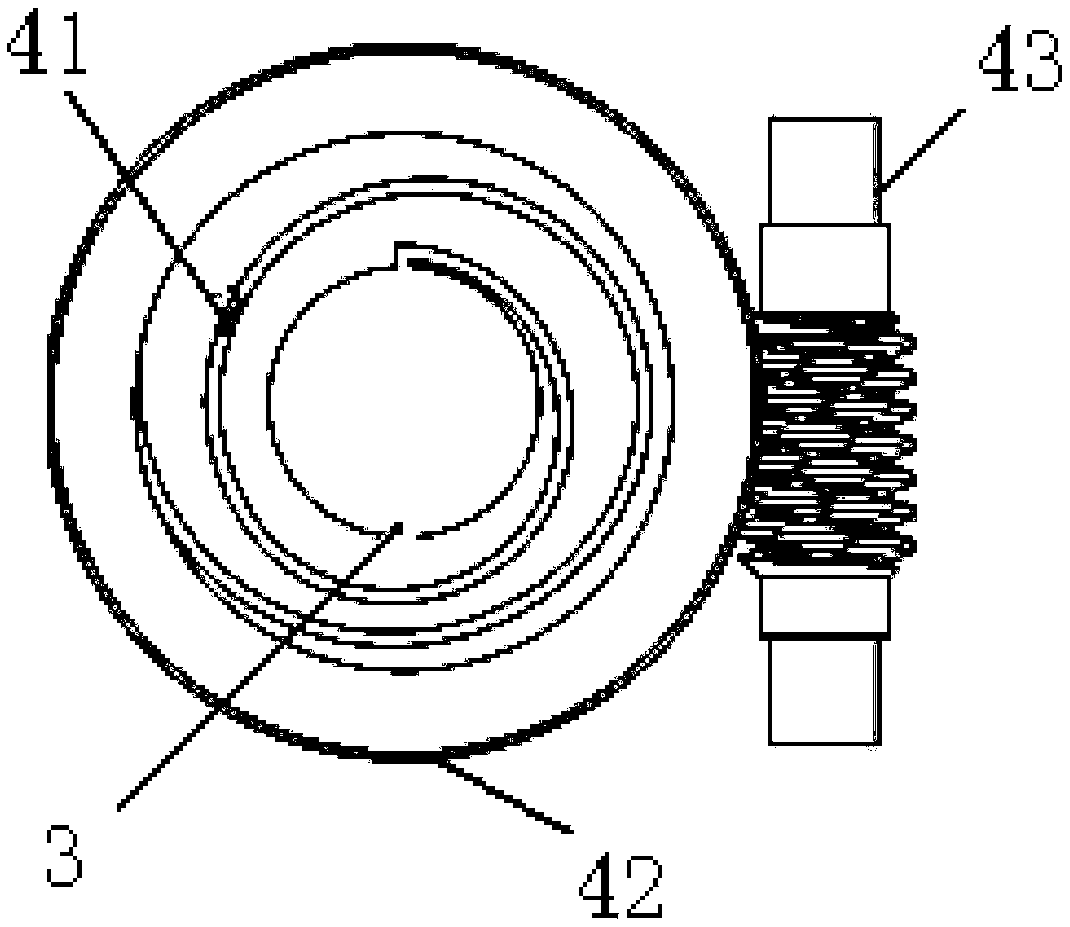

Spring resetting mechanism for electric actuator

PendingCN108626464AAchieve preloadRealize resetOperating means/releasing devices for valvesWound springsEngineeringActuator

The invention relates to a spring resetting mechanism for an electric actuator. The spring resetting mechanism for the electric actuator comprises a main shaft, a volute spiral spring and a turbine ring, wherein the main shaft, the volute spiral spring and the turbine ring are capable of driving a valve rod to rotate; the main shaft is arranged in the volute spiral spring in a sleeved mode, the volute spiral spring is arranged in the turbine ring in a sleeved mode, and the inner side starting end of the volute spiral spring is in transmission fit with the main shaft; and the outer side end ofthe volute spiral spring is in transmission fit with the inner side of the turbine ring, so that when the main shaft rotates, the volute spiral spring can be driven to rotate, energy storage is carried out, when the volute spiral spring is released, the main shaft can be driven to rotate in the reverse direction, so that the valve can be reset.

Owner:李伟

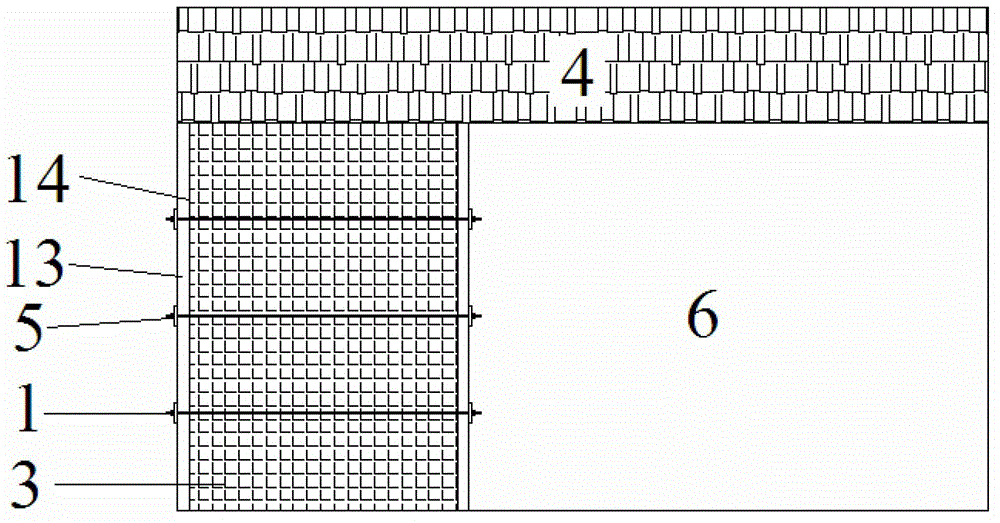

Active reinforced filling wall and construction method

ActiveCN102979572AHigh strengthImprove carrying capacityMaterial fill-upPolyesterUltimate tensile strength

The invention relates to an active reinforced filling wall and a construction method. The active reinforced filling wall comprises a hollow tubular anchoring agent, and the construction method is as follows: 1 the length of an anchor rod or an anchor cable is greater than the thickness of the wall; 2 the hollow tubular anchoring agent is of a hollow tube shape alternatively prefabricated by an anchoring agent and daub which are separated by a polyester film, and the anchoring rod or the anchoring cable is embedded with the hollow tubular anchoring agent; 3 the anchoring rod or the anchoring cable is laid in a predetermined position on a template; 4 a filling material is filled; 5 the template is dismounted; 6 a tray and a screw cap or a rigging are mounted; 7 the anchoring rod or the anchoring cable is rotated, the polyester film of the hollow tubular anchoring agent is cracked at once, the anchoring agent and the daub react after being mixed, and the anchoring rod or the anchoring cable is integratedly anchored with consolidated filling material around; and 8 pre-tightening force is applied. According to the active reinforced filling wall and the construction method, due to the adoption of a solution of embedding the hollow tubular anchoring agent on the anchor rod body, the problems that reinforcing ribs are difficult to be laid on the wall, the early strength of a masonry wall is low and a long time is needed to increase the strength are solved; the anchor rod or the anchor cable is transversely consolidated in the wall by the anchoring agent and the pre-tightening force is applied.

Owner:HUNAN LIANSHAO CONSTR ENG GRP

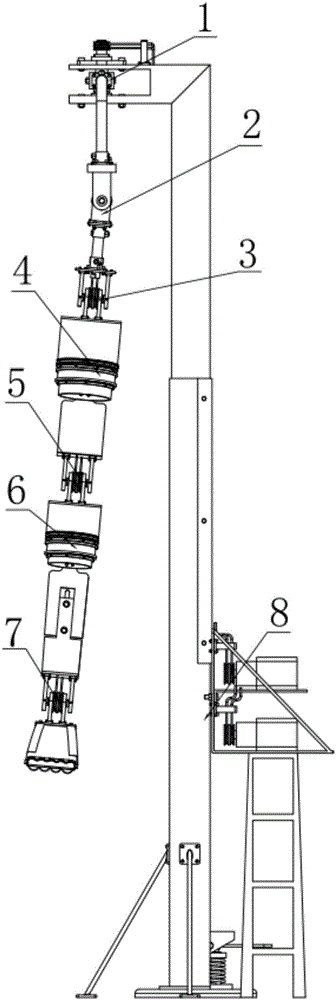

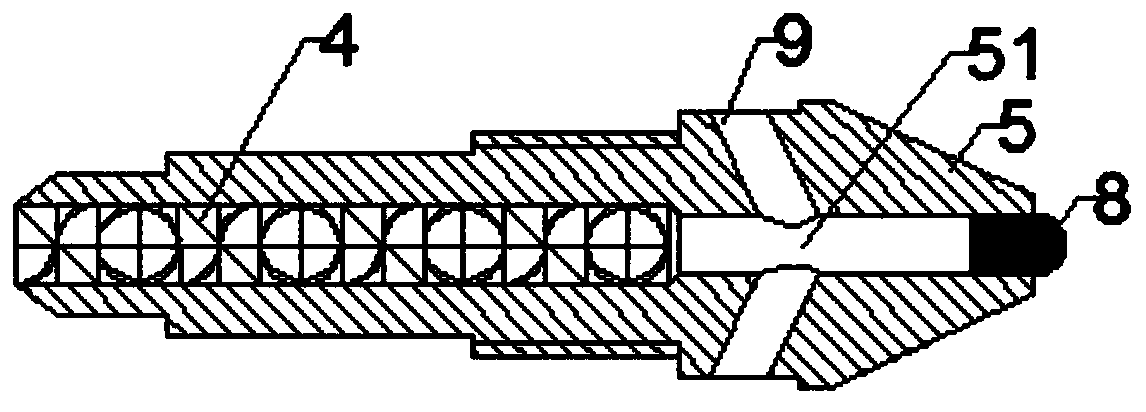

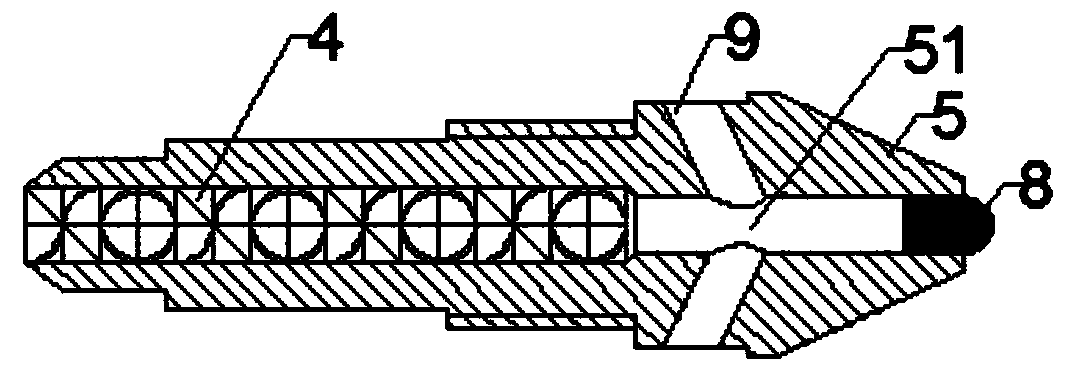

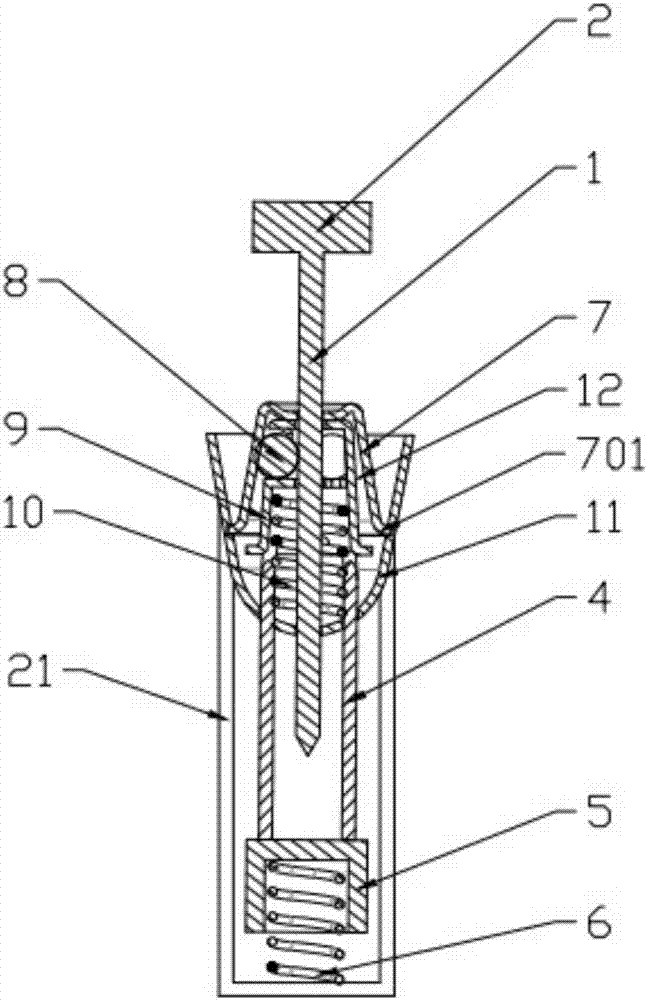

Drilling anchor high-pressure grouting integrated anchor device

PendingCN109869172AAchieve preloadReduce labor intensityAnchoring boltsEngineeringHigh pressure water

The invention discloses a drilling anchor high-pressure grouting integrated anchor device. The drilling anchor high-pressure grouting integrated anchor device comprises a rotary joint and an anchor rod, and the rotary joint comprises a rotary shaft (13) and a sleeve (16); the anchor rod comprises a rod body (3) and an anchor head (5), the rotary shaft (13) is internally provided with a grouting through hole (132), the sleeve (16) is provided with an injection hole (161), the anchor head (5) is of an arrowhead-shaped structure, an anchoring agent through hole (9) is formed in the outer wall, close to an arrowhead part, of the anchor head, and a choke plug (8) is arranged on the small end part of the anchor head (5); the rotary shaft (13) is detachably connected with the rod body (3), and the grouting through hole (132) communicates with the inner part of the rod body (3). In use, the rotary shaft (13) is connected with the rod body (3), the other end of the rotary shaft (13) is connected with a drilling machine, and the injection hole (161) is connected with high-pressure water. An anchoring agent package is pushed by the high-pressure water, and an anchoring agent is fixed to the rod body (3) and surrounding rock in an anchoring mode. Then the high-pressure water is introduced, the choke plug (8) is opened by the anchoring agent, and thus high-pressure grouting is achieved.

Owner:PANZHIHUA UNIV

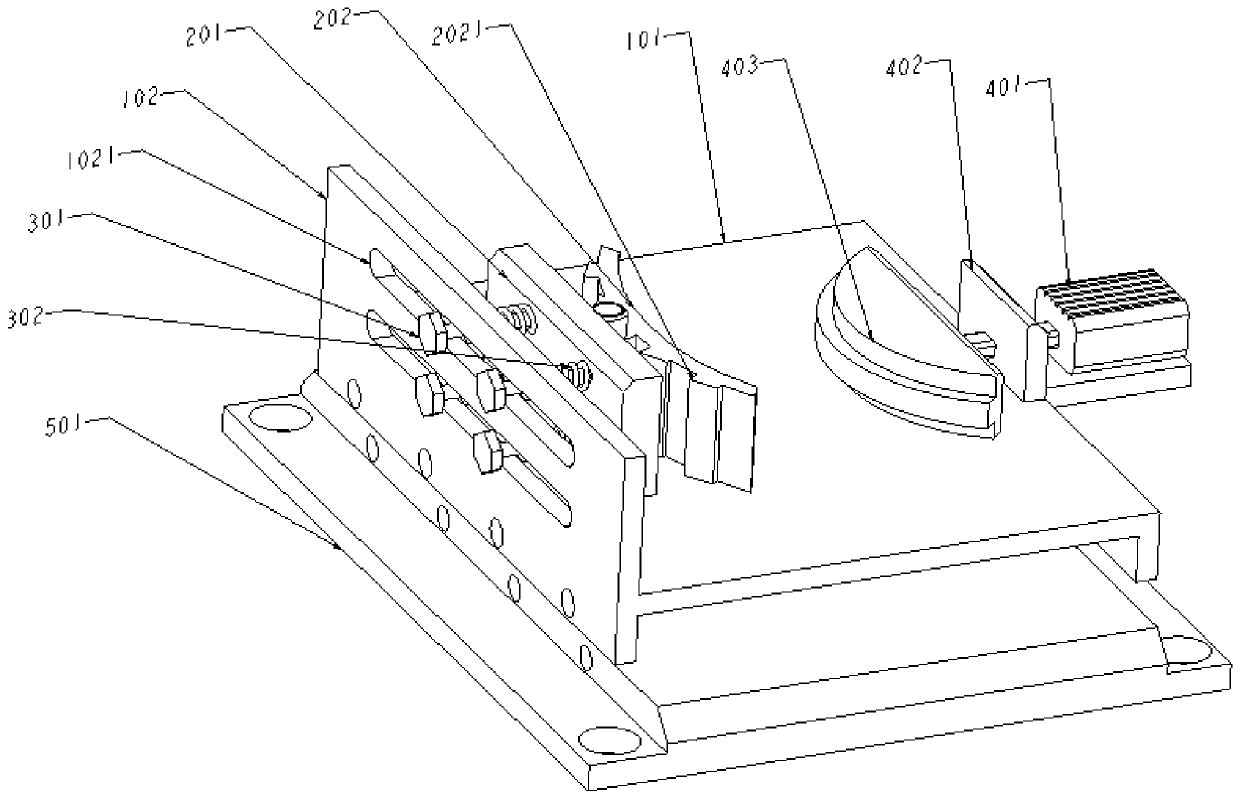

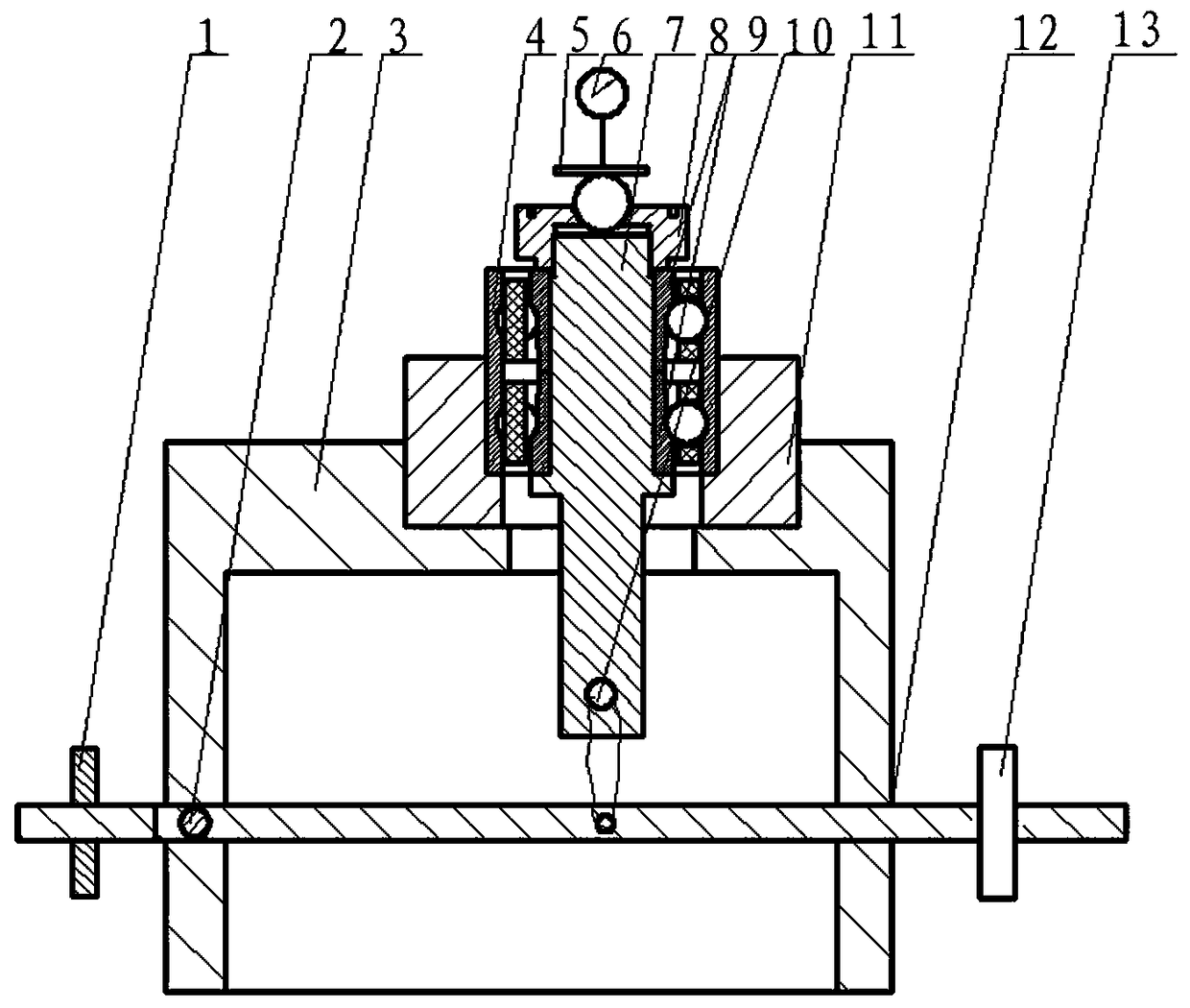

Fixing clamp for automobile brake caliper

PendingCN110385596AGuaranteed positioning accuracyAchieve preloadPositioning apparatusMetal-working holdersEngineeringCalipers

The invention provides a fixing clamp for an automobile brake caliper. The fixing clamp comprises a fixing plate structure, a pre-tightening mechanism and a clamping mechanism; the fixing plate structure comprises a fixing plate and a positioning plate; the positioning plate is vertically arranged on the left end surface of the fixing plate; the fixing plate is fixedly connected with the positioning plate; the positioning plate is provided with two oblong holes formed side by side; the pre-tensioning mechanism comprises a positioning block, an arc-shaped positioning plate and four elastic mechanisms; each oblong hole is internally and slidably provided with two corresponding elastic mechanisms; the end portions, away from the oblong holes, of all the elastic mechanisms are connected with the positioning block; the arc-shaped positioning plate is hinged to the positioning block; the clamping mechanism comprises a driving mechanism and a clamping block; the driving mechanism is arrangedon the right end surface of the fixing plate; the extension end of the driving mechanism is connected with the clamping block; and the clamping block directly faces the two oblong holes. Through the fixing clamp for the automobile brake caliper, the technical problem that conventional automobile brake caliper clamps cannot hold workpieces stably is solved.

Owner:中联精工(天津)有限公司

Linear ultrasonic motor stator and electric excitation method thereof

ActiveCN111464070AShorten the lengthReduced Thickness DimensionsPiezoelectric/electrostriction/magnetostriction machinesElectric machineEngineering

The invention discloses a linear ultrasonic motor stator and an electric excitation method thereof. The stator comprises a stator elastic body and piezoelectric ceramic pieces, wherein an open slot isformed in the stator elastic body along the length direction, and the stator elastic body is divided into a driving body and two symmetrical driving legs by the open slot; the piezoelectric ceramic pieces in axial symmetry are attached to the two opposite outer side surfaces of the two driving legs, and driving feet extending outwards are arranged at the upper ends of the two driving legs respectively; and the piezoelectric ceramic pieces are coated with an electrode layer. The electric excitation method comprises the steps of 1) bonding the piezoelectric ceramic pieces; 2) preparing electrifying electrodes; and 3) simultaneously exciting local second-order bending vibration of the driving legs and overall first-order longitudinal vibration of the stator twice by using two paths of same-frequency sinusoidal voltage signals, and finally realizing forward and reverse movement of a driving rotor. According to the invention, the local second-order bending vibration of the two driving legsof the stator and overall first-order longitudinal vibration of the stator are combined and degenerate, and elliptical vibration of the driving feet is achieved.

