Bearing preloading device for electric motor

A motor and motor shaft technology, applied in the directions of electromechanical devices, electric components, casings/covers/supports, etc., can solve the problems of inability to meet the requirements of use, and achieve the effect of simple structure, few parts and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

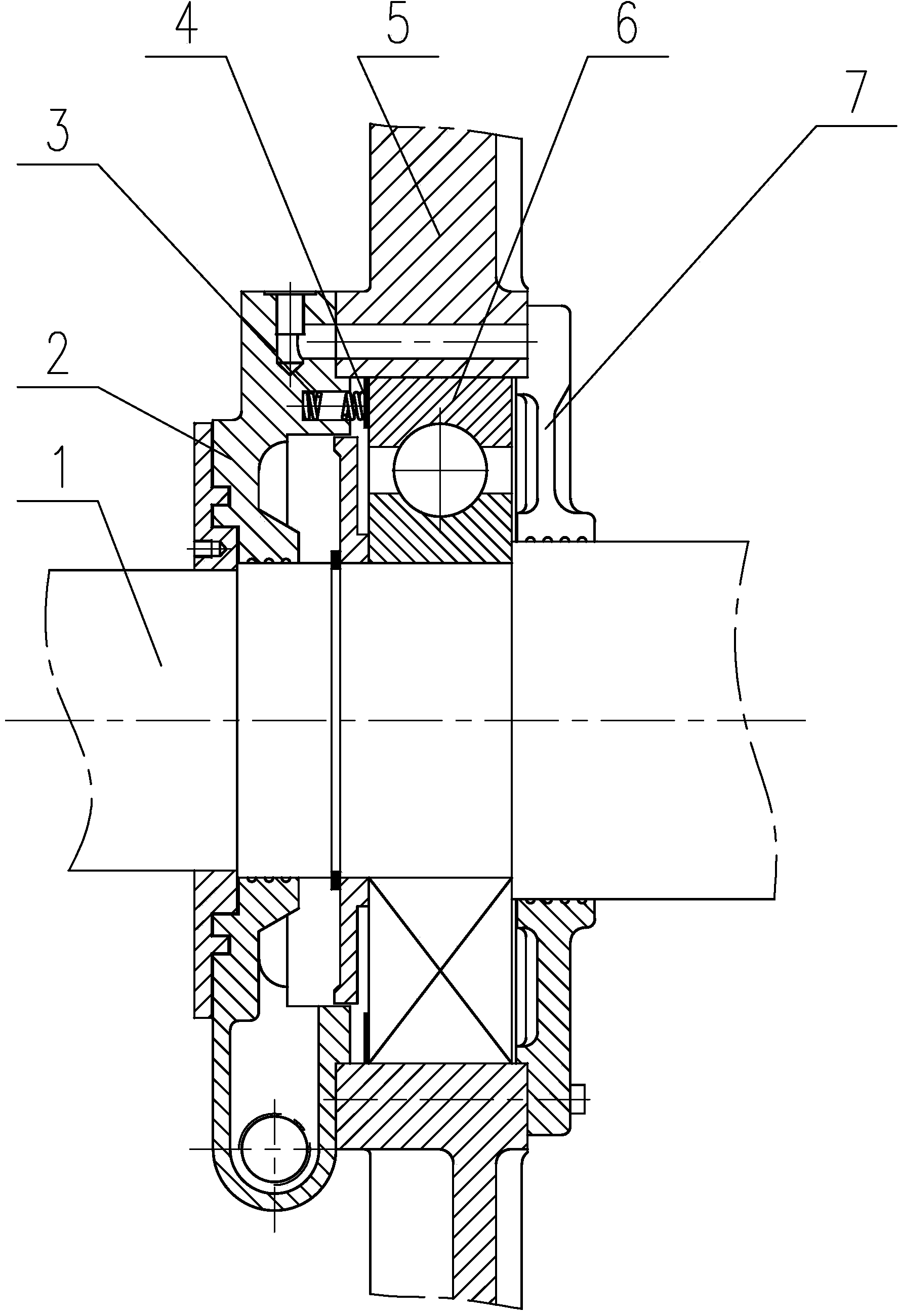

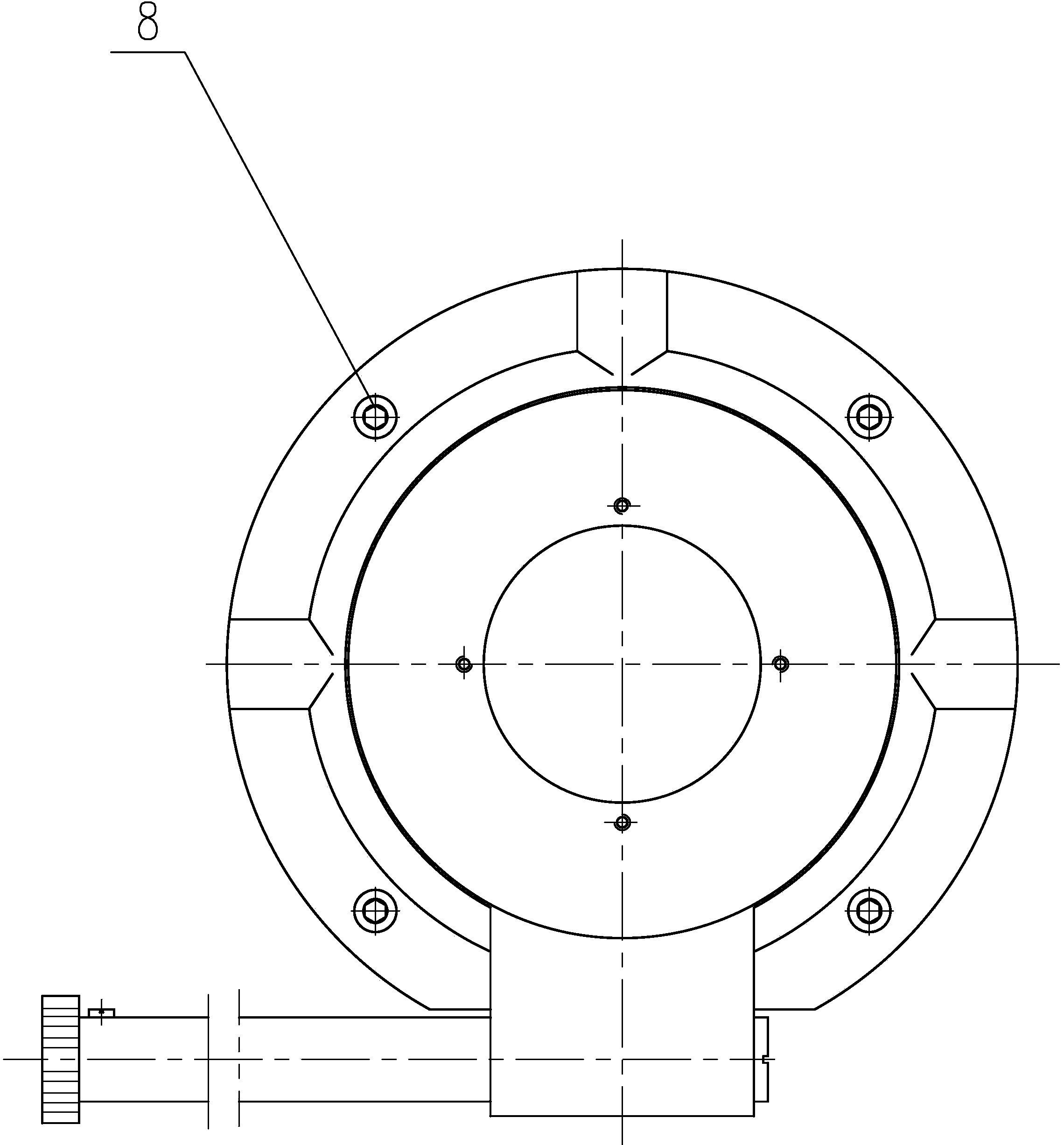

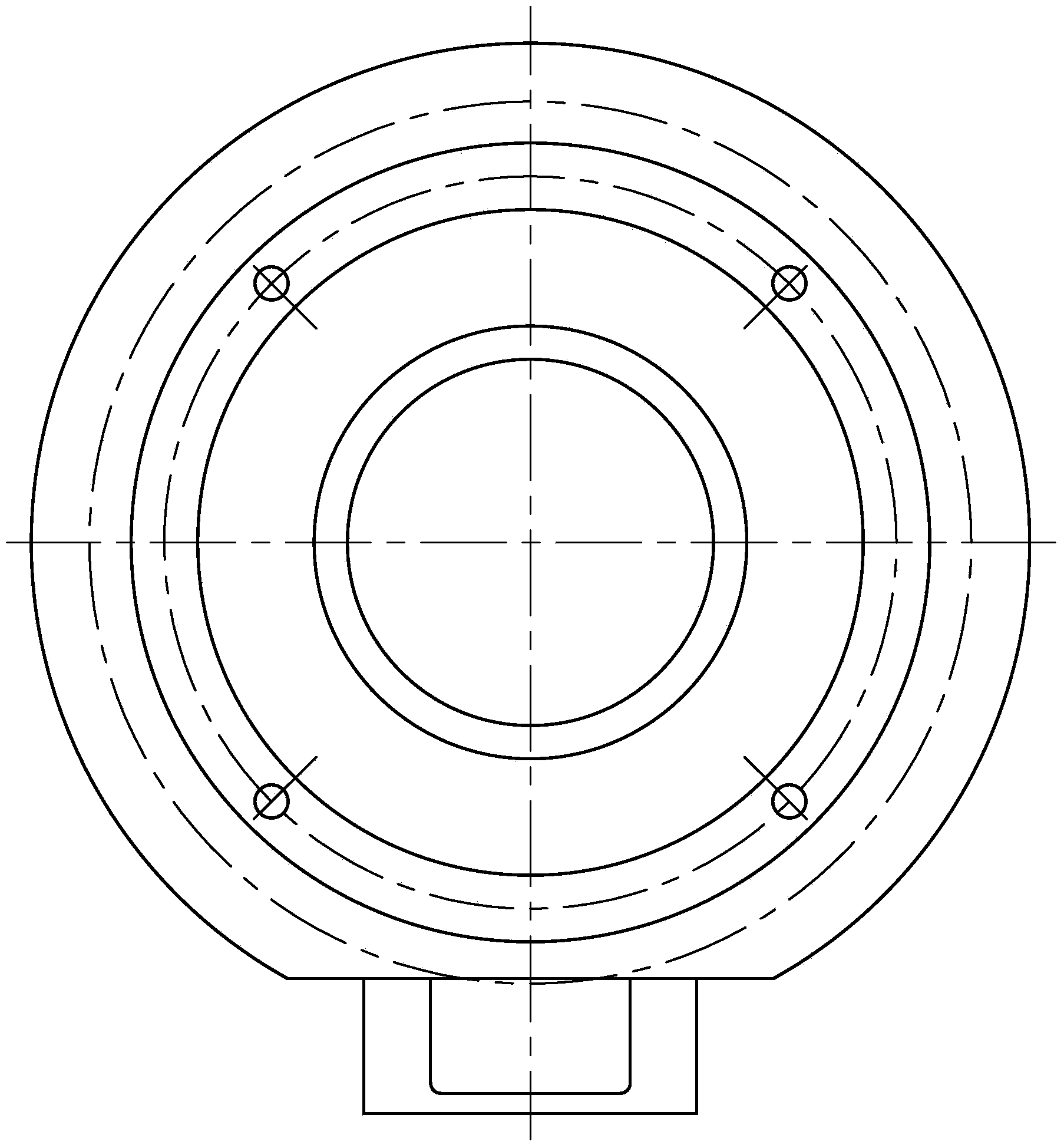

[0012] Below in conjunction with specific accompanying drawing and embodiment the present invention will be further described:

[0013] like Figure 1-Figure 3 As shown, the present invention includes a motor shaft 1, a bearing outer cover 2, a bearing spring 3, a bearing gasket 4 for preloading, an end cover 5, a bearing 6, an inner bearing cover 7, and hexagonal bolts for connecting the outer bearing cover and the inner cover 8.

[0014] The material of the bearing spacer 4 for preloading in the present invention is a steel plate, the outer diameter is the same as that of the bearing outer ring, and the inner diameter is larger than that of the bearing inner ring.

[0015] The outer bearing cover 2 of the present invention is uniformly provided with four circular holes for installing bearing springs.

[0016] In the present invention, the bearing inner cover 7 is installed on the motor shaft 1 first, and then the bearing 6 is fixed on the corresponding position of the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com