Patents

Literature

61results about How to "Accurate and reliable adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blood treatment apparatus

ActiveUS8449487B2Economical and efficientEfficient and effectiveDialysis systemsMedical devicesBlood treatmentsProduct gas

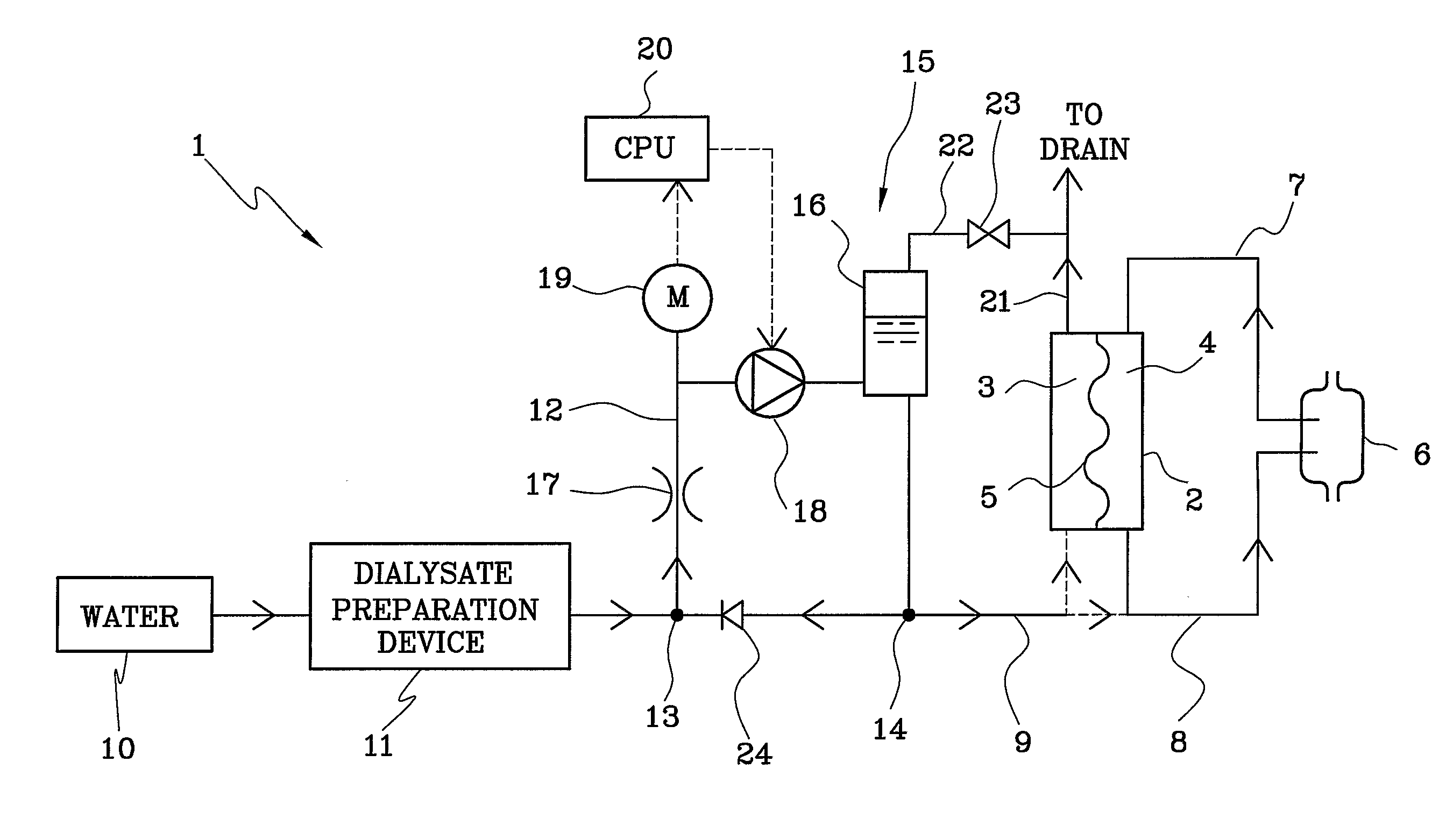

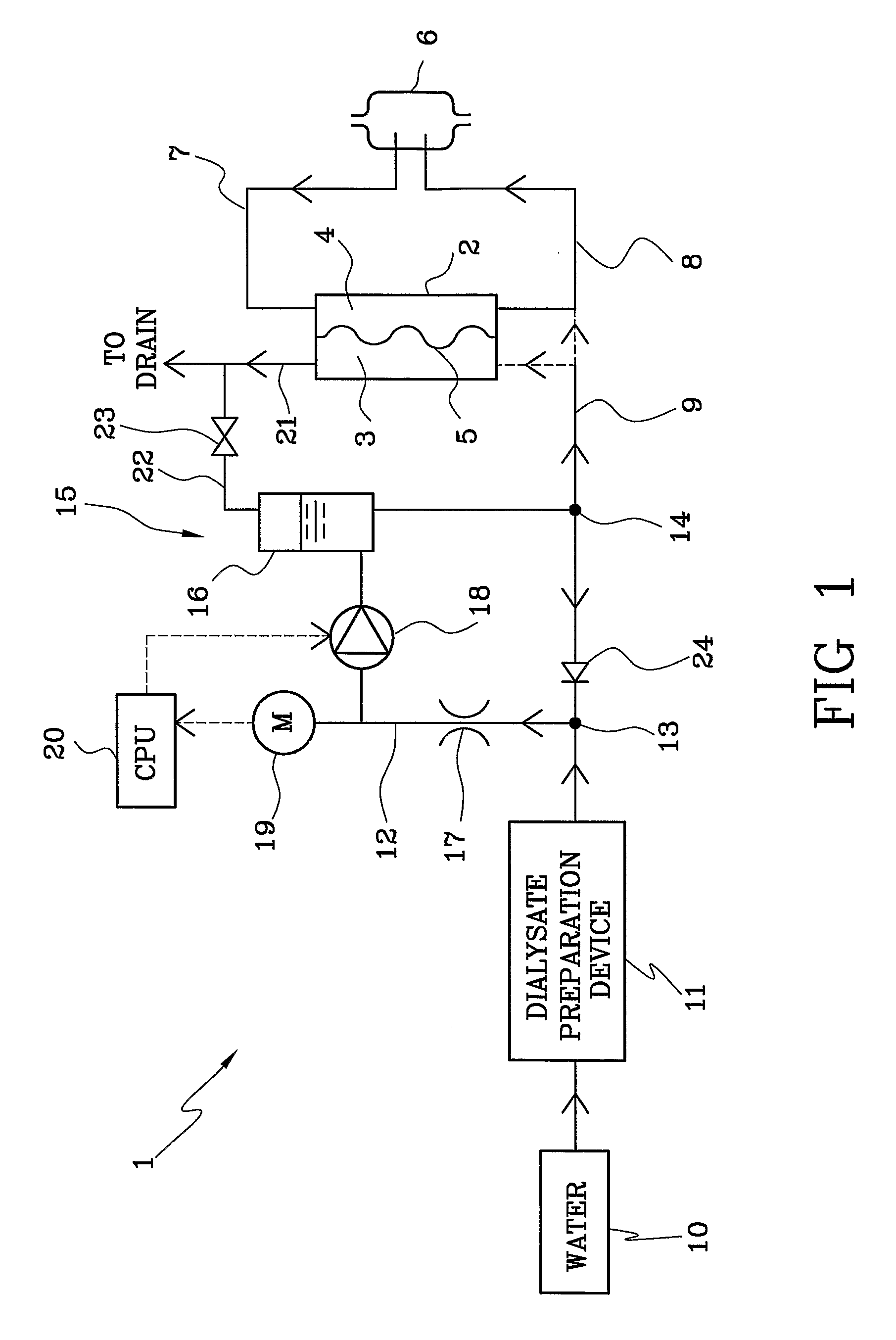

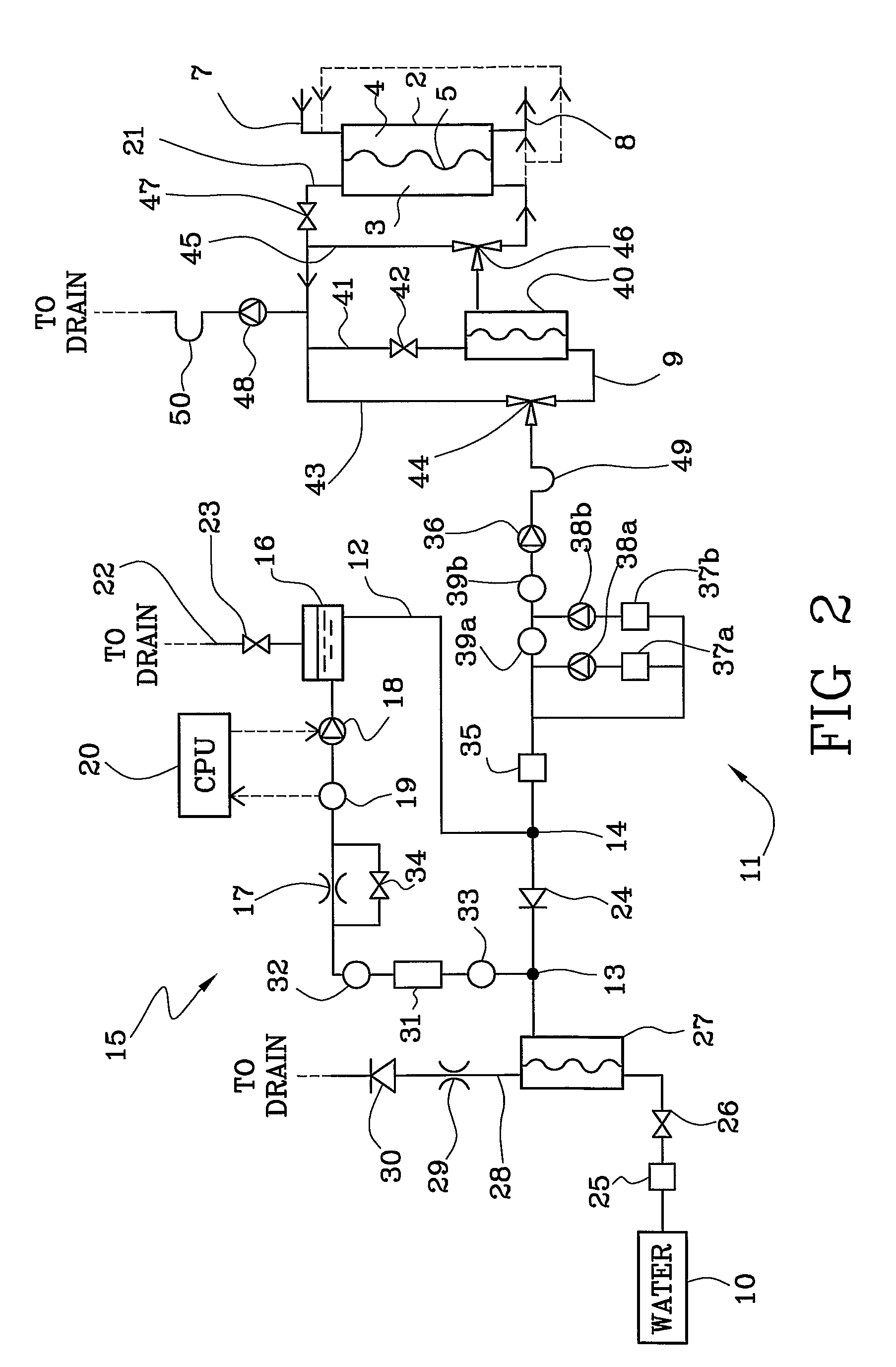

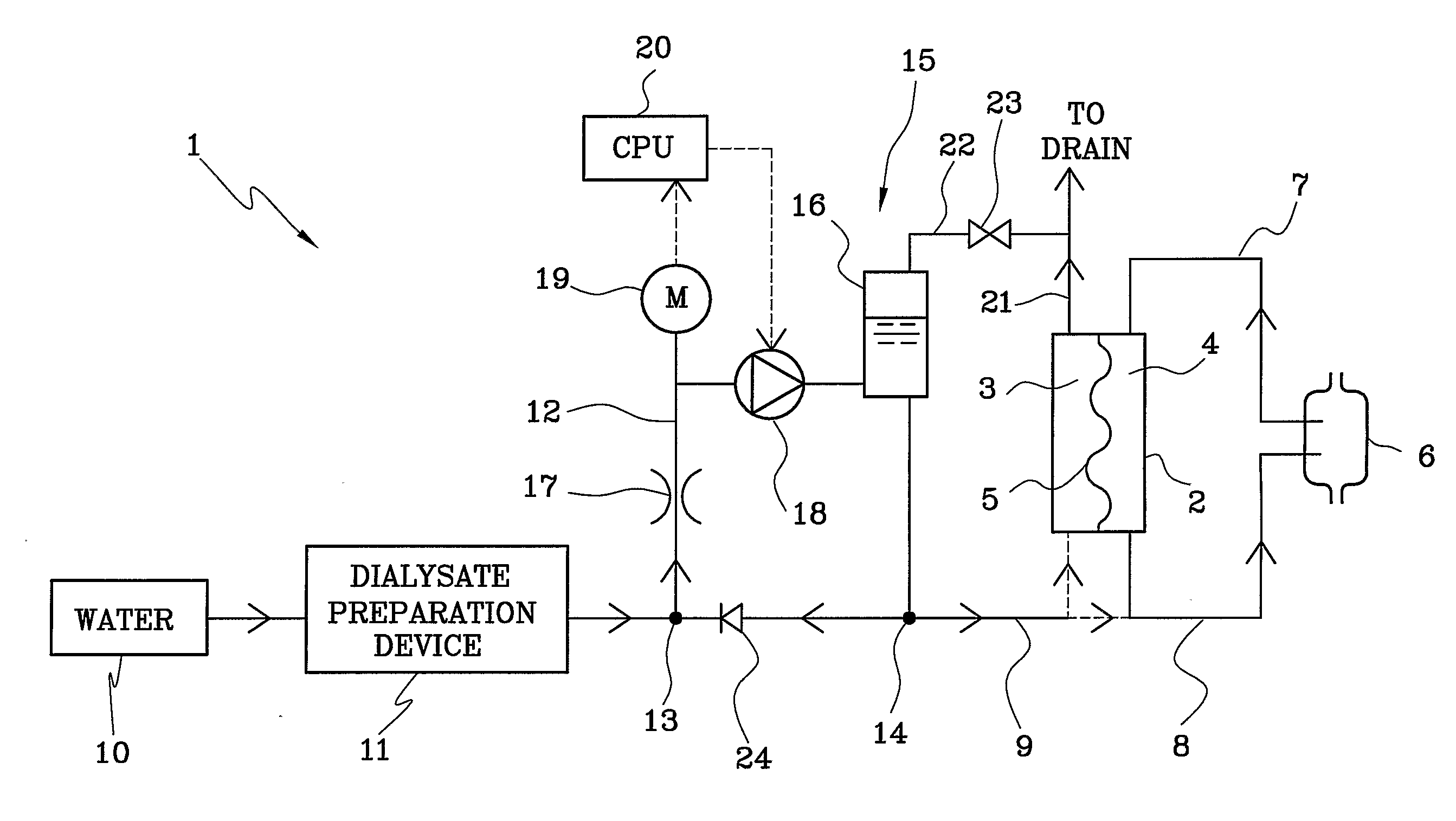

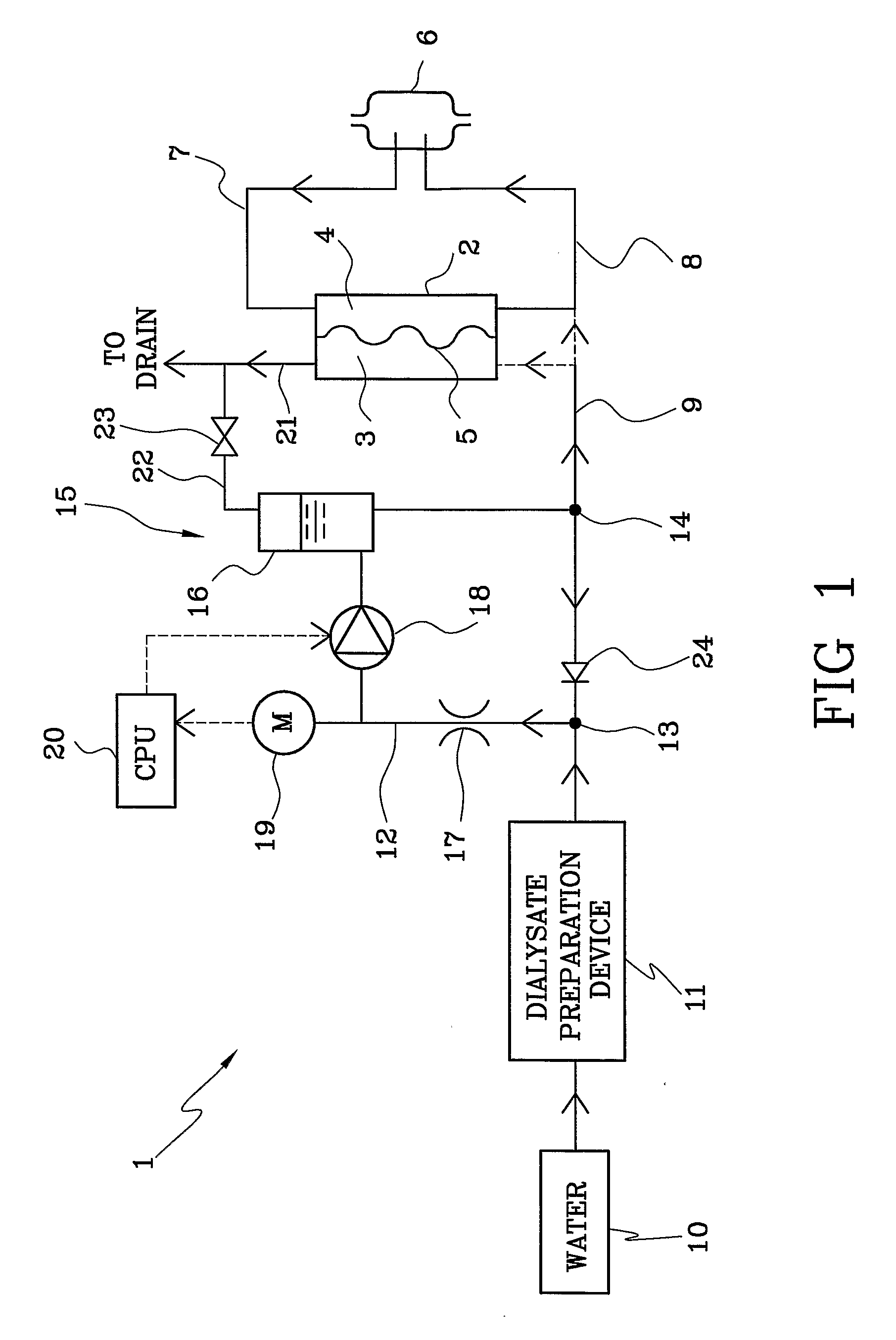

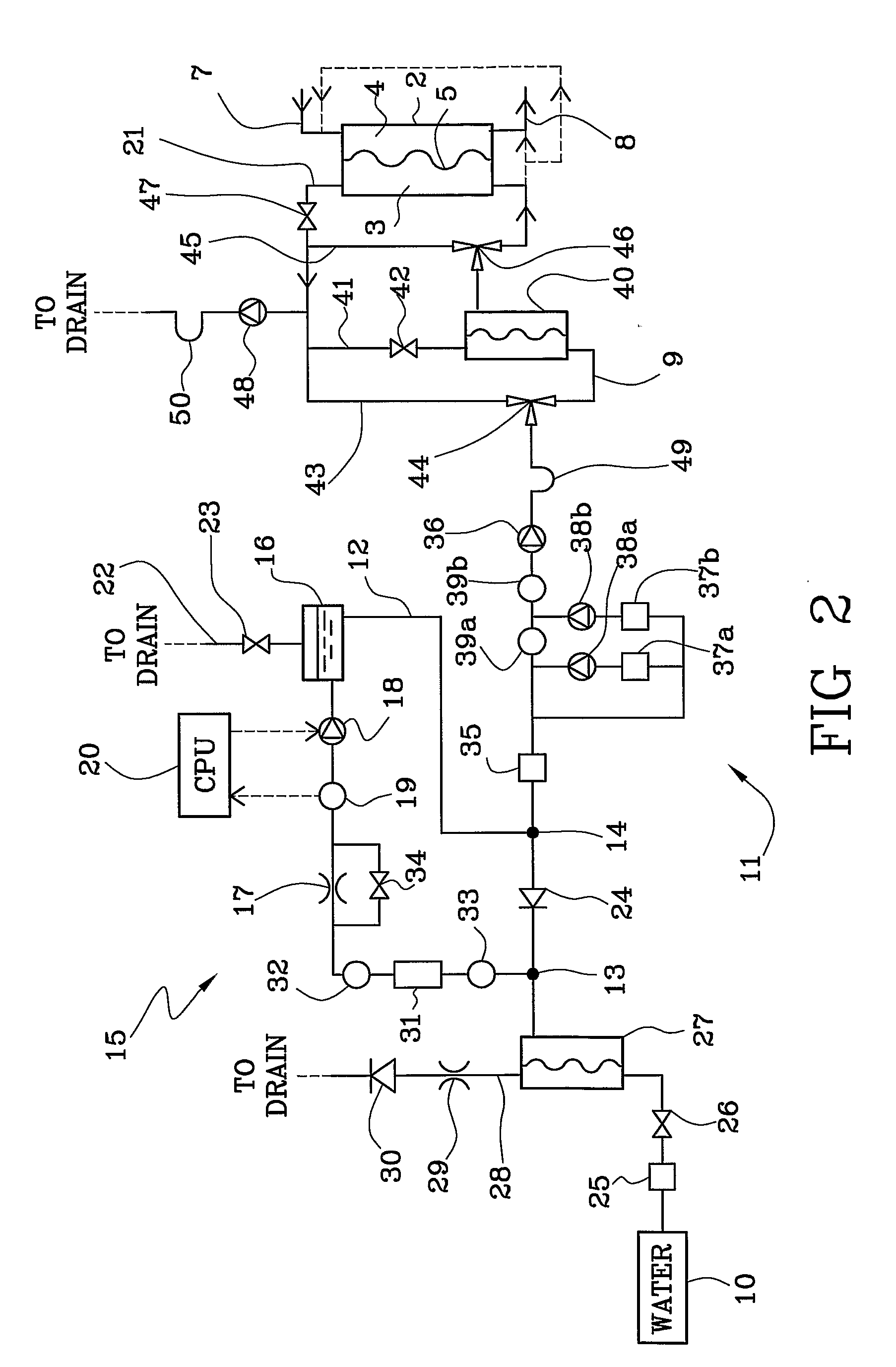

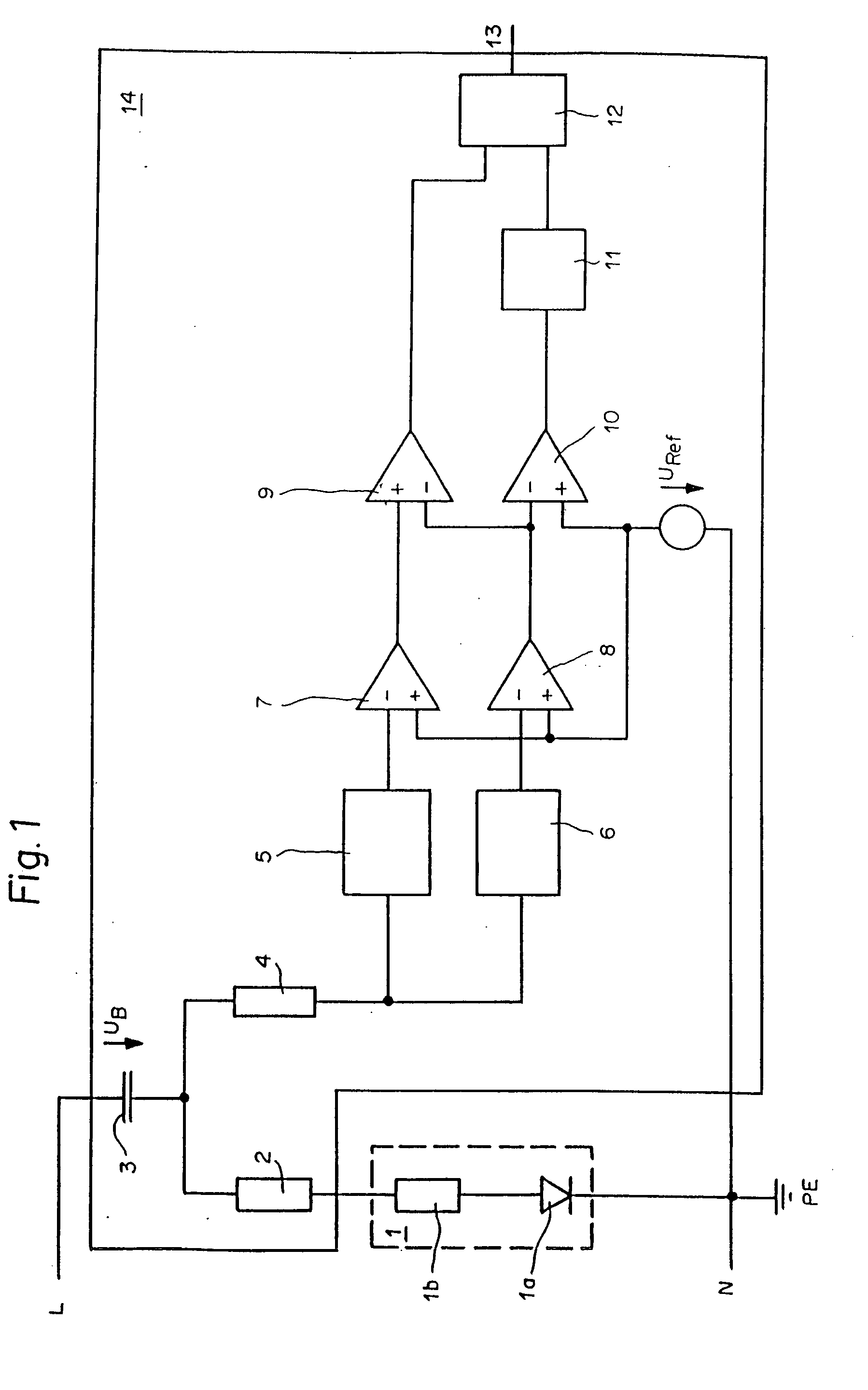

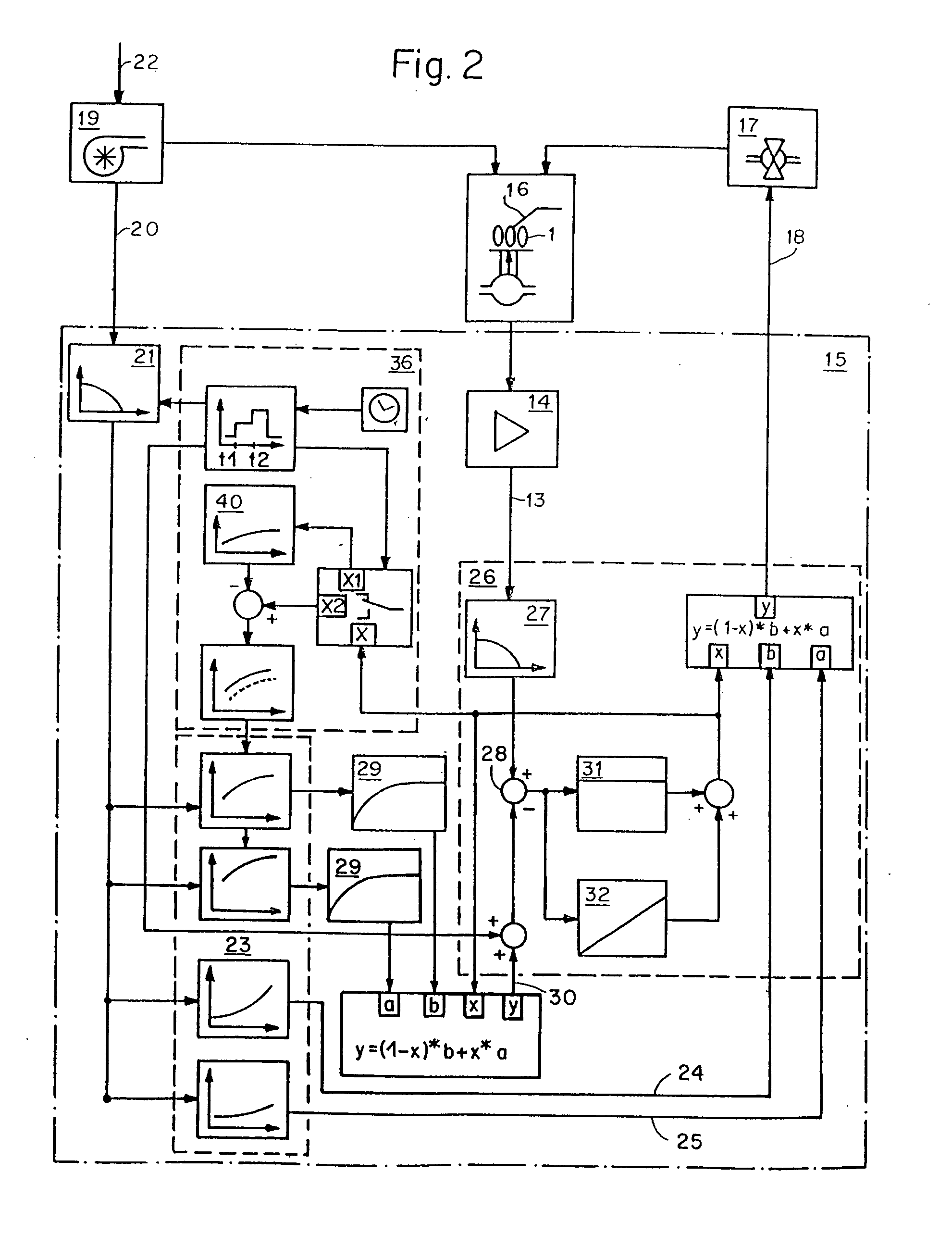

A blood treatment apparatus (1) comprising a degassing unit (15) receiving gas-containing fluid and supplying degassed fluid to a fluid chamber (3) of a blood treatment unit (2). The degassing unit has a gas separator (16), a degassing pump (18) to circulate fluid in a degassing line (12), a flow restrictor (17) for reducing the pressure in the degassing line (12), an absolute pressure sensor (19), and a control unit (20) designed to control the speed of said degassing pump from the absolute pressure signal emitted by the pressure sensor. The apparatus comprises a dialysis machine provided with a device for preparing on-line a dialysis liquid from water and concentrates. The apparatus achieves an accurate and reliable regulation of a desired concentration of gas in the dialysis liquid.

Owner:GAMBRO LUNDIA AB

Blood treatment apparatus

ActiveUS20100106071A1Economical and efficientEfficient and effectiveDialysis systemsMedical devicesBlood treatmentsProduct gas

A blood treatment apparatus (1) comprising a degassing unit (15) receiving gas-containing fluid and supplying degassed fluid to a fluid chamber (3) of a blood treatment unit (2). The degassing unit has a gas separator (16), a degassing pump (18) to circulate fluid in a degassing line (12), a flow restrictor (17) for reducing the pressure in the degassing line (12), an absolute pressure sensor (19), and a control unit (20) designed to control the speed of said degassing pump from the absolute pressure signal emitted by the pressure sensor. The apparatus comprises a dialysis machine provided with a device for preparing on-line a dialysis liquid from water and concentrates. The apparatus achieves an accurate and reliable regulation of a desired concentration of gas in the dialysis liquid.

Owner:GAMBRO LUNDIA AB

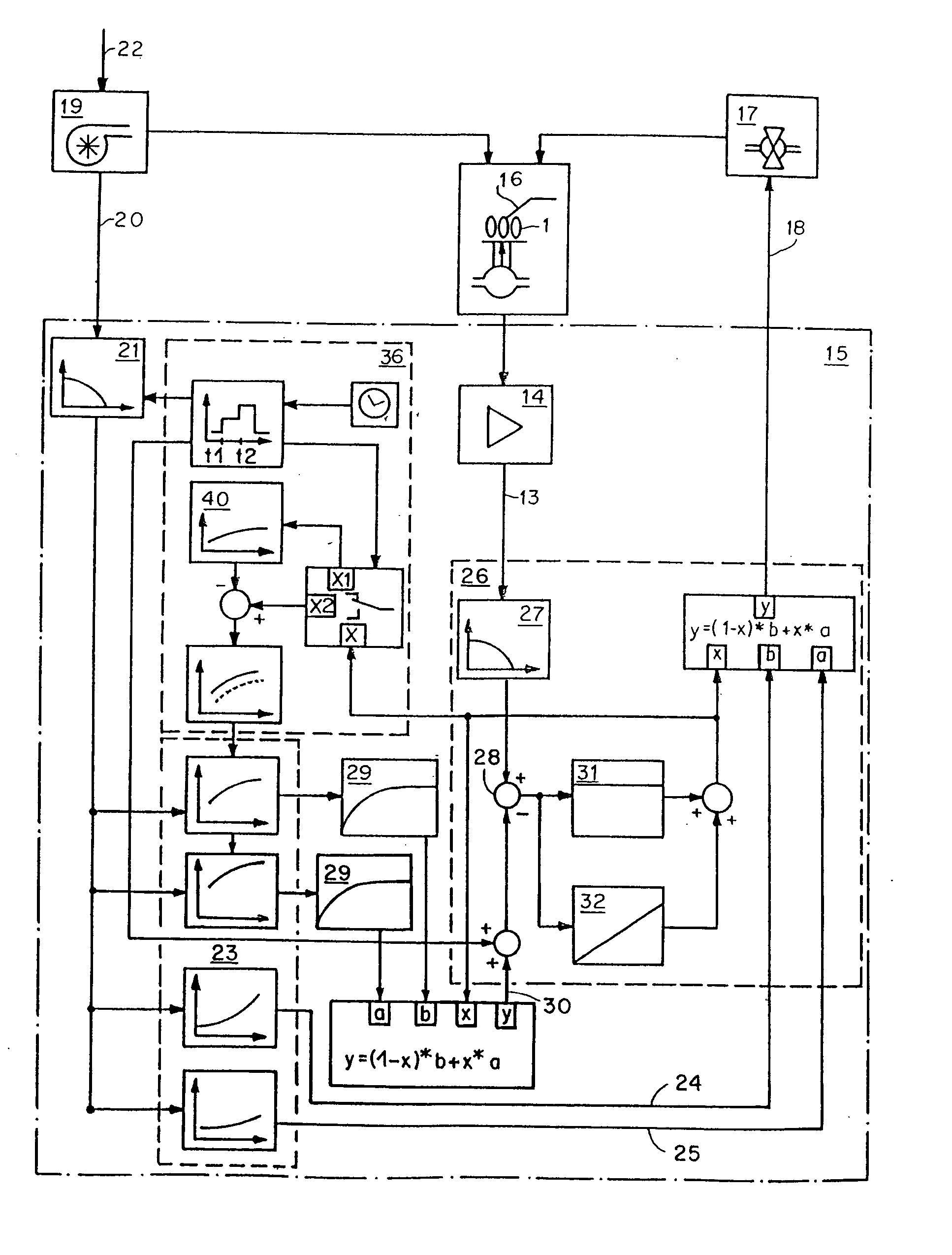

Burner controller and adjusting method for a burner controller

InactiveUS20050250061A1Accurate and reliable adjustmentFuel supply regulationCombustorControl theory

A burner controller (15) regulates the air index, with a combustion sensor. In accordance with the invention the reference value of the sensor signal is determined not only with the current burner power output but also on the basis of a measure for the current fuel energy content.

