Online adjustable exciting vibration equipment

An adjustment type, vibration excitation technology, applied in the direction of fluid using vibration, can solve the problems of complex excitation force adjustment, inability to adjust, affecting work efficiency, etc., to achieve low noise, good sealing, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

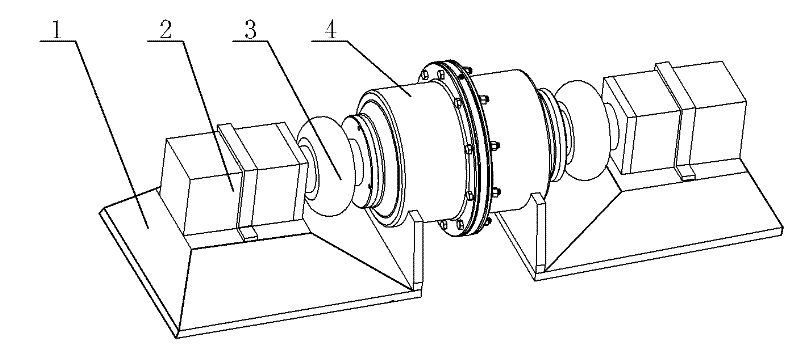

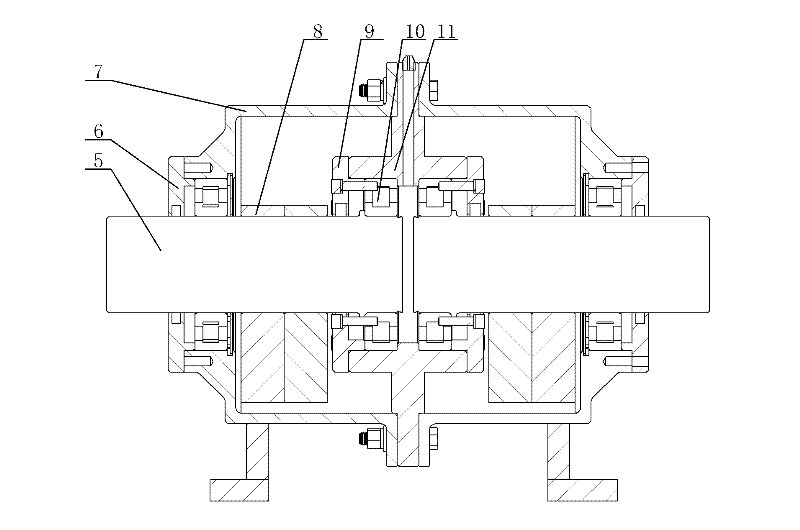

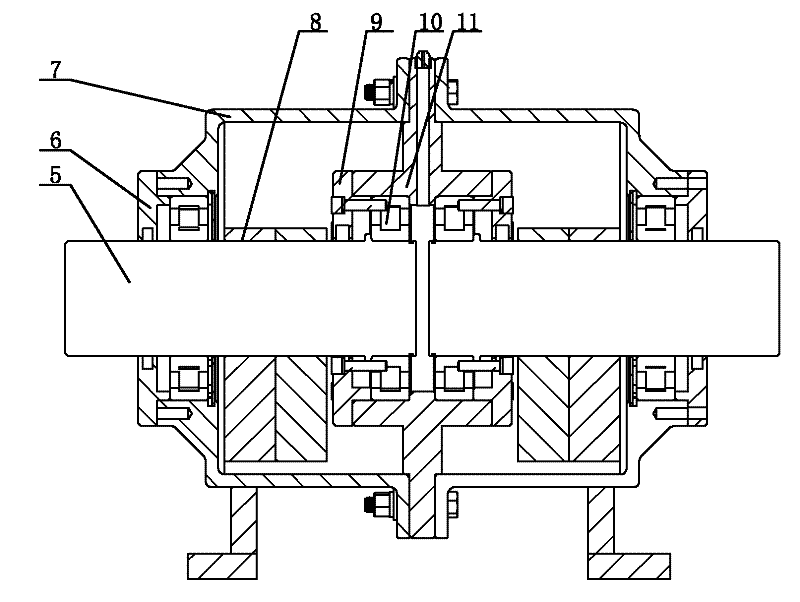

[0014] Such as figure 1 , 2 As shown, the online adjustable vibration excitation equipment includes an installation platform 1, a vibration exciter 4 and a servo motor 2 controlled by a PLC control system. The specific structure of the vibration exciter 4 includes a short shaft 5, an end cover 6, and a casing 7 , eccentric block 8, gland 9, bearing 10 and bearing seat 11, the shell of the exciter 4 is formed by connecting two left and right symmetrical casings 7, the bearing seat 11 is assembled in the inner hole of the casing 7 and the casing 7 and the bearing seat 11 are positioned by a notch, and the bearing seat 11 is provided with a lubricating device. The two short shafts 5 provided in the vibrator 4 are left and right symmetrical and coaxial, and the eccentric block 8 is fixed on the short shaft 5, and the two short shafts 5 are respectively connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com