Owner:HARBIN INST OF TECH

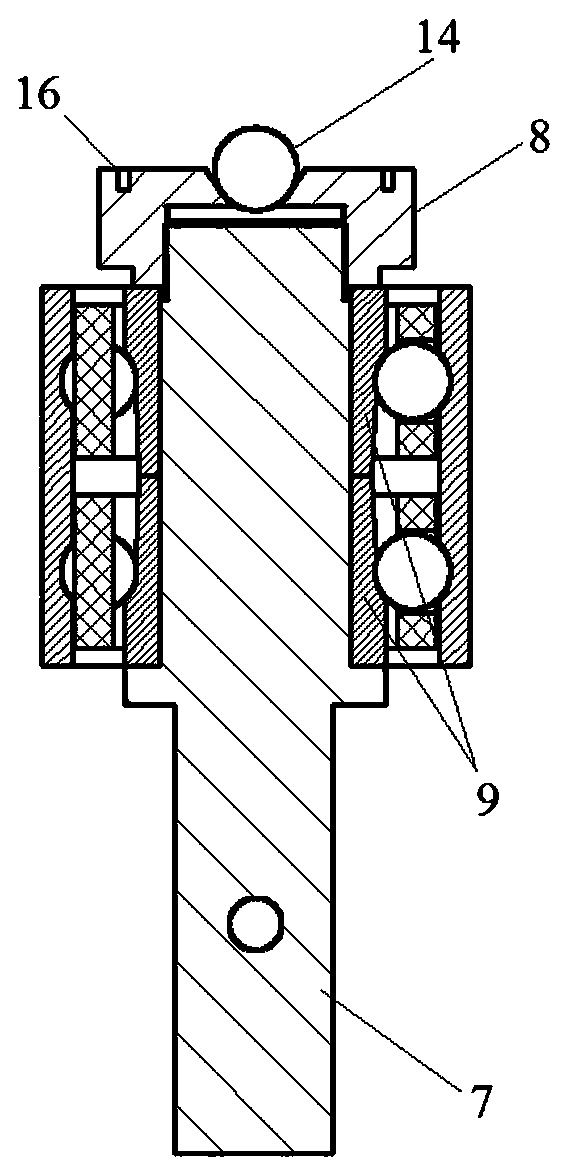

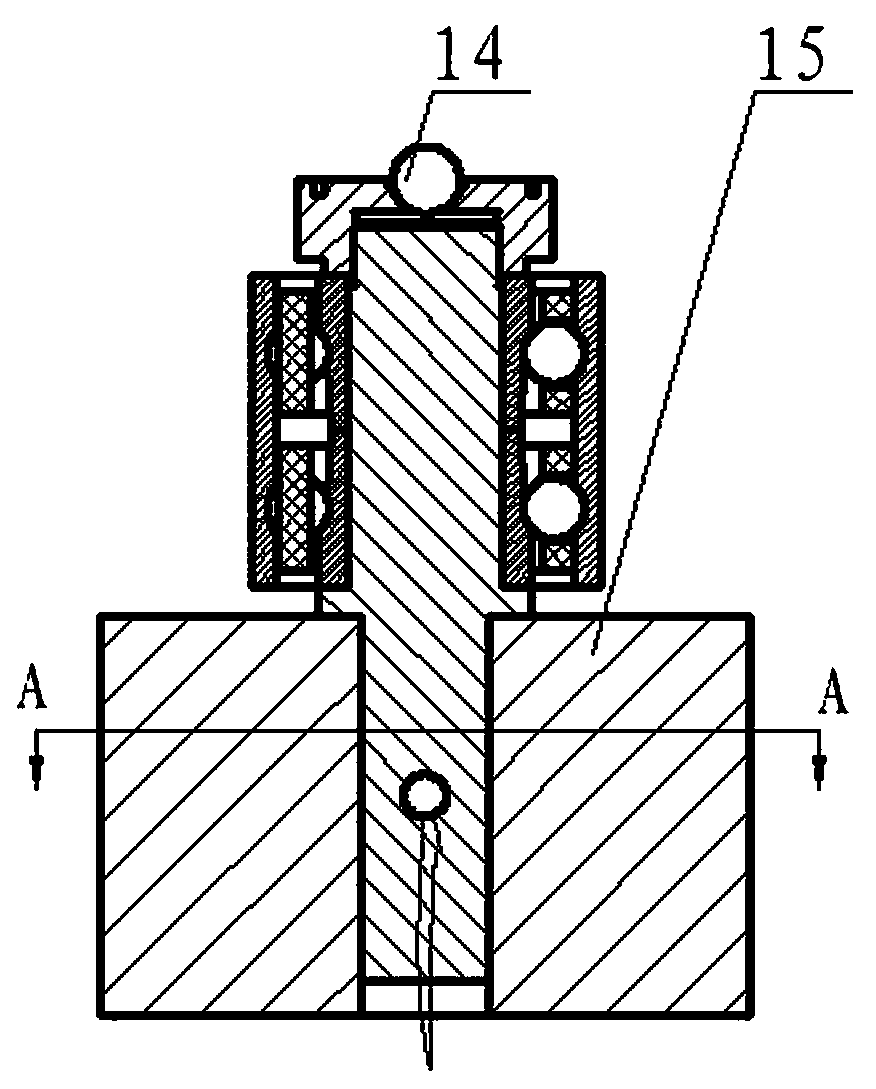

Axial deformation measurement tooling for dual-inner ring dual-row ball bearings

InactiveCN109282753AAccurate measurementAvoid inconsistent axial preloadMachine bearings testingMaterial strength using tensile/compressive forcesMeasurement deviceEngineering

The invention relates to an axial deformation measurement tooling of dual-inner ring dual-row ball bearings. The axial deformation measurement tooling for the dual-inner ring dual-row ball bearings comprises a pretensioning device for applying a set preloading load to the dual-inner ring in the axial direction of a bearing; the measurement tooling further comprises a support frame for supporting the dual-row ball bearing in a pretensioning state and an axial loading device for axially loading the bearing in the pretensioning state; one of the support frame and the axial loading device which cooperate with each other correspondingly stops an outer ring of the bearing, and the other of the support frame and the axial loading device correspondingly stops an inner ring of the bearing; and themeasurement tooling also includes a measurement device for measuring the axial deformation of the dual-row ball bearing in an axial loading state. The measurement tooling can measure the axial deformation of the bearing, which can avoid the situation that the axial pretensioning forces of the inner rings of the bearings are inconsistent during manual loading due to individual differences of the detecting personnel, and can make the measurement result of the axial deformation of the inner ring more accurate.

Owner:LUOYANG BEARING RES INST CO LTD

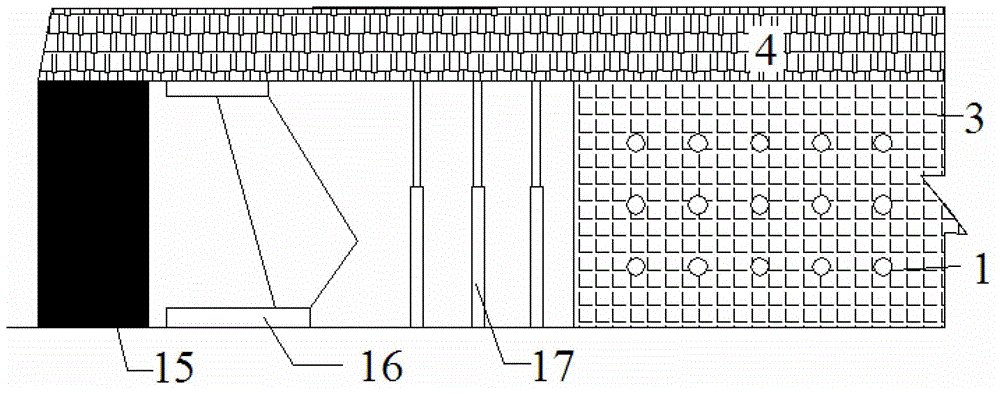

Temporary supporting and drilling-grouting integrated anchor rod composite supporting system and construction method

ActiveCN112360501AImprove adsorption capacityReliable temporary supportMining devicesUnderground chambersSupporting systemRock bolt

The invention relates to the technical field of coal mine roadway supporting, and provides a temporary supporting and drilling-grouting integrated anchor rod composite supporting system and a construction method. The temporary supporting and drilling-grouting integrated anchor rod composite supporting system comprises a first supporting device and a second supporting device, wherein the first supporting device comprises a sucker frame, a drilling pipe and a vacuum pipe; and the second supporting device comprises an anchor rod mechanism, a driving mechanism, a grouting mechanism and a propelling mechanism. Negative pressure can be rapidly formed in roadway surrounding rock, the surrounding rock is reliably and temporarily supported through atmospheric pressure, and the supporting effect isimproved; and drilling, grouting anchoring and pre-tightening of the anchor rod supporting device are integrated, the structure is simple, operation is convenient, the construction procedure is simplified, the supporting effect is guaranteed, the supporting efficiency is improved, and automatic operation is achieved.

Owner:CCTEG COAL MINING RES INST +1

Locking device for article surveillance

PendingCN107393245ASuccessful unlockingIncrease the stroke of the unlockBurglar alarm electric actuationEngineeringMagnet

The invention relates to a locking device for article surveillance. The locking device comprises a locking shell, a plurality of locking balls, a telescopic body, a locking and resetting spring, an article connecting unit, a traction body and sliding steel wires, an upper inner cavity of the locking shell is a locking cavity, the section of the locking cavity is in a trapezoidal shape, the locking balls are arranged in the locking cavity, the telescopic body is arranged in the locking shell in a lifting manner and positioned on the lower side of the locking balls, a locking ball holding mechanism is arranged on the upper portion of the telescopic body, the locking and resetting spring is arranged in the locking shell of the lower side of the telescopic body, the article connecting unit vertically penetrates the locking shell and the telescopic body, the locking balls are uniformly arranged on the periphery of the article connecting unit, the traction body is provided with a magnet or an iron block and arranged in an antitheft shell, the upper ends of the sliding steel wires penetrate the locking shell and are fixedly connected with the telescopic body, and the lower ends of the sliding steel wires are connected with the traction body. According to the locking device, the traction body and the sliding steel wires drive the telescopic body to move, remote unlocking is achieved, and the locking device is applicable to articles with various specifications.

Owner:XUZHOU DRAGON GUARD IND CO LTD

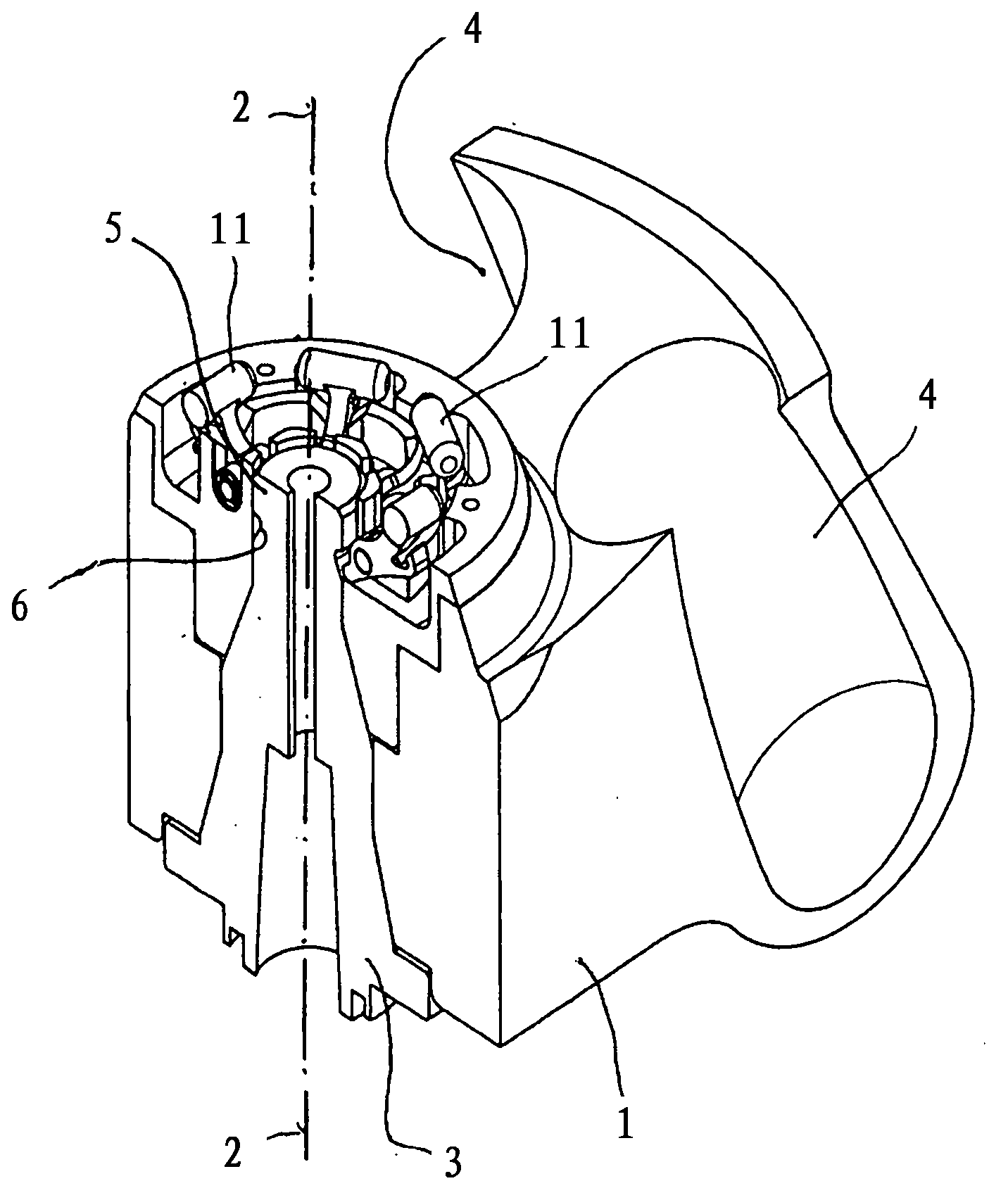

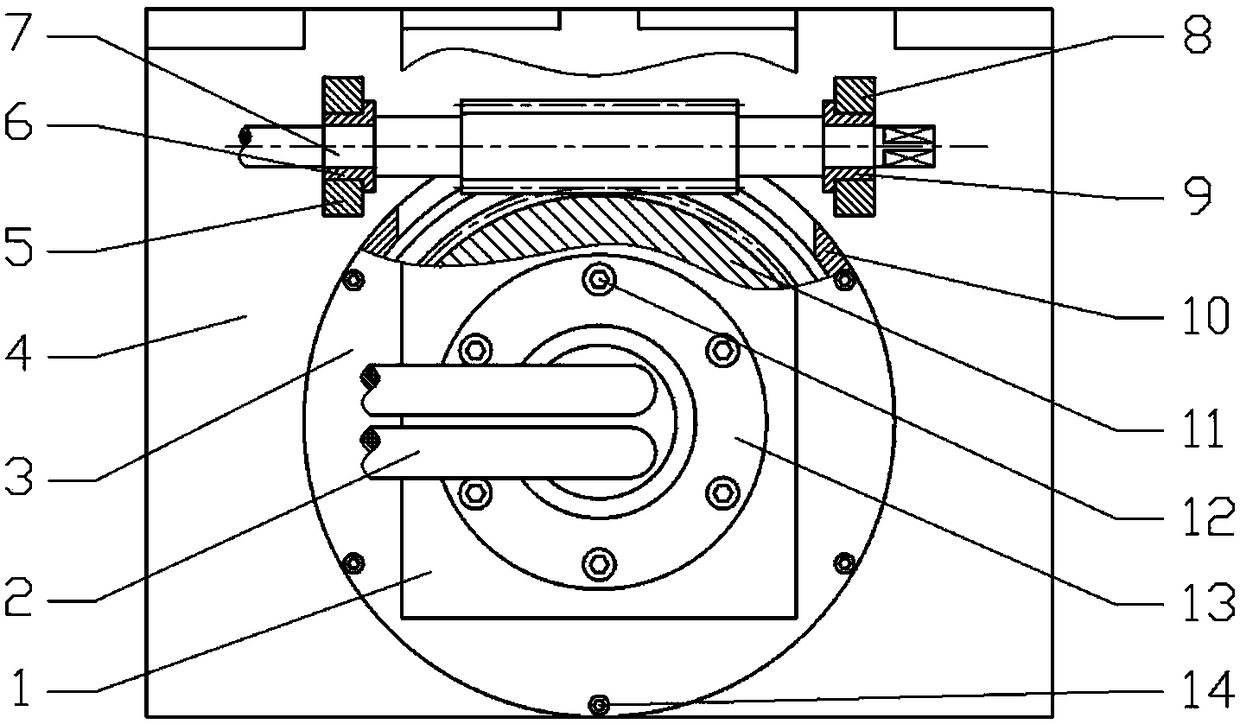

Rotor bearing for a laboratory centrifuge

InactiveCN103180049AQuick changeStable switch positionCentrifugesFastening meansIn planeMechanical engineering

The locking system, which is intended to axially secure the rotor (1), of a laboratory centrifuge, wherein said rotor can be placed onto a rotatably mounted shaft (3) that extends vertically, is characterized by an arrangement of a plurality of locking levers (7), which are each pivotably mounted about axes (8) extending perpendicularly to the shaft (3) between a locking position and an unlocking position in planes containing the axes (2), wherein said locking levers can each be automatically transferred from the unlocking position to the locking position and from the locking position to the unlocking position depending on rotational speed. The locking levers (7) are mounted on the rotor (1), and an annular groove (6) is provided on the shaft (3), said annular groove engaging with the locking levers (7) in the locking position, wherein the locking levers (7) are prestressed in the unlocking position. An advantage over the prior art is achieved, namely that the rotor can be both installed and removed without tools by merely placing the rotor onto or removing the rotor from the shaft (3), in each case depending on rotational speed.

Owner:SIGMA LABORZENTRIFUGEN

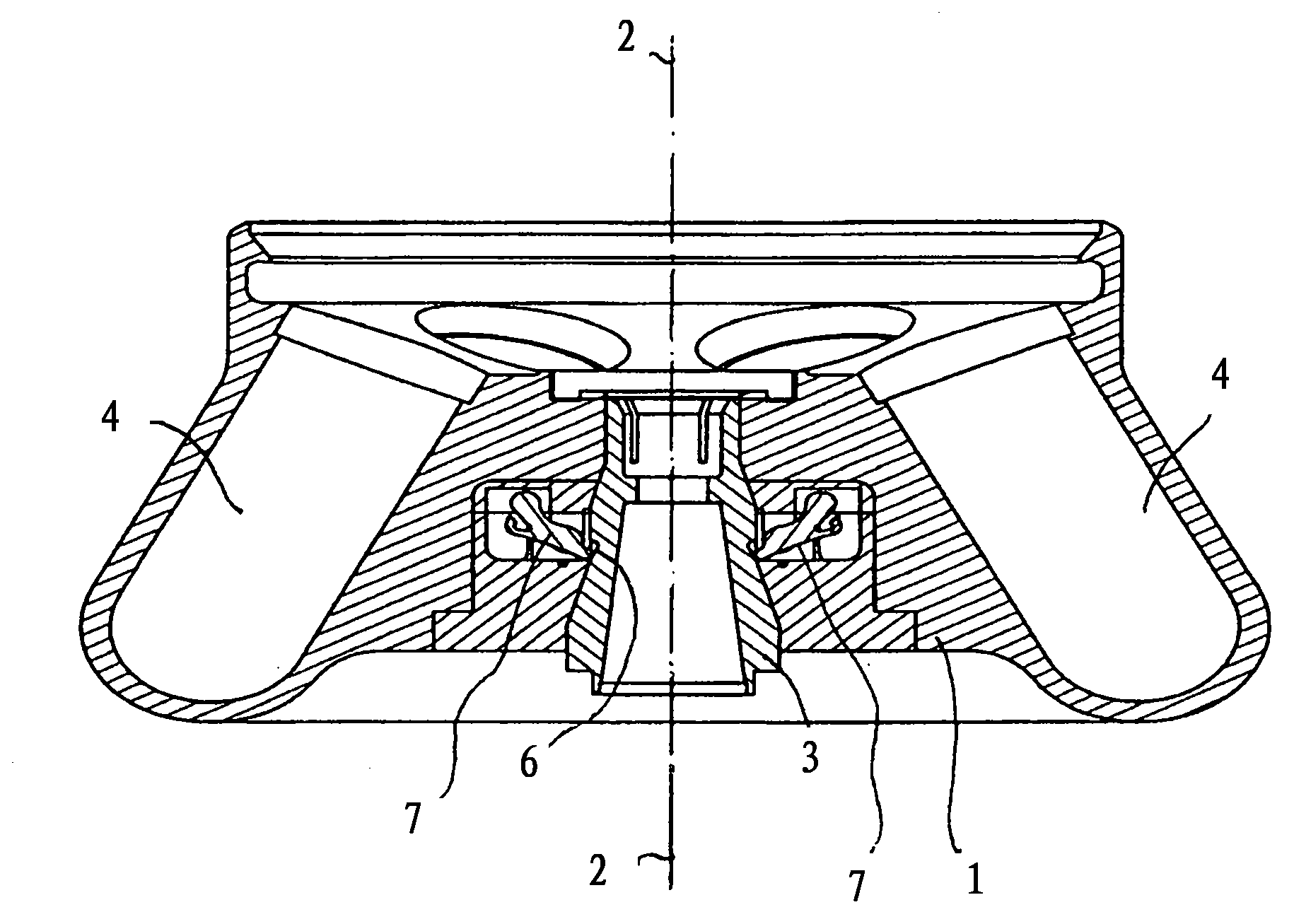

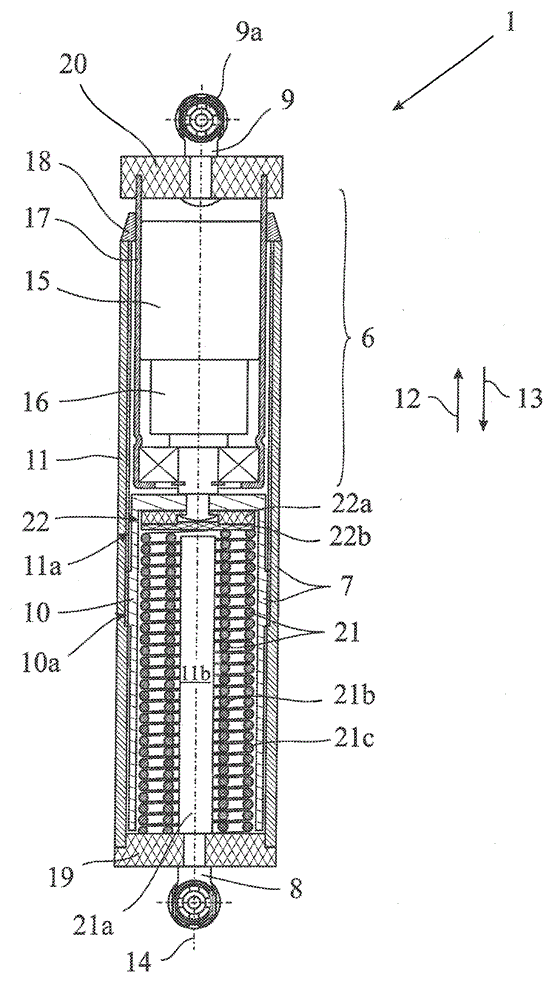

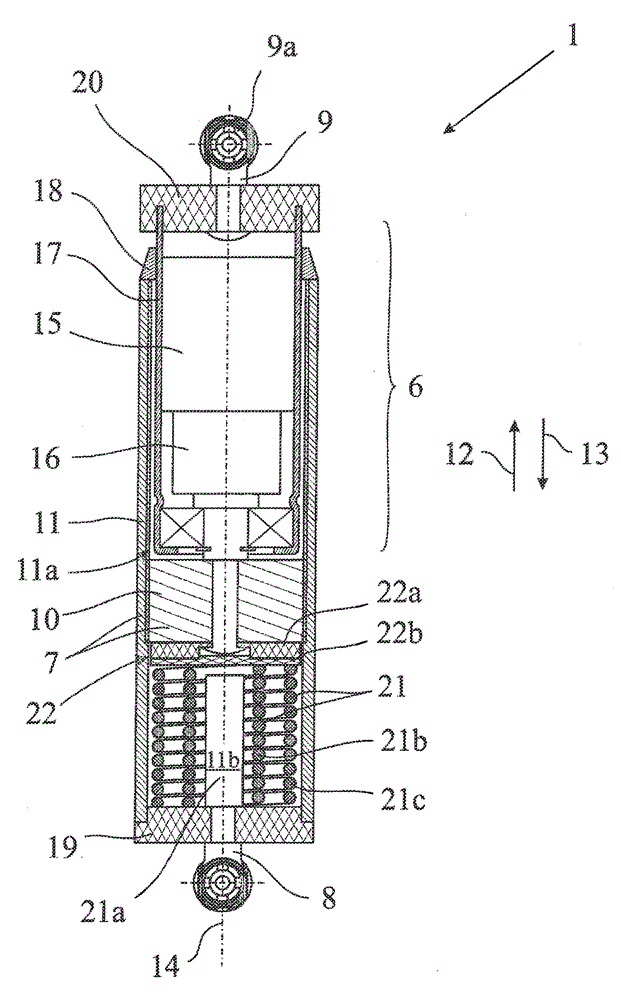

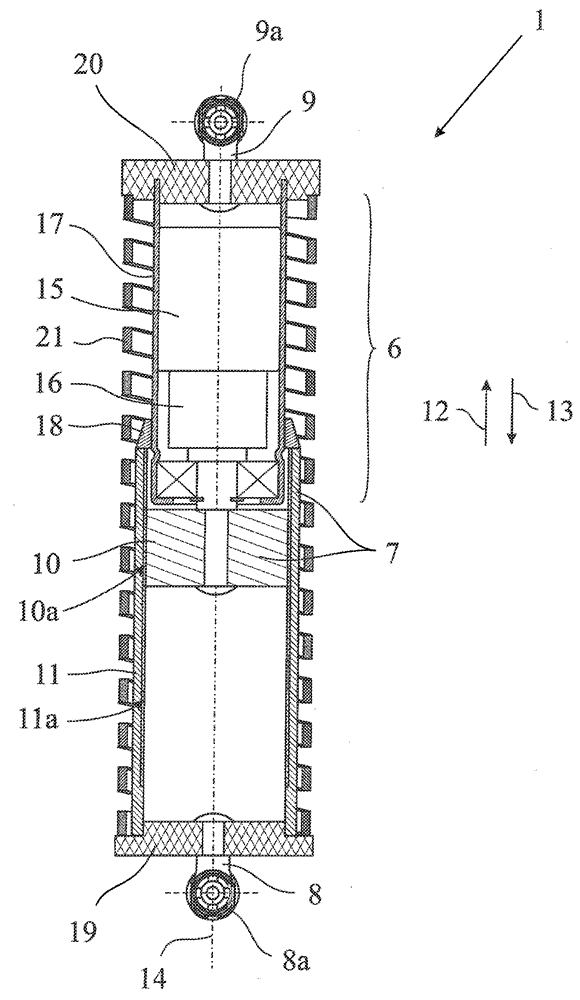

Spindle drive

ActiveCN104822891AIncrease the lengthImproved radial compactnessGearingPower-operated mechanismMotor drive