Owner:SIEMENS BUILDING TECHNOLOGIES

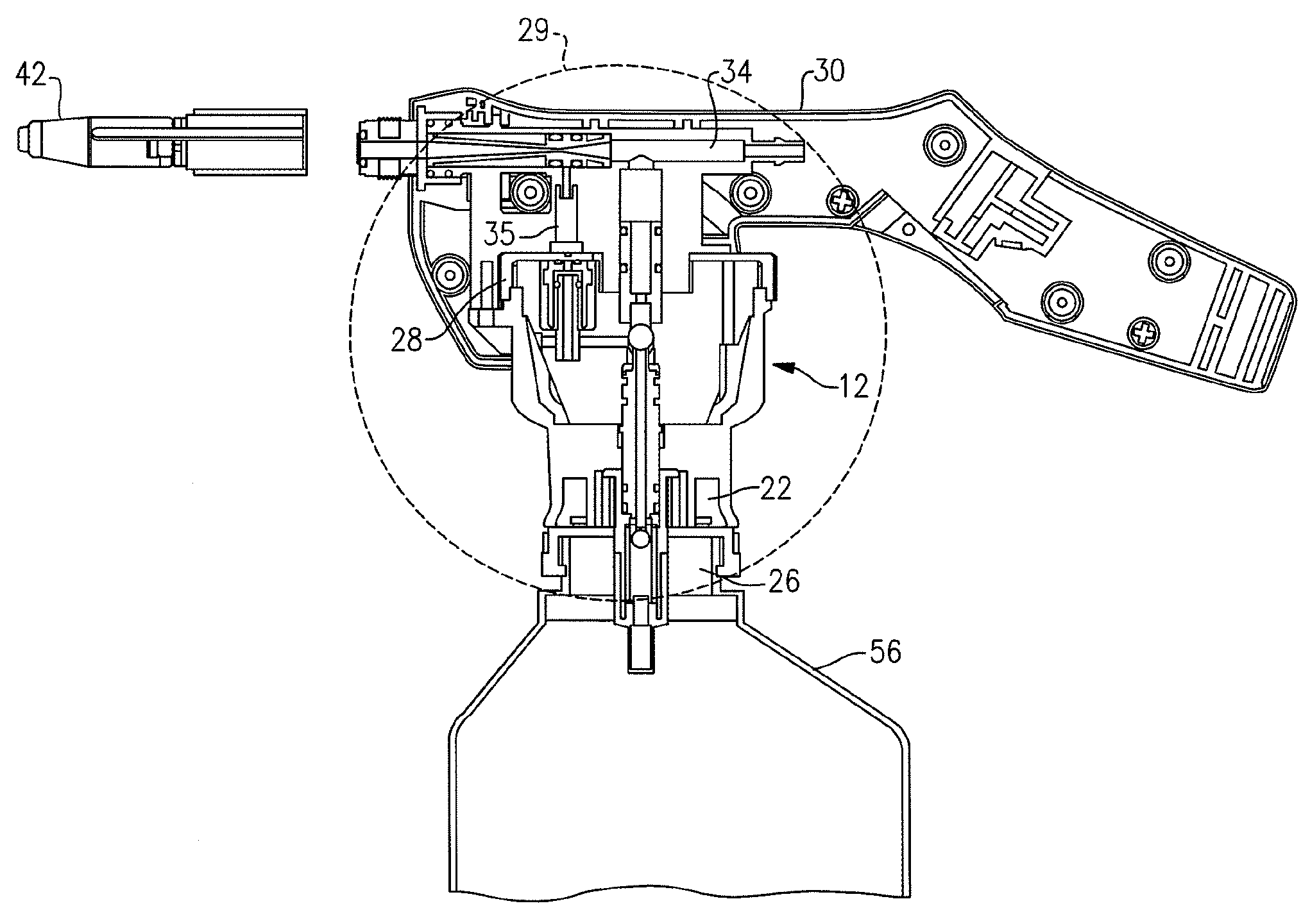

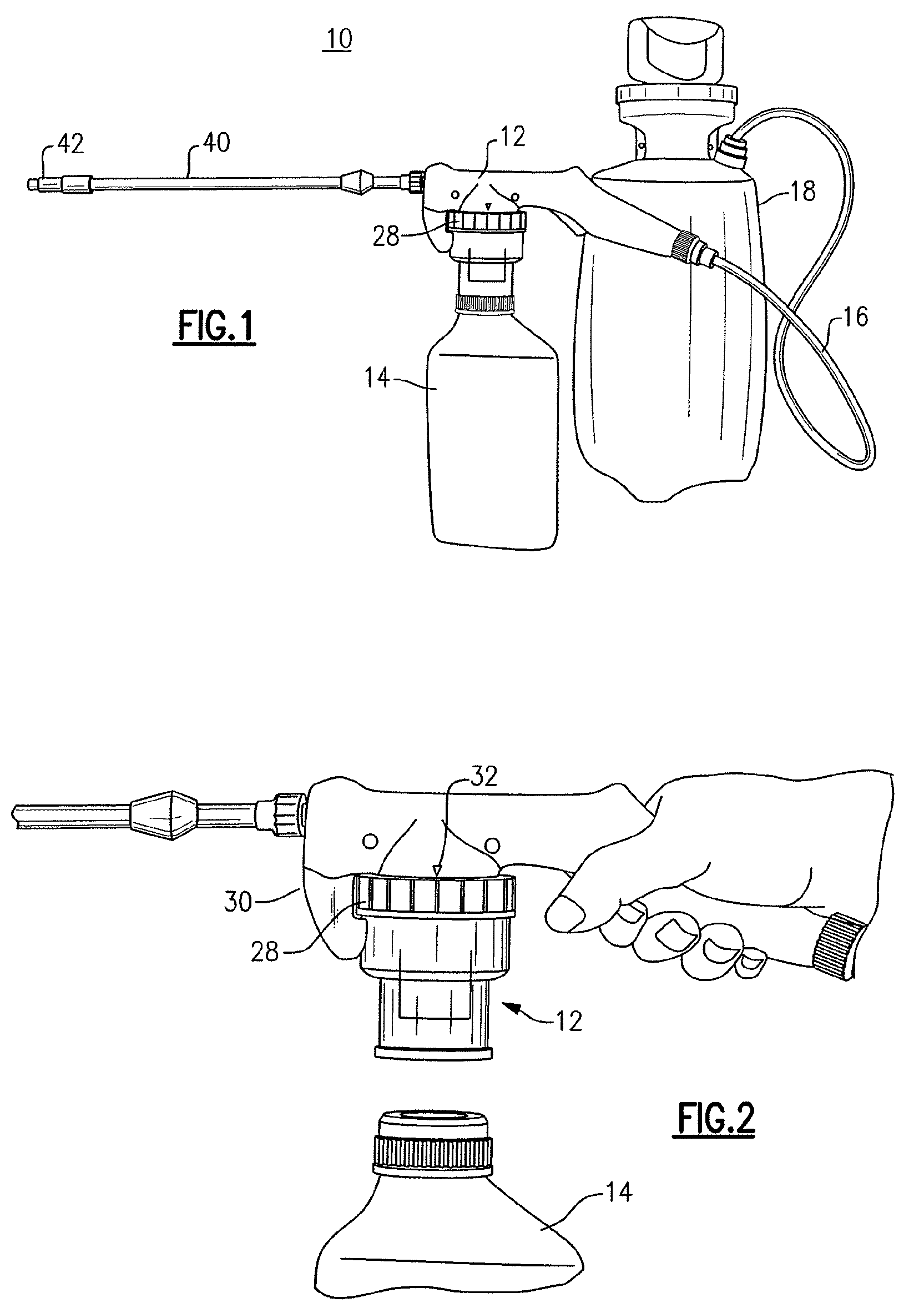

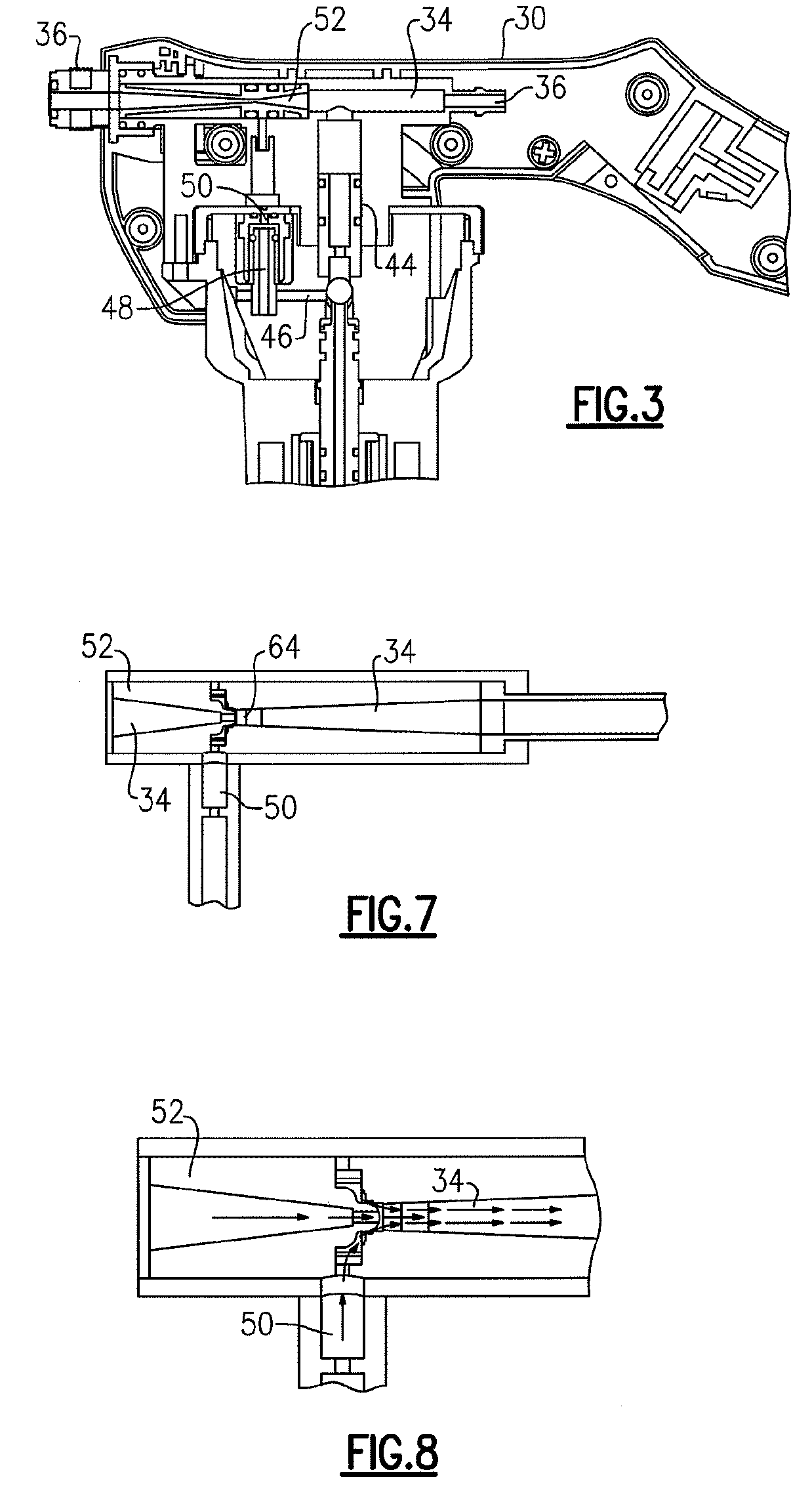

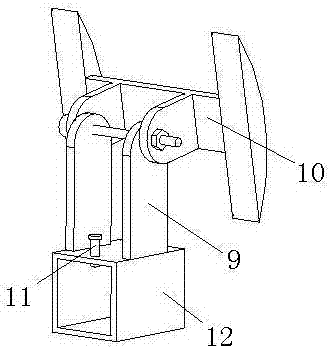

Sprayer

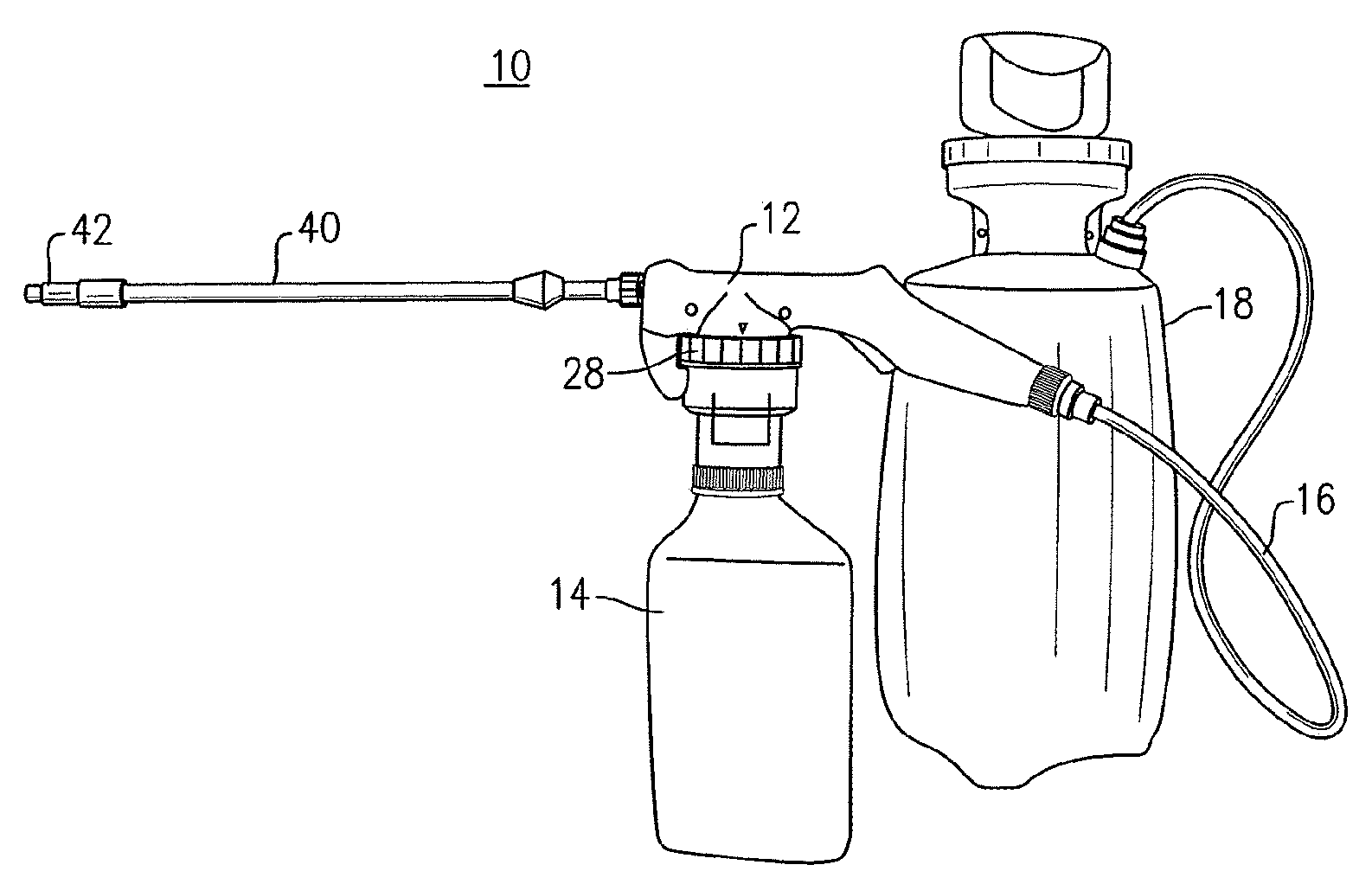

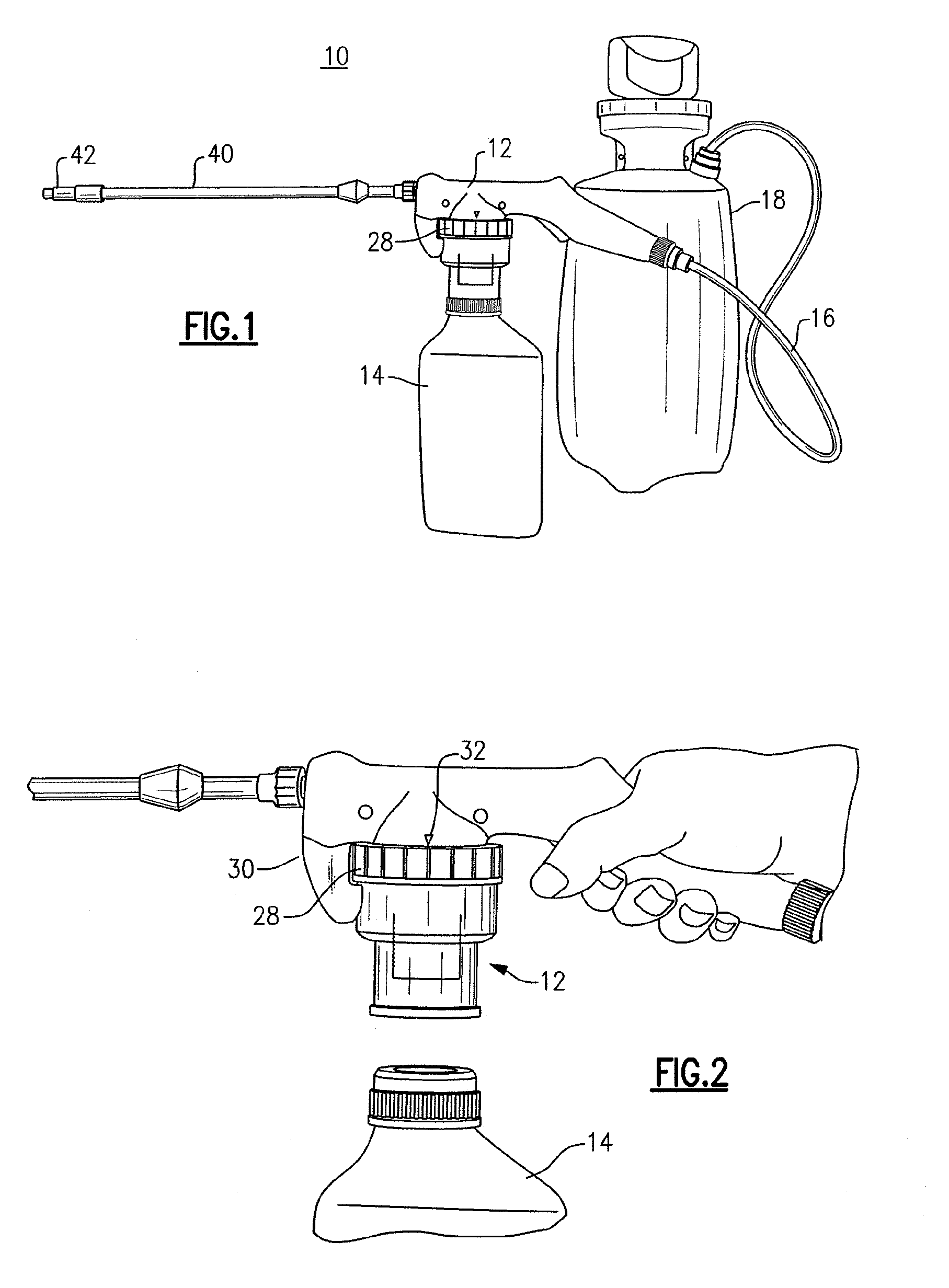

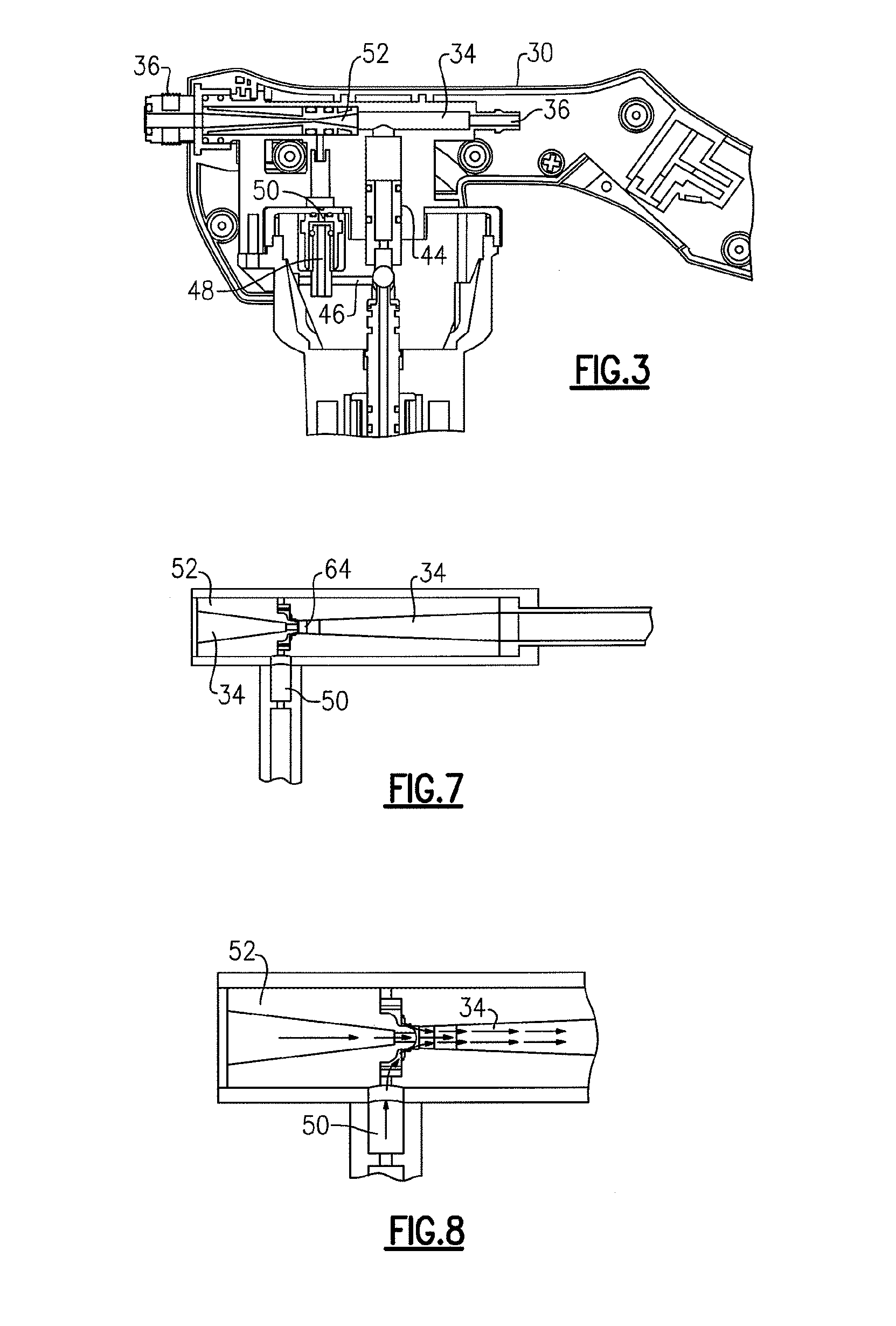

ActiveUS20100059605A1Accurate and reliable adjustmentConsistent flowFlow mixersTransportation and packagingSprayerEngineering

A sprayer system having a sprayer assembly adaptable to a variety of sizes and shapes of containers. The sprayer assembly includes a dual venturi in the flow conduit to provide even pressure and consistent flow in the spray volume. A metering device is coupled to the flow conduit for accurate and reliable regulation of mixture ratios. A dip tube, coupled to the fluid conduit, is adaptable to a variety of container orifices. In addition to acting as a conduit for passage of concentrate into the sprayer assembly, the dip tube may also be used as a cutting device to open the container into which it will be inserted. By adapting to a variety of container orifices, the dip tube allows the sprayer assembly to fit to a variety of containers.

Owner:THE FOUNTAIN HEAD GROUP INC

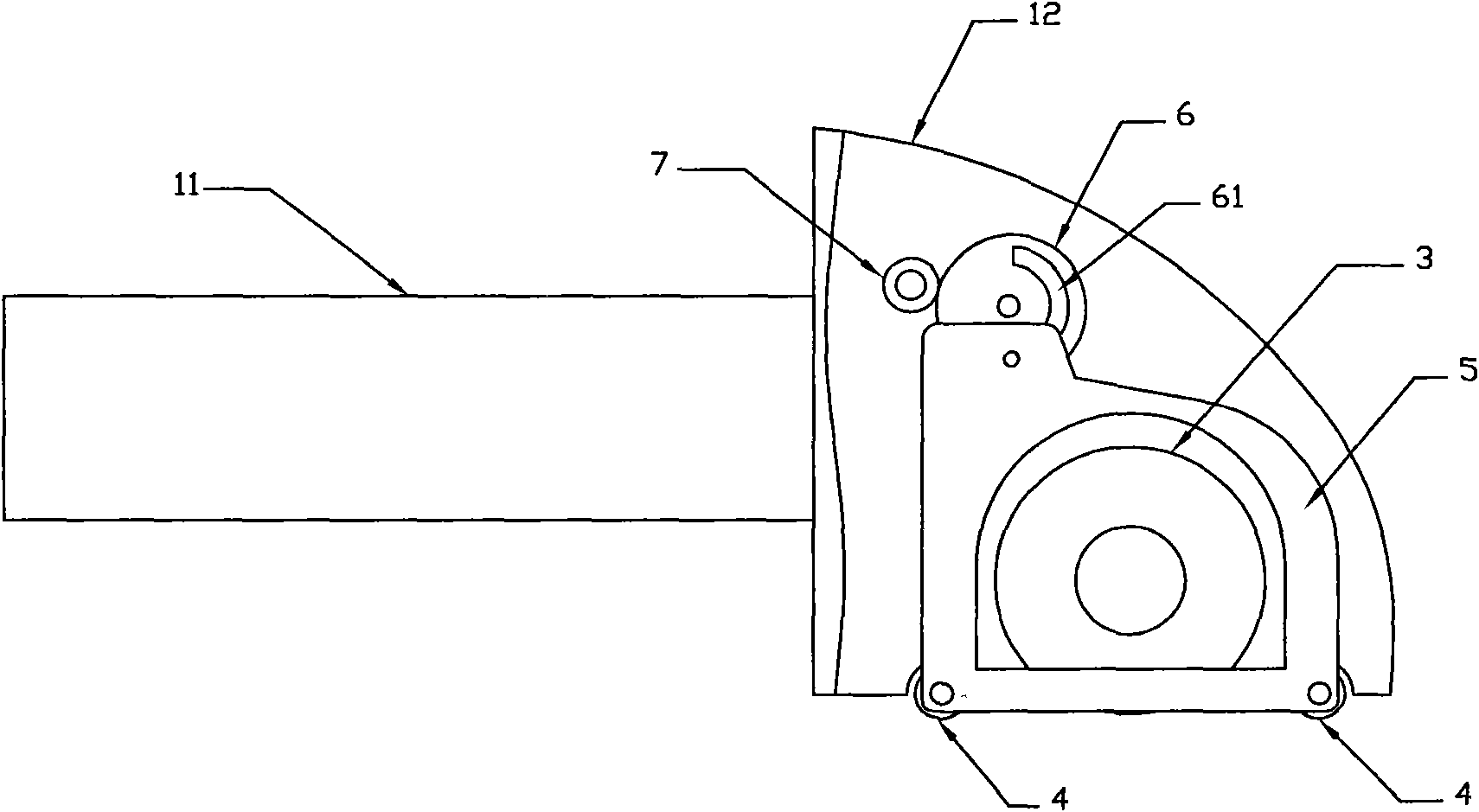

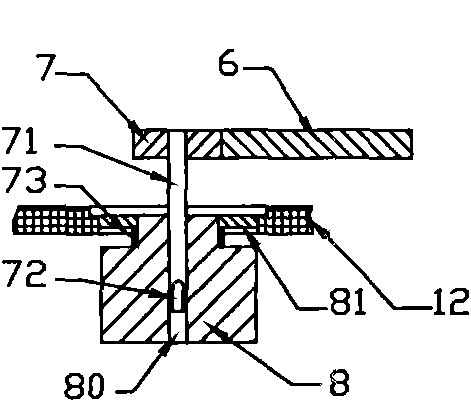

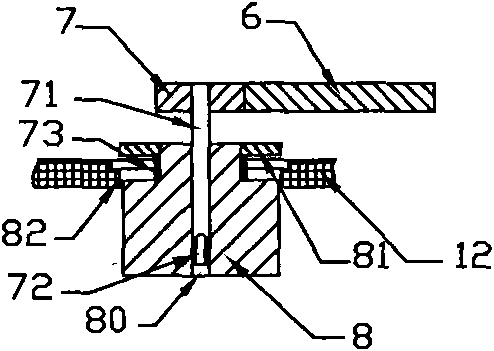

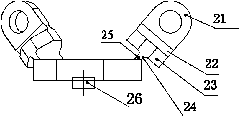

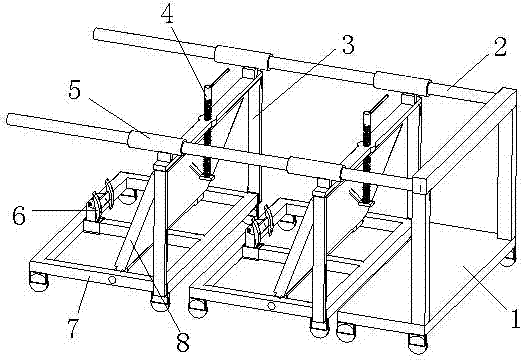

Scab grinding machine

The invention relates to a scab grinding machine, which comprises a handle and a shell fixedly connected with the handle, wherein a shell opening is arranged at the lower end of the shell, and a motor and a rotary cutter connected with the motor are arranged in the motor; and the rotary cutter grinds outwards through the shell opening. The scab grinding machine also comprises an adjusting support, wherein the adjusting support comprises rotary rollers arranged at the two sides of the shell opening at the lower end of the shell, and an adjusting mechanism capable of adjusting the rotary rollers to move up and down. When adjusting, the adjusting mechanism moves up and down instead of opening or closing the rotary rollers to move back and forth; and the scab grinding machine has accurate adjustment, reliable locking after adjusting and easy operation.

