Hydraulic rotary power device

A technology of power plant and hydraulic rotation, which is applied in the direction of applying stable torsion to test the strength of materials, can solve the problem of not meeting the testing requirements of the comprehensive mechanical properties of the bolt, and achieve the effect of stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

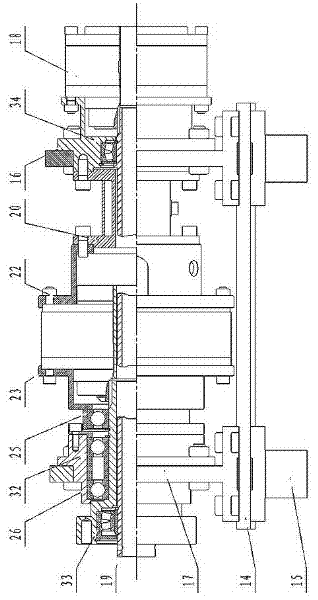

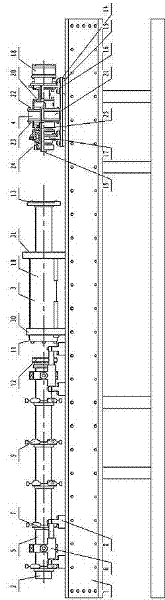

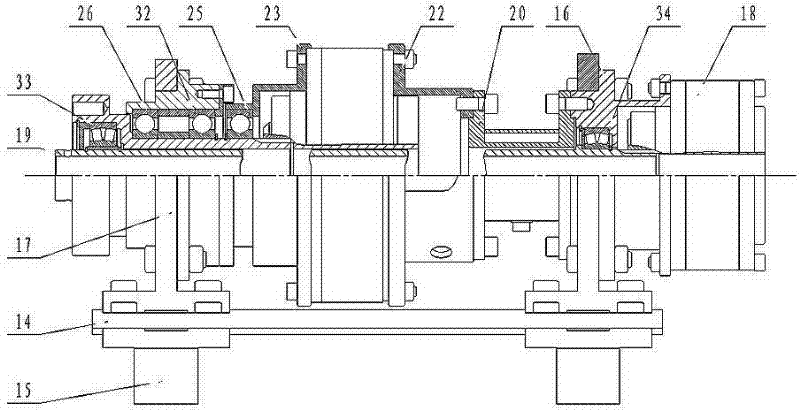

[0011] like figure 1 As shown, the hydraulic rotary power unit includes: a first machine head base plate 14, a first machine head support 16, a second machine head support 17, a high-speed motor 18, a first torque sensor 20 and a low-speed motor 21, the first machine head The bottom of the head base plate 14 is provided with the first slide rail 15, the two ends of the first base plate 14 are provided with the first head support 16 and the second head frame 17, the first head support 16 The first hollow high-speed shaft 19 of the high-speed motor 18 is set on the second head support 17, the high-speed motor 18 is fixed on the first head support 16, and the first torque sensor 20 is set on the first hollow high-speed shaft 19, the low-speed motor 21 is sleeved on the first hollow high-speed shaft 19 through the first low-speed shaft 24, and the first torque sensor 20 and the low-speed motor 21 are located between the first head support 16 and the second head support 17 During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com