The invention relates to a spindle drive for a valve (2) of a motor vehicle, comprising a motor drive arrangement (6), comprising a spindle gear mechanism (7) drivingly connected downstream of the motor drive arrangement (6), and comprising two drive connections (8, 9) for transmitting drive movements. The spindle gear mechanism (7) has a spindle (10) which can be rotated by the motor drive arrangement (6) and a spindle nut (11) which is engaged with the spindle in a rotationally fixed manner. The spindle nut (11) carries out an axial retraction movement (12), in which the distance between the two drive connections (8, 9) is reduced, and an axial extension movement (8, 9), in which the distance between the two drive connections (7, 8) is increased, according to the rotational direction of the spindle (10). The spindle nut thread (11a) extends beyond the spindle thread (10a) in the direction of the retraction movement (12) at least in the fully retracted position and surrounds at least one part of the motor drive arrangement (6).

Owner:博泽(哈尔施塔特)汽车零部件有限公司

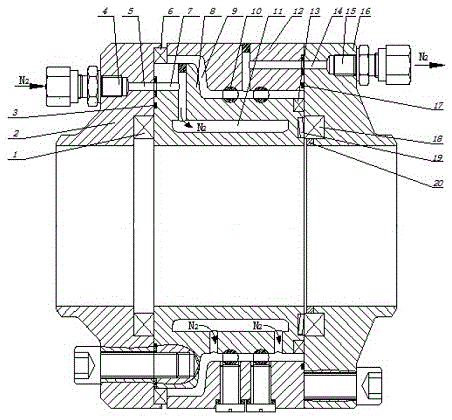

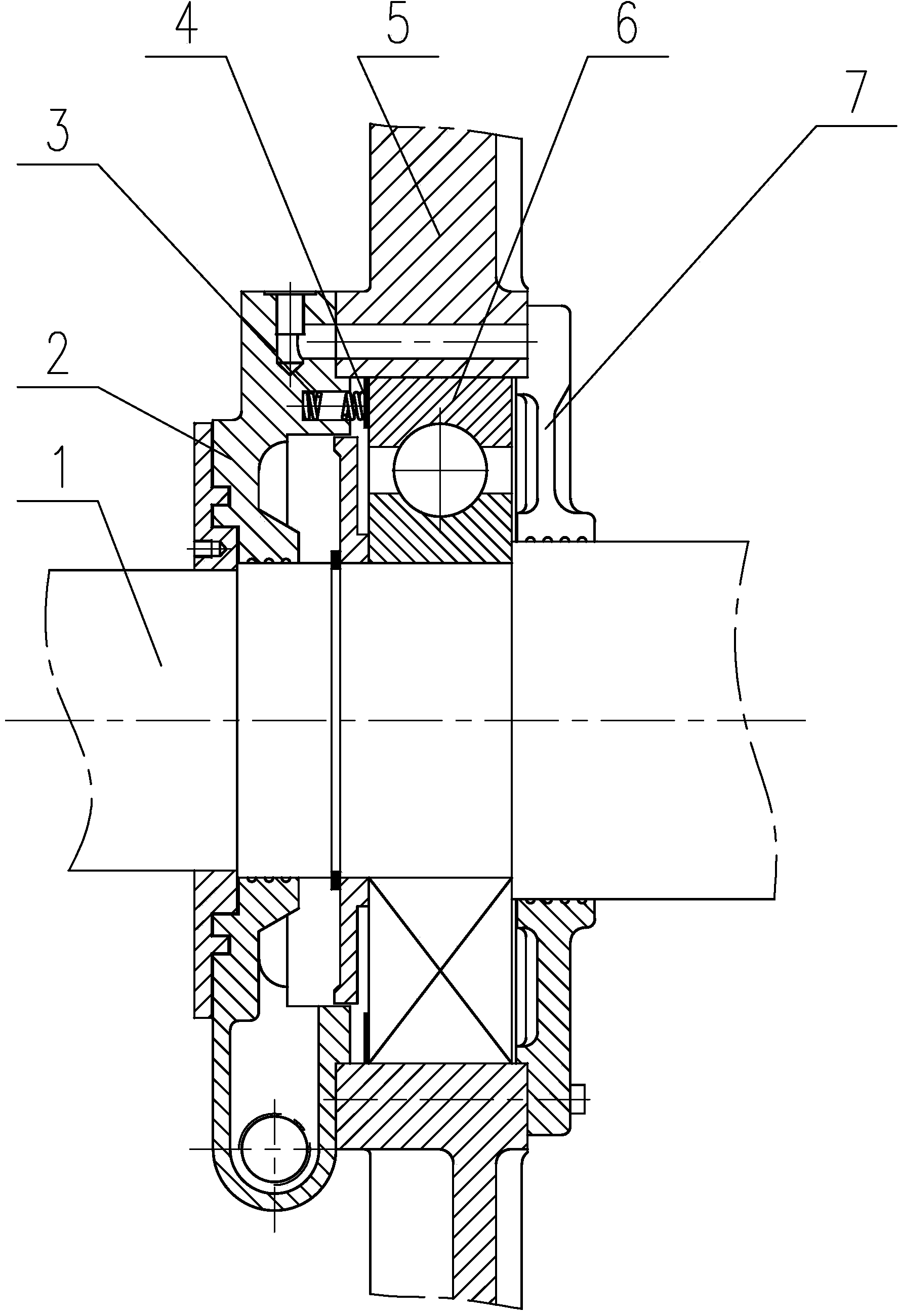

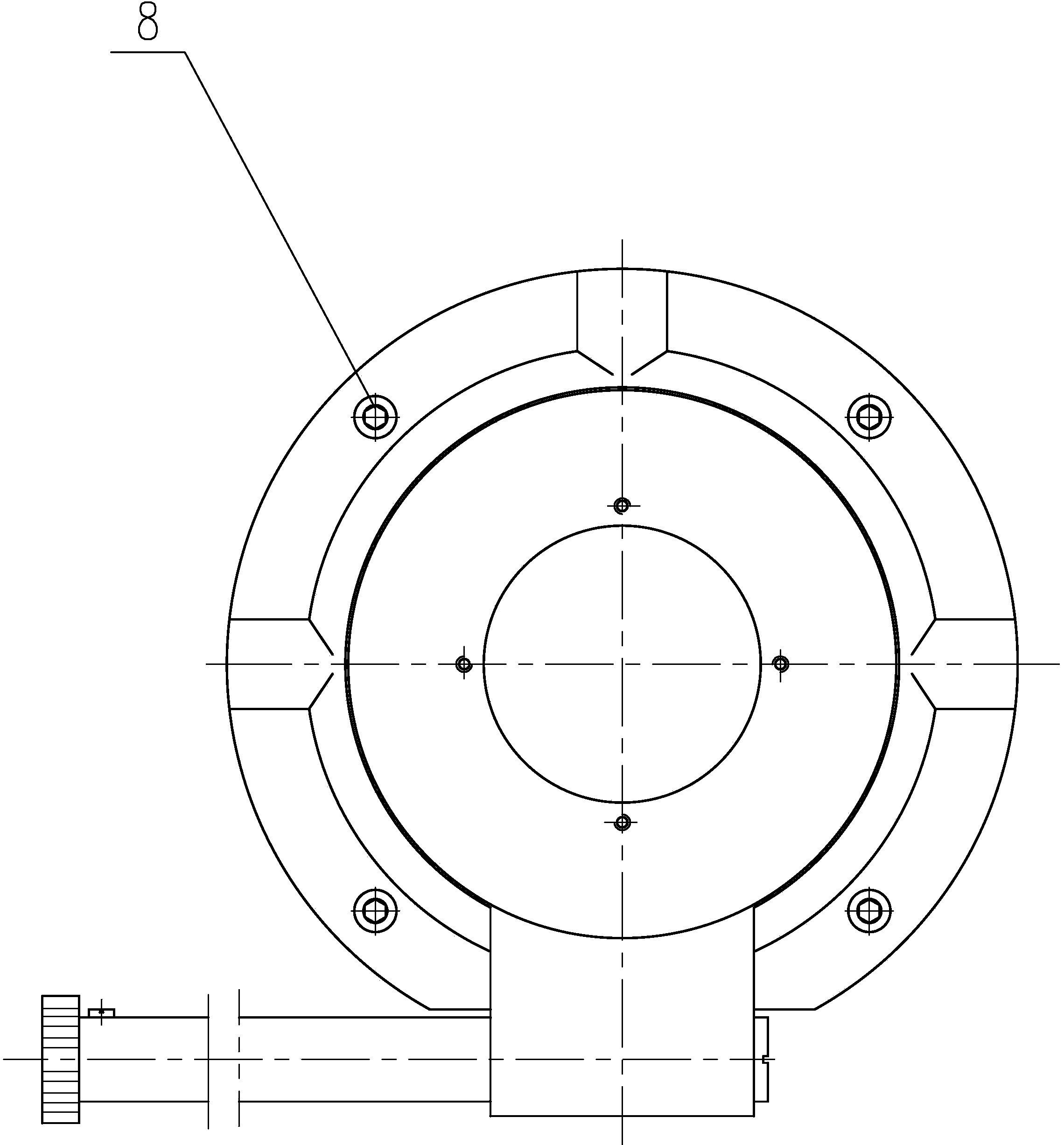

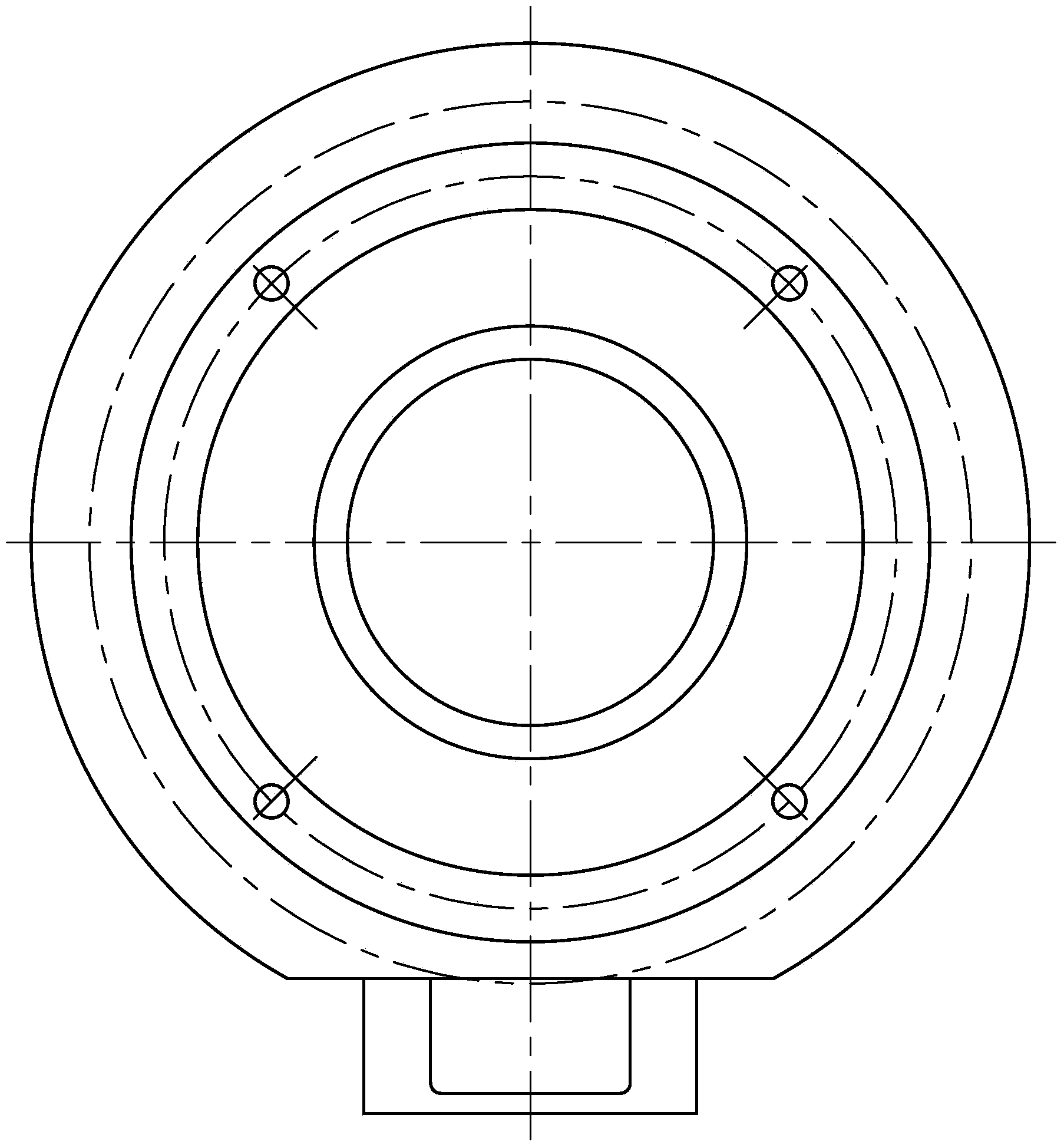

Rotating joint special for ultra-low temperature fluid loading arm

ActiveCN105546330AImprove liquidityAvoid destructionVessel mounting detailsPressure vesselsNitrogenEngineering

Disclosed is a rotating joint special for an ultra-low temperature fluid loading arm. An inner ring is sleeved with an outer ring. A left flange is connected with the left end of the inner ring. A right flange is fixedly connected with the outer ring. A thermal insulating cavity is formed in the inner ring. A nitrogen purging channel is arranged between the inner ring and the outer ring and provided with an annular roller path. A ball valve capable of enabling the inner ring and the outer ring to rotate independently is mounted in the annular roller path. The left flange is provided with a left nitrogen channel, the inner ring is provided with an inner nitrogen channel, the left flange is provided with a nitrogen inlet, and the inner ring is provided with two nitrogen via holes. The right flange and the outer ring are provided with a right nitrogen channel, the right flange is provided with a nitrogen outlet, and the outer ring is also provided with nitrogen via holes. An open type nitrogen channel is formed by the nitrogen inlet, the left nitrogen channel, the nitrogen via holes of the inner ring, the thermal insulating cavity, the nitrogen purging channel, the nitrogen via holes of the outer ring, the right nitrogen channel and the nitrogen outlet sequentially. By means of the rotating joint, the inner ring and the outer ring can rotate independently, so that the nitrogen circulation is improved and moisture is easy to bring out and discharge into the atmosphere.

Owner:YANGZHOU UNIV

Wheel nut tightening device

PendingCN108705293AImprove stabilityExtended service lifeMetal working apparatusHydraulic cylinderVehicle frame

The invention discloses a wheel nut tightening device which comprises a movable platform and an automatic nut tightening device. The movable platform comprises wheels, a vehicle frame, a rail plate, alifting hydraulic cylinder, a pushing hydraulic cylinder and an installing base plate, the lifting hydraulic cylinder is used for adjusting the height between the rail plate and the vehicle frame, the installing base plate can slide front and back along the rail plate, and the pushing hydraulic cylinder is used for controlling the installing base plate to slide front and back on the rail plate; and the automatic nut tightening device comprises a power device, a first coupling, a dynamic torque transducer, a second coupling and a tightening device, and the tightening device comprises a shell,a transmission shaft, a driving gear, a driven gear and a driven shaft. According to the wheel nut tightening device, dynamic torque transducer is used for achieving dynamic torque monitoring of wheelnuts in the tightening process, accurate control over the wheel nut tightening force is achieved, and meanwhile, the power device is used for driving for quickly and easily complete assembly of the wheel nuts.

Owner:XIAN AERONAUTICAL UNIV

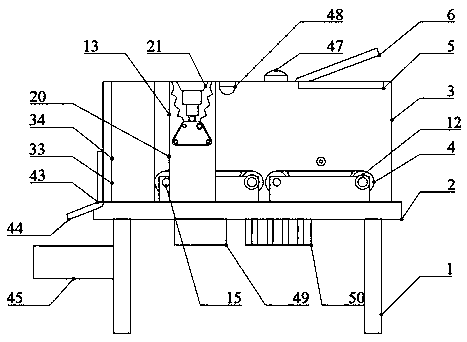

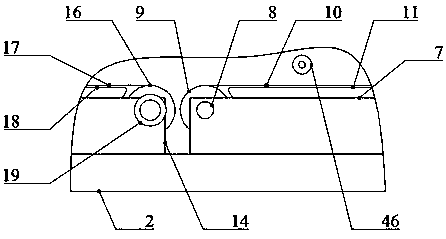

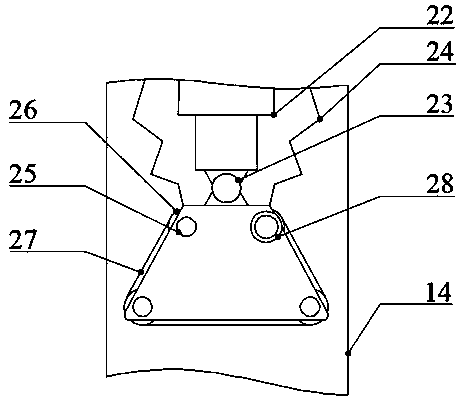

Full-automatic cooked meat processing equipment for production of meat products

The invention discloses full-automatic cooked meat processing equipment for production of meat products. The full-automatic cooked meat processing equipment comprises an equipment support, and the equipment support is fixedly arranged on the ground. A support plate is arranged above the equipment support, and a protection case body is arranged above the support plate. A meat feeding device is arranged at the upper right end of the support plate, and a compaction device is arranged on the left side of the meat feeding device. The compaction device is composed of a mounting seat, a compaction cylinder, a connecting piece, a compaction seat, tension springs, a guide wheel shaft, a guide wheel, a compaction belt and a driving motor II, wherein the mounting seat is positioned under an upper pressing frame and is fixedly connected with the middle position of the lower surface of the upper pressing frame, and the compaction cylinder is arranged in the mounting seat in a sleeving mode; the connecting piece is fixedly connected with the lower surface of a cylinder rod of the compaction cylinder, and the compaction seat is positioned under the connecting piece and is rotationally connected with the connecting piece; the tension springs are respectively positioned on the left side and the right side of the compaction cylinder, one end of each tension spring is fixedly connected with the upper pressing frame, and the other end of each tension spring is fixedly connected with the compaction seat; the guide wheel shaft is positioned in the compaction seat and is rotationally connected with the surface of the inner side of the compaction seat, and the guide wheel is arranged outside the guide wheel shaft in the sleeving mode; the compaction belt is arranged outside the guide wheel inthe sleeving mode; and the driving motor II is fixedly connected with the rear surface of the guide wheel shaft. The full-automatic cooked meat processing equipment has the beneficial effects of simple structure and good practicability.