Owner:周洪春 +1

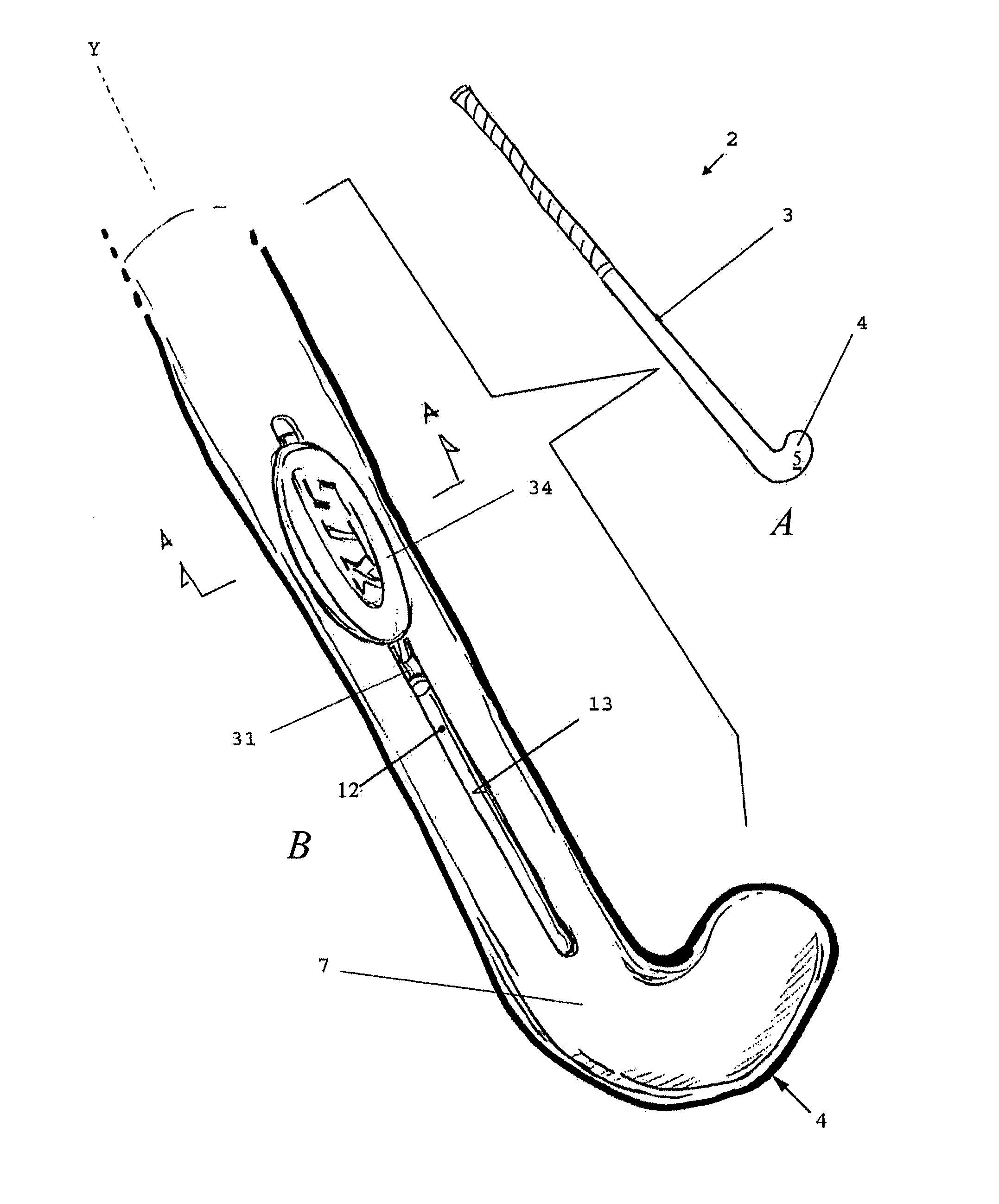

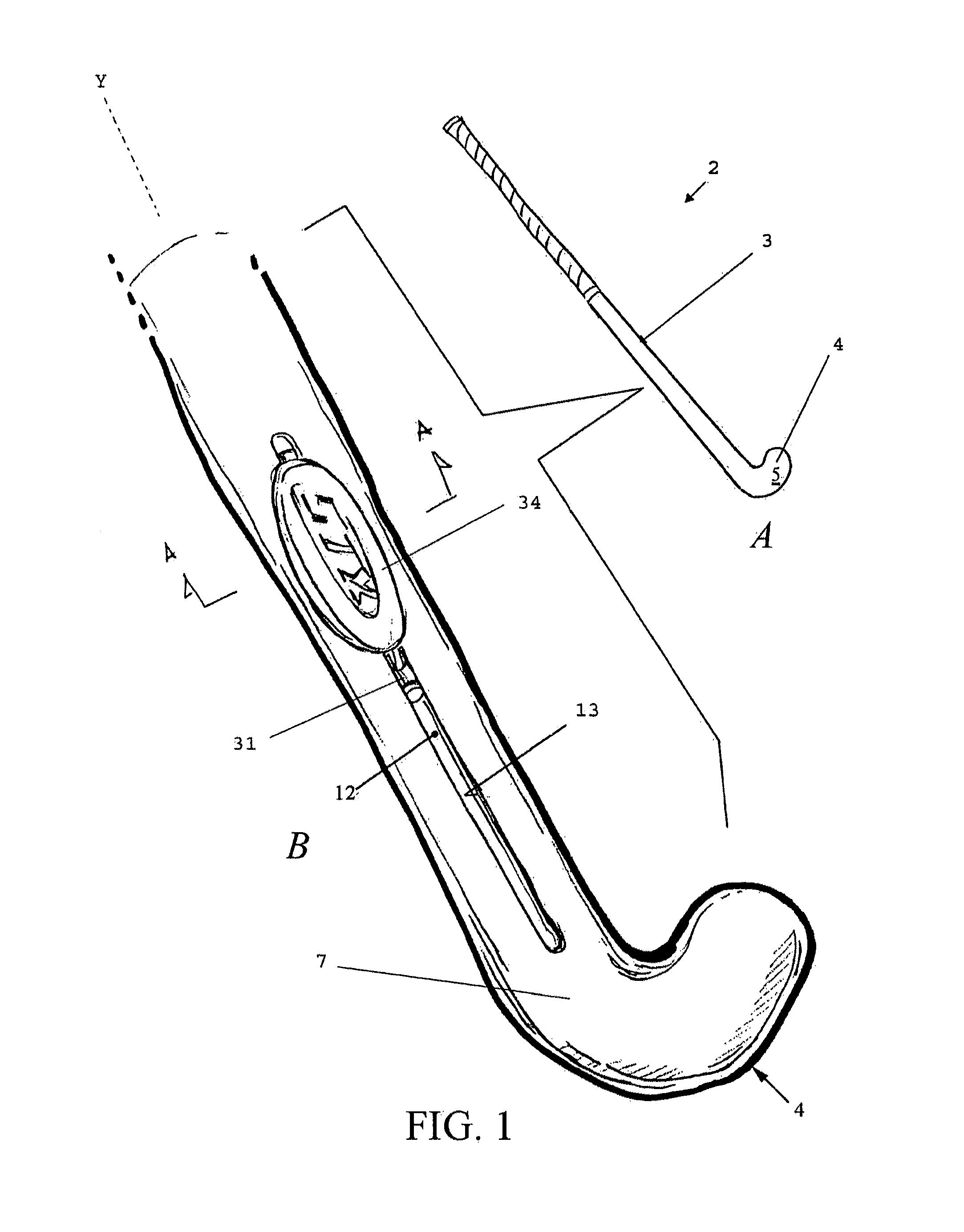

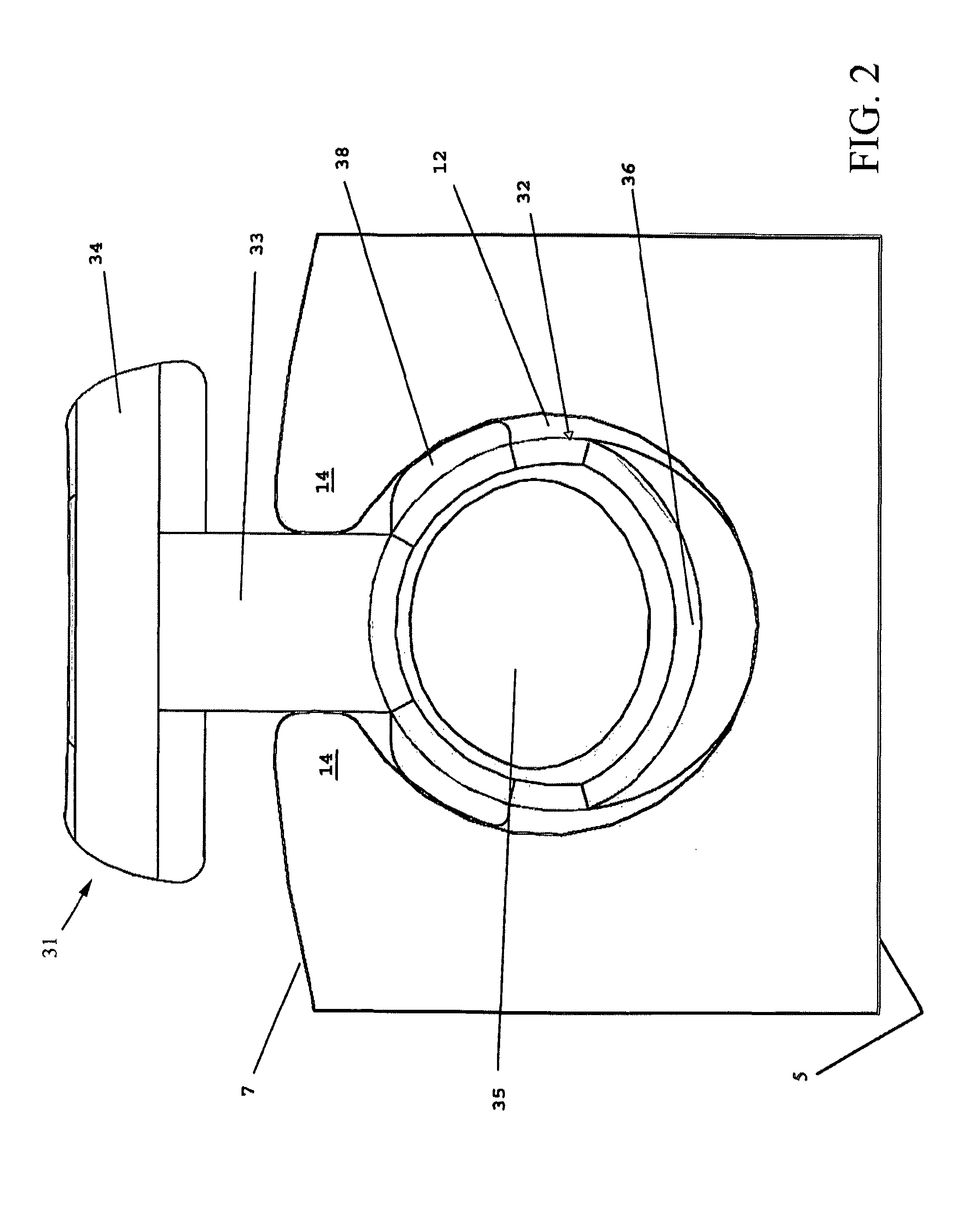

Adjustable weighted field hockey stick

A weighting system for a sports stick, particularly a field hockey stick, comprising a surface, recess, channel, hole or plurality of pockets formed along the length of the sports stick, and one or more weights moveably or selectively attachable along the surface and / or within the channel / pockets to allow a player to freely adjust the weight and balance point of the stick by slideably moving to or selectively adding or eliminating weight and points along the stick. A variety of embodiments are herein described, all providing an adjustable field hockey stick that allows players to adapt to play on different surfaces or in different conditions.

Owner:WM T BURNETT IP

Sprayer

ActiveUS8622320B2Accurate and reliable adjustmentConsistent flowFlow mixersTransportation and packagingSprayerEngineering

A sprayer system having a sprayer assembly adaptable to a variety of sizes and shapes of containers. The sprayer assembly includes a dual venturi in the flow conduit to provide even pressure and consistent flow in the spray volume. A metering device is coupled to the flow conduit for accurate and reliable regulation of mixture ratios. A dip tube, coupled to the fluid conduit, is adaptable to a variety of container orifices. In addition to acting as a conduit for passage of concentrate into the sprayer assembly, the dip tube may also be used as a cutting device to open the container into which it will be inserted. By adapting to a variety of container orifices, the dip tube allows the sprayer assembly to fit to a variety of containers.

Owner:THE FOUNTAIN HEAD GROUP INC

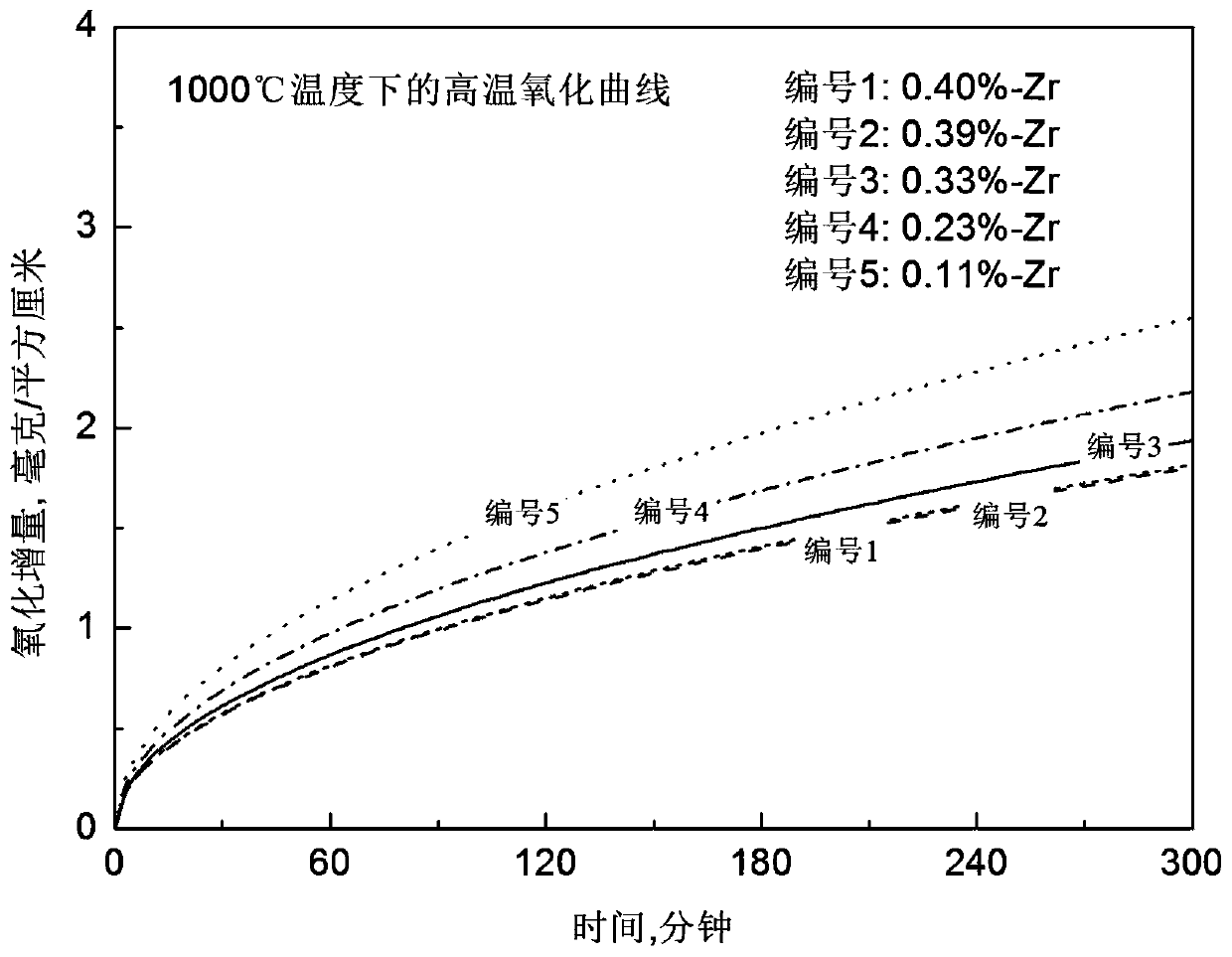

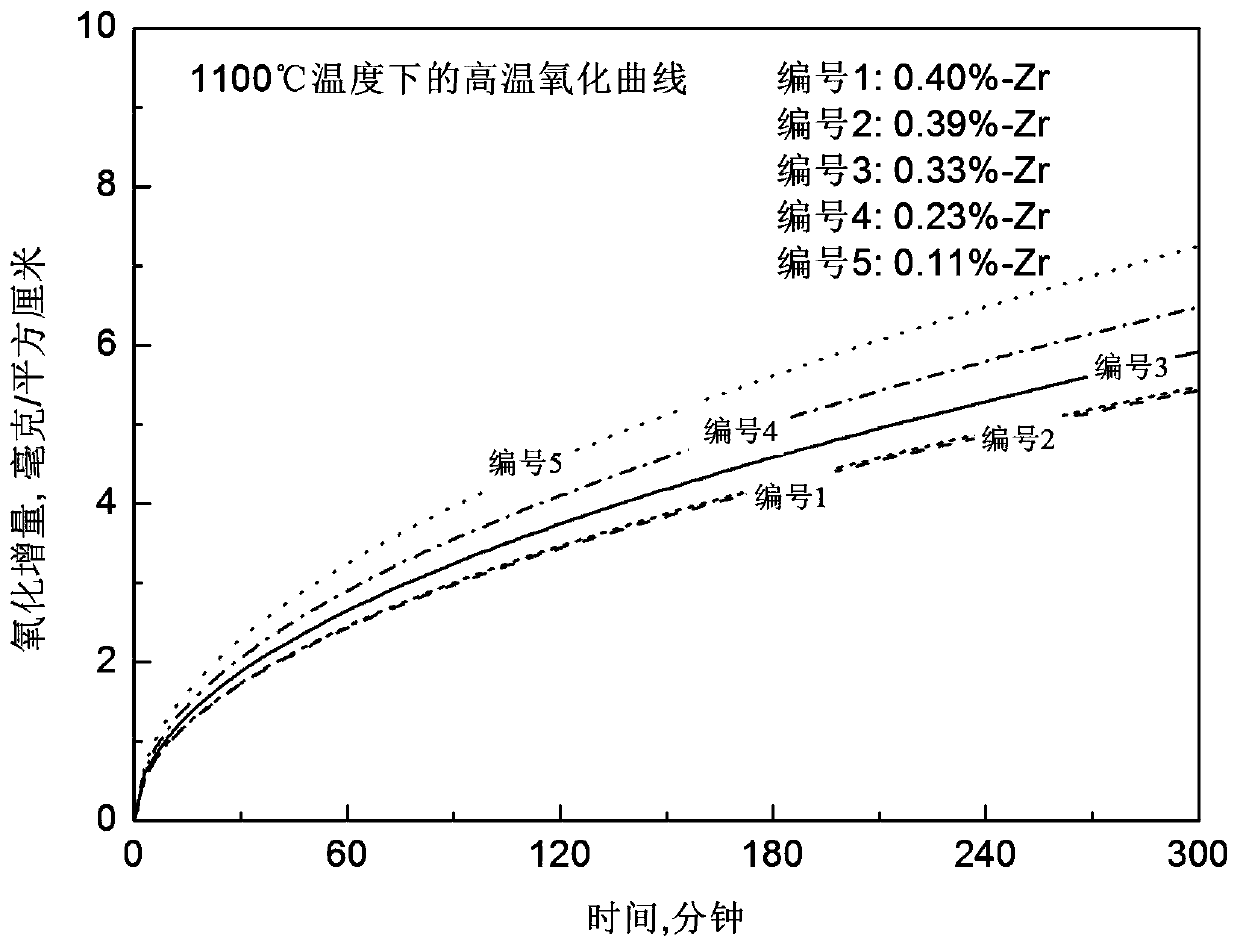

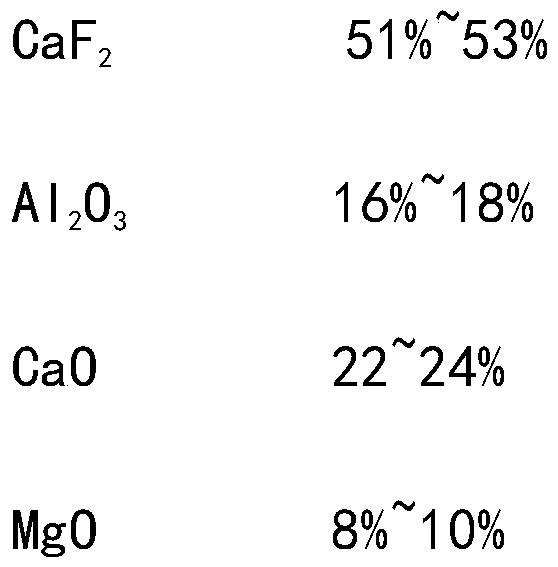

Zirconium-containing electrothermal alloy and preparation method of zirconium-containing alloy

ActiveCN110172648AGuaranteed high temperature strengthImprove adhesionIncreasing energy efficiencySlagZirconium alloy

The invention discloses zirconium-containing electrothermal alloy. The zirconium-containing electrothermal alloy comprises, by mass, 0-0.03% of carbon, 19-22% of chrome, 3.3-3.6% of aluminium, 0.35-0.43% of zirconium, 0-0.5% of silicon, 0.2-0.6% of titanium, 0-0.5% of manganese, 0-0.004% of magnesium, 0-0.01% of sulphur, 0-0.03% of phosphorus and the balance Fe. The invention further provides a method for preparing the zirconium-containing electrothermal alloy through vacuum induction melting and electroslag remelting. The initial slag system CaF2-CaO-MgO-Al2O3-ZrO2 is extracted during electroslag remelting, in the temperature rise period of the initial stage of remelting, Al2O3 powder is additionally added into the slag, therefore the content of zirconium in ingots is controlled precisely, and the zirconium is distributed evenly. According to the alloy and the preparation method, a right amount of zirconium is added into the electrothermal alloy, so that the high-temperature oxidationresistance of the electrothermal alloy is improved, and the high-quality effect is achieved through process control.

Owner:SUZHOU UNIV +1

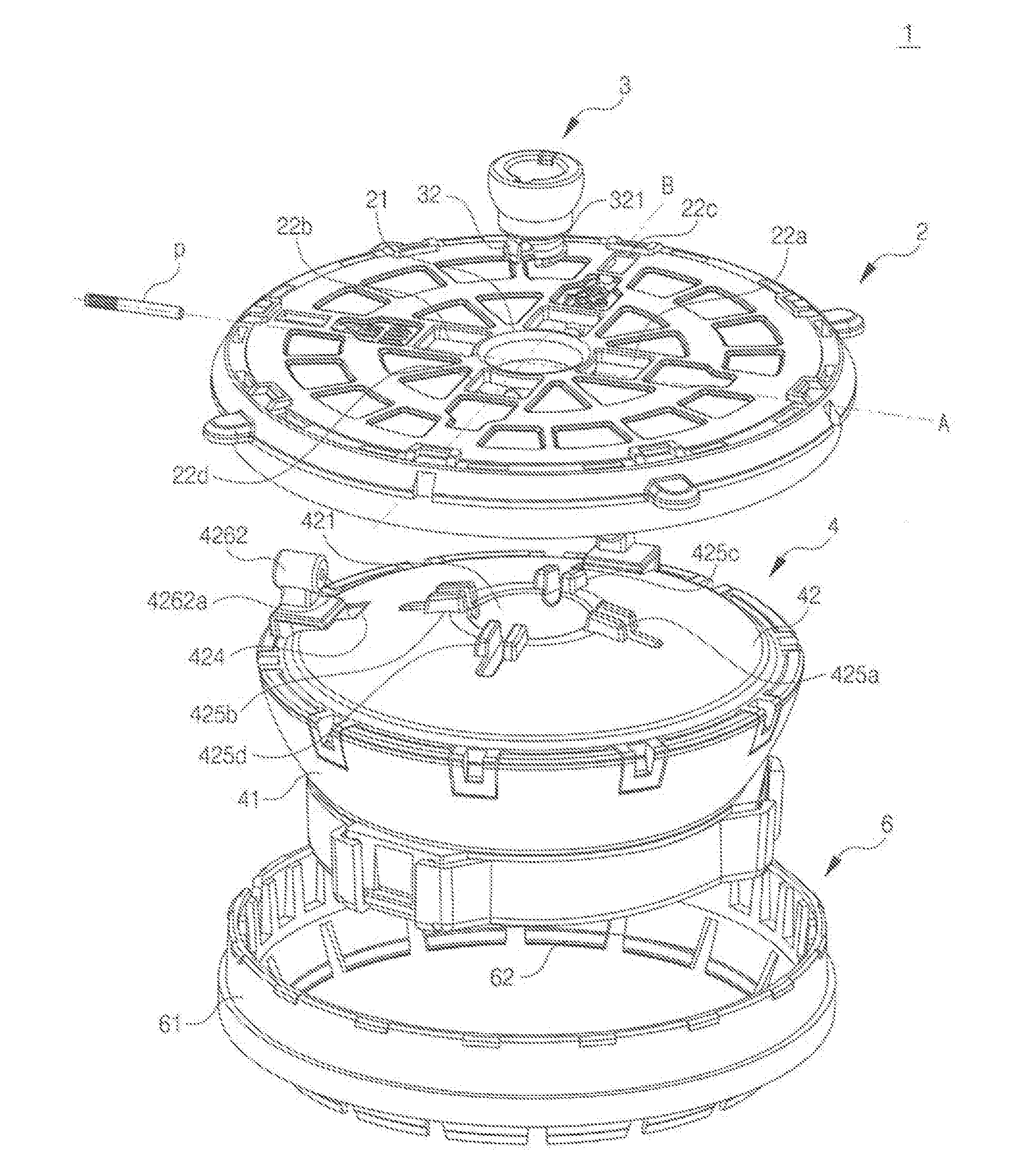

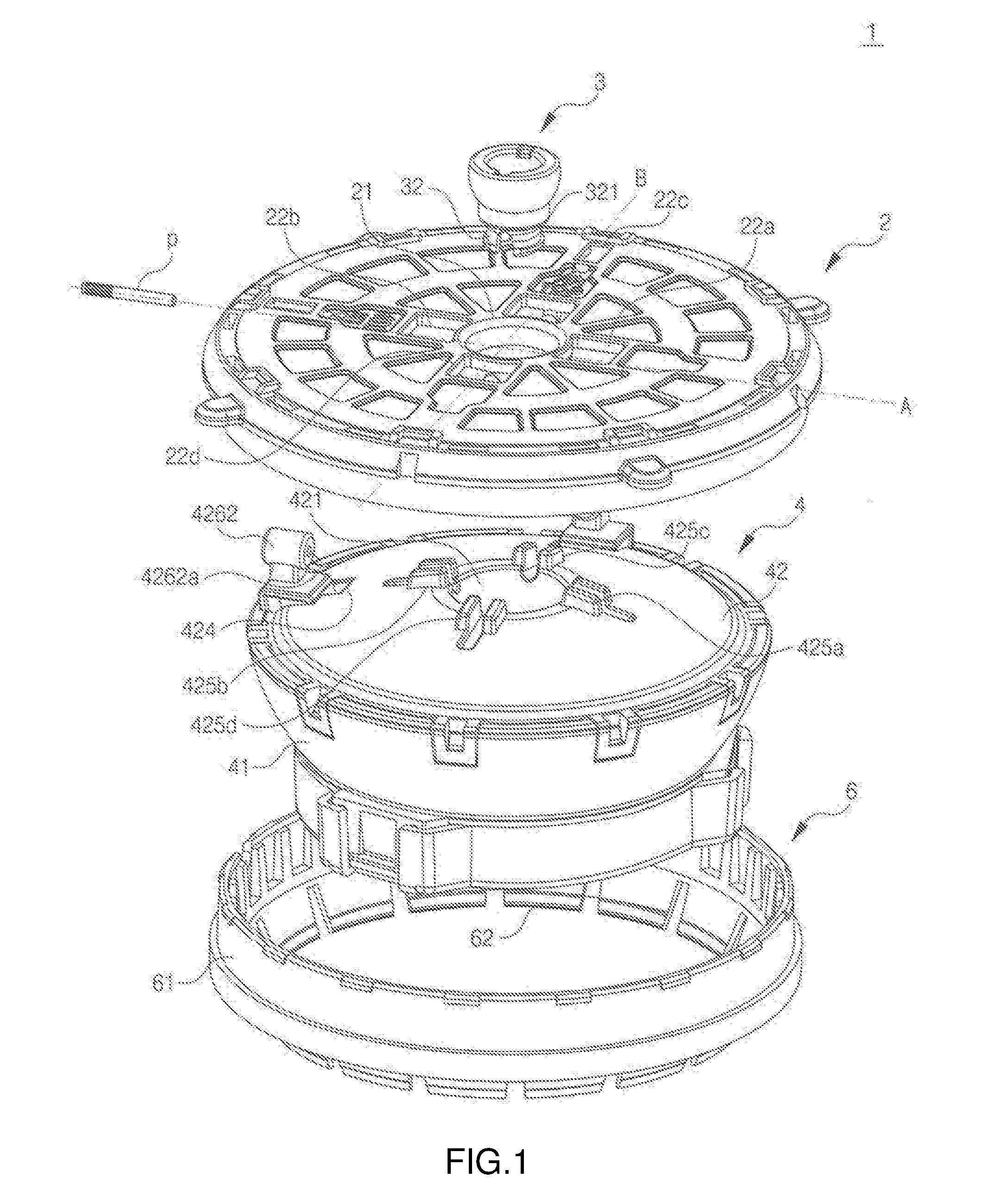

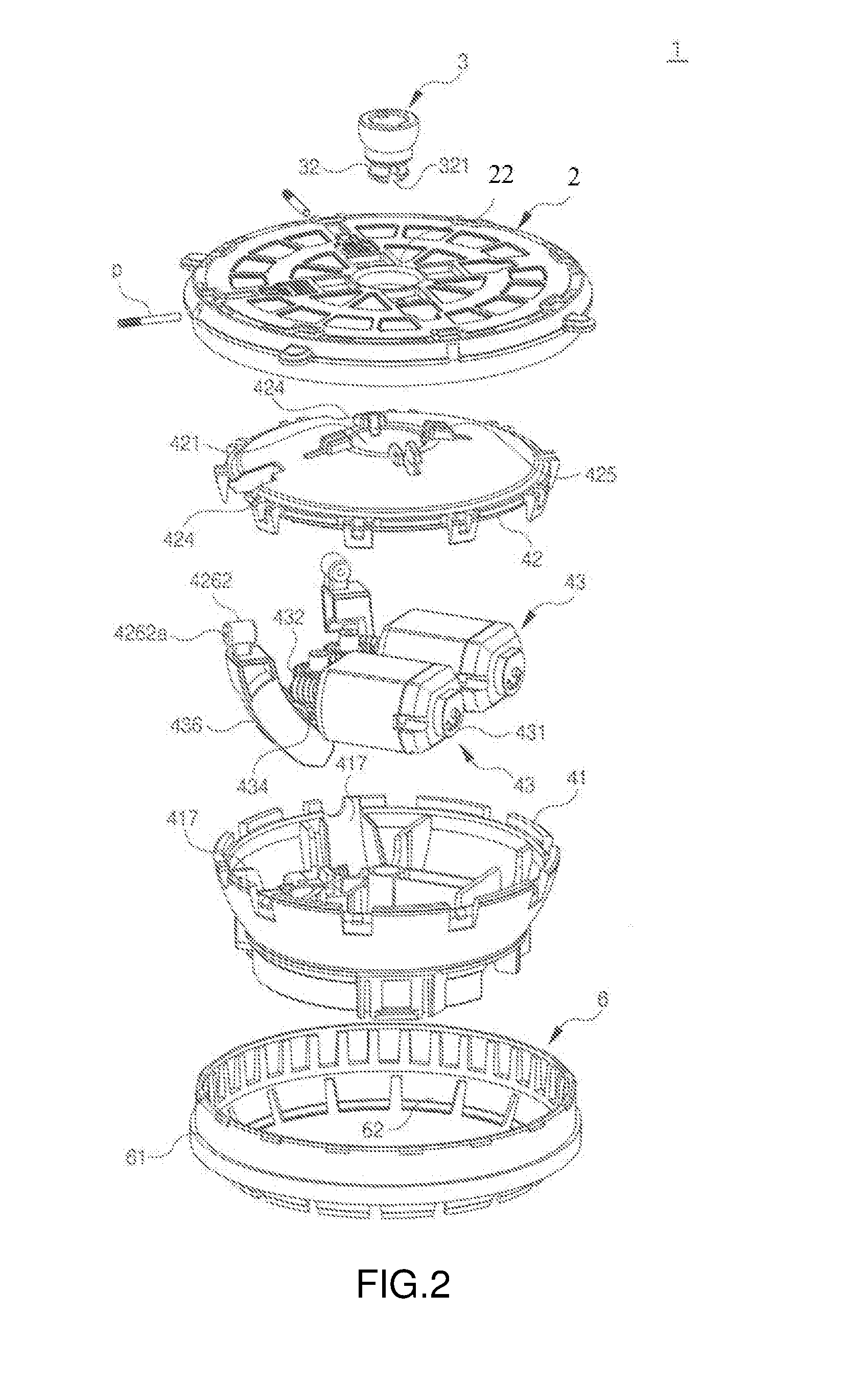

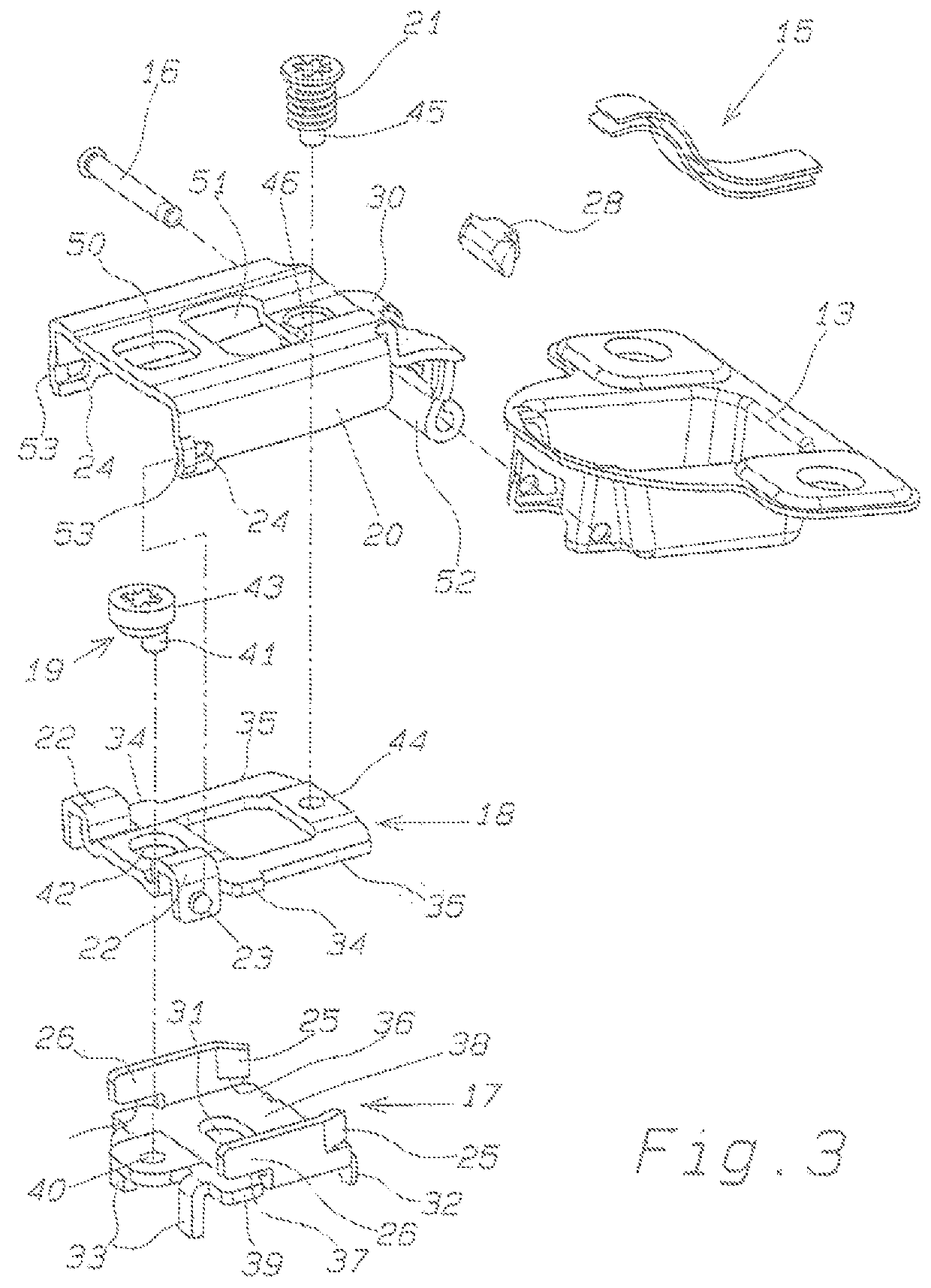

Adjustment device for an automotive wing mirror

ActiveUS20160264055A1Accurate and reliable adjustmentEffective absorptionGear vibration/noise dampingToothed gearingsDrive motorActuator

An adjustment device for an automotive wing mirror includes an adapter fixed to the wing mirror and having a virtual rotation center and first and second virtual axes perpendicularly intersecting with each other relative to the virtual rotation center, and an adapter driving module to drive the adapter. The adapter driving module includes a bowl-shaped lower shell, an upper shell covering on the lower shell, and two actuator mechanisms. Each actuator mechanism includes a driving motor, a reduction gear set, a clutch assembly meshing with the reduction gear set, and a ring gear meshing with the clutch assembly. The ring gears partially extend through the upper shell and are connected to the adapter on the first virtual axis and the second virtual axis. The adapter is operable of revolving relative to the virtual rotation center in two intersecting directions.