Owner:滨州市棣棠花食品科技有限公司

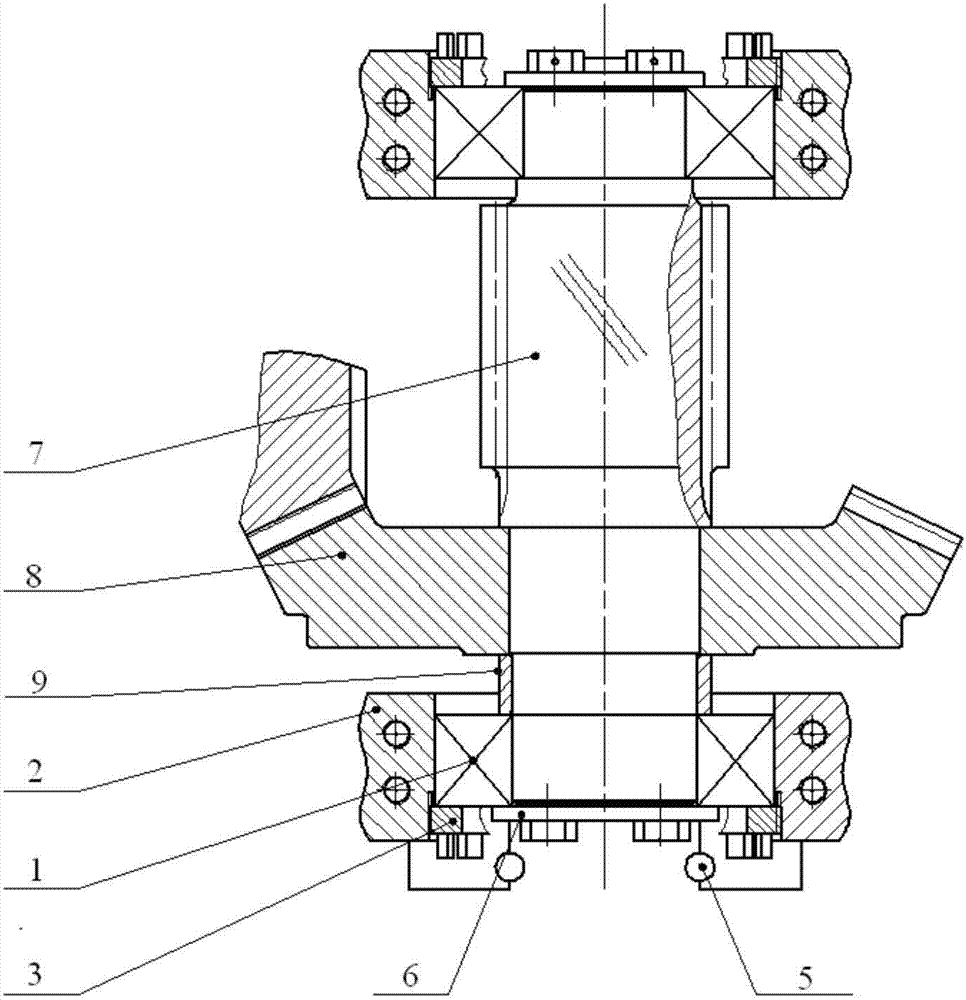

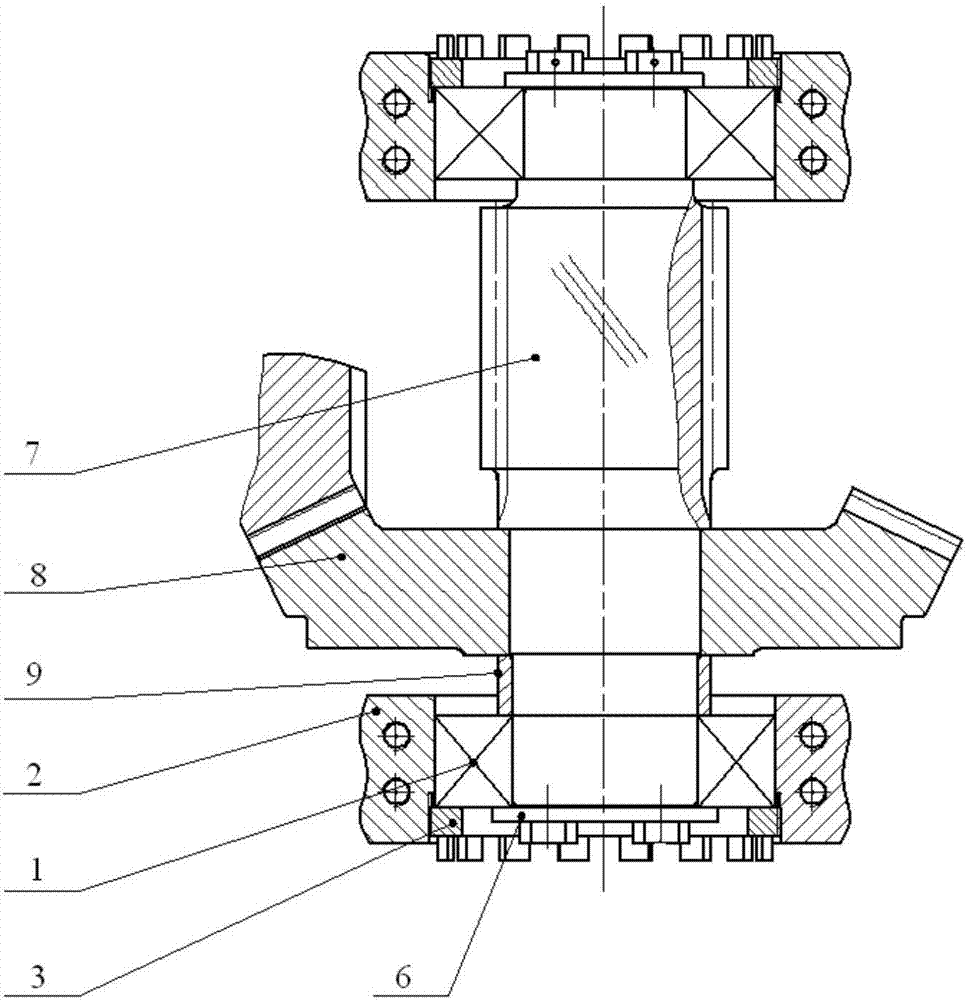

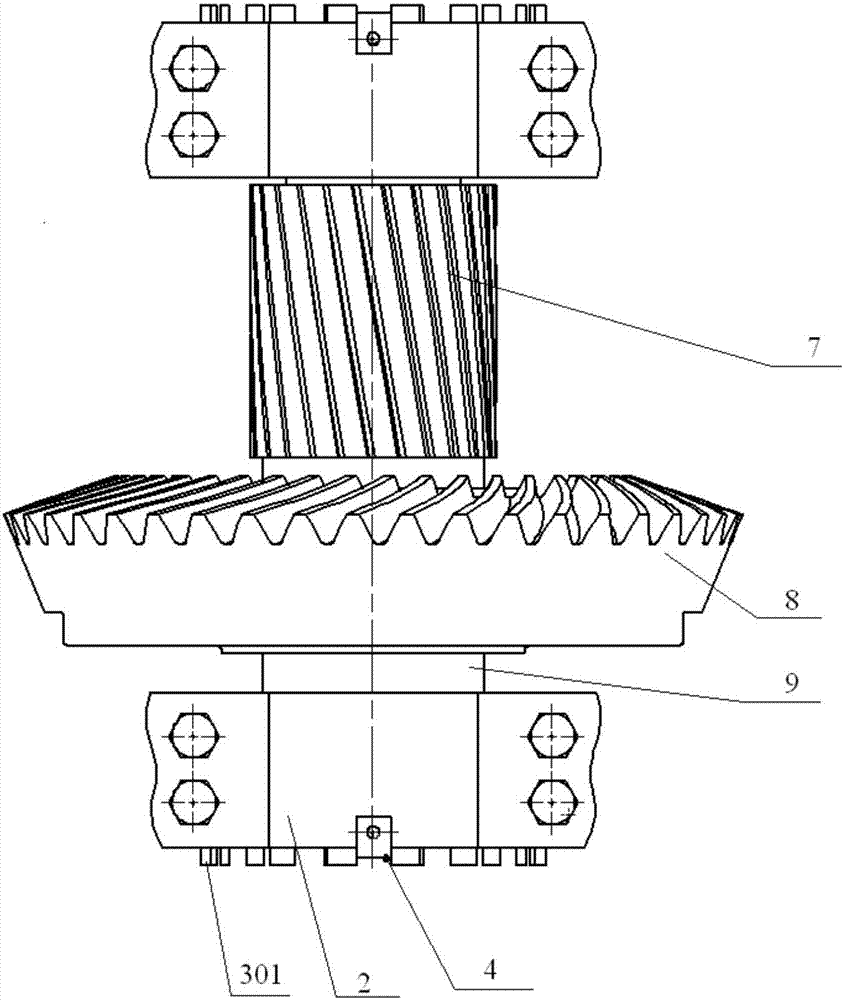

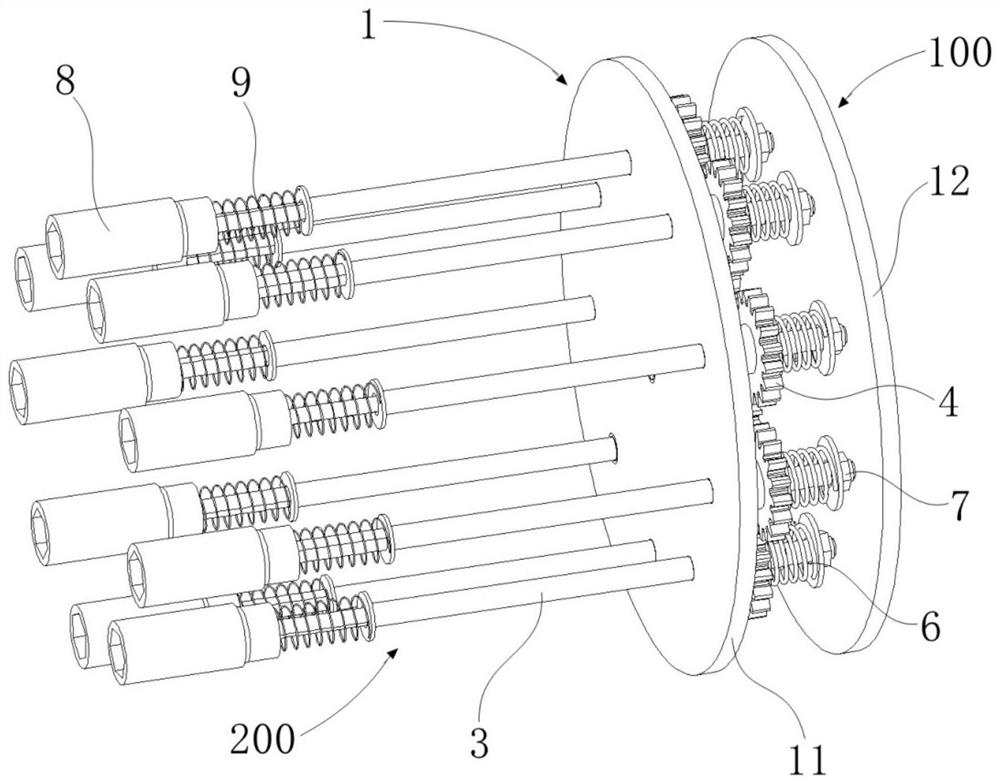

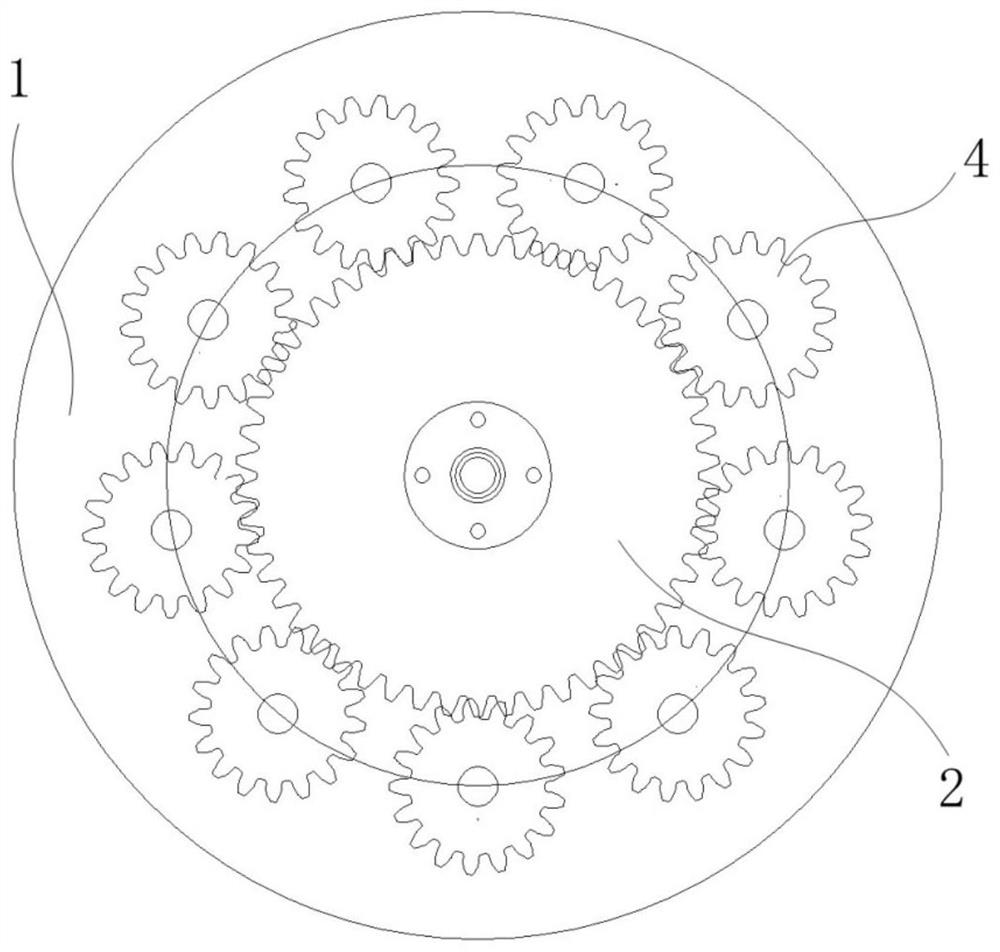

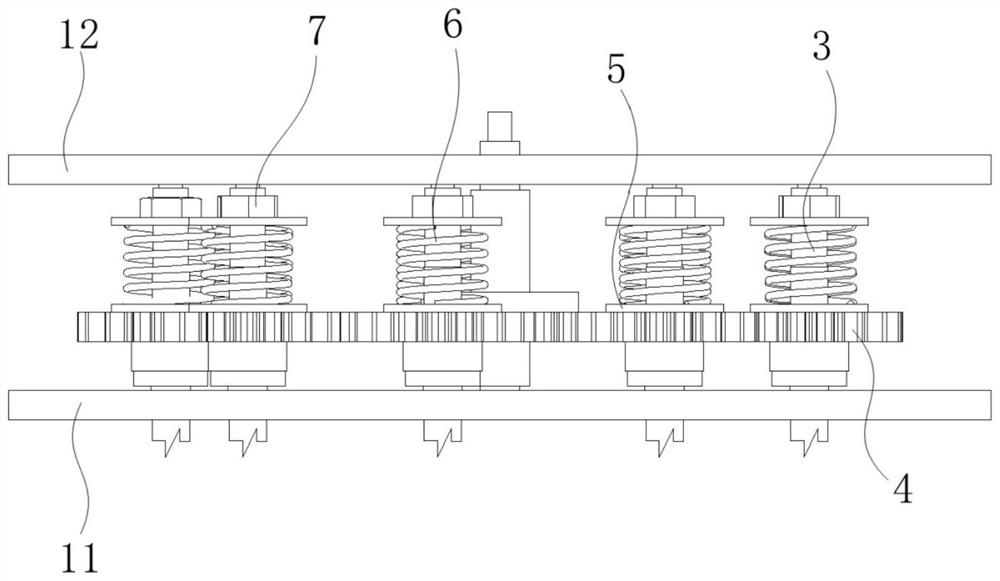

Nut pre-tightening tool

InactiveCN111843457AAchieve preloadChange the preload torqueMetal working apparatusGear wheelIndustrial engineering

The invention relates to a nut pre-tightening tool. The nut pre-tightening tool comprises a transmission device and output devices, wherein the transmission device comprises a rack and a driving gear,the driving gear is arranged on the rack through a bearing and can rotate along the axis of the bearing, each output device comprises a tightening shaft arranged on the rack, as well as a driven gear, a friction plate, a compression spring and a limiting piece which are sequentially arranged on the tightening shaft in a penetrating mode, each tightening shaft can rotate with the tightening shaftas the axis, the end of each tightening shaft is connected with a sleeve, each driven gear is meshed with the driving gear and can rotate along the axis of the corresponding tightening shaft, and twoor more sets of output devices are available. According to the nut pre-tightening tool, a plurality of nuts can be tightened at a time, so that the pre-tightening efficiency is improved, meanwhile, the nut pre-tightening tool can accurately control the pre-tightening torque of each bolt, then the situation that the post-procedure operation is difficult due to the fact that the pre-tightening torque is too large is avoided, the operation is easy, and the use is convenient.

Owner:DONGFENG LIUZHOU MOTOR

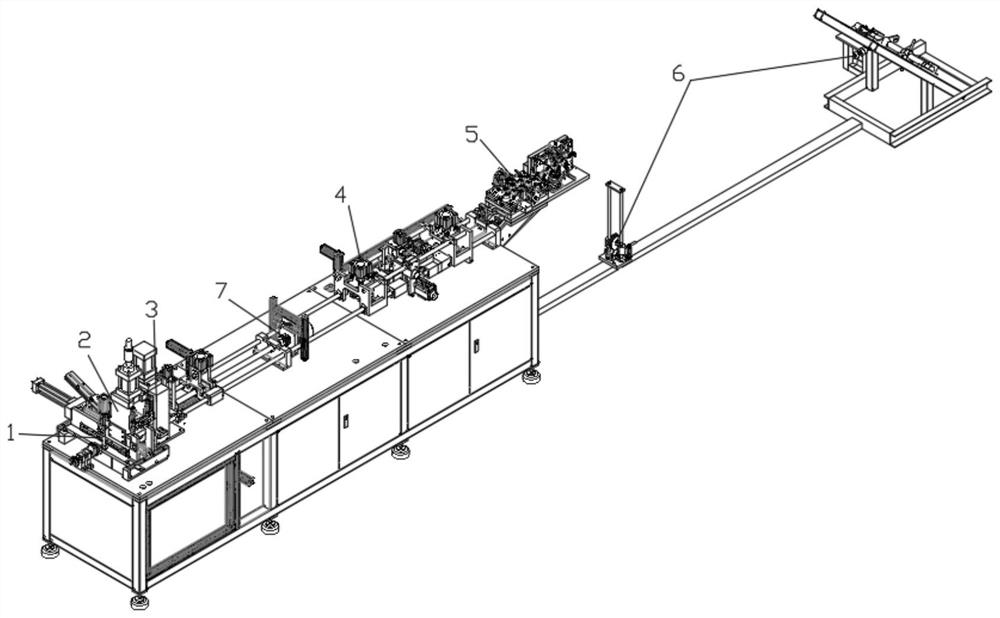

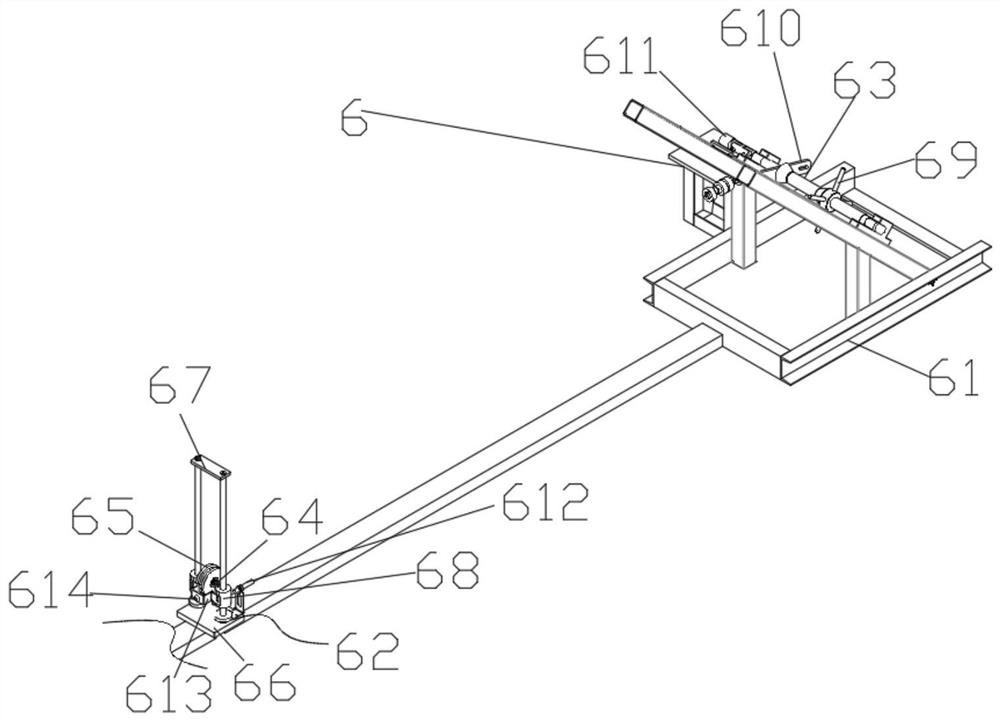

Flat wire automatic unloading forming machine of flat wire hairpin motor of new energy automobile

PendingCN112953140ARealize automatic feedingAvoid damageManufacturing dynamo-electric machinesNew energyElectric machine

The invention discloses a flat wire automatic unloading forming machine of a flat wire hairpin motor of a new energy automobile. An automatic wire pre-feeding mechanism, a flat wire straightening mechanism, a profiling cutter lossless enameled sheath removing mechanism, a flat wire feeding mechanism, a flat wire chamfering and primary cutting mechanism, a hairpin profiling equal-length positioning and rotary wire breaking mechanism and a hairpin profiling forming and automatic blanking mechanism are sequentially installed in the advancing direction of a flat wire. Automatic feeding, automatic straightening, automatic paint removing, chamfering, rotary wire breaking, forming and discharging of the flat wire are achieved, damage to the flat wire is small, the hairpin profiling length and shape of the flat wire are consistent, and the machining efficiency and quality of the flat wire are improved.