Owner:HAOYONG AUTOMOTIVE CONTROLS LTD

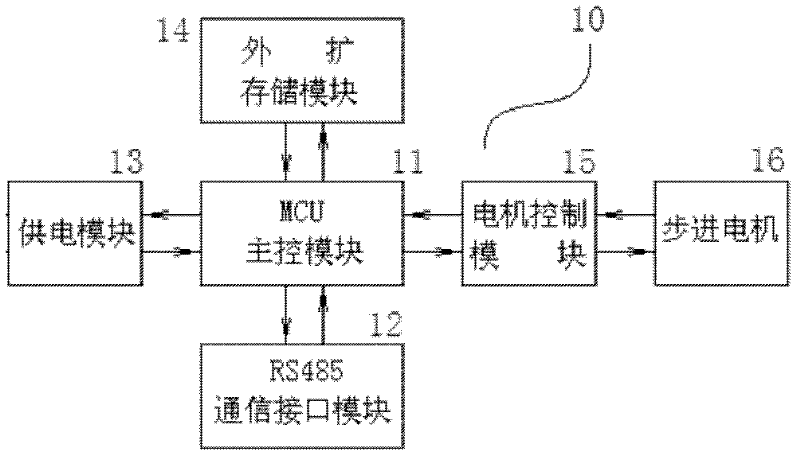

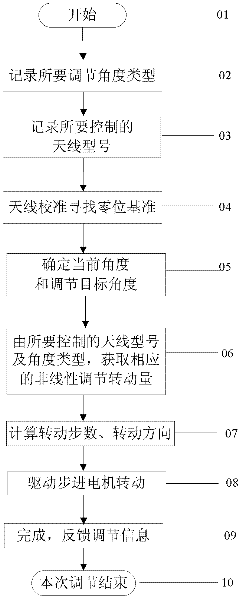

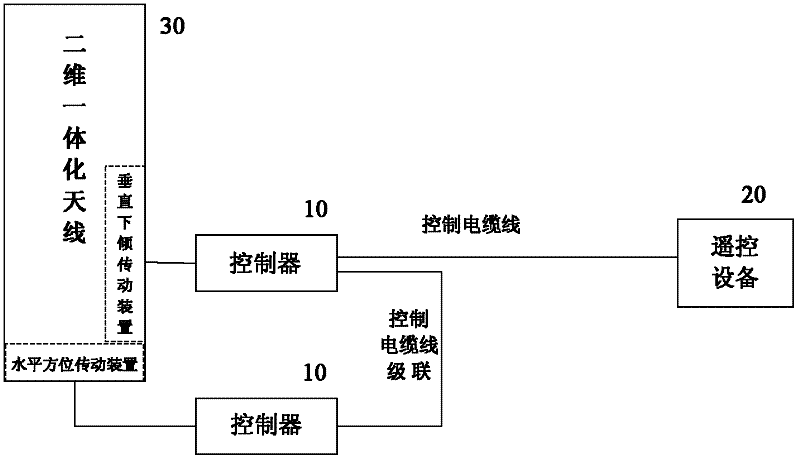

Multi-dimensional angle adjusting method with universality and nonlinearity for base station antennas

ActiveCN102496780AImprove job safety and flexibilityReduce maintenance costsAntennasEngineeringAzimuth

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

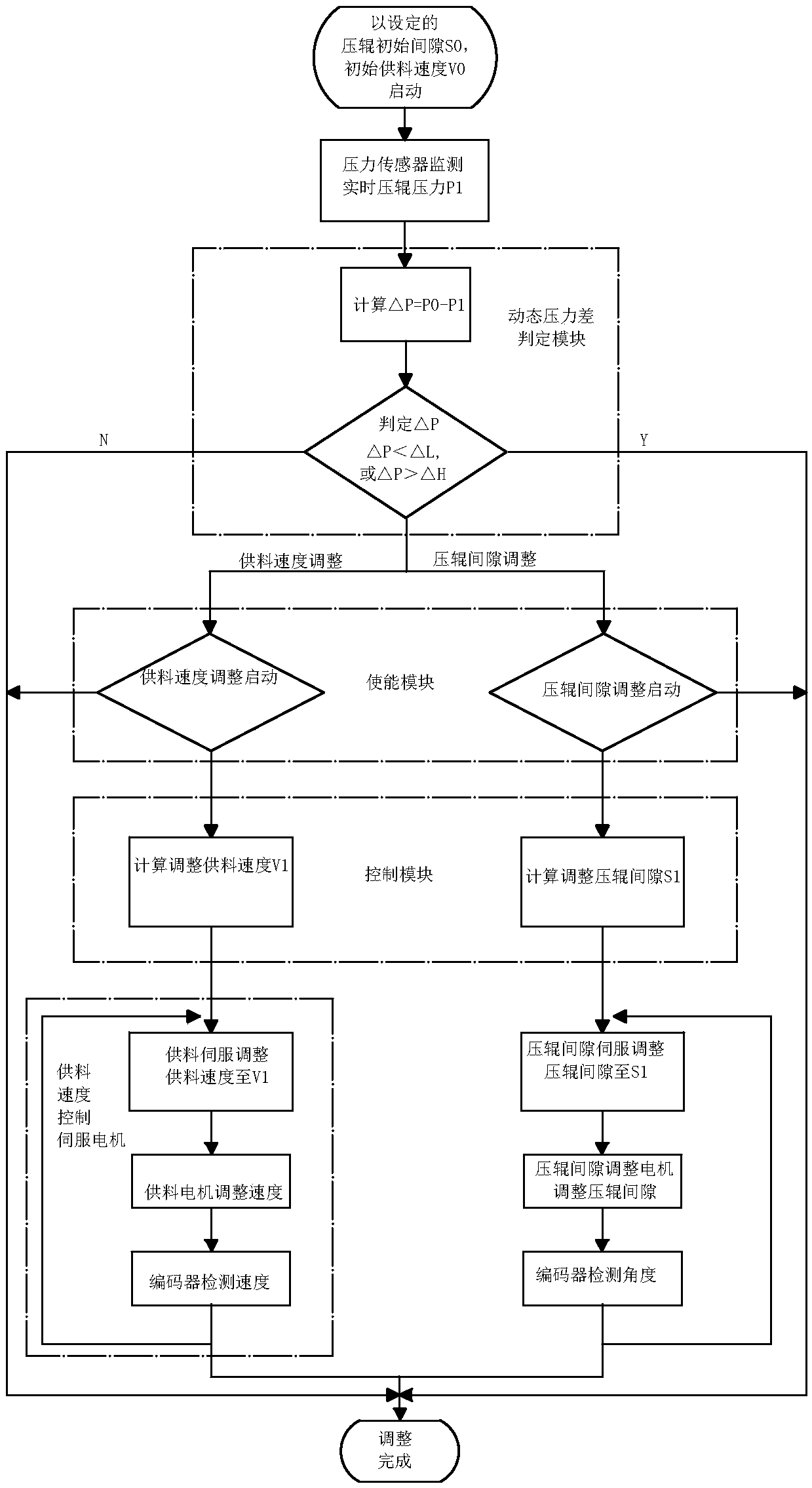

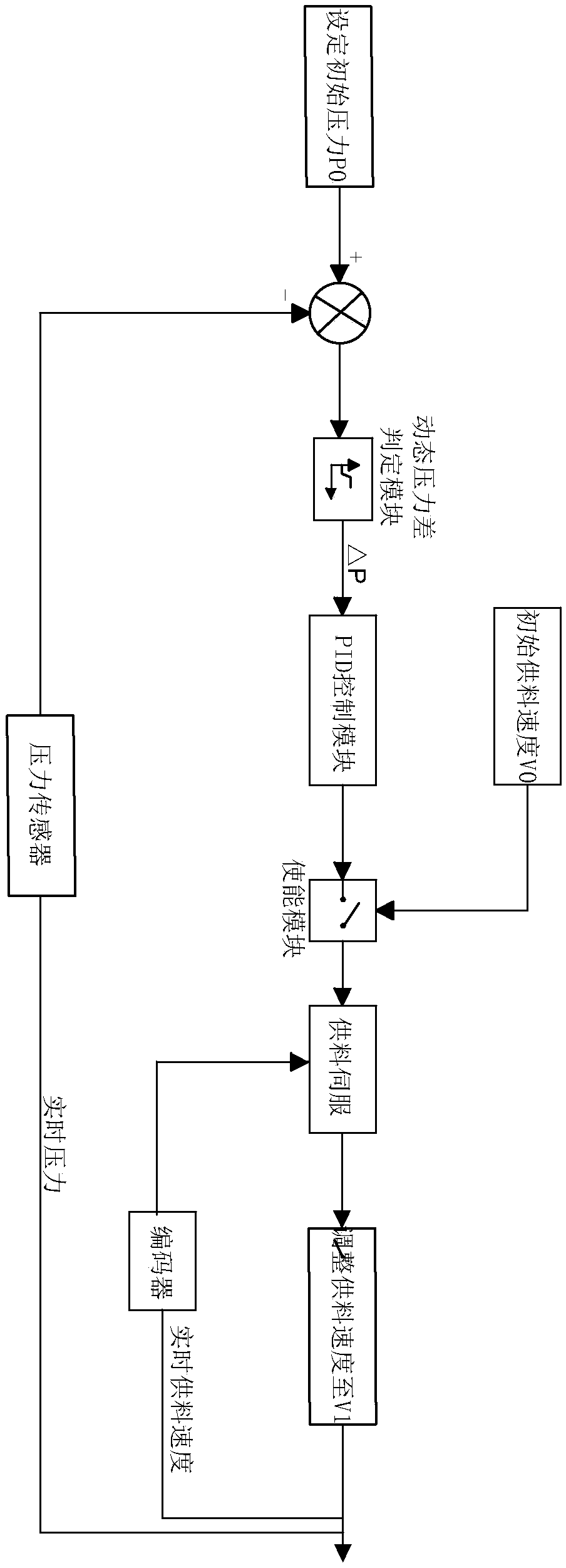

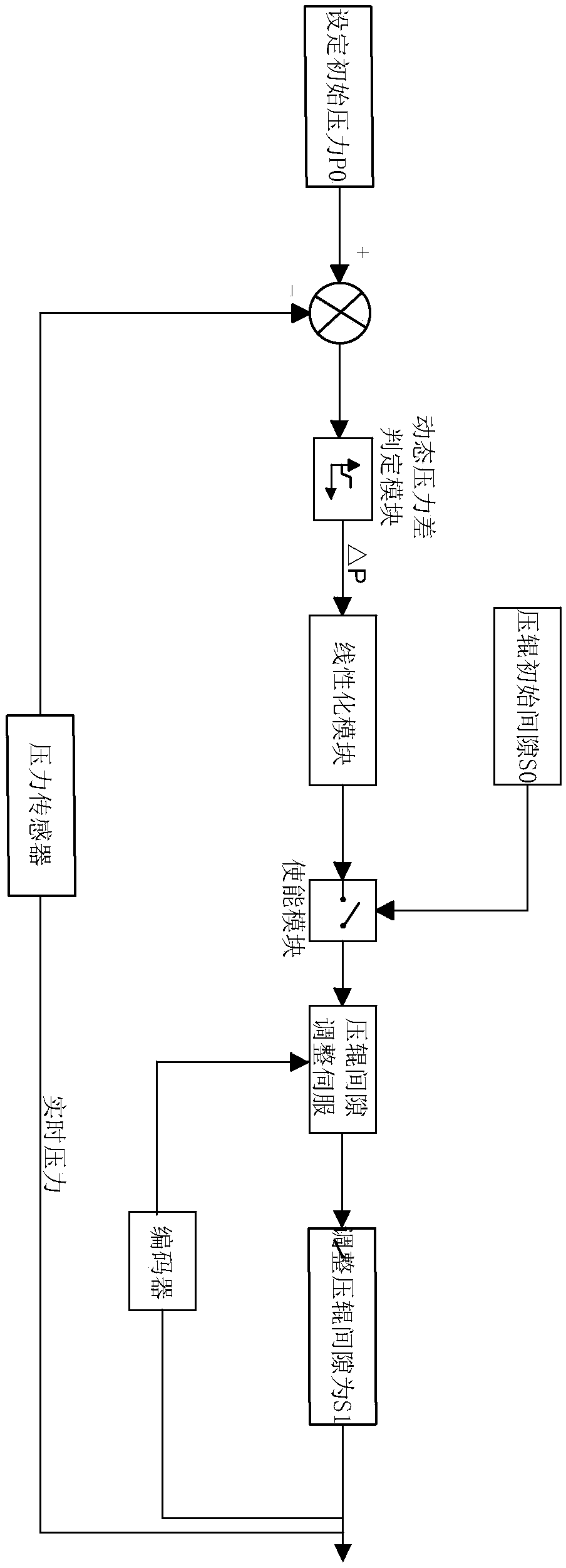

Dry type granulator tabletting pressure control system and method

The invention relates to dry type granulator tabletting pressure control system and method. A pressure sensor measures the real-time pressure roller pressure P1; an enabling module drives a pressure roller clearance adjusting servo motor to adjust a pressure roller clearance or drives a feeding speed control servo motor to adjust the feeding speed; a control module sets a pressure roller initial clearance S0, the initial pressure P0, the initial feeding speed V0, an allowable pressure increment upper limit as delta H, a pressure decrement lower limit as delta L, an allowable pressure maximum value as H, and a pressure lower limit value as L; a dynamic pressure different judgment module acquires a dynamic pressure difference delta P; judging the section on which the delta P is located; whenthe delta P is larger than the delta L and is smaller than the delta H, the system runs according to the current feeding speed and the current compression roller clearance; and when the delta P is larger than the delta H and is smaller than the delta L, and the time for maintaining the state exceeds the duration time t0, the pressure roller clearance adjusting servo motor adjusts the pressure roller clearance or drives the feeding speed control servo motor to adjust the feeding speed. The dry type granulator tabletting pressure control system and the method have the advantages of stability and reliability in control.

Owner:ZHEJIANG CANAAN TECH

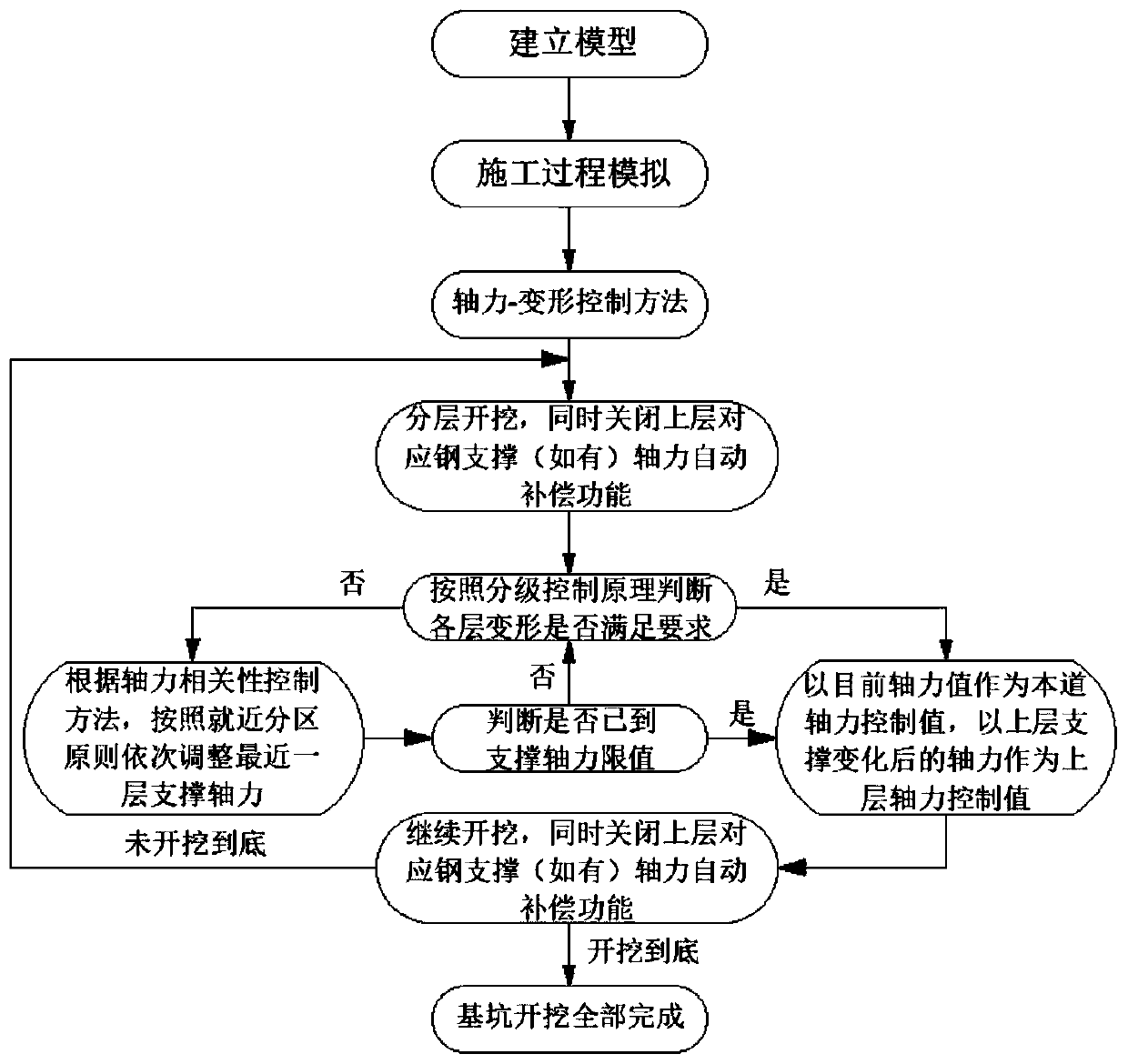

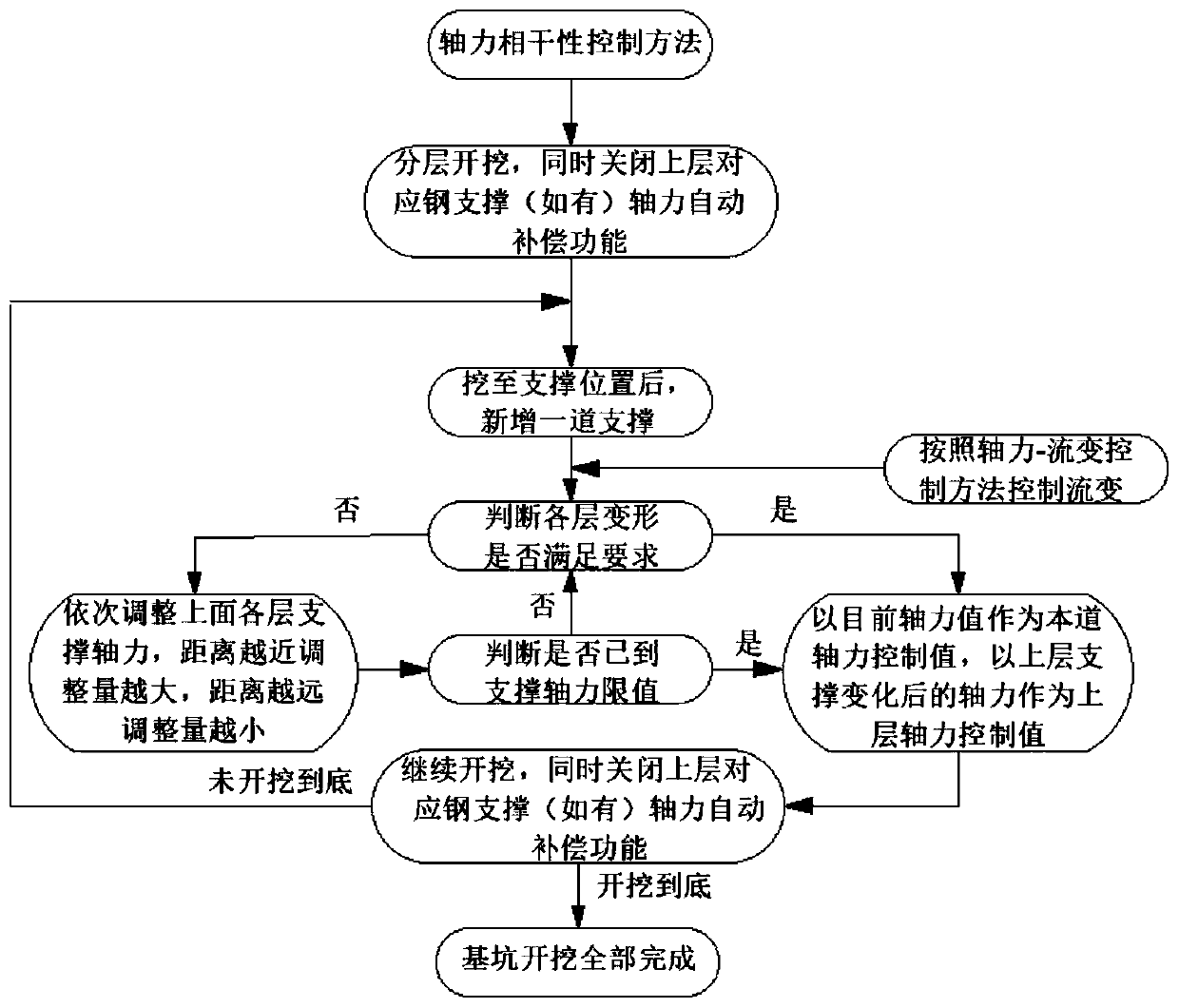

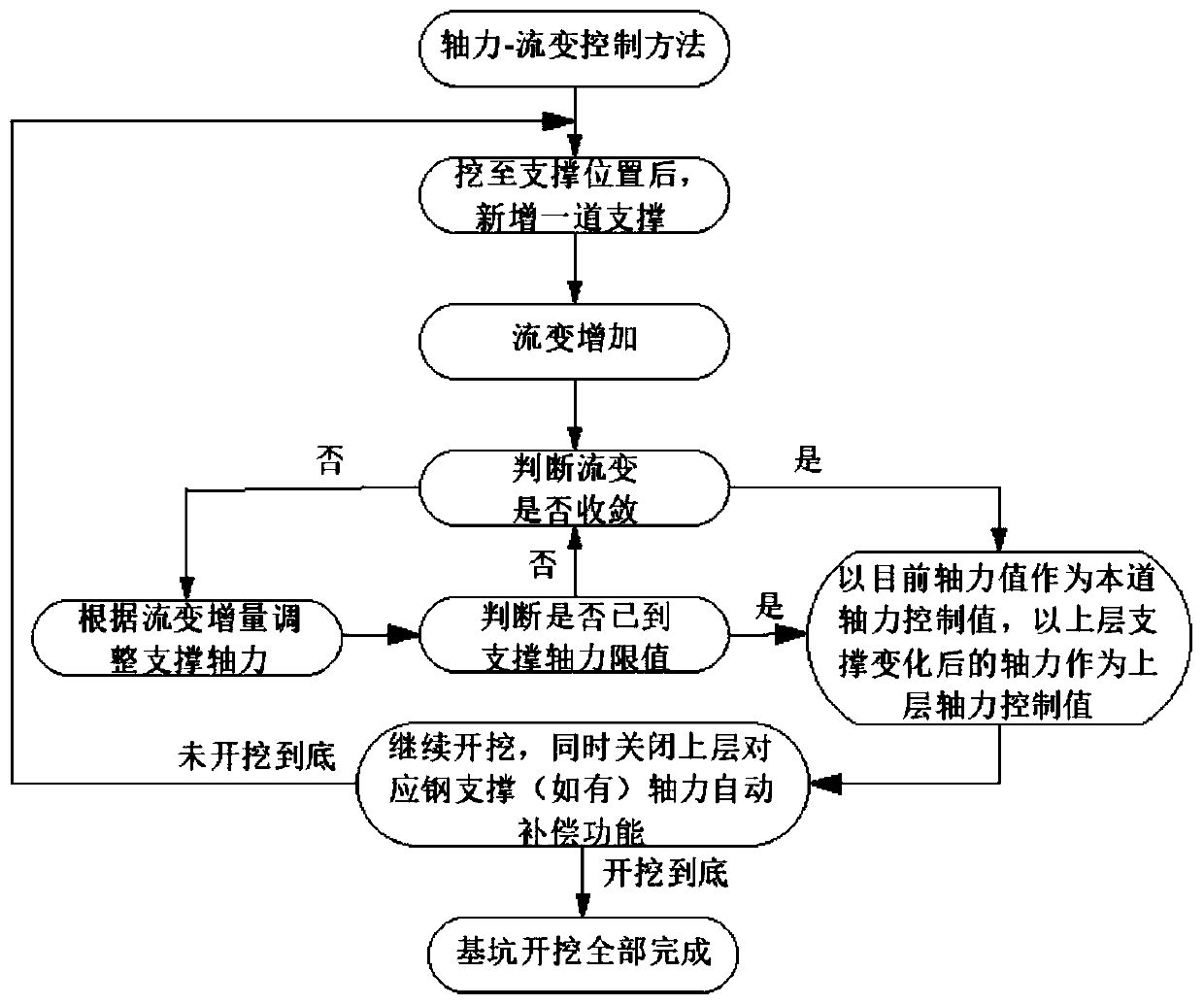

Construction method for foundation pit excavation

ActiveCN109811769AAccurate and reliable adjustmentAccurate measurementExcavationsAxial forceDeformation control

The invention relates to the technical field of building construction, in particular to a construction method for foundation pit excavation. The construction method comprises the following steps: construction conditions are determined and a foundation pit model is established; the construction process is simulated and the axial force and deformation control method is utilized for carrying the construction; layered excavation is adopted and the automatic compensation function to the corresponding support axial force of the upper layer is simultaneously closed; the support axial force of the closest layer is adjusted in turn according to the axial force coherence control method; whether the support axial force reaches the support axial force limit value is judged, the current axial force value is taken as the axial force control value of the current layer, and the changed support axial force of the upper layer is taken as the axial force control value of the upper layer; then the excavation is continued and the automatic compensation function to the support axial force of the upper layer is simultaneously closed; and the excavation of the next layer is carried after the excavation ofthe current layer is finished and the process is repeated until the whole foundation pit is finished. By combining the axial force and deformation control method with the axial force coherence control method, the invention can be used for compensating and controlling the deformation of the excavation face and realizing the main control to the lateral soft soil for enclosing.

Owner:TENGDA CONSTR GROUP CORP

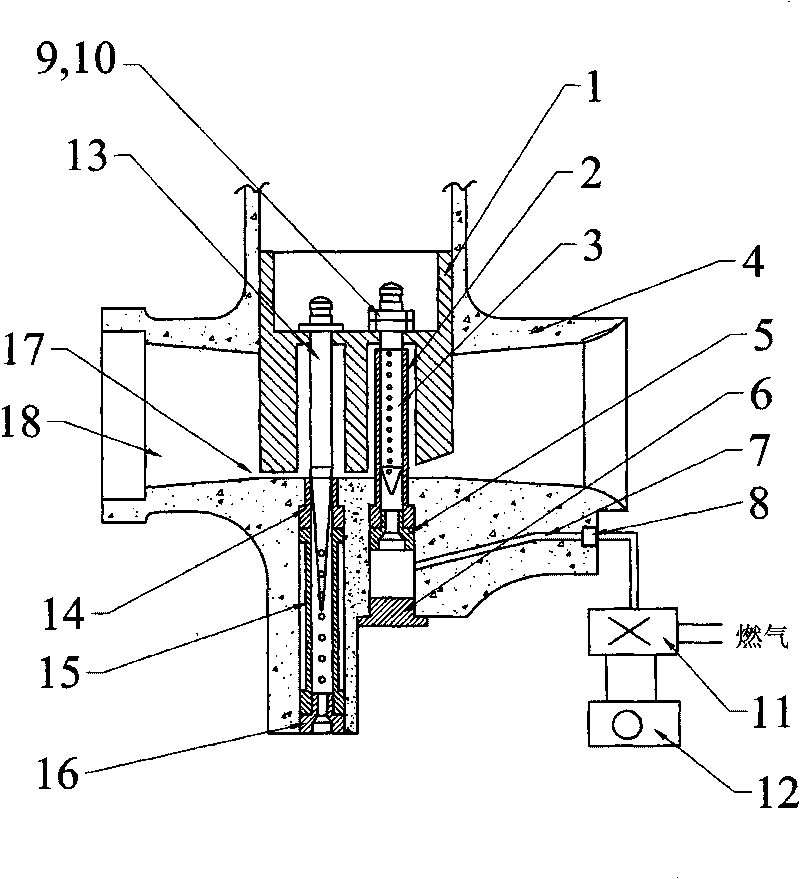

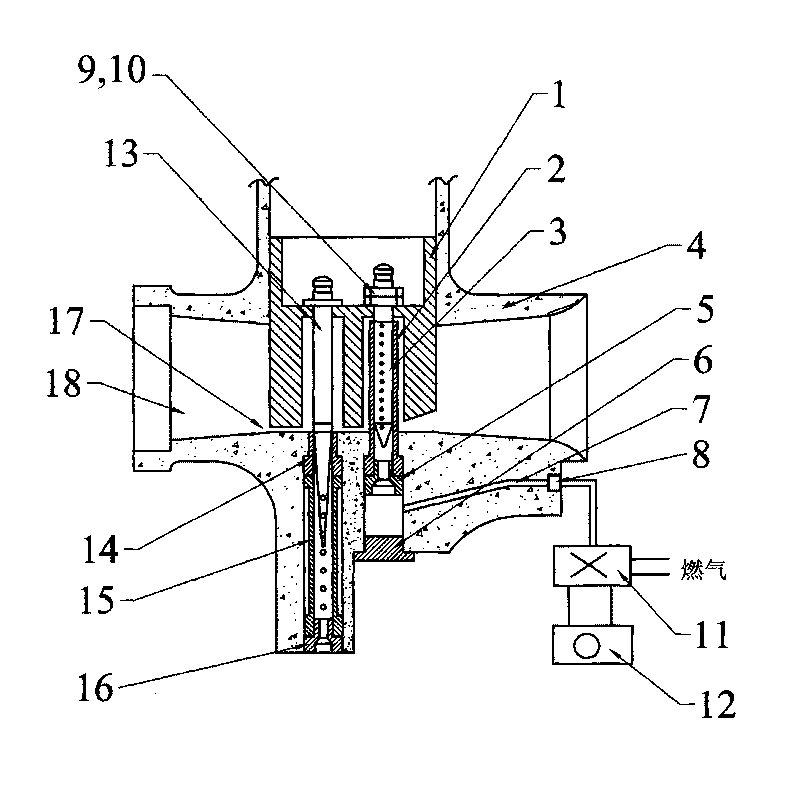

Fuel gas and gasoline dual-use controller for small engine

InactiveCN101713353ASimple structureLow costMachines/enginesCarburettorsSynchronous controlSolenoid valve

The invention relates to a fuel gas and gasoline dual-use controller for a small engine, which is more suitable for motorcycles and the like having variable torques and rotation speeds. The dual-use controller controls the flow rate of fuel gas and gasoline through a gas pin and a gasoline pin arranged on the same plunger; and the gas pin arranged on the plunger correspondingly opens orifices of a regulating tube along with the change of the plunger position when the fuel gas is used, and the number of the opened orifices makes fuel gas amount optimally matched with air amount to supply ideal air-fuel ratio to the engine all the time. The dual-use controller is same as a prior plunger type carbureter and has no change in structures and working process when the gasoline is used, The arranged double-solenoid valve and magnetor synchronously control circuit, which not only makes opening and closing of the fuel gas consistent with the working condition of the engine, and but also solves the problems of blowout and downtime during quickly accelerating speed.

Owner:上海非常化油器有限公司

Flexible joint and flexible connecting device

InactiveCN101799109AReduced effects of thermoelastic deformationBlocking pathStands/trestlesEngineeringDistortion

The invention relates to a flexible joint and a flexible connecting device. The flexible joint comprises a flexible transition sheet, a connection lug sheet and a flexible plate, wherein the connection lug sheet and the flexible plate are respectively and vertically arranged on two side surfaces of the flexible transition sheet, the connection lug sheet and the flexible plate are mutually vertical, two sides of the corner joint of the connection lug sheet and the flexible transition sheet are respectively provided with an upper groove, and two sides of the corner joint of the flexible plate and the flexible transition sheet are respectively provided with an inner groove. The invention solves the technical problem that the existing flange or support is always affected by satellite thermoelastic distortion when installing a telescope. The invention has the advantages of high positioning precision and the like and lowers thermoelastic distortion influence.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

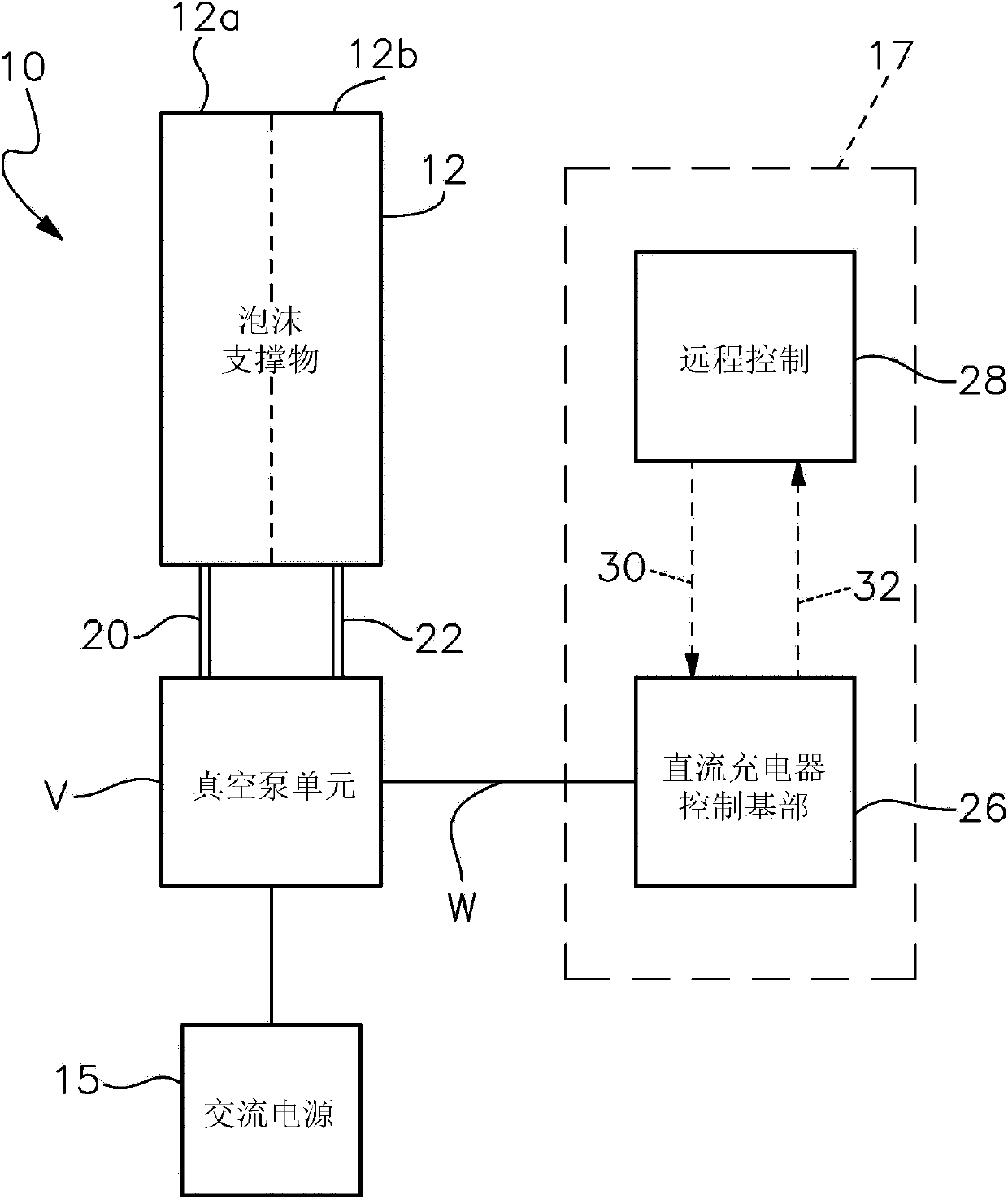

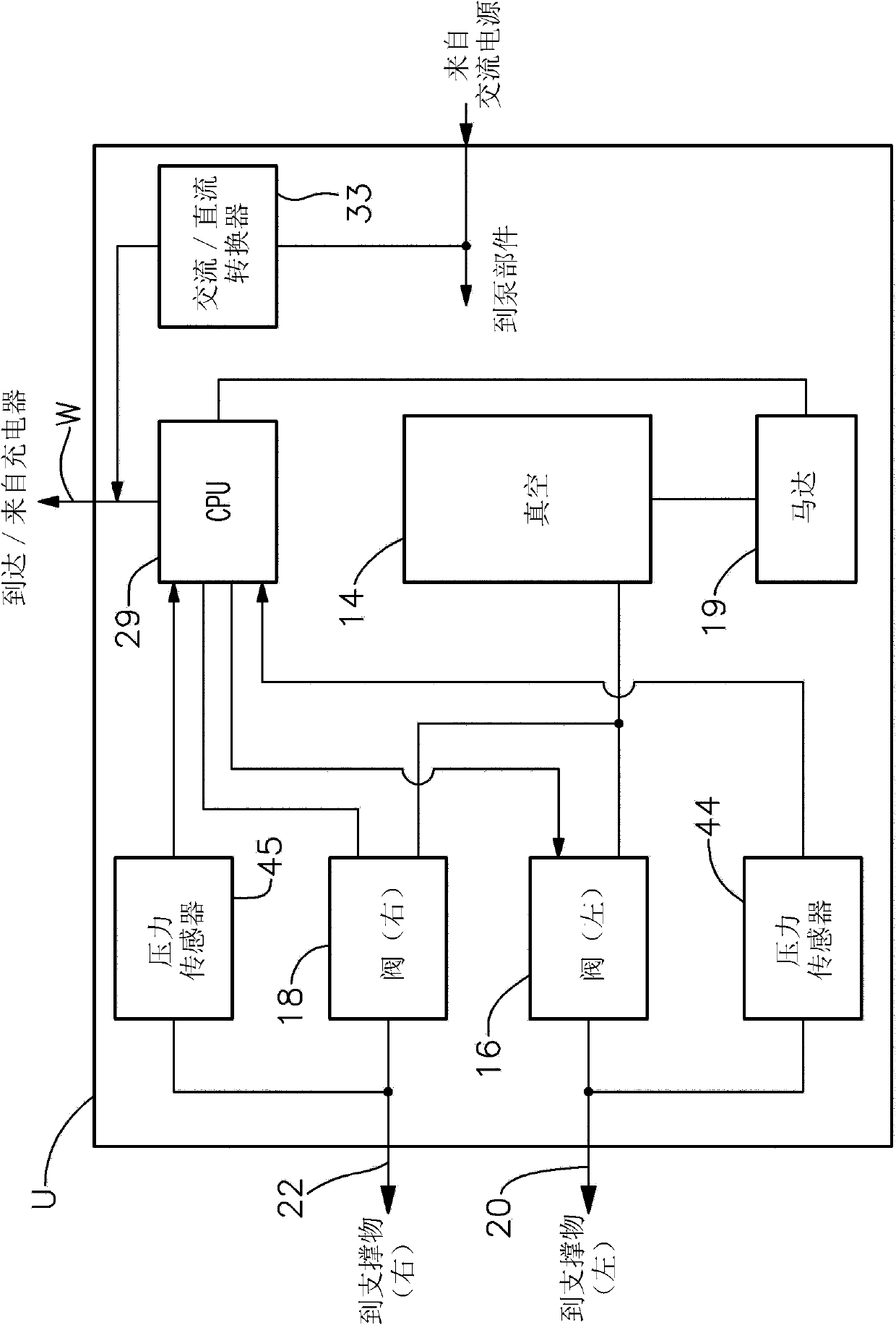

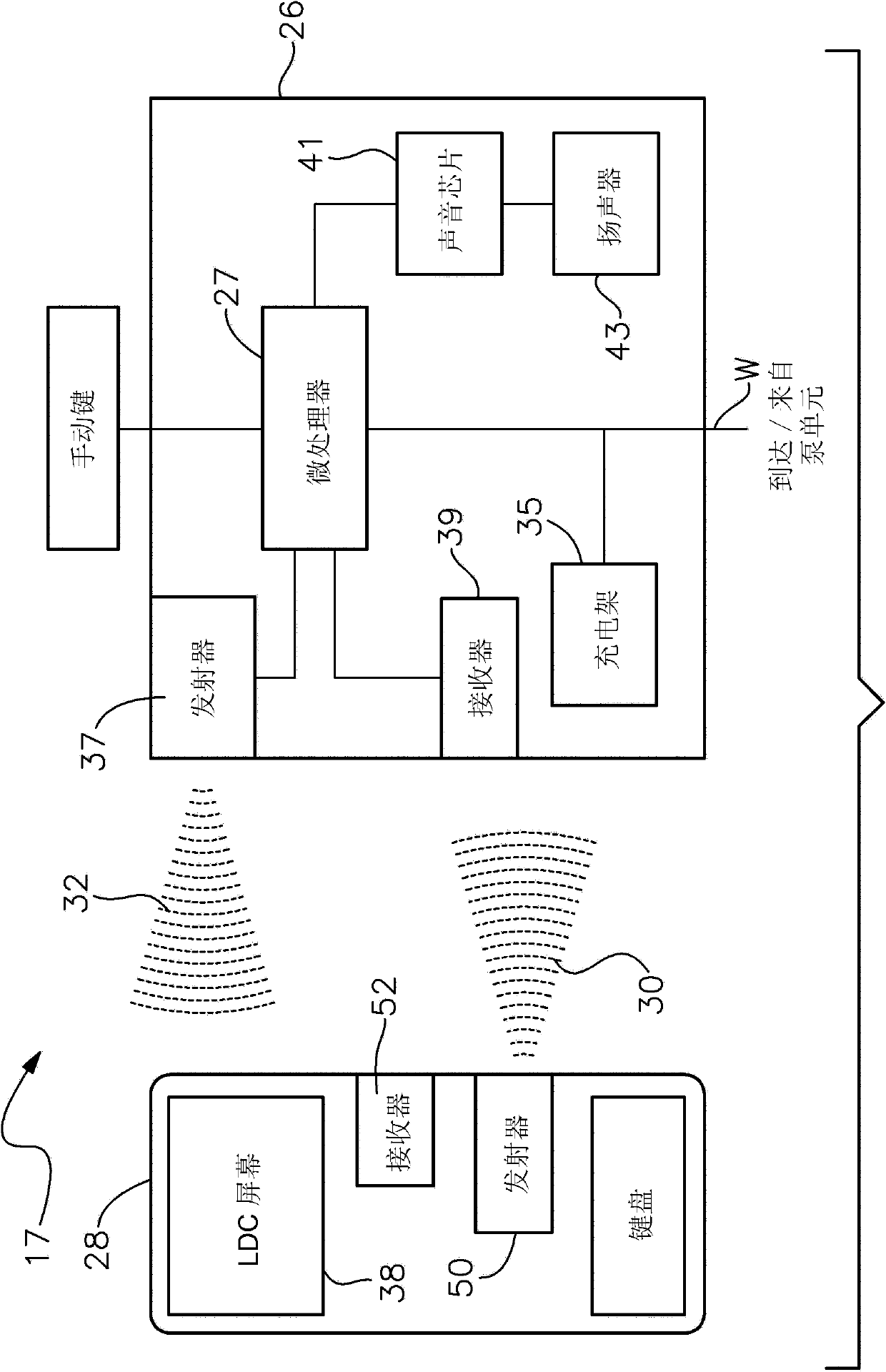

Pressure control and feedback system used for adjustable foam support equipment

The invention provides a pressure control and feedback system used for adjustable foam support equipment. The system comprises a vacuum pump which is communicated with gas of a sealed foam core body, and air is pumped out from the core body, so that the hardness of the core body is reduced and the softness of the core body is increased. A valve is opened and closed alternatively, so as to allow the air to enter into the core body or prevent the air from leaving the core body. A controller operated remotely generates and sends out a selected control signal by a programmable CPU (central processing unit) so as to operate the pump and the valve. Each control signal represents a corresponding hardness level in multiple hardness levels of the core body. The control signal selectively starts and stops the operation of the pump and selectively opens and closes the valve, so as to provide air pressure and corresponding hardness of a selected level in the core body. A pressure sensor detects the pressure and hardness of the core body and generates a feedback signal representing the pressure and hardness. An indicator device responds the feedback signal, so as to indicate the sending hardness of the core body.

Owner:NOVORAY

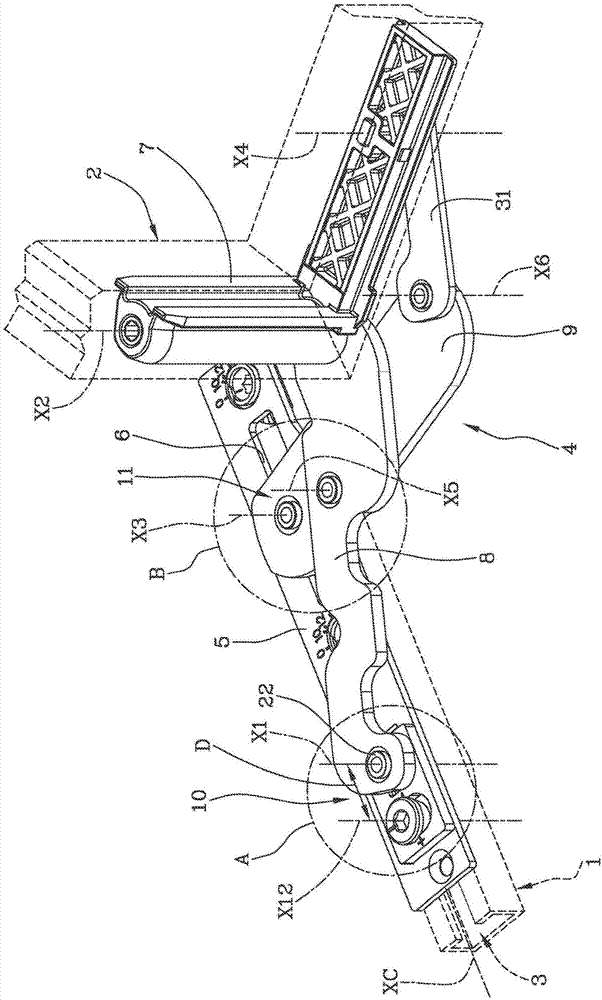

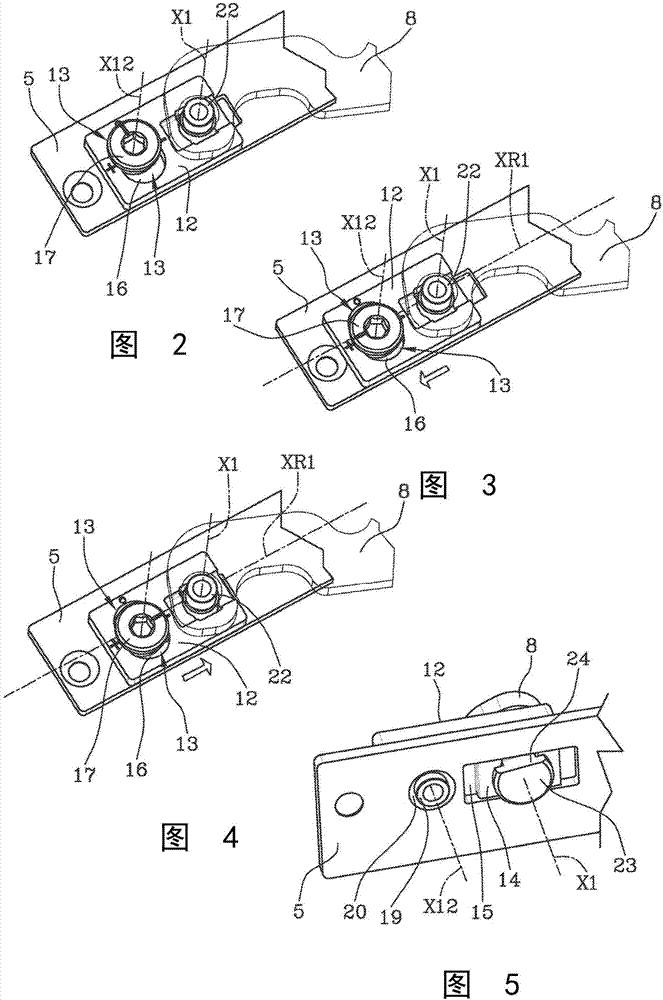

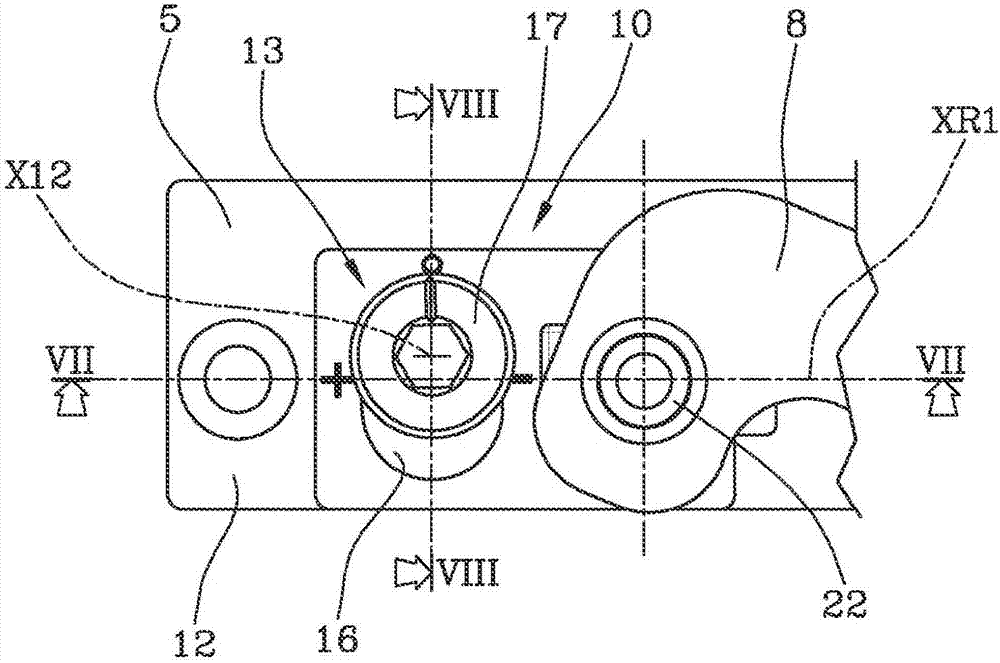

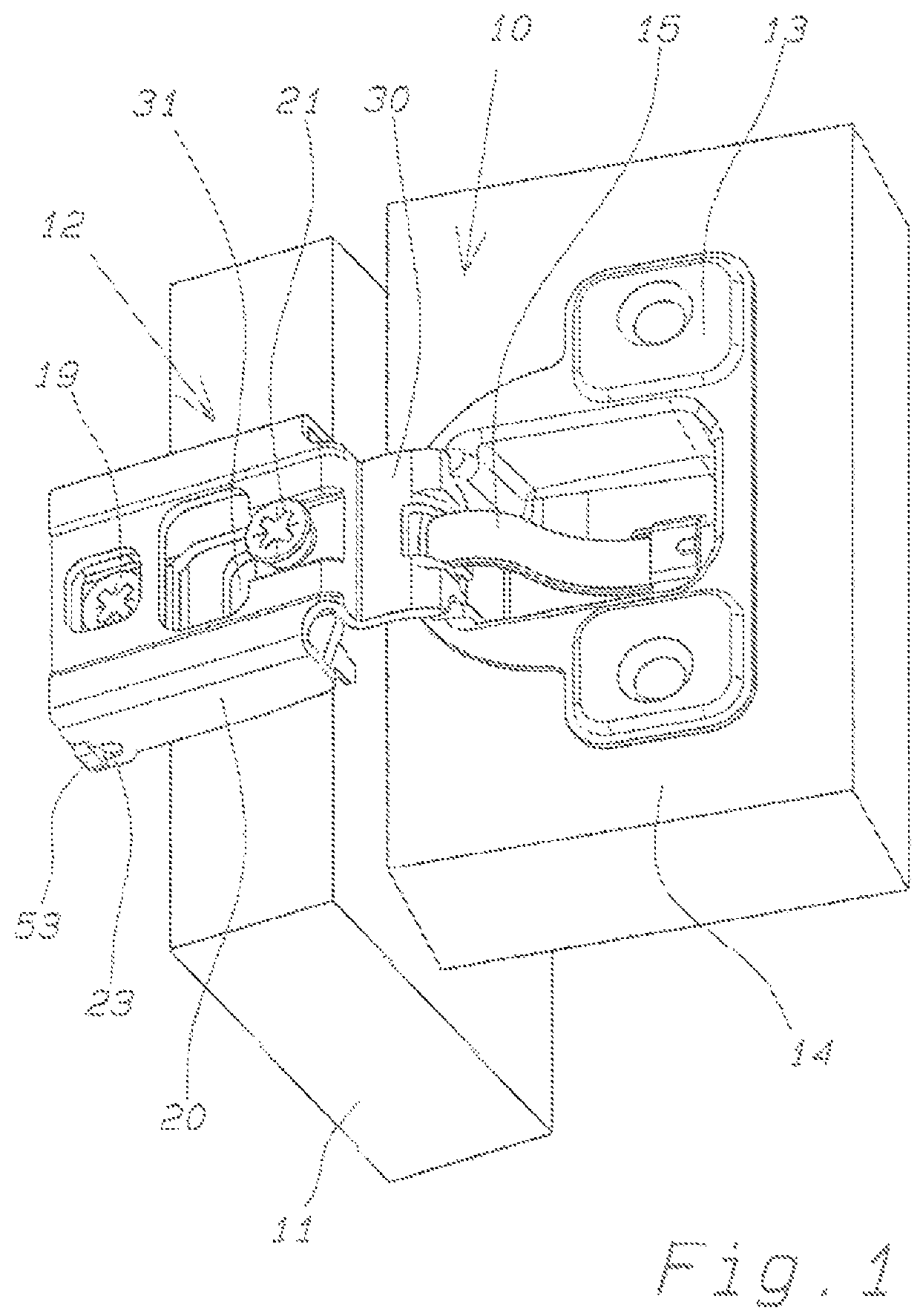

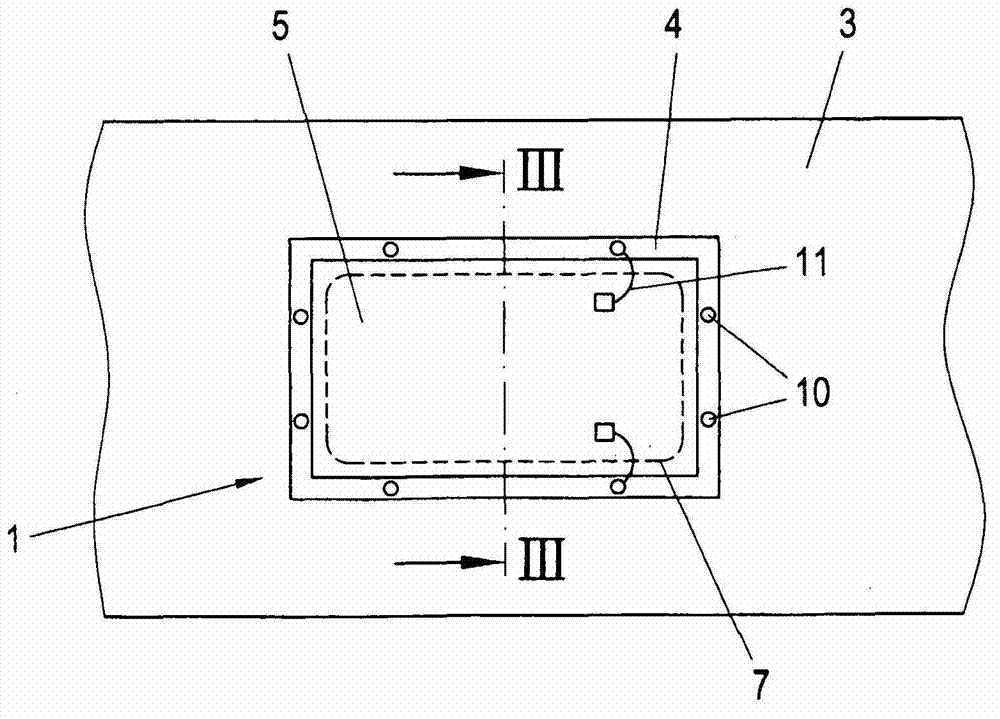

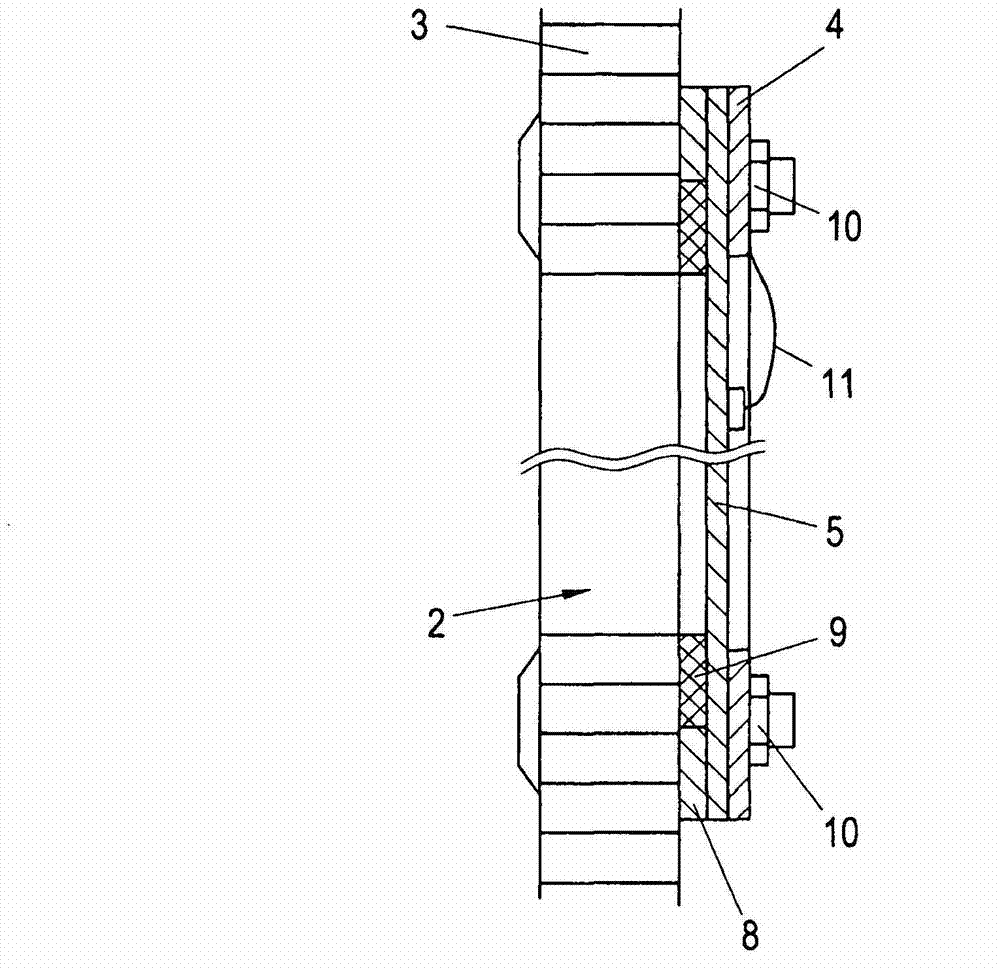

Hinge for doors or windows

ActiveCN107208439AAccurate and reliable adjustmentHingesWing suspension devicesHorizontal axisEngineering

Described is a hinge for doors or windows comprising: a first fixed body (5) associated with a fixed frame (1) and having a first axis (X1) of fixed articulation and a slot (6) made parallel to the axis (XC) of longitudinal extension of the first fixed body (5); a second movable body (7) connected to a movable sash (2); a first lever (8) having a first end articulated to the first fixed body (5) about the first axis (X1) of fixed articulation, a second end articulated to the second movable body (7), defining a second axis (X2) of articulation, and an intermediate zone; a second lever (9) having a first end articulated inside the slot (6) of the first fixed body (5) to define a third slidable axis (X3) of articulation, a second end articulated to the second movable body (7) definng a fourth axis (X4) of articulation and an intermediate zone; the first (8) and the second (9) levers are articulated to each other in the corresponding intermediate zone to define a fifth axis (X5) of shared articulation; means (10, 11) for adjusting at least one between the first axis (X1) of articulation and the third slidable axis (X3) of articulation along at least a first horizontal axis (XR1) parallel to the axis (XC) of longitudinal extension of the first fixed body (5) or a second horizontal axis (XR2) perpendicular to the axis (XC) of longitudinal extension of the first fixed body (5); the adjustment means (11) are interposed between the first end of the second lever (9) articulated inside the slot (6) of the first fixed body (5) and the first fixed body (5) for adjusting the position of the third axis (X3) of articulation along the second horizontal axis (XR2) perpendicular to the first horizontal axis (XR1), in both directions.

Owner:GIESSE

Abrasion compensation device of driving disc brake and self-compensation method of abrasion compensation device

PendingCN113531017APrecisely adjust the initial positionReduce maintenance and operation costsBrake actuating mechanismsSlack adjustersInterference fitPiston

The invention discloses an abrasion compensation device of a driving disc brake and a self-compensation method of the abrasion compensation device, and belongs to the field of brakes. The compensation device is arranged on a fixing rod and is suitable for adjusting the relative position between a clamp body and a piston; and the abrasion compensation device comprises a spring pressing plate, a fixing nut, an adjusting expansion sleeve, and adjusting lining, a spring guide sleeve and an elastic piece, wherein the spring pressing plate is installed on the fixing rod in a sliding mode, the fixing nut is installed on the inner wall of the piston in an interference mode and is suitable for limiting the position of the spring pressing plate, the adjusting expansion sleeve is in interference fit with the fixing rod, the adjusting lining is arranged on one side of the adjusting expansion sleeve and is in an L shape, the spring guide sleeve is placed on the adjusting expansion sleeve and the adjusting lining, one end of the elastic piece is arranged on the spring guide sleeve, and the other end of the elastic piece is connected with the spring pressing plate. The piston is pressed back through the elastic piece, it is guaranteed that a friction plate cannot be in dragging abrasion with the brake disc, and therefore the situation that a brake sealing failure is caused by continuous heat generation, and driving safety is caused is avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

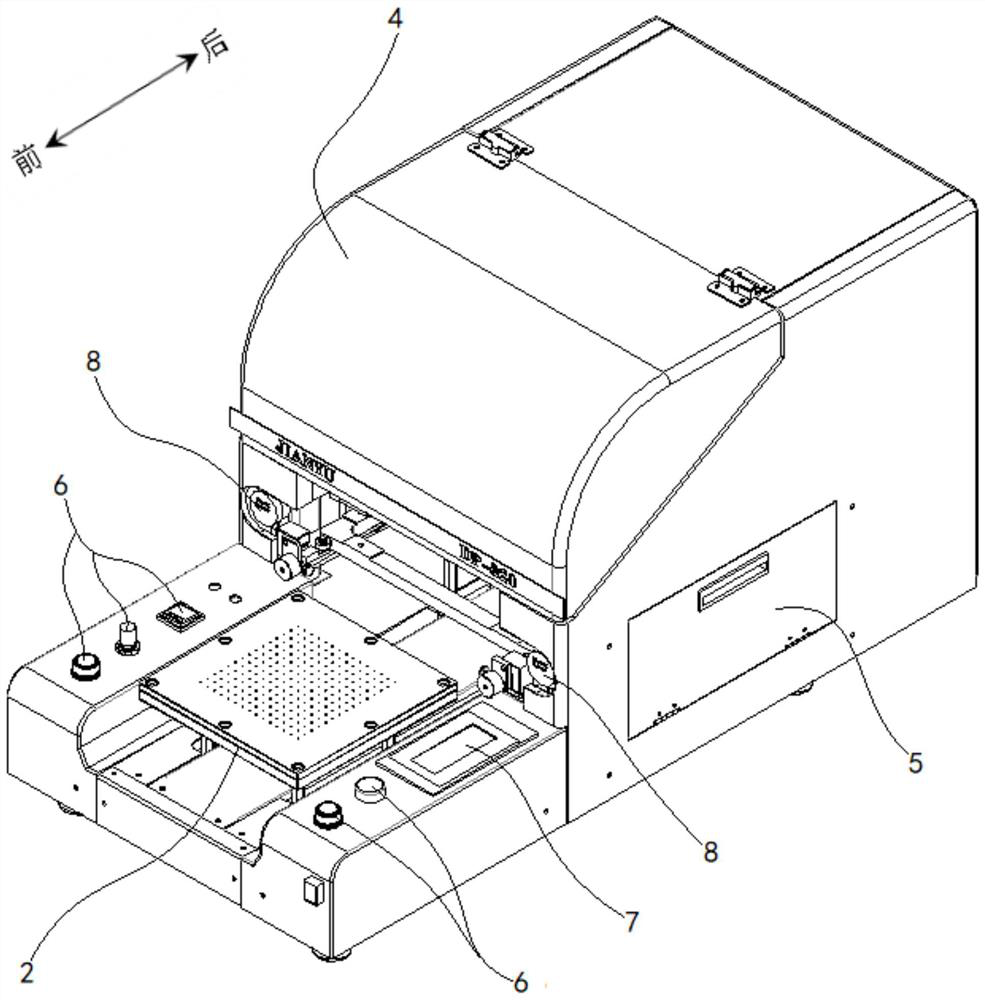

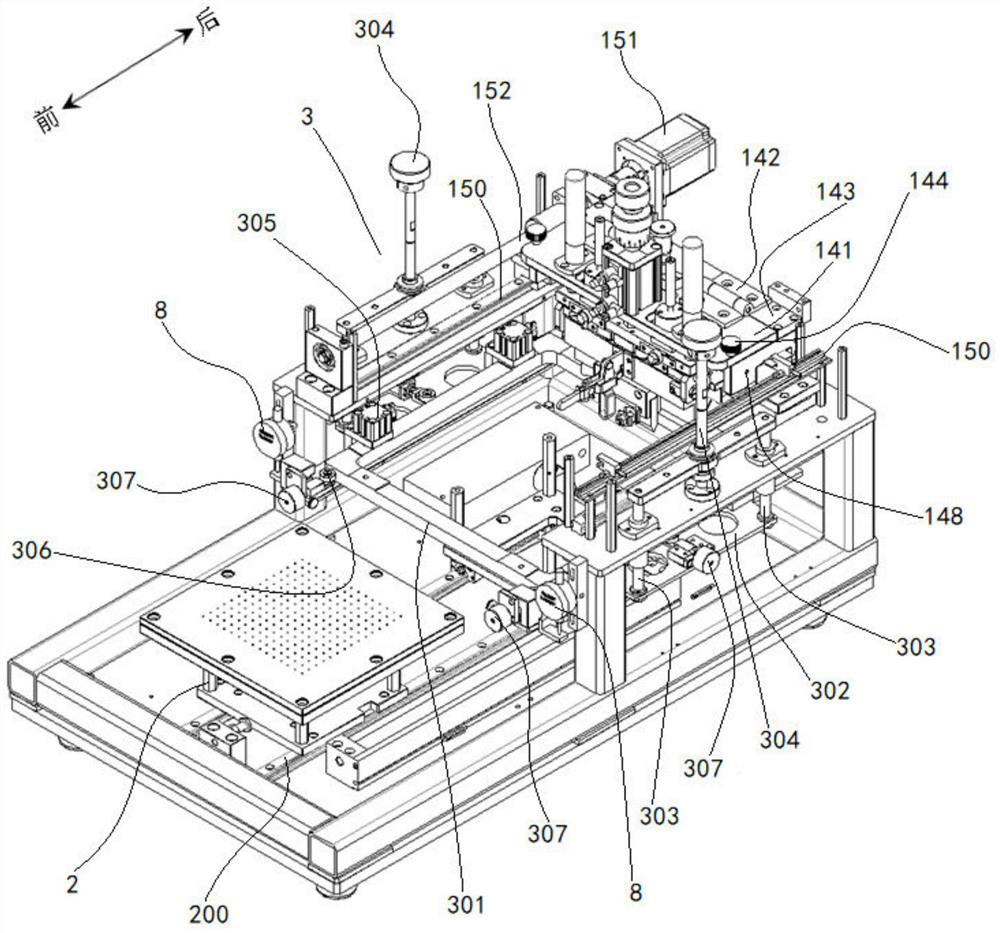

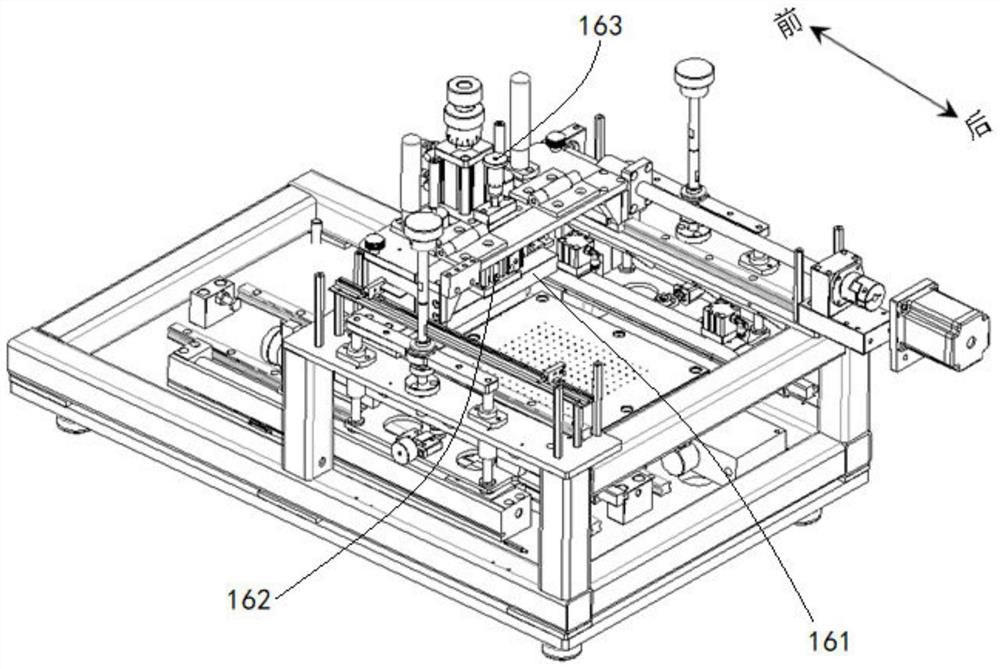

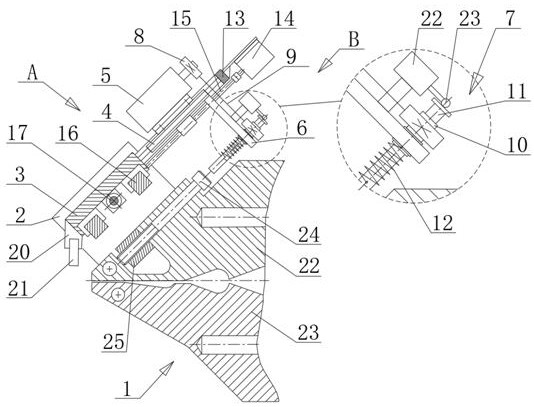

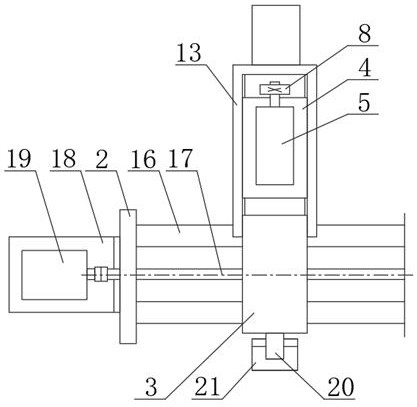

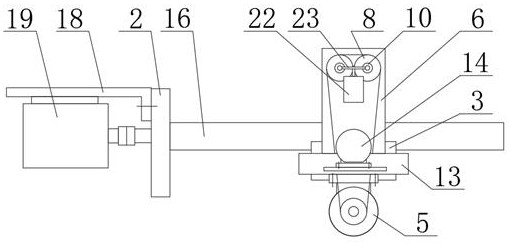

Table board type silk-screen printing device

The invention discloses a table board type silk-screen printing device. The device comprises a printing machine head, a printing table and a screen printing plate positioning mechanism. According to the device, all the components precisely and accurately cooperate, so that the lifting height adjustment, left-right height balance adjustment and front-back pitching posture adjustment of a scraper and an ink return cutter are achieved, adjusting is accurate, locking is firm, and working is stable; an additional box body provides reliable support for a support plane and forms a reliable adsorptionpositioning effect on a printing stock; the height, the left-right position and the front-back position of a screen printing plate are accurately, stably and reliably adjusted; the device is high inintegration degree, compact in overall structure, small in size and precise in cooperation, and the purpose of effectively using a table board is achieved; and meanwhile, all the working mechanisms are conveniently, accurately and reliably connected and locked so that the stable printing precision can be kept all the time, and the printing quality is conveniently and effectively improved.

Owner:CHANGSHA JIANYU SCREEN PRINTING MACHINERY

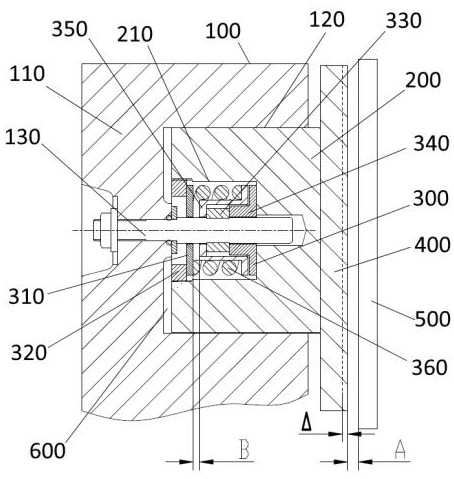

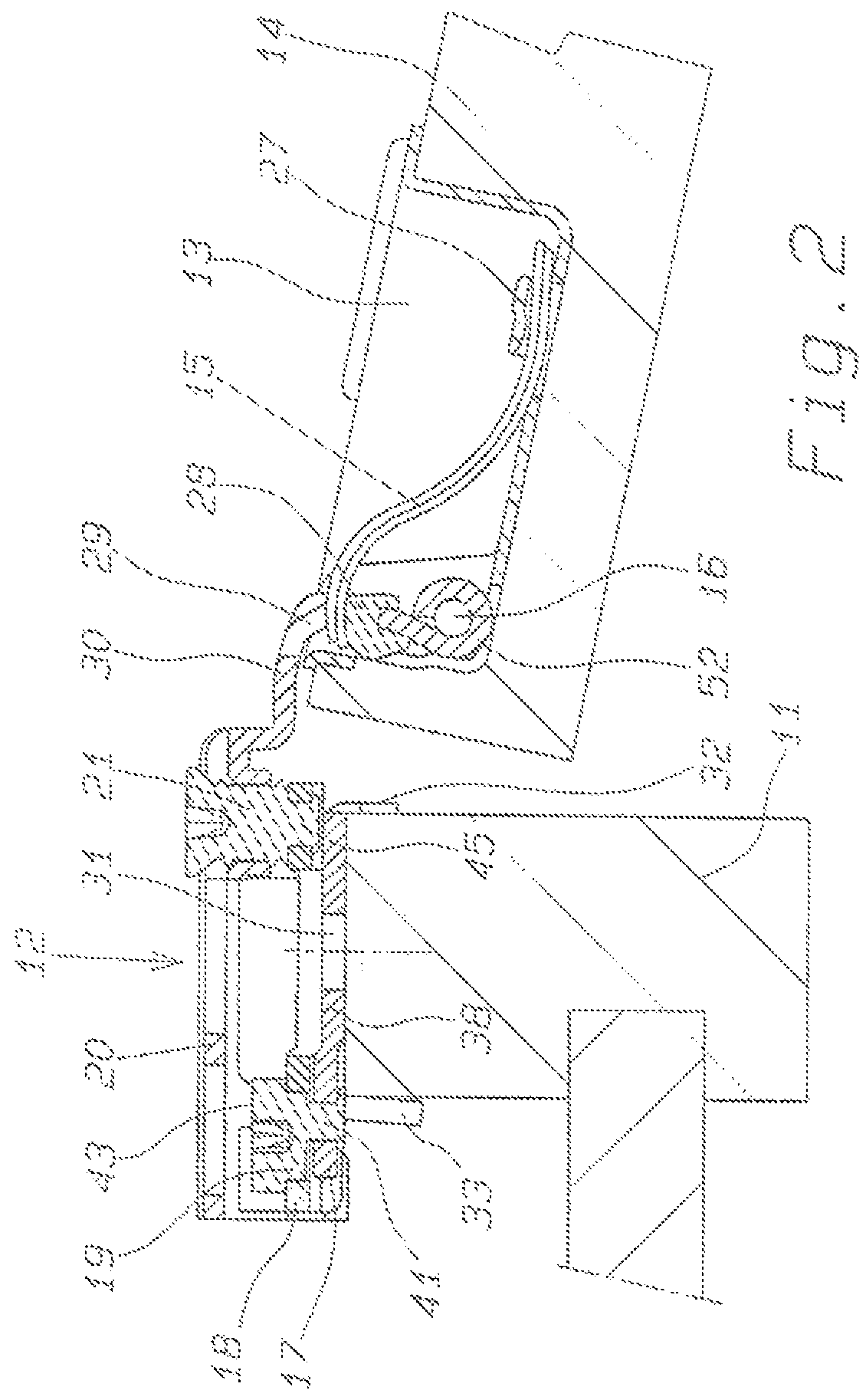

Hinge for pieces of furniture with a frame

ActiveUS9376847B2Accurate and reliable adjustmentIncrease resistanceWing accessoriesHingesPerpendicular directionMechanical engineering

The hinge for mounting a door on a piece of furniture provided with a front frame comprises a base plate fixable to the front frame of the piece of furniture, an intermediate plate slidably connected to the base plate and movable by an adjusting cam, a hinge arm connected to the intermediate plate swingably according to a transversal axis and mobile by means of an adjusting screw; the intermediate plate, at a rear end thereof, exhibits side wings having hinging projections which project on opposite sides according to the transversal axis so as to engage rotatably in rear side holes of the hinge arm. The base plate exhibits retaining side parts for the intermediate plate, conformed and arranged such as to retain the side edges of the intermediate plate in a perpendicular direction to the longitudinal extension plane of the base plate.

Owner:ARTURO SALICE

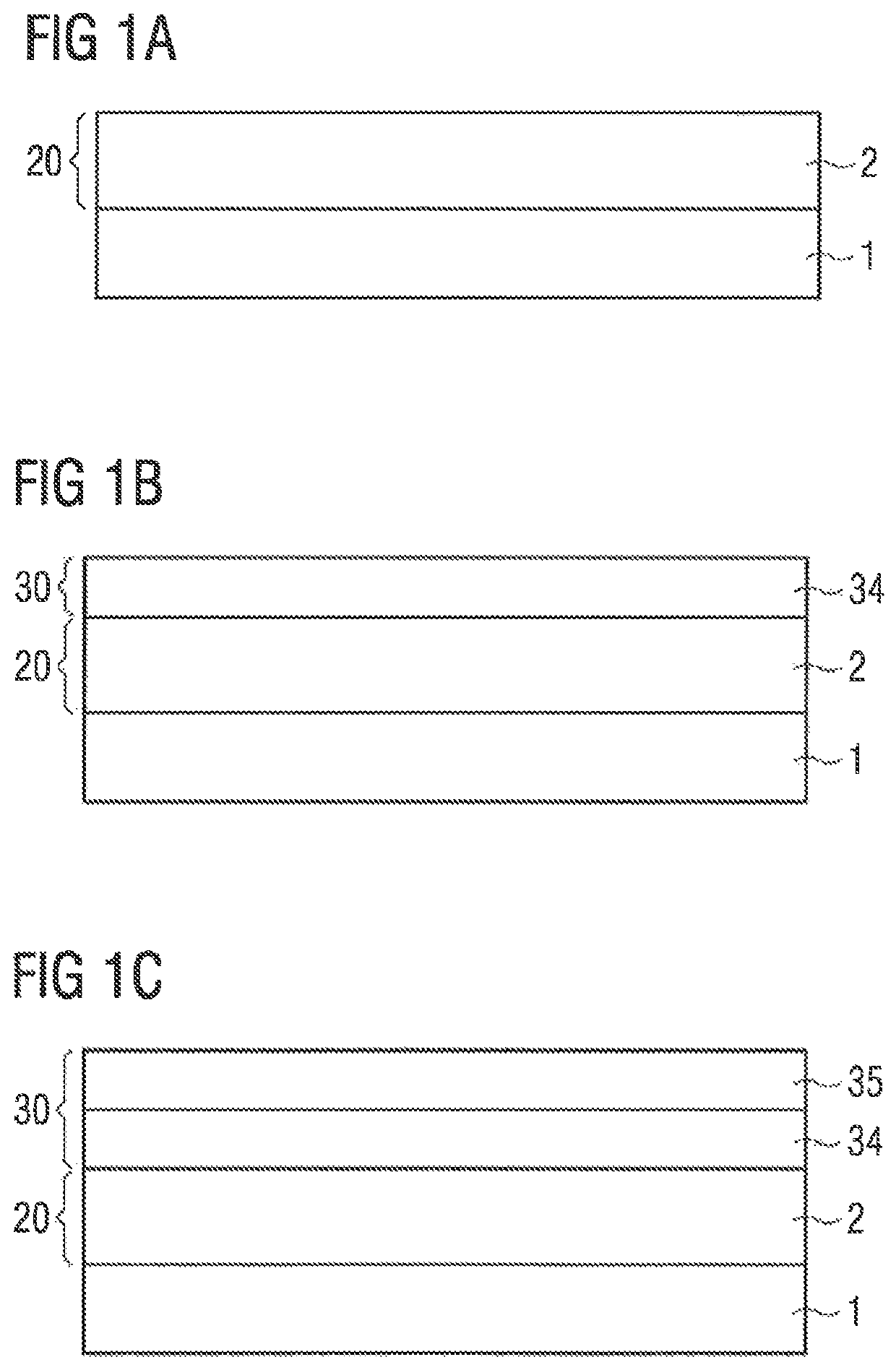

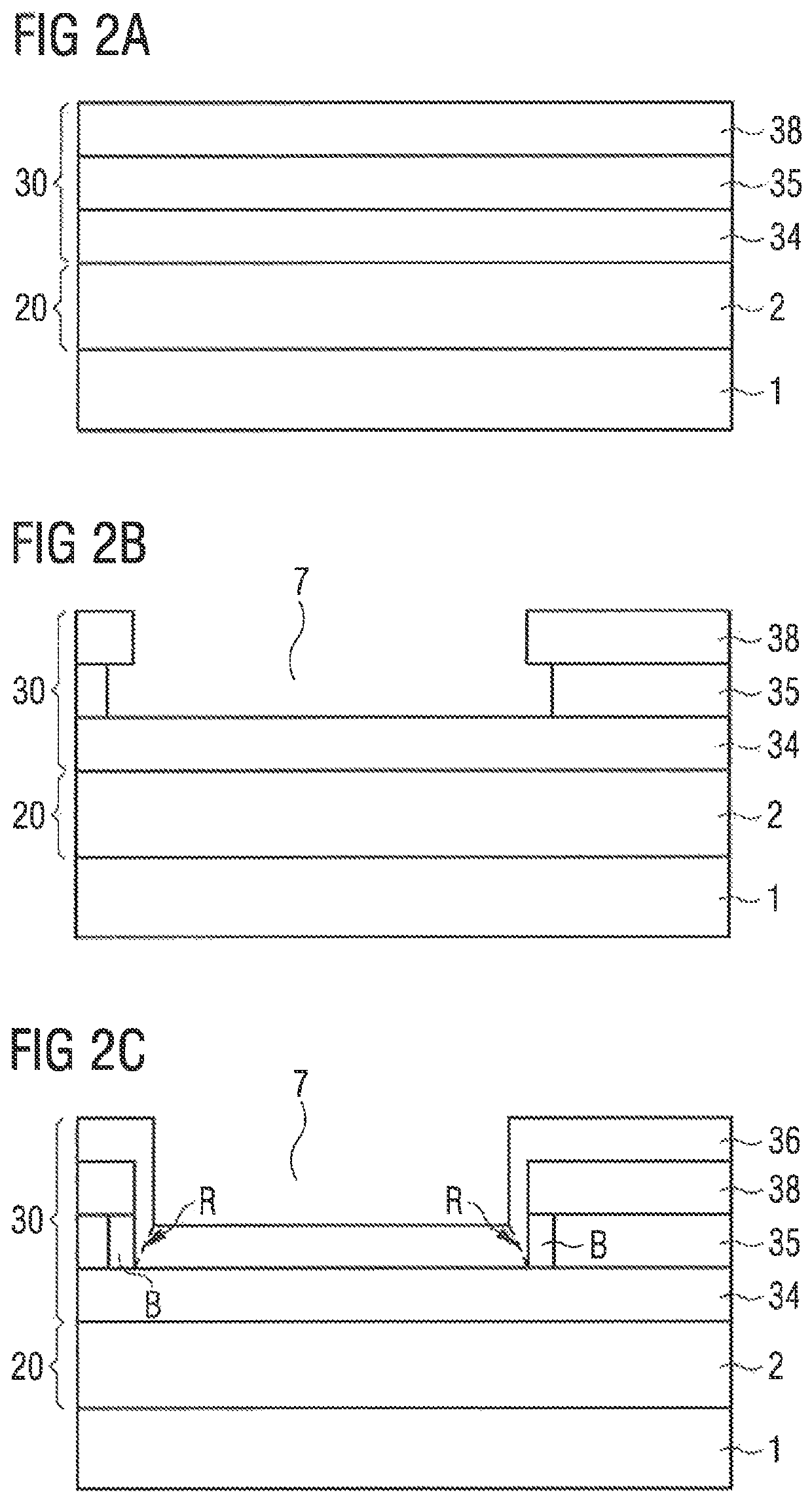

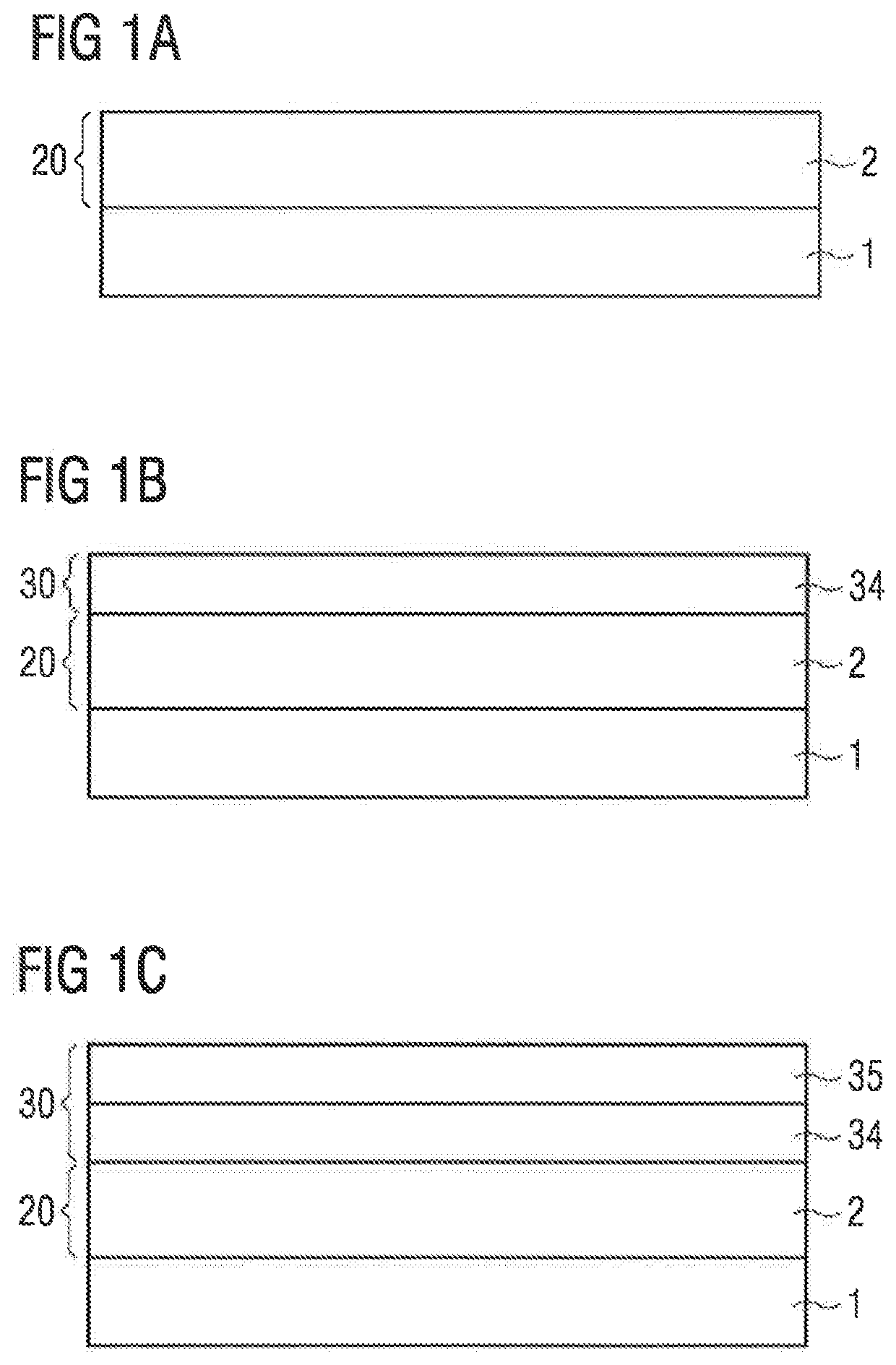

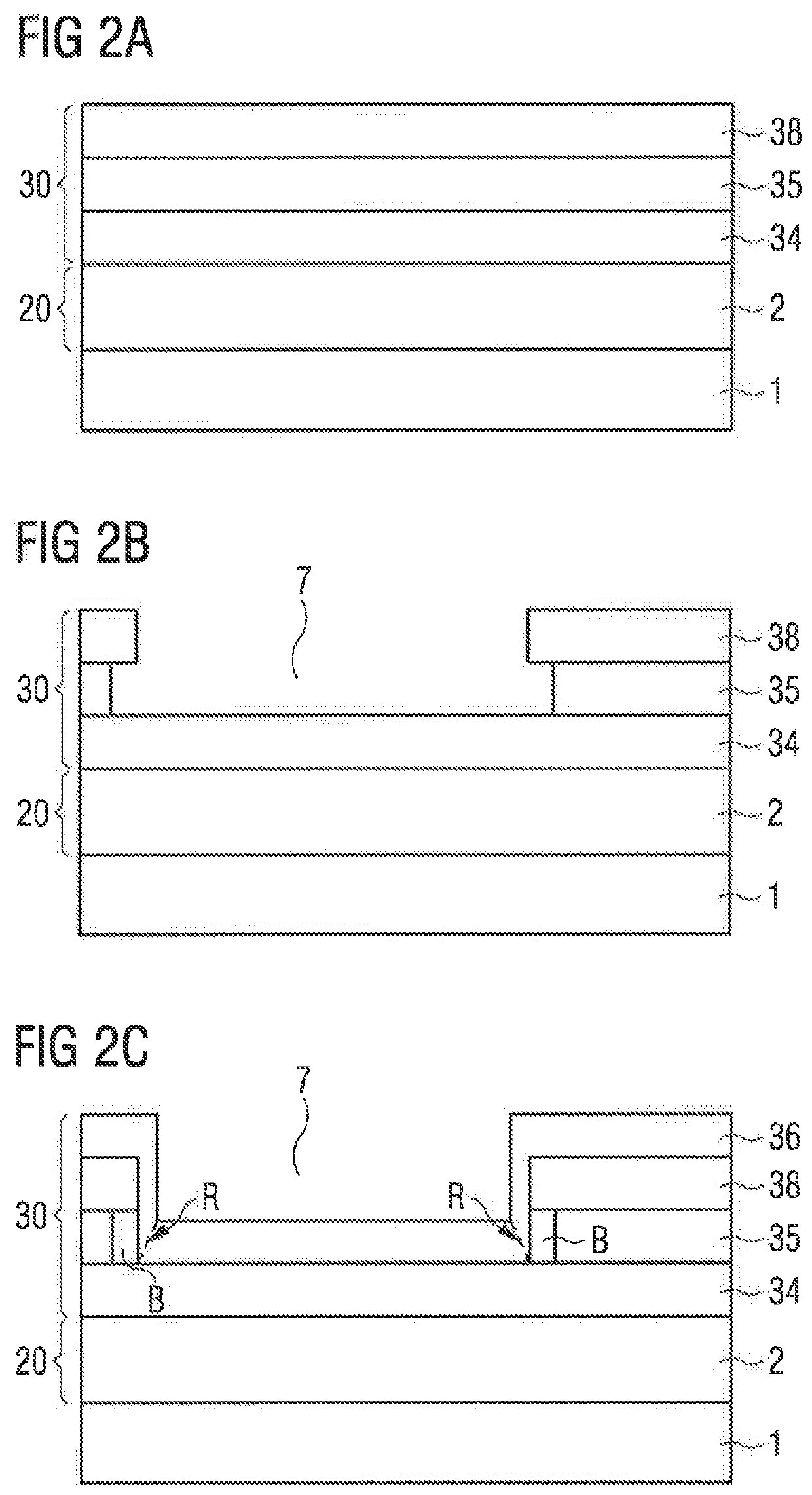

Method of separating a component using predetermined breaking position and a component obatined by such method

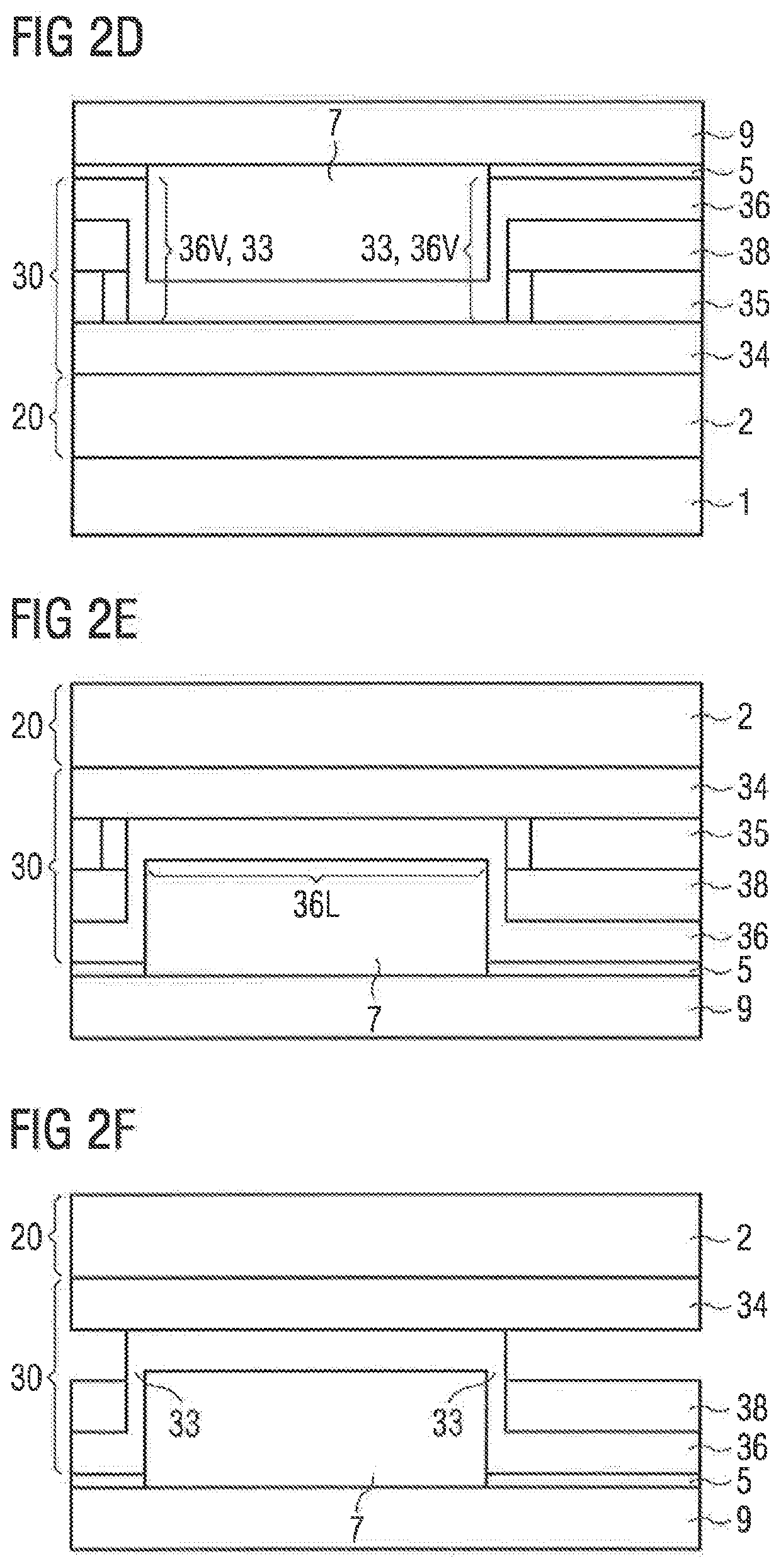

ActiveUS11088297B2Reliable removalAccurate and reliable adjustmentSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMechanical engineering

Owner:OSRAM OLED

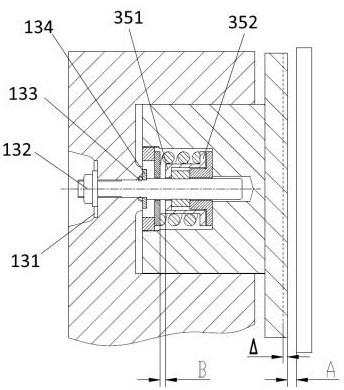

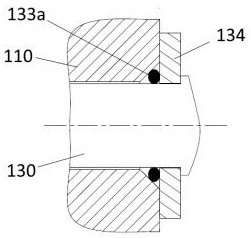

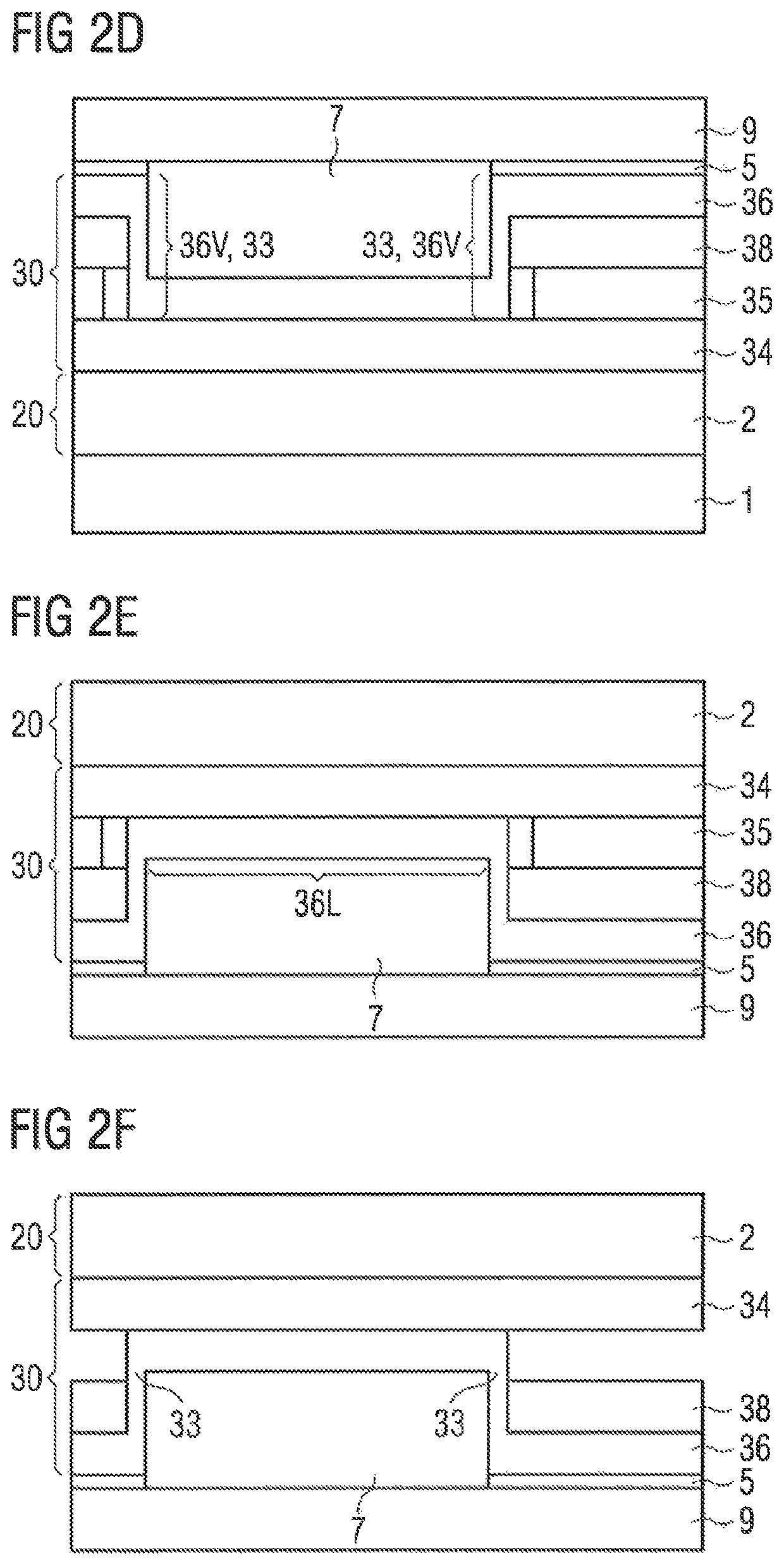

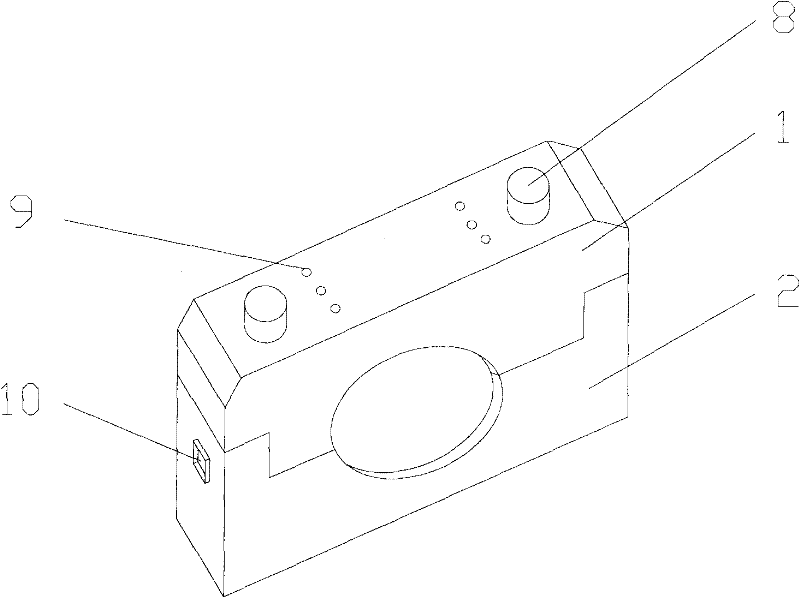

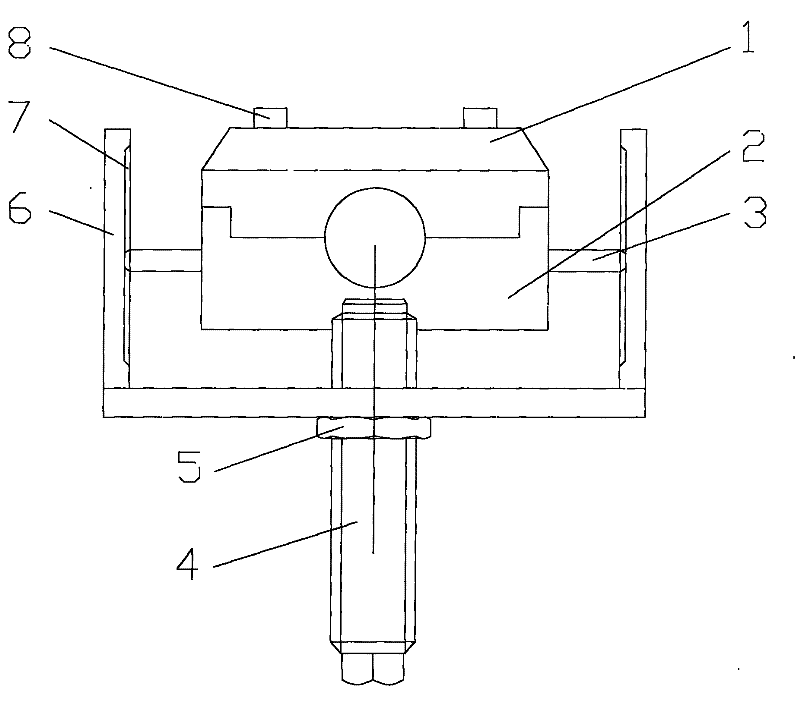

Detachable adjustable bearing pedestal

InactiveCN102454709ASimple structureImprove the fixing strengthBearing unit rigid supportAgricultural engineering

Owner:常熟市宏达印染机械有限公司

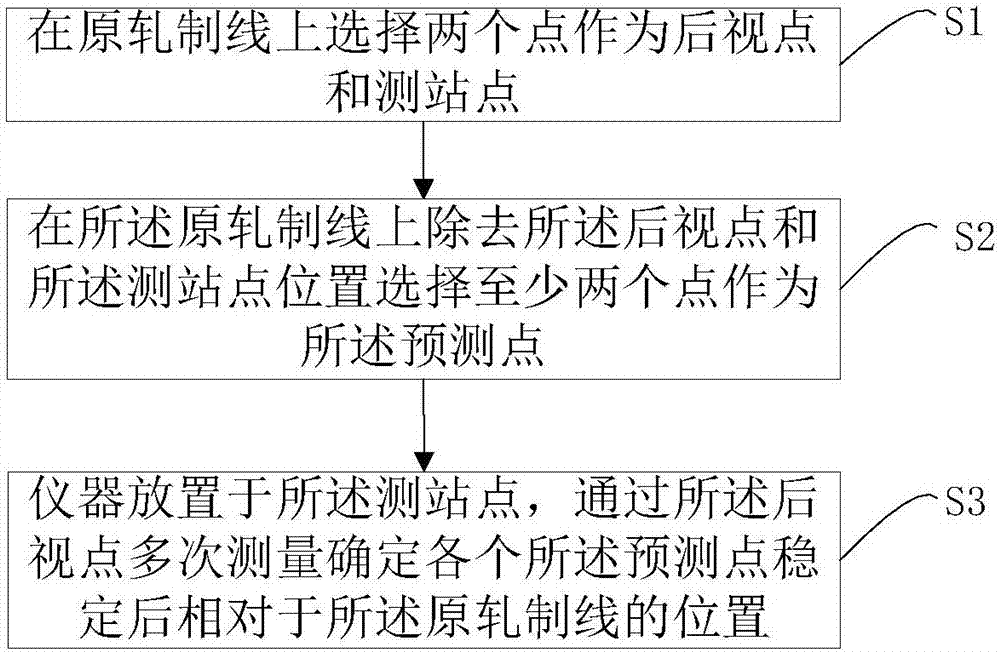

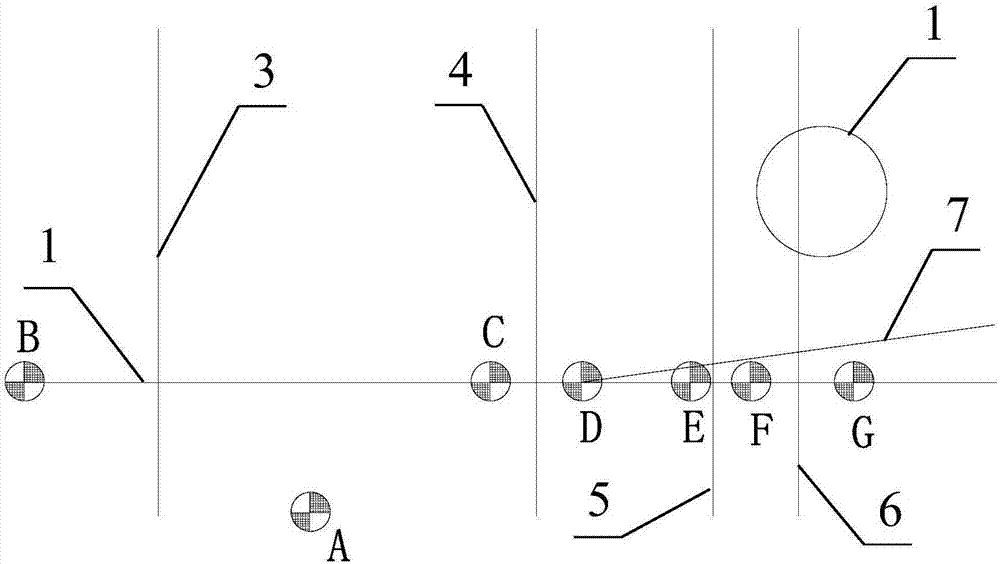