Owner:长沙华锐机电实业有限公司

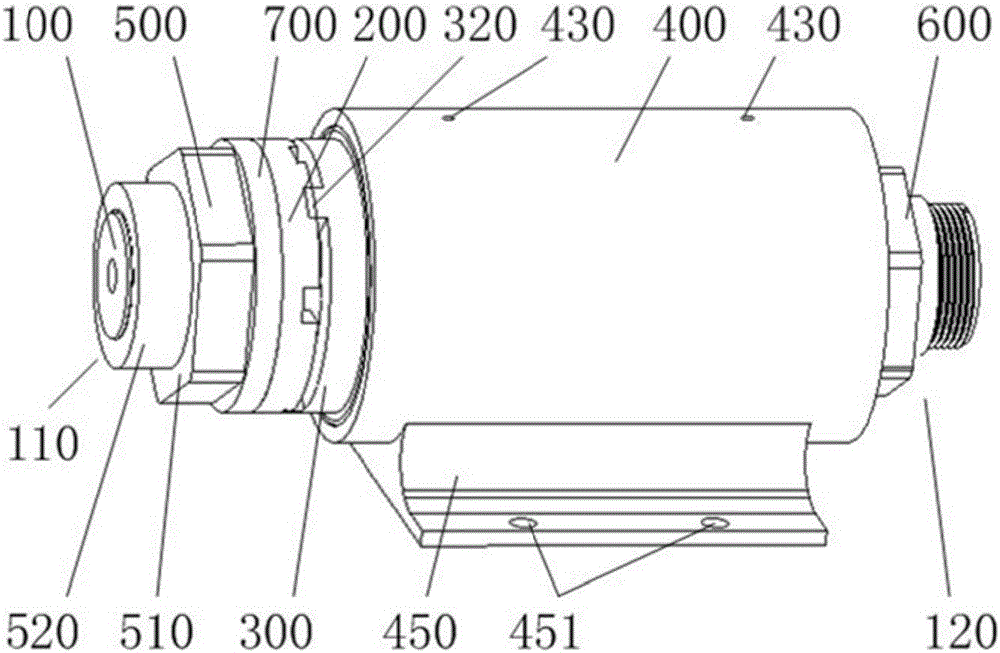

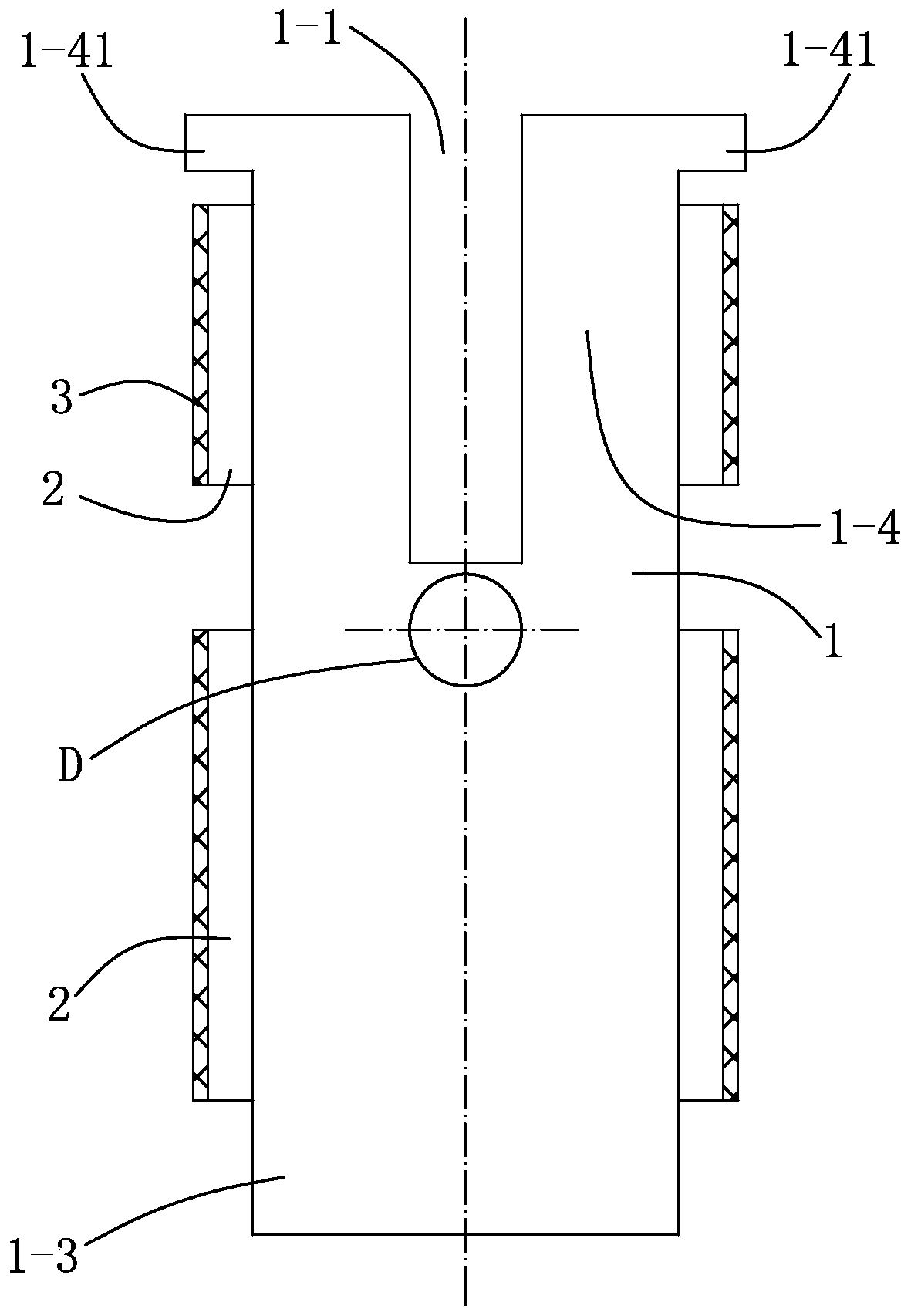

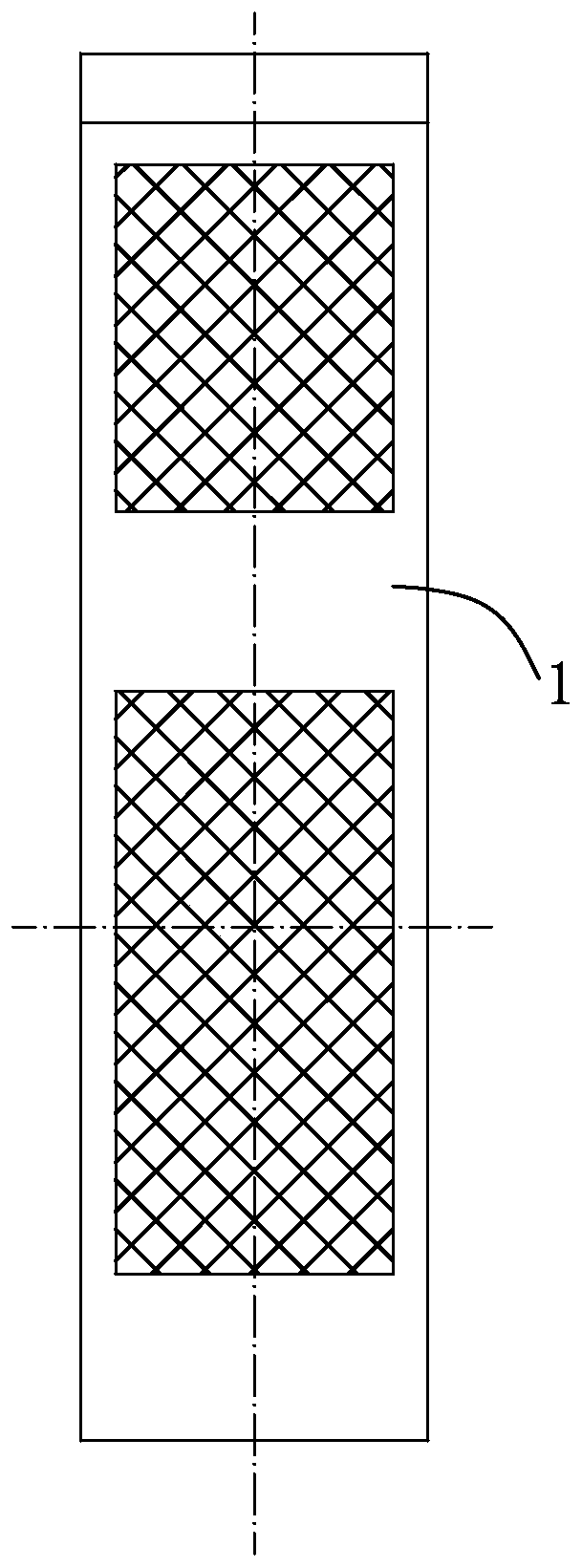

Bearing preloading device for electric motor

InactiveCN103532288AAchieve preloadSimple structureSupports/enclosures/casingsMotor shaftEngineering

The invention relates to a bearing preloading device for an electric motor. The bearing preloading device comprises a motor shaft, a bearing outer cover, an end cover, a bearing and a bearing inner cover, wherein the bearing inner cover is mounted on the motor shaft; the bearing supports the motor shaft; the end cover is fixed on an outer ring of the bearing; the bearing outer cover is mounted in the end cover; and the bearing outer cover and the bearing inner cover are connected and fixed by using hexagon bolts. The bearing preloading device is characterized by further comprising bearing springs and a bearing gasket; four bearing springs are mounted on the bearing outer cover of the motor; the bearing gasket is mounted on the outer side of the bearing; and the bearing springs are contacted with the bearing gasket. According to the bearing preloading device, the structure is simple and reasonable, the assembly is convenient, few parts exist, and on the basis that any assembling manner of an original electric motor is not changed, four circular holes used for installing the bearing springs are formed in the bearing outer cover, so that the preloading function for the bearing of the electric motor can be realized more conveniently.

Owner:WUXI ZHONGDA MOTORS

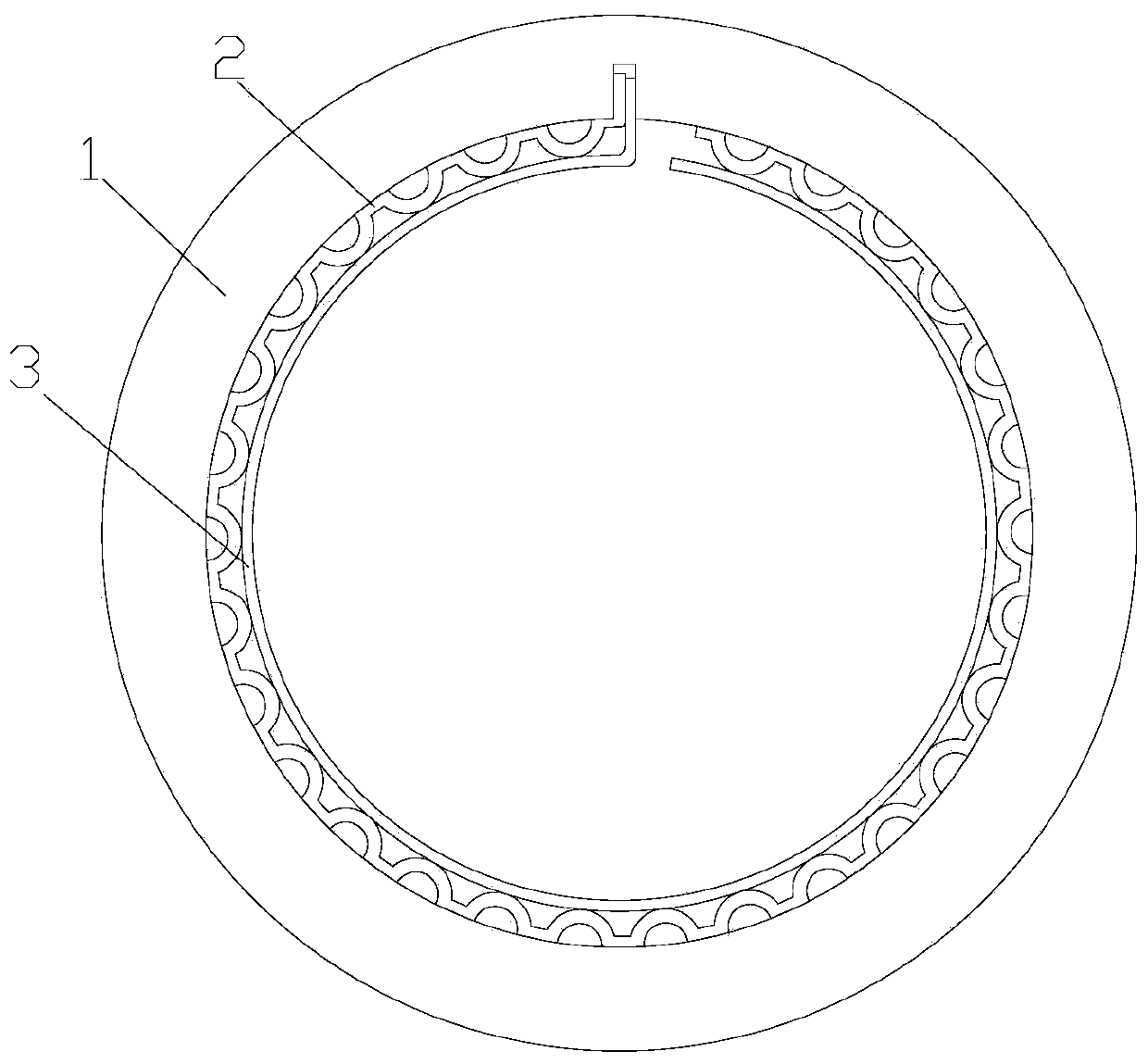

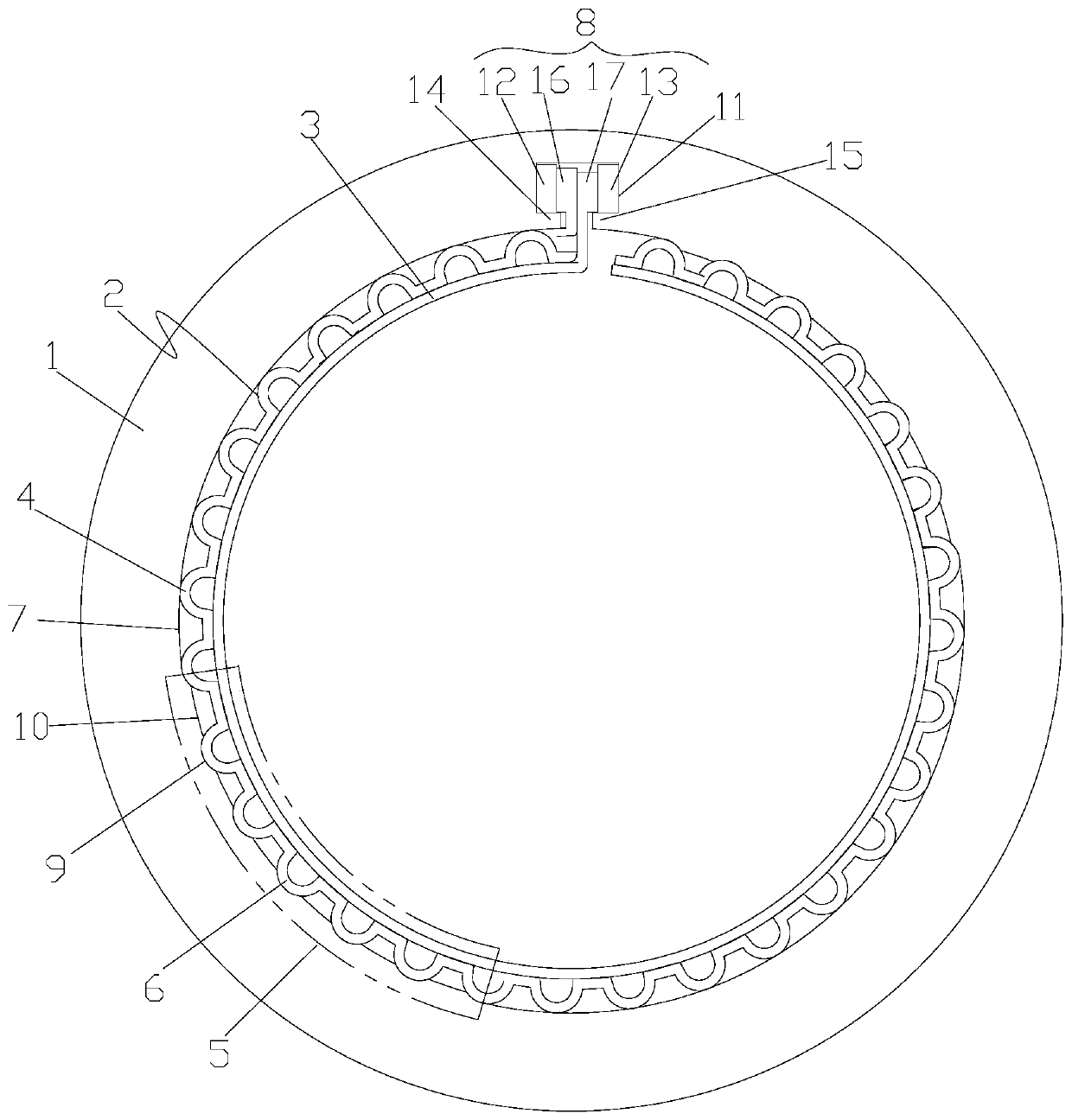

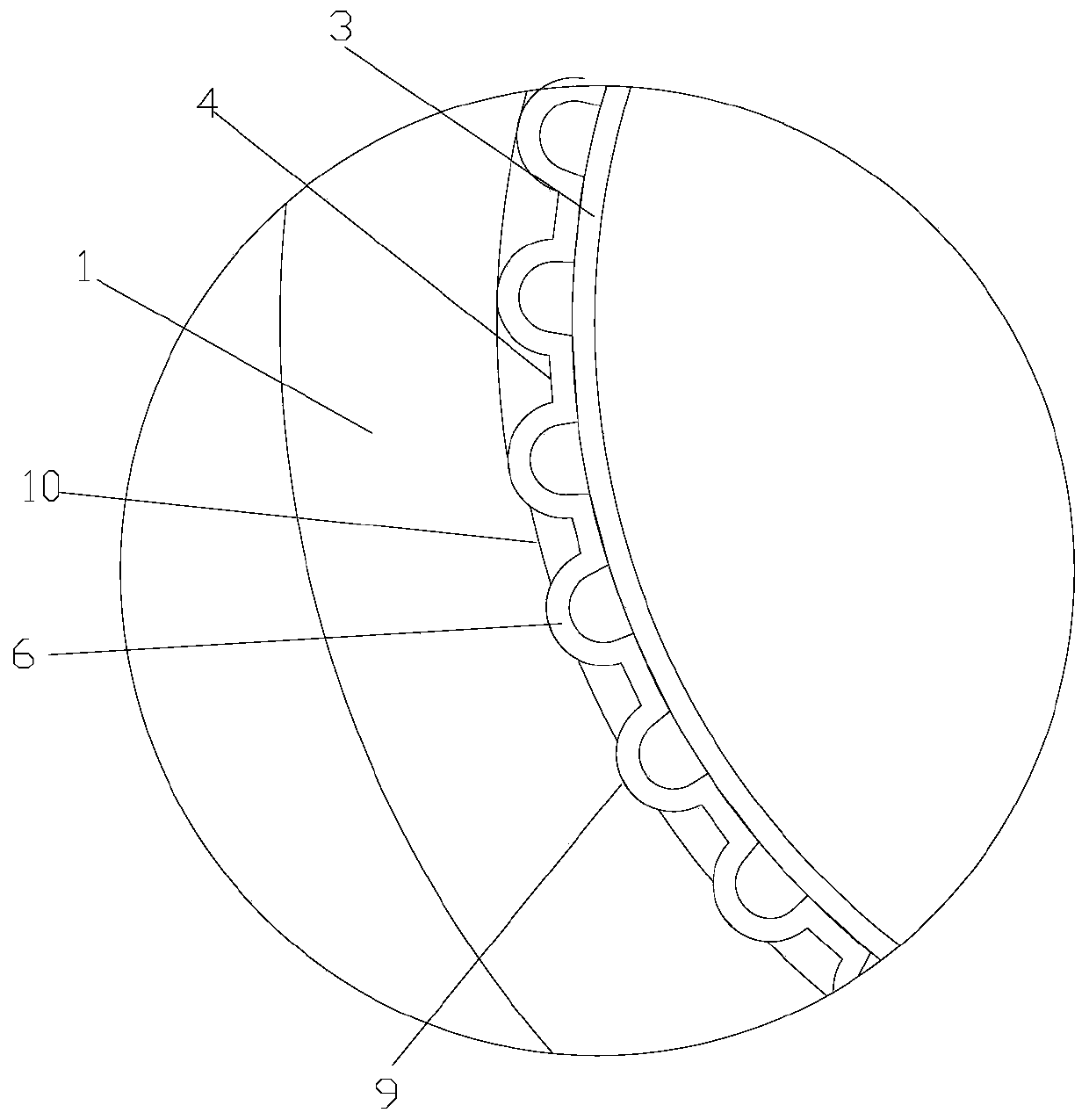

Aerodynamic bearing, manufacturing method thereof and mechanical device

ActiveCN111005935AAchieve preloadImprove bearing capacityShaftsBearing componentsClassical mechanicsStructural engineering

The present application provides an aerodynamic bearing, a manufacturing method thereof and a mechanical device. The aerodynamic bearing comprises a bearing pedestal, an arch foil and a top foil, wherein the arch foil is located between the bearing pedestal and the top foil and comprises connecting sections and arch sections, which are sequentially arranged in a circumferential direction of the arch foil; the connecting sections are connected between roots of the arch section; and the arch sections protrude toward an inner peripheral wall of the bearing pedestal, which comprises grooves corresponding to the arch sections. The aerodynamic bearing further comprises an adjusting structure for adjusting a circumferential position of the arch foil relative to the bearing pedestal. The adjustingstructure adjusts the circumferential position of the arch foil to make the arch sections slide into or out of the grooves. The aerodynamic bearing provided by the present application can be pre-tightened so as to be improved in bearing capacity and working performance.

Owner:GREE ELECTRIC APPLIANCES INC

Underwater electromechanical release device driven by two-stage force-amplifier

ActiveCN108214542ALow powerSelf-locking and reliableJointsGripping headsMarine engineeringSelf locking

The invention discloses an underwater electromechanical release device driven by a two-stage force-amplifier. The underwater electromechanical release device is characterized in that when the underwater electromechanical release device works, a power source drives a worm wheel to rotate through a worm, the worm wheel drives a nut shaft to rotate through key connection, the nut shaft pushes a plugsleeve fixed on a shoulder joint of a mechanical arm to move downwards through a threaded pair inside the nut shaft, meanwhile, a socket sleeve is driven to slide downwards in a sealing sleeve, the nut shaft loses the suspension constraint on the plug sleeve when the plug sleeve moves to the end of the threaded pair, meanwhile, the plug sleeve and the sealing sleeve are unsealed, the mechanical arm is separated from an underwater robot under the action of gravity, and electromechanical release is completed. According to the underwater electromechanical release device, a worm wheel and worm pair and a lead screw and nut pair are connected in series to achieve two-stage force amplifying and self-locking, the release action required smaller power, and the self-locking connection is reliable;and the underwater electromechanical release device is suitable for underwater operation robots and can also be applied to other underwater electromechanical equipment.

Owner:JIANGSU UNIV OF SCI & TECH

Punching device for paper processing based on rolling wheel pre-pressing technology

InactiveCN109227723AGuarantee punching qualityPrevent clogged punchingMetal working apparatusScrapCardboard

The invention discloses a punching device for paper processing based on a rolling wheel pre-pressing technology. The device comprises a base, a punched hole and a vertical frame are arranged in the middle of the top end surface of the base, and the vertical frame is arranged on the back side of the punched hole; a hydraulic cylinder is arranged at the top end of the vertical frame, the bottom endof a telescopic rod on the hydraulic cylinder penetrates through the top wall of the vertical frame and is fixedly connected with a punching head cooperating with the punched hole, and the telescopicrod is slidably connected with the vertical frame; connecting rods are symmetrically arranged at the bottoms of the left and right side ends of the vertical frame, telescopic sleeves are arranged at the bottom ends of the connecting rods, and telescopic rods are sleeved with inner cavities of the telescopic sleeves; pressing plates cooperating with the base are fixedly connected to the bottom endsof the telescopic rods, and several pressing wheels are uniformly arranged at the bottom ends of the pressing plates; by arranging the pressing plates and the pressing wheels, pre-pressing can be conducted on paper boards, the punching head can cooperate with the punched hole, the paper boards can be punched, and the punching quality of products can be effectively ensured; by arranging a suctionfan, paper scraps in the punched hole can be timely discharged, and it is effectively avoided that due to the fact that the paper scraps block the punched hole, the processing work is influenced.

Owner:WENZHOU SHI AN PACKING CO LTD

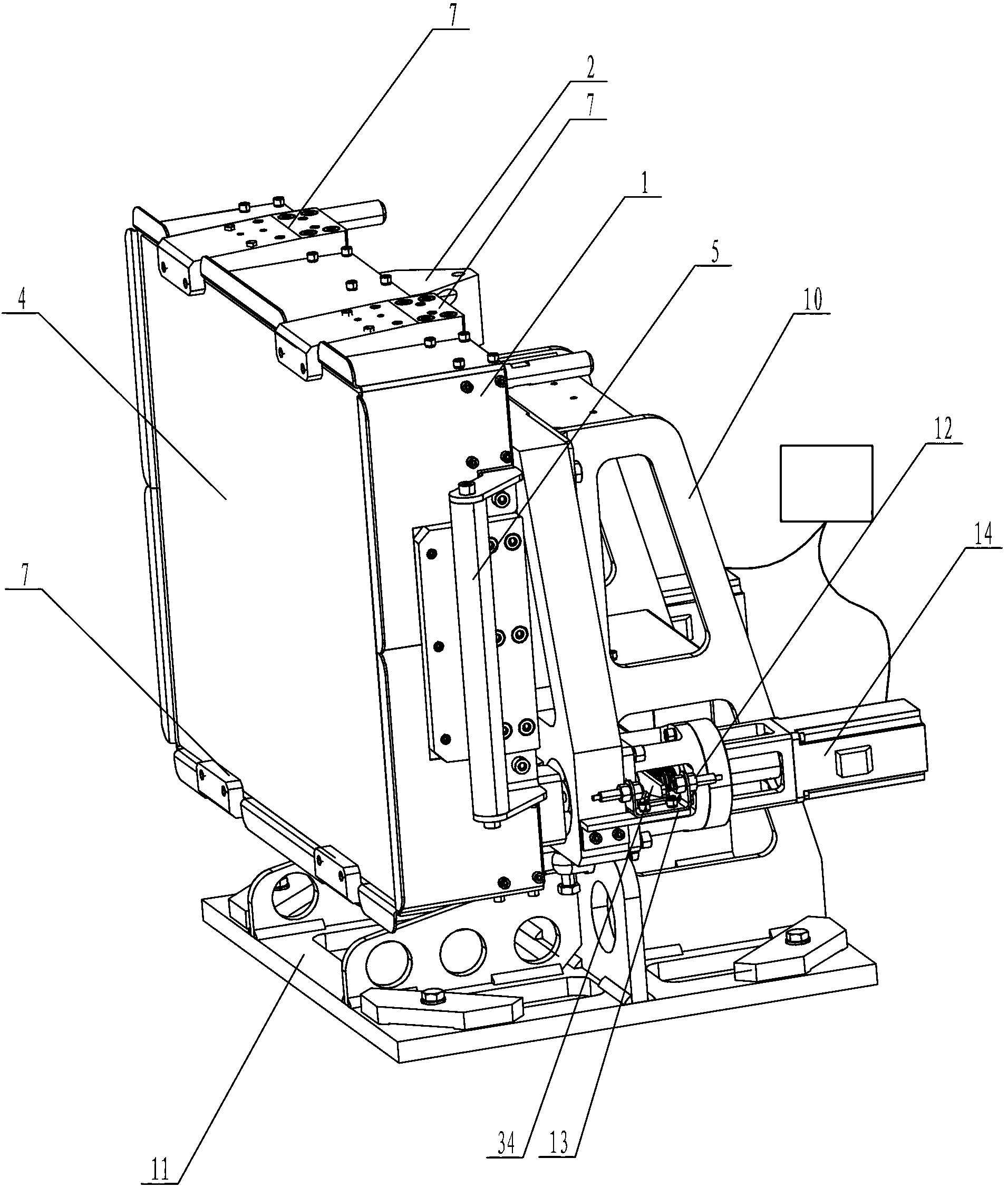

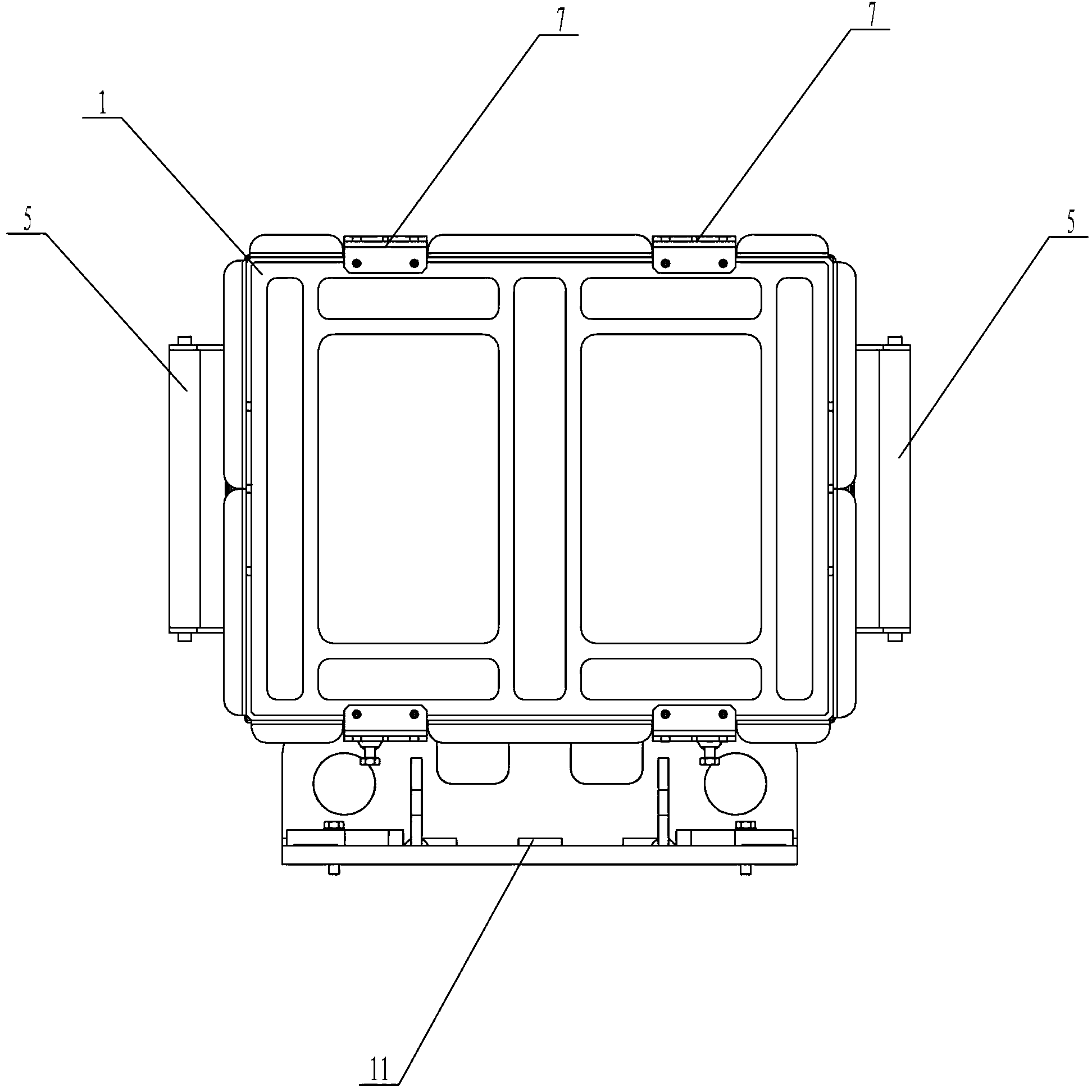

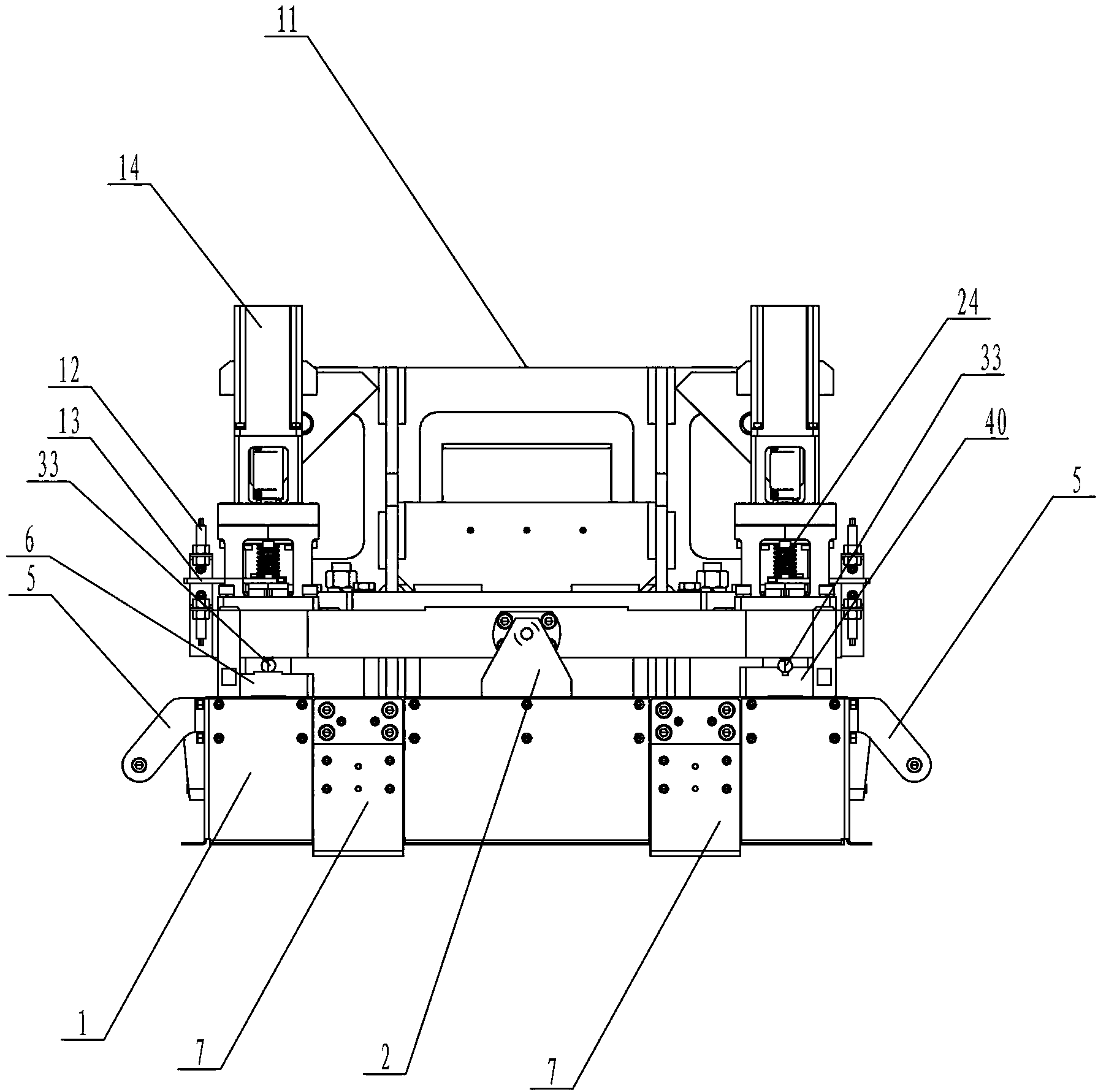

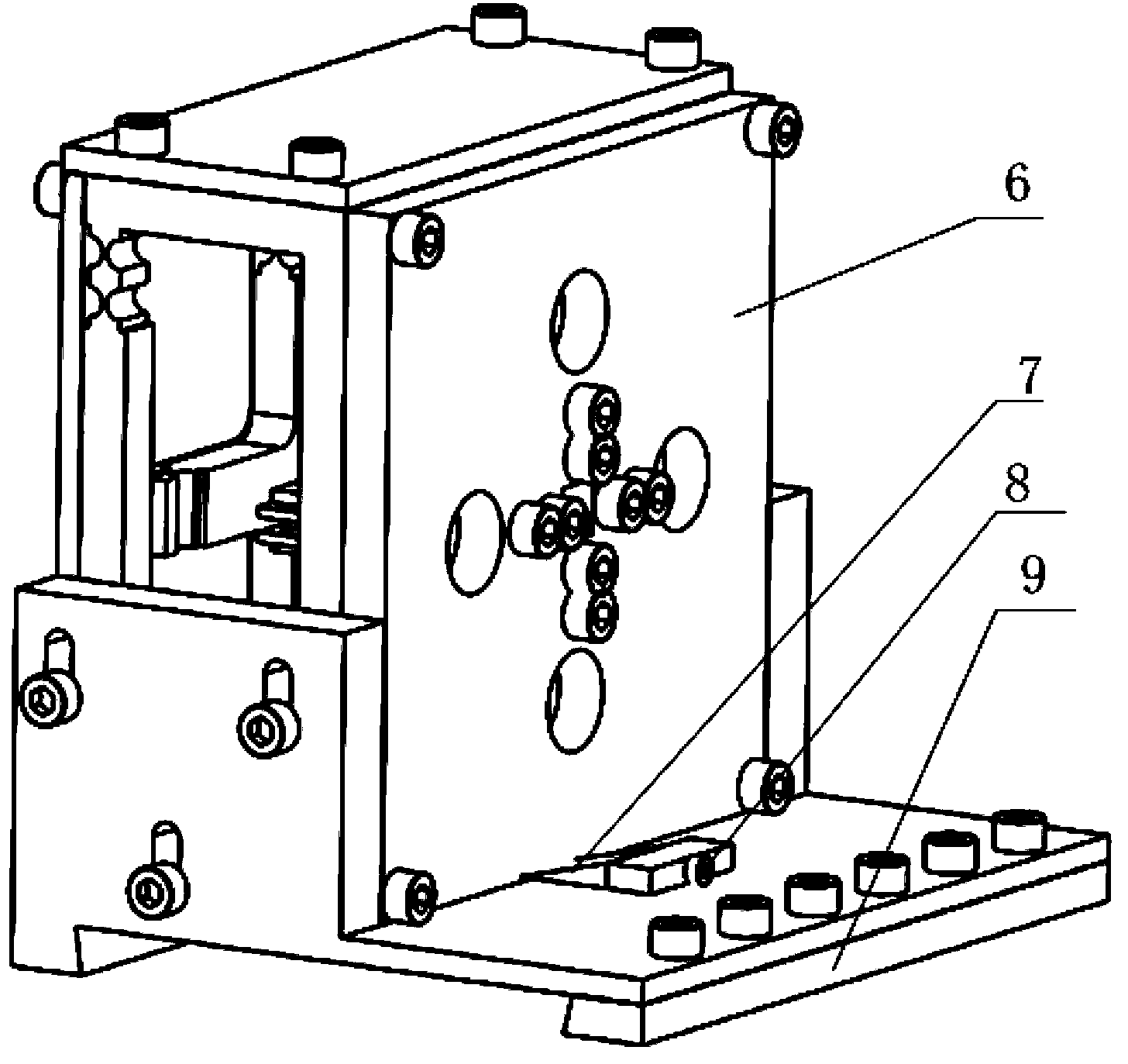

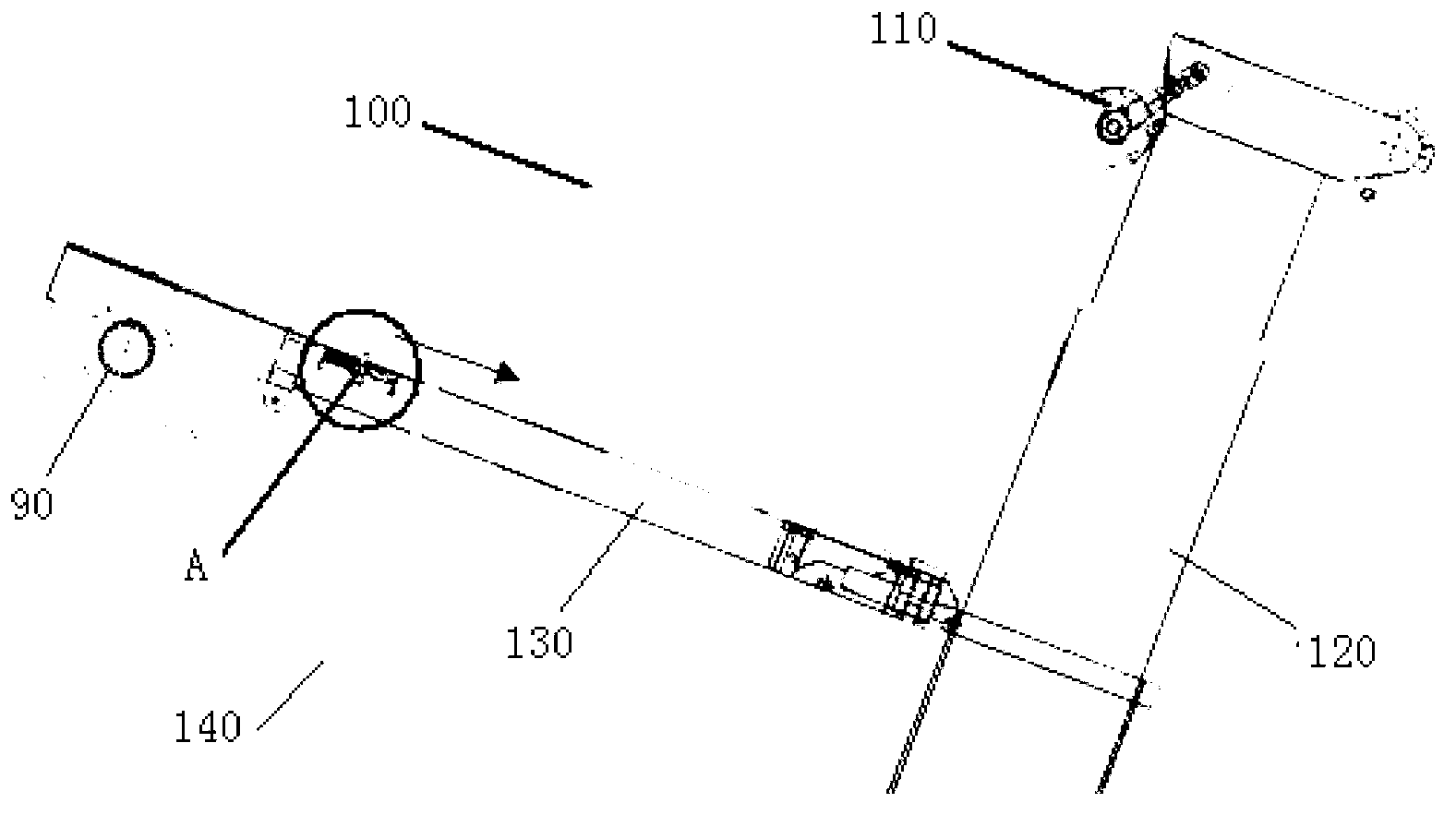

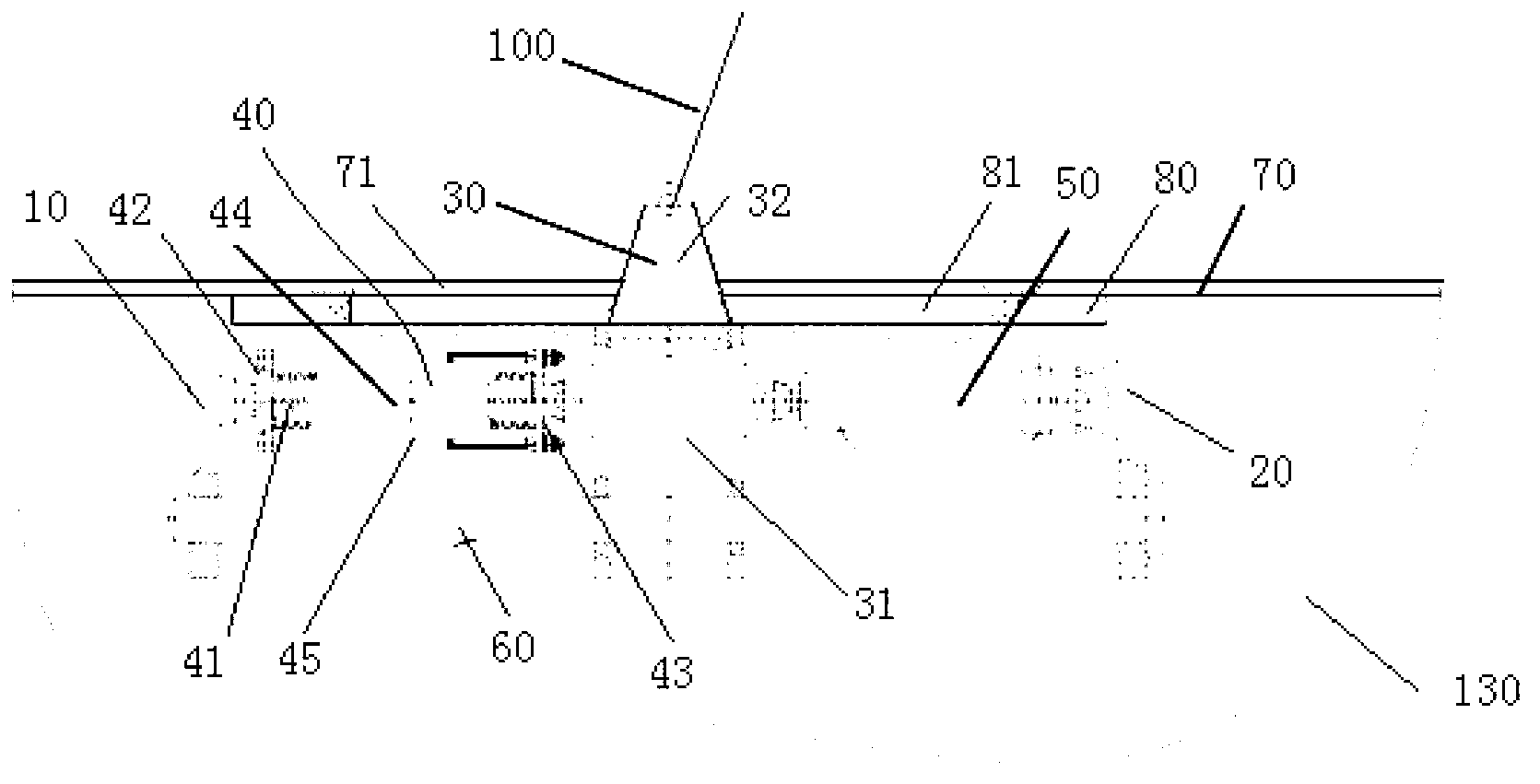

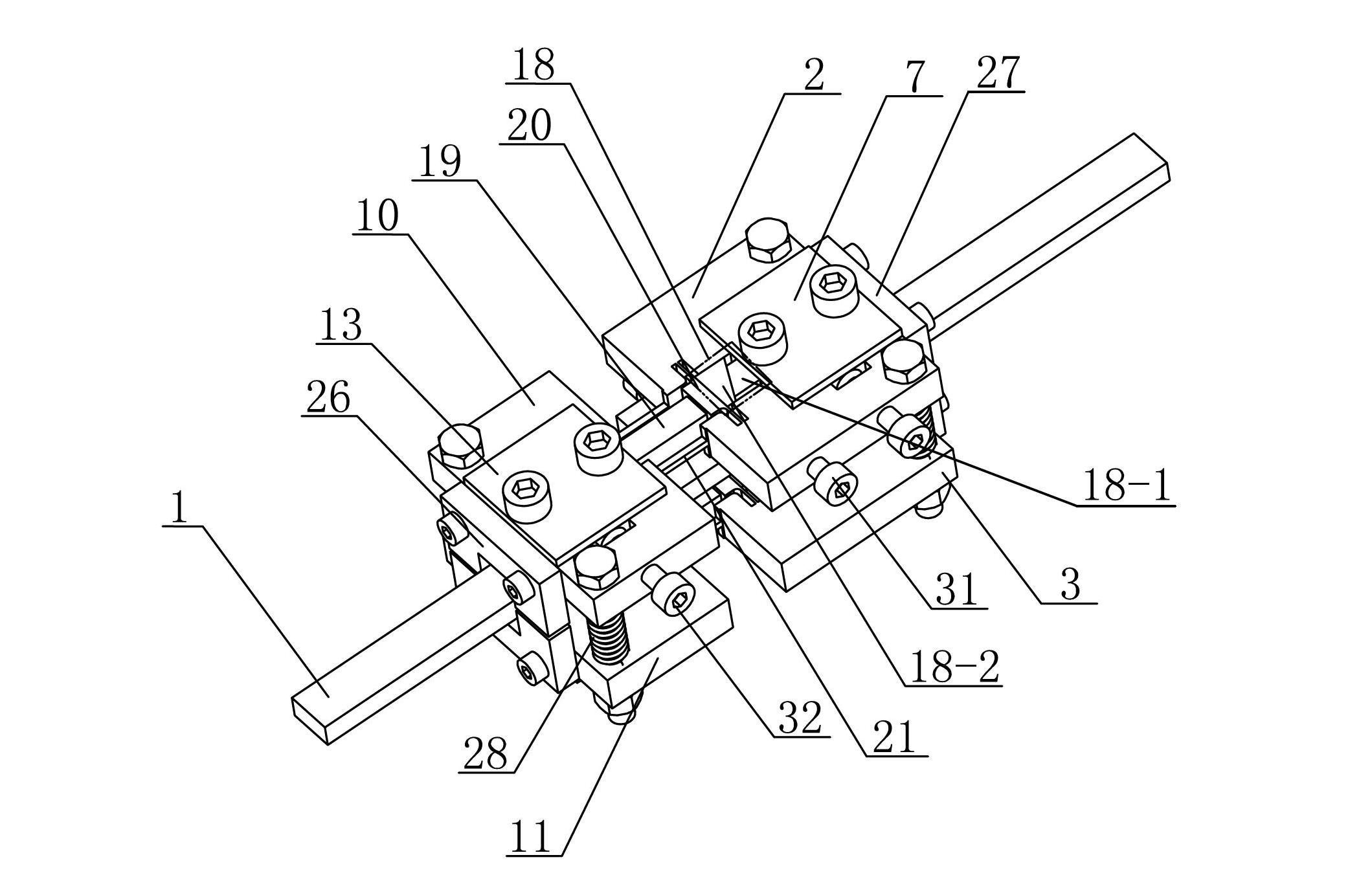

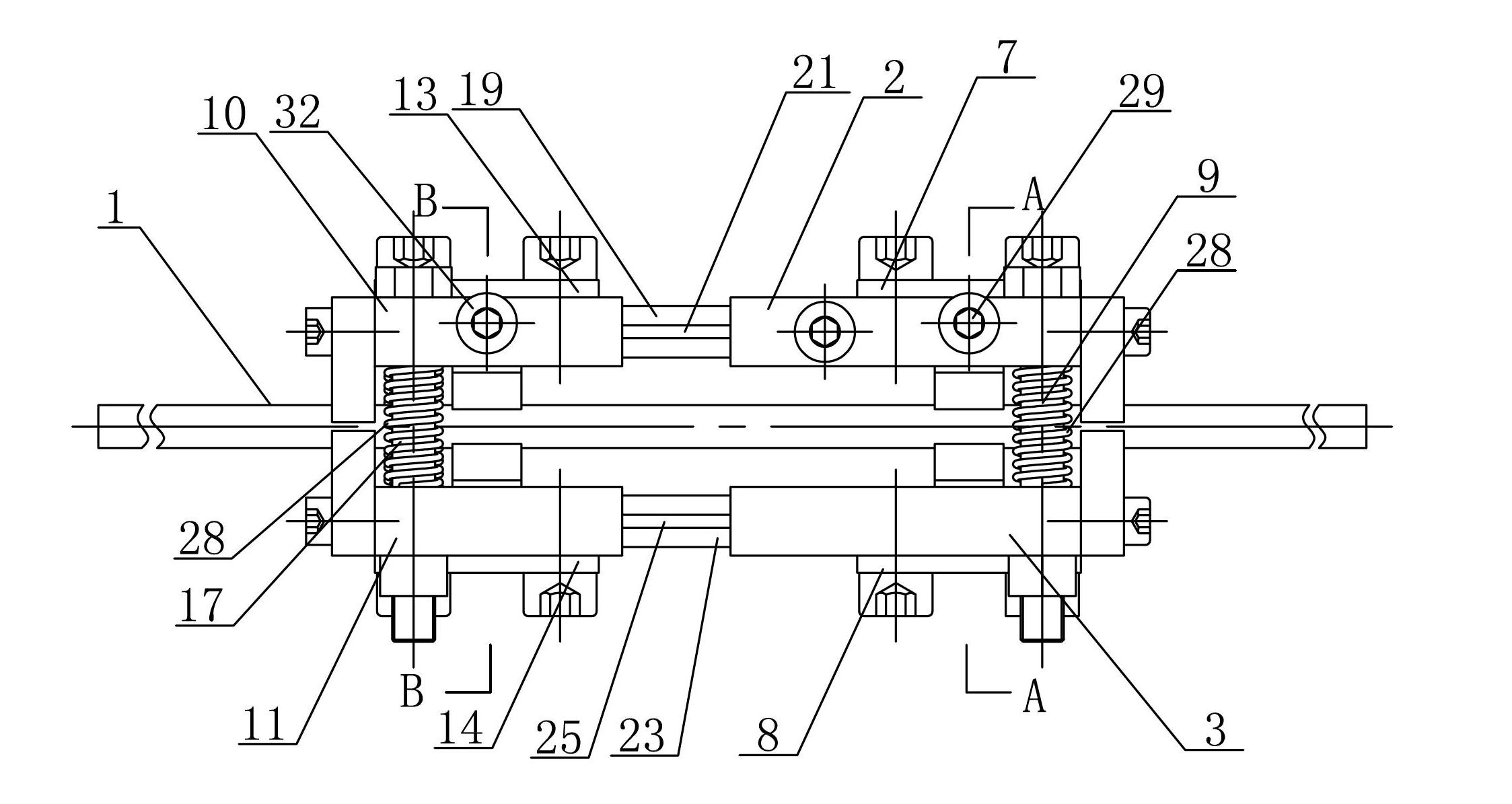

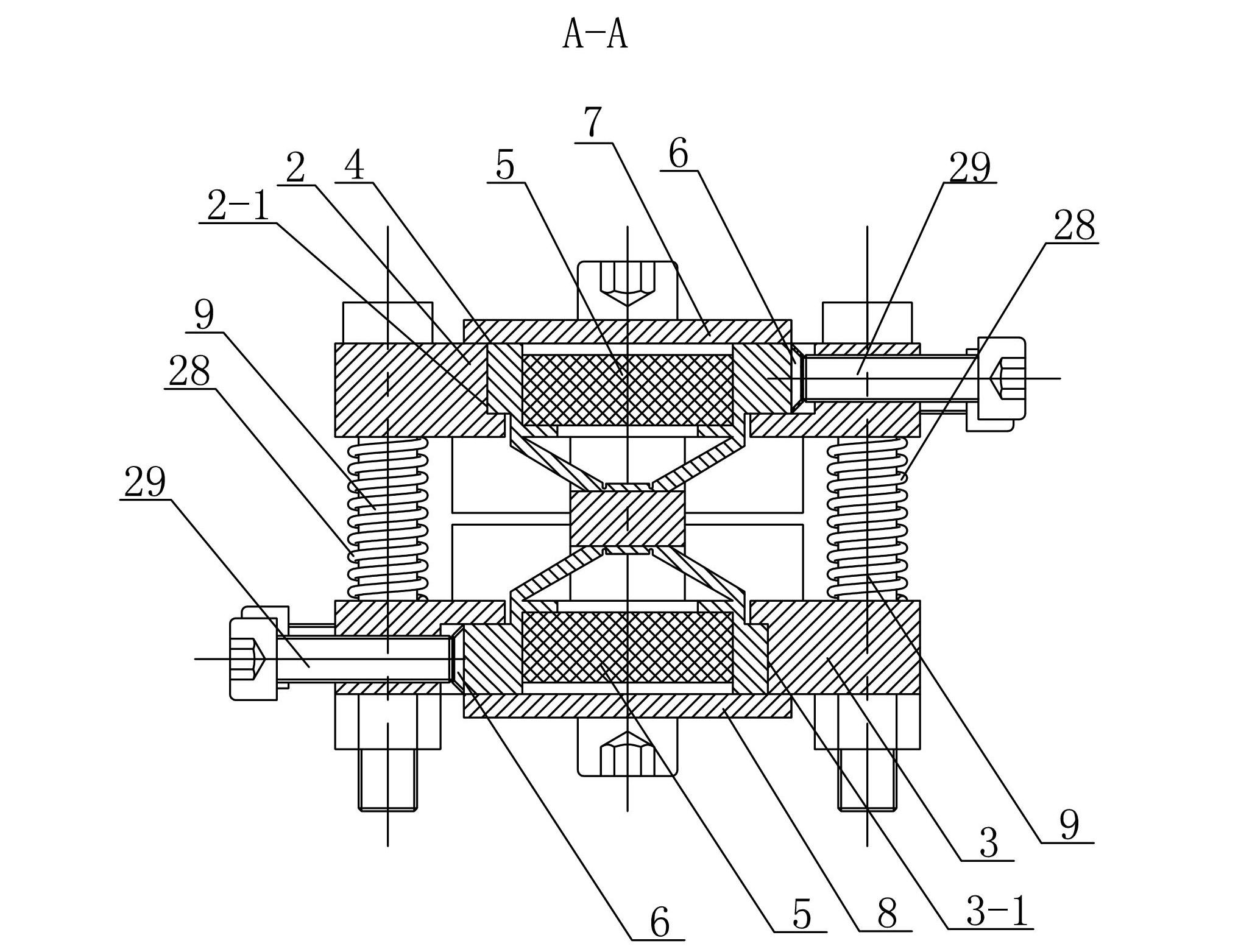

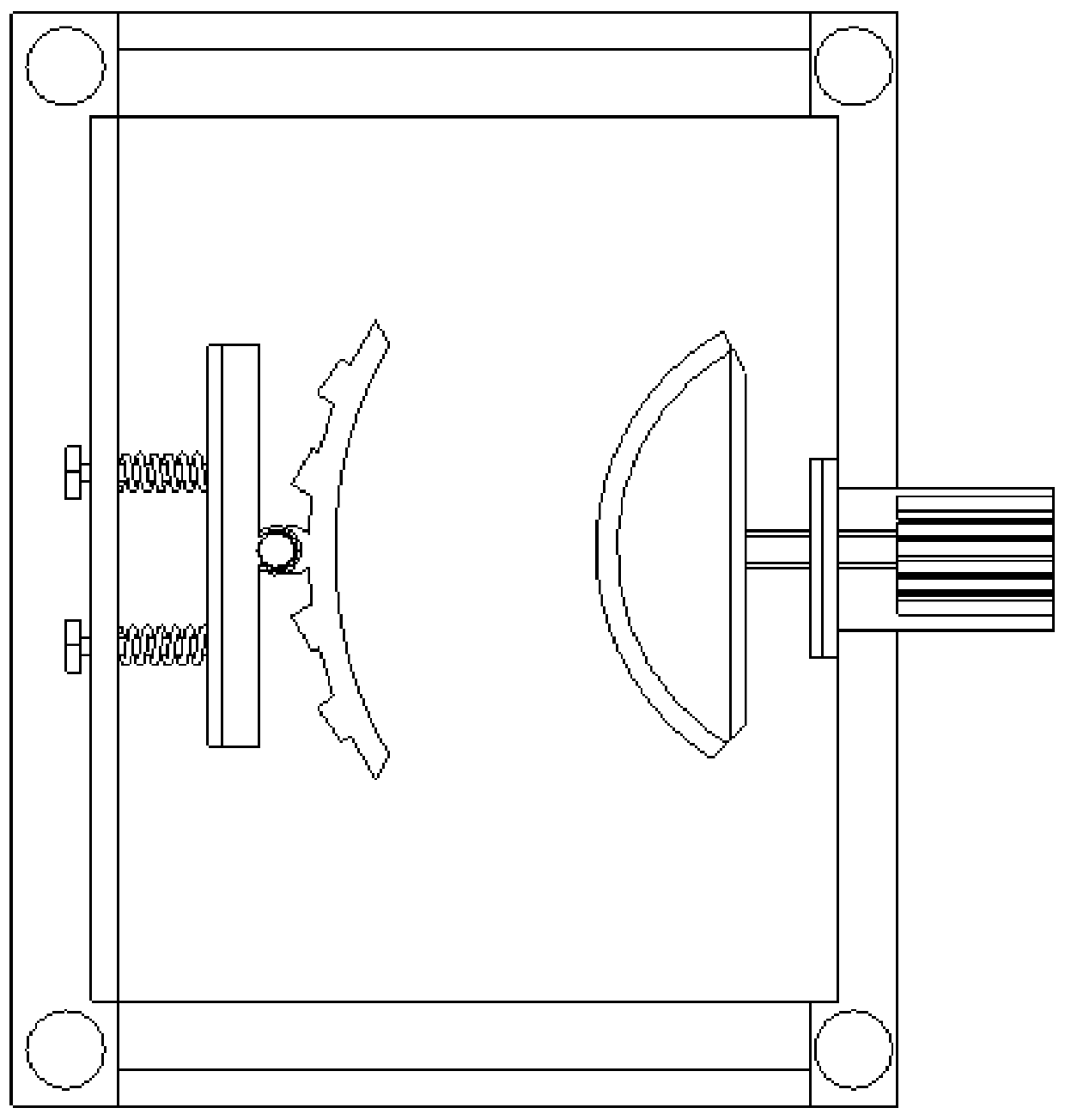

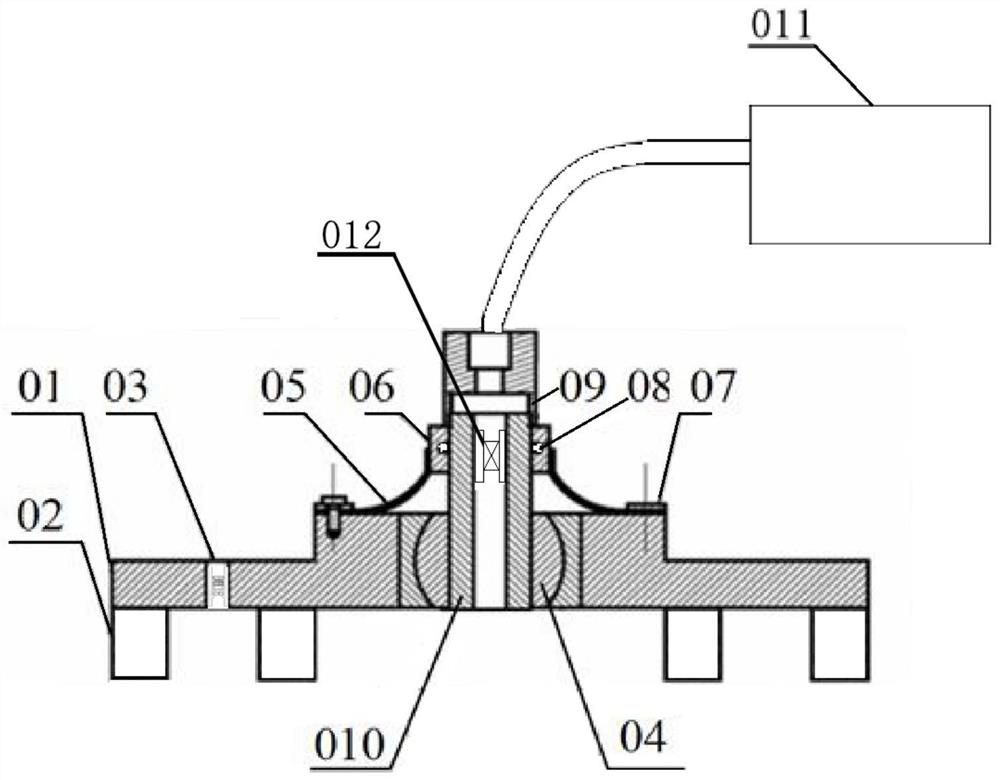

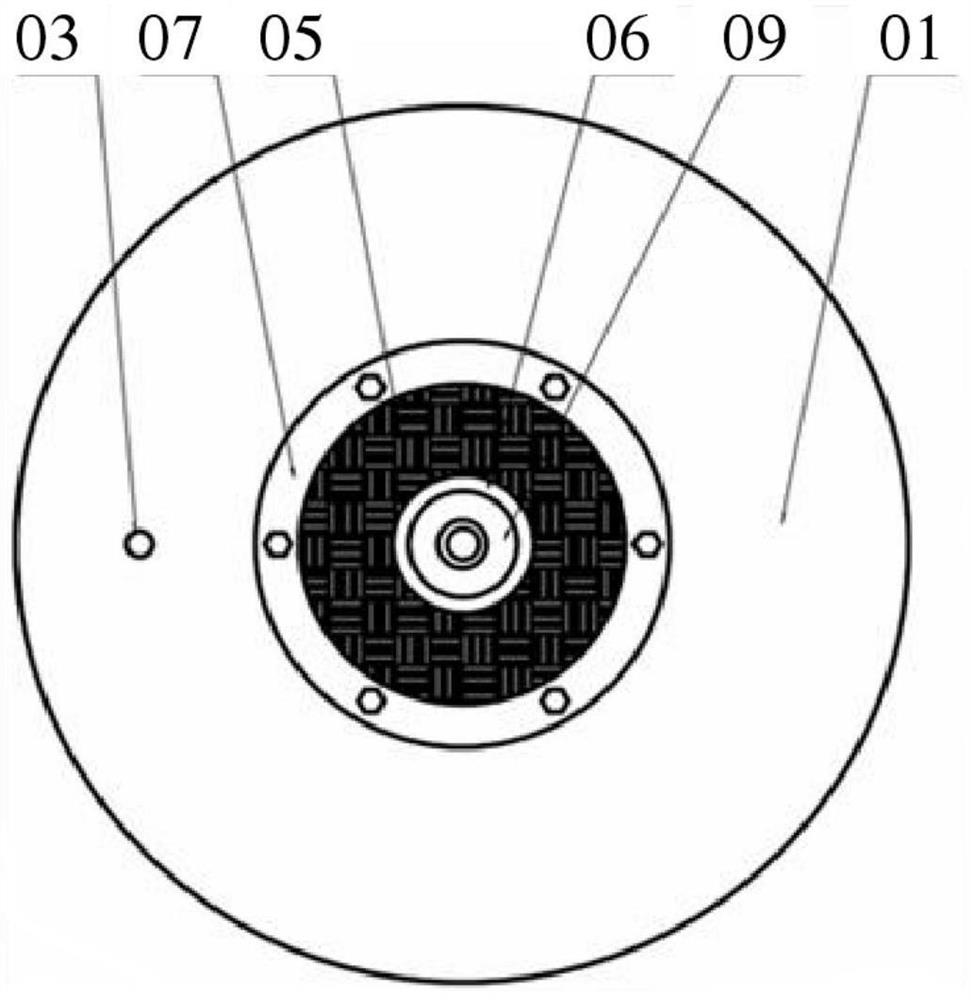

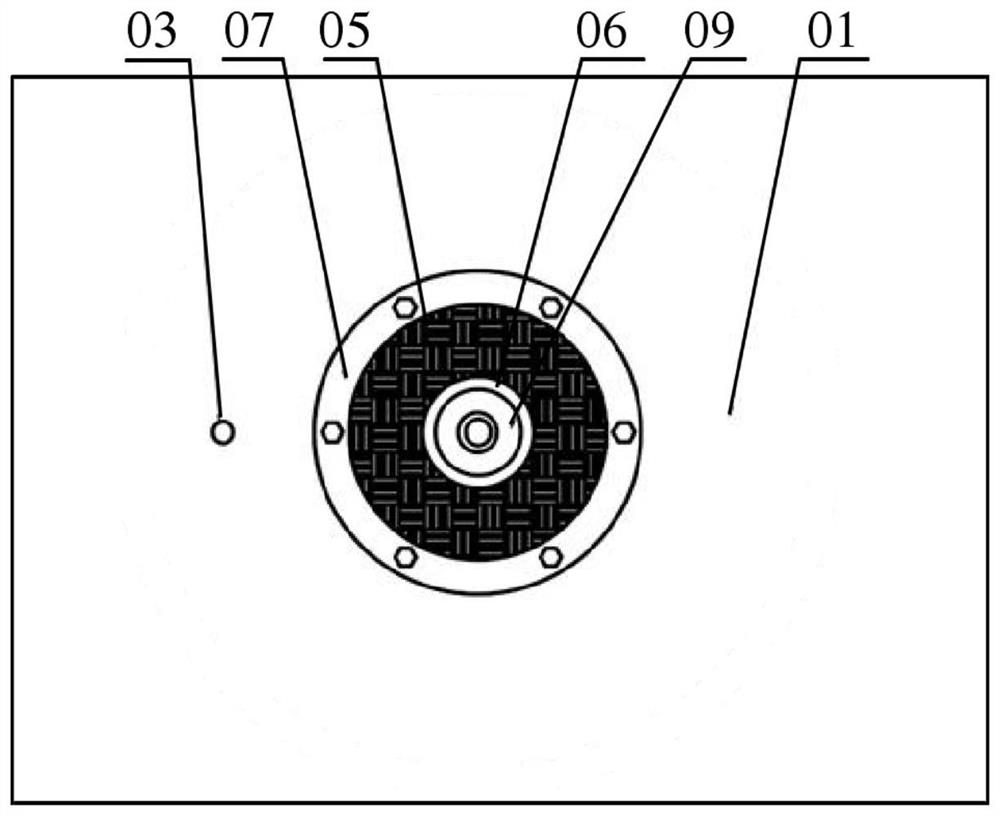

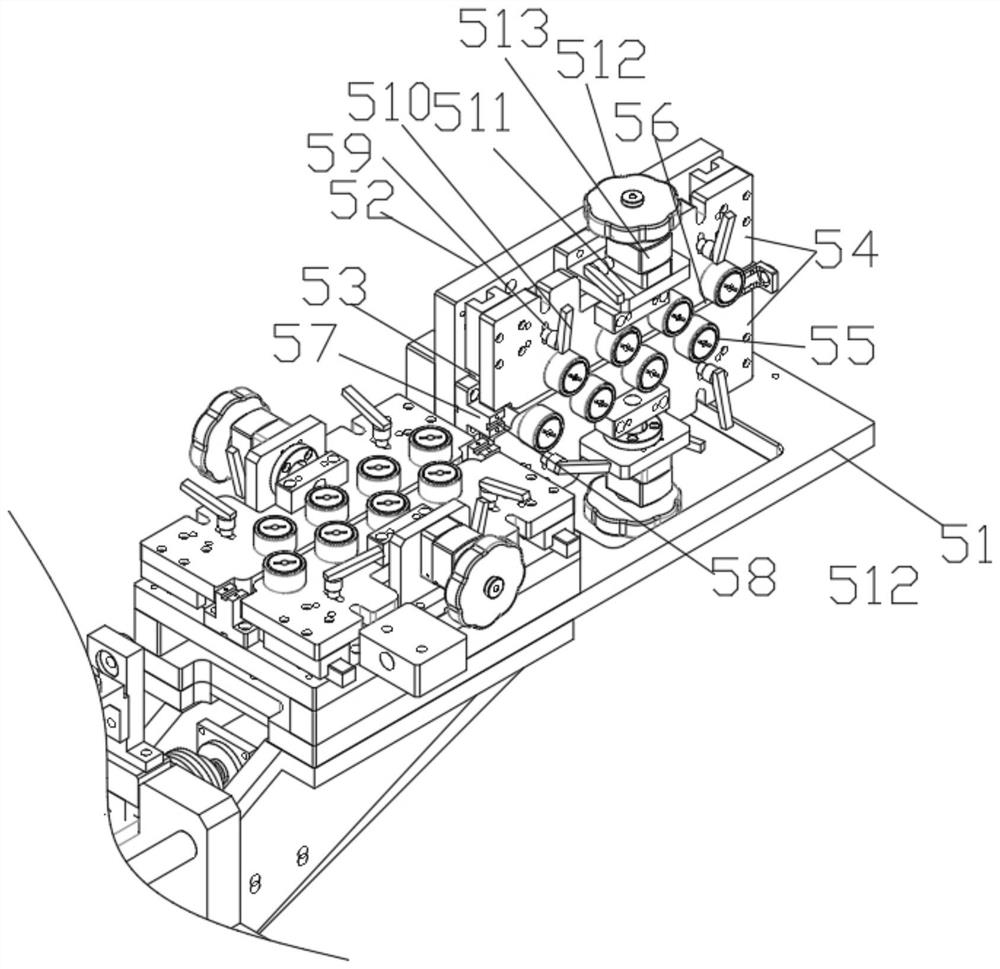

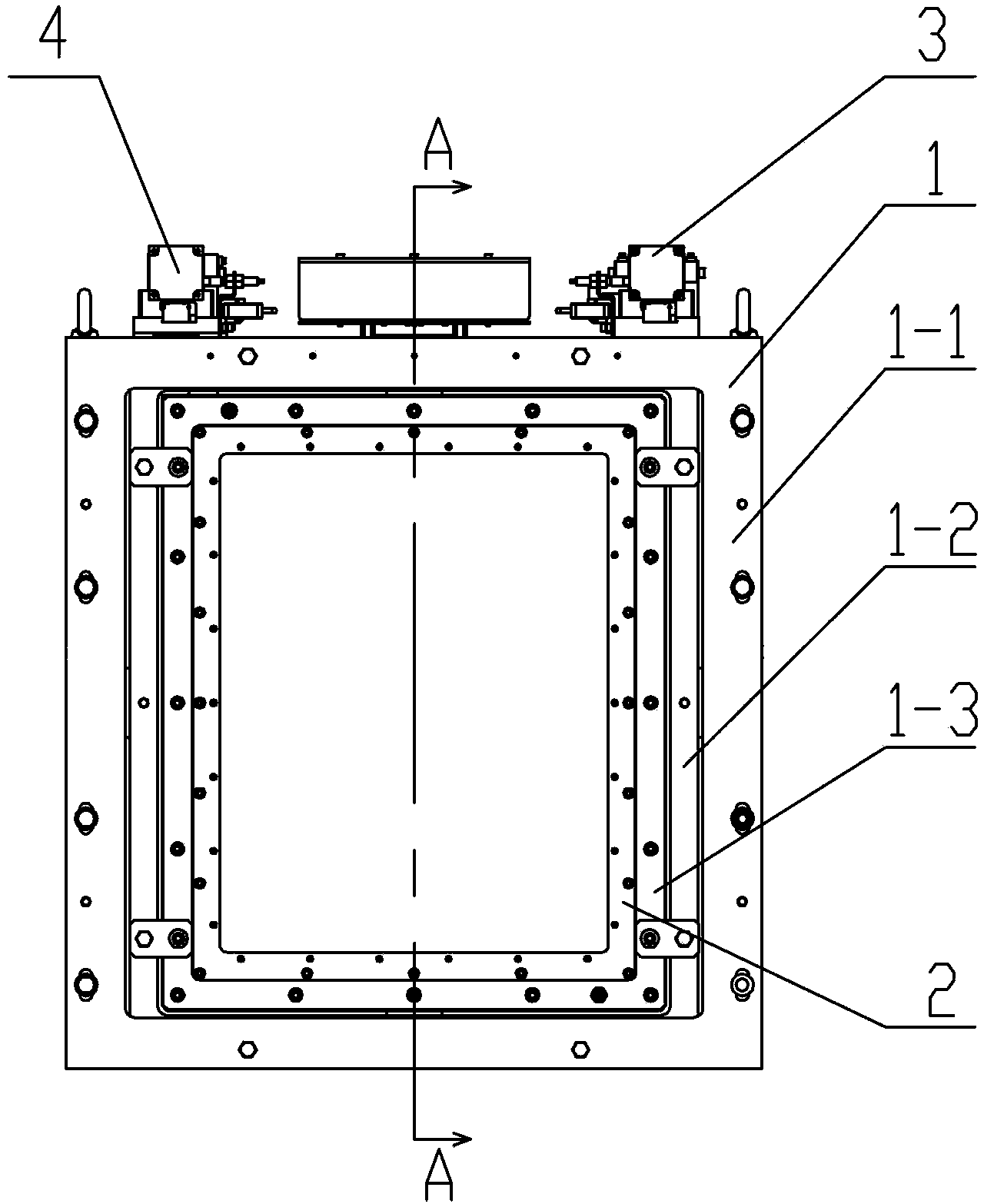

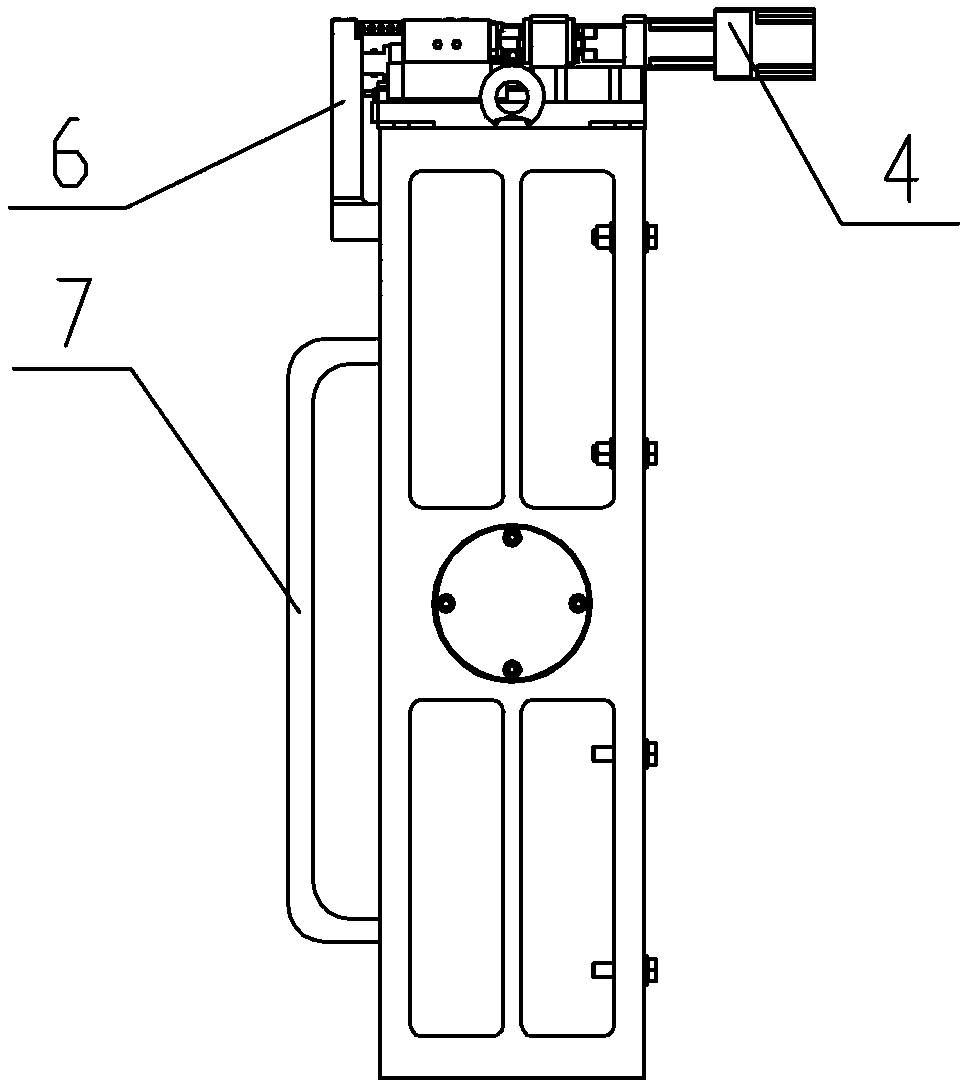

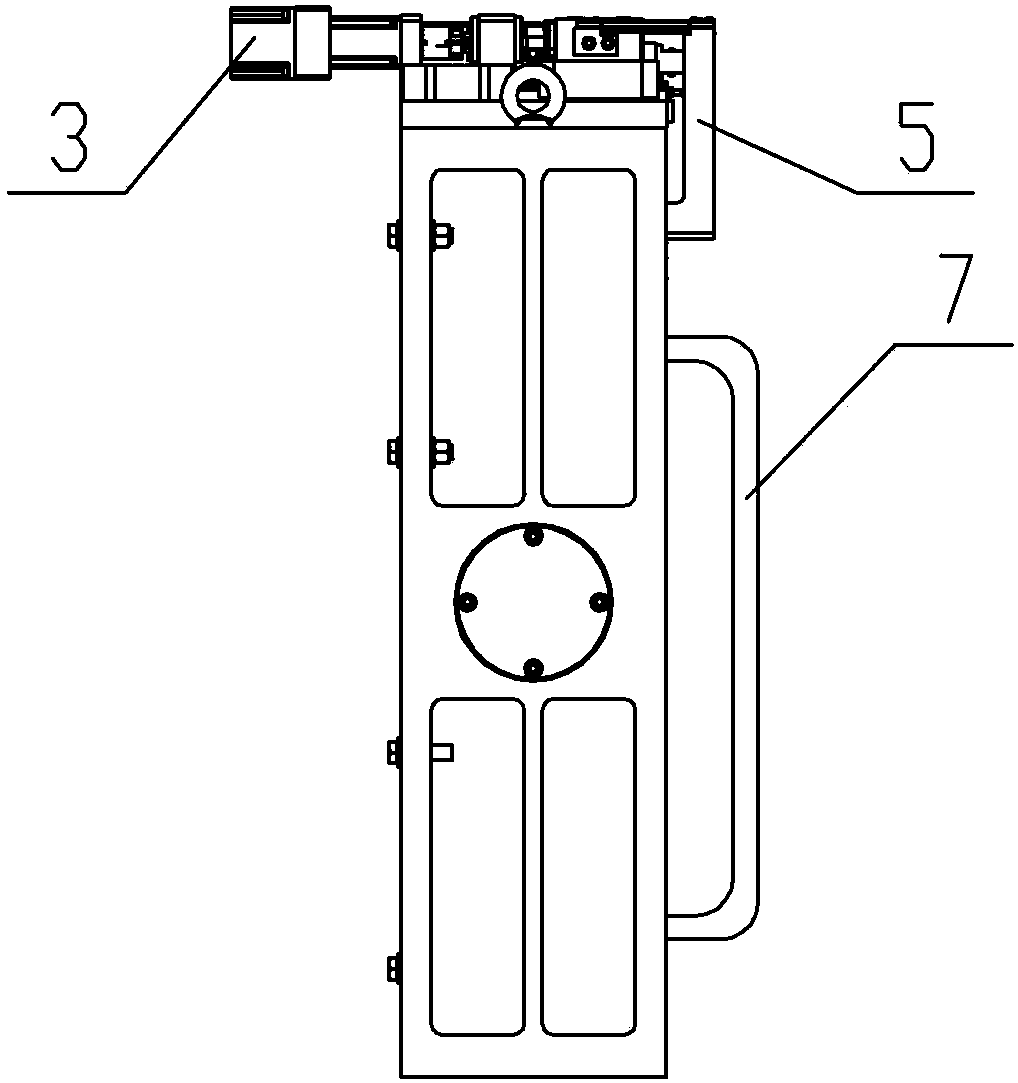

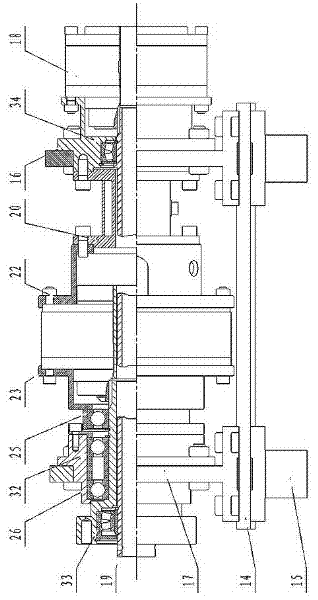

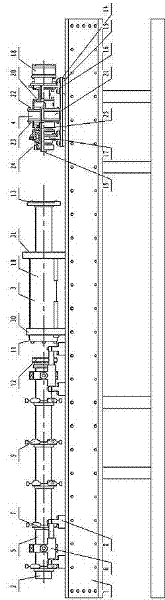

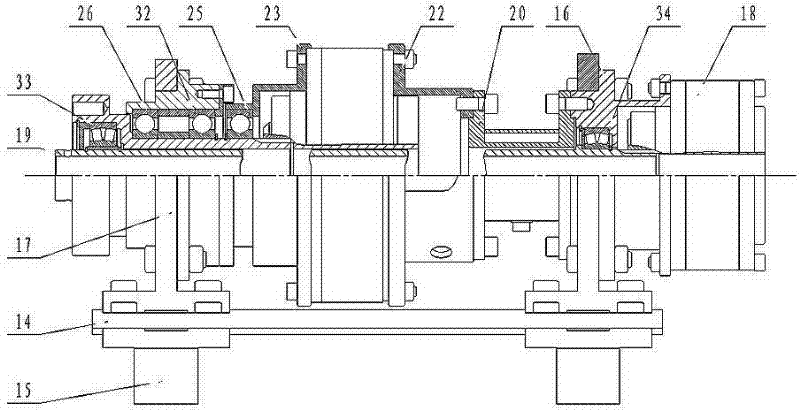

High-precision large-caliber electric reflecting mirror frame based on orthogonal axis

InactiveCN103018879BEasy to controlRealize blind adjustment functionMountingsFrame basedMicro actuator

The invention discloses a high-precision large-caliber electric reflecting mirror frame based on an orthogonal axis, relates to an electric reflecting mirror frame, and aims to solve the problems that the process of guiding the transmission direction of a large-caliber laser beam is not precise enough and is not easily controlled, and collimated guide and near-field adjustment for the laser beam are poor in flexibility. A rack is connected with a pitching shaft frame through a rotation shaft, the pitching shaft frame is used for adjusting pitching angles relative to the rack, the pitching shaft frame and the rotation shaft are connected with a deflection shaft frame, the deflection shaft frame is used for adjusting deflection relative to the pitching shaft frame, a transverse positioning barrier strip is close to the inner side surface of a transition frame, an axial positioning barrier strip is close to the inner side surface of a second positioning frame, a mini-driver output end of a pitching shaft micro-actuator is connected with the pitching shaft frame through a pitching connection block, and a mini-driver output end of a deflection shaft micro-actuator is connected with the deflection shaft frame through a deflection connection block. The high-precision large-caliber electric reflecting mirror frame is used for a light beam guide system of an inertial confinement laser fusion device or other optical path adjustment systems needing large calibers.

Owner:HARBIN INST OF TECH

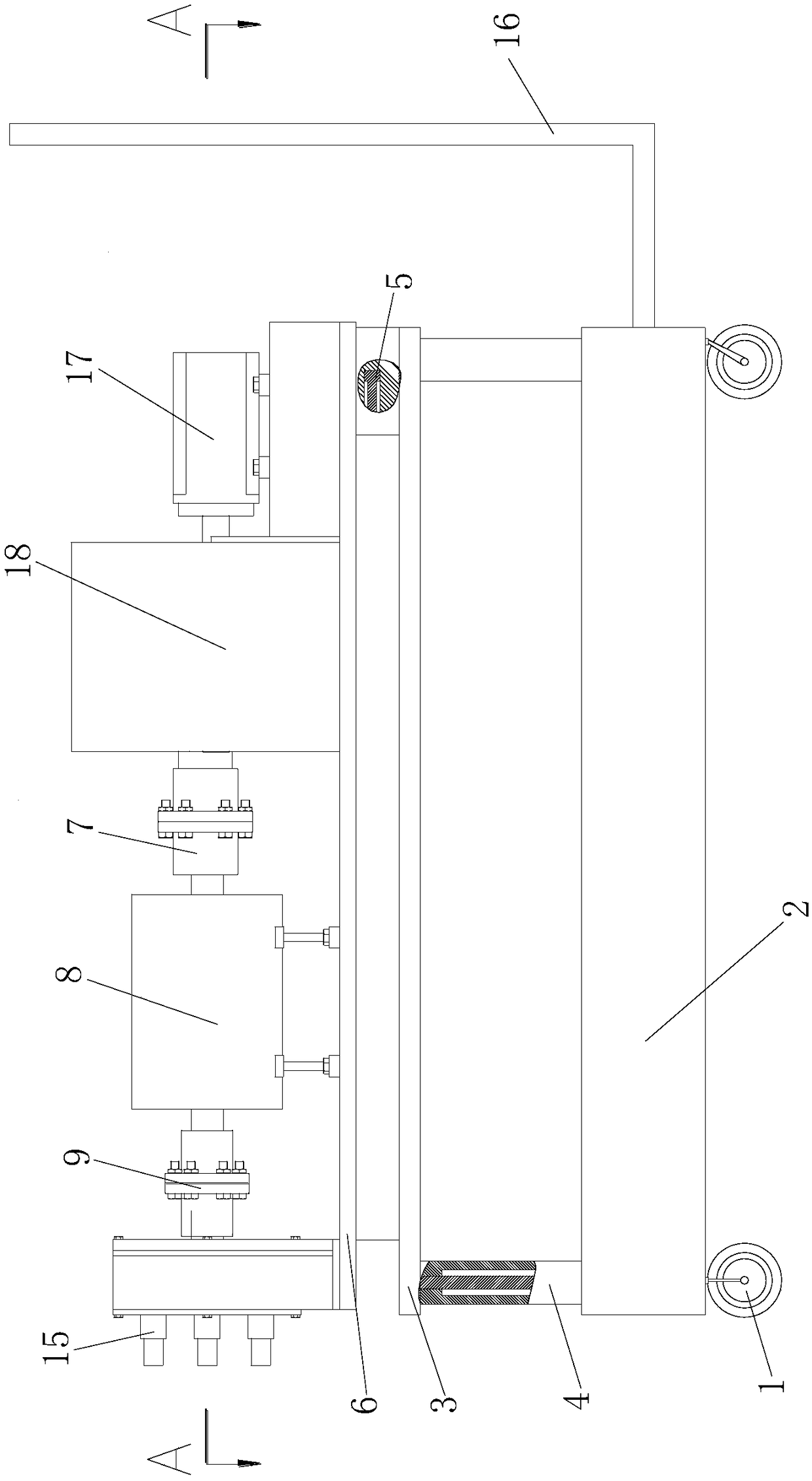

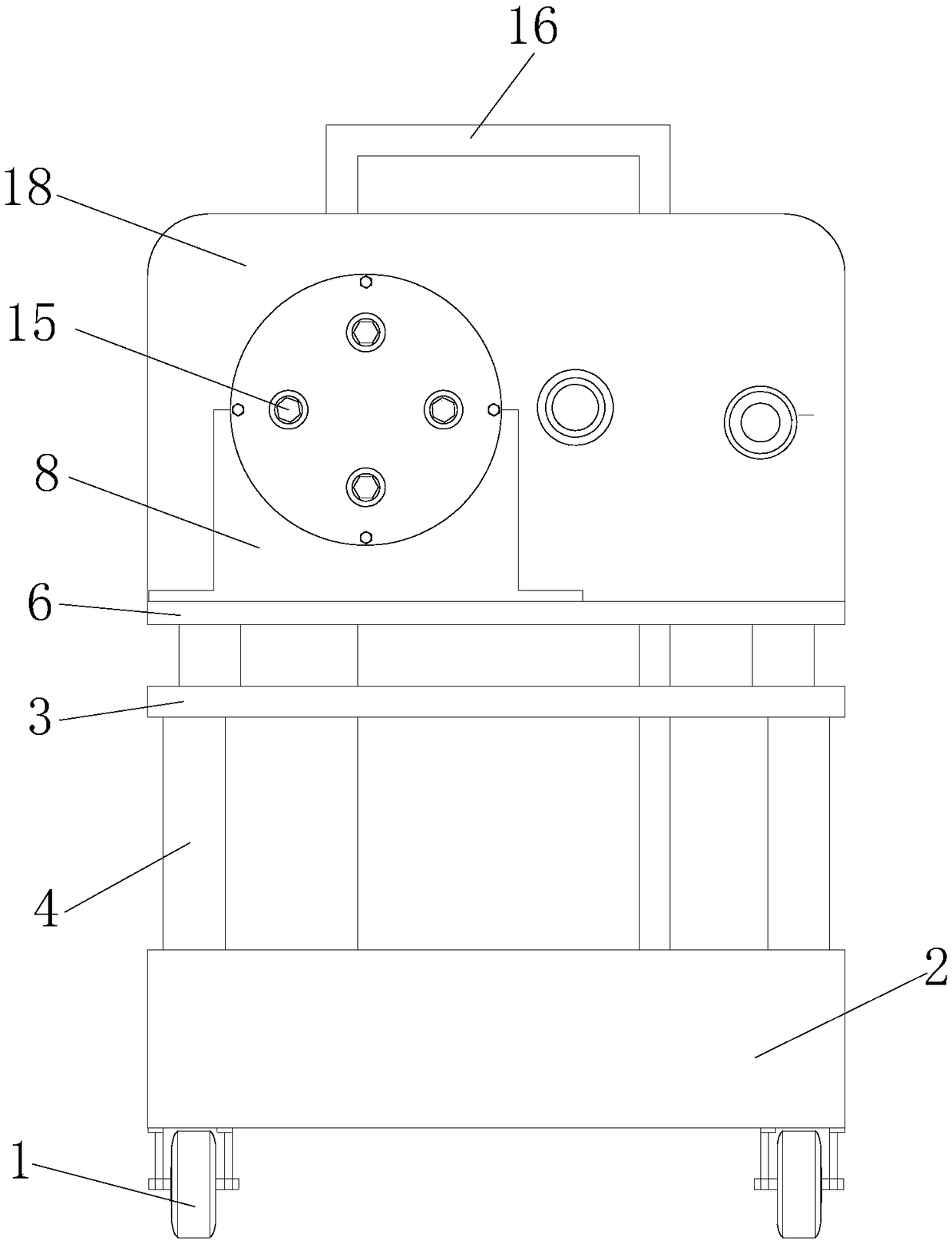

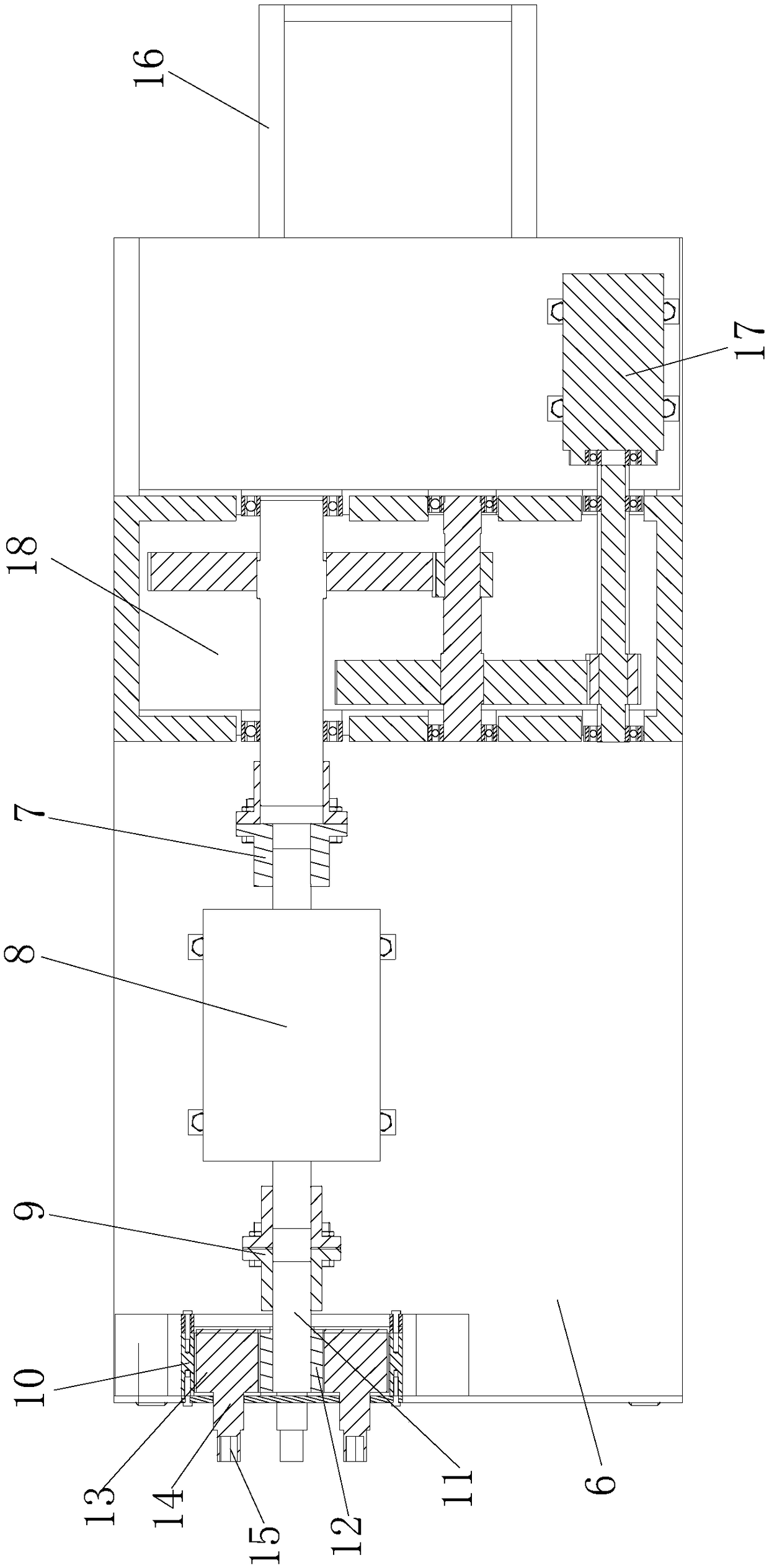

Hydraulic rotary power device

ActiveCN102645381ARun smoothlyAchieve preloadMaterial strength using steady torsional forcesTorque sensorLow speed

The invention relates to a hydraulic rotary power device and belongs to the technical field of anchor rod detection torque loading devices. The invention aims to provide the hydraulic rotary power device which is stable, safe and reliable in running and can output the double power. The technical scheme provided by the hydraulic rotary power device is that a first machine head bracket and a second machine head bracket are arranged above the two ends of a first machine head bottom plate; a first hollow high-speed shaft of a high-speed motor is sleeved on the first machine head bracket and the second machine head bracket; the high-speed motor is fixed on the first machine head bracket; a first torque sensor is sleeved on the first hollow high-speed shaft; a low-speed motor is sleeved on the first hollow high-speed shaft through a first low-speed shaft; the first torque sensor and the low-speed motor are positioned between the first machine head bracket and the second machine head bracket; the first torque sensor is fixed on the first machine head bracket; and one end of the low-speed motor is connected with and fixed with the first torque sensor through a third flange. The hydraulic rotary power device is mainly used for detecting the uploading of rotating power of an anchor rod.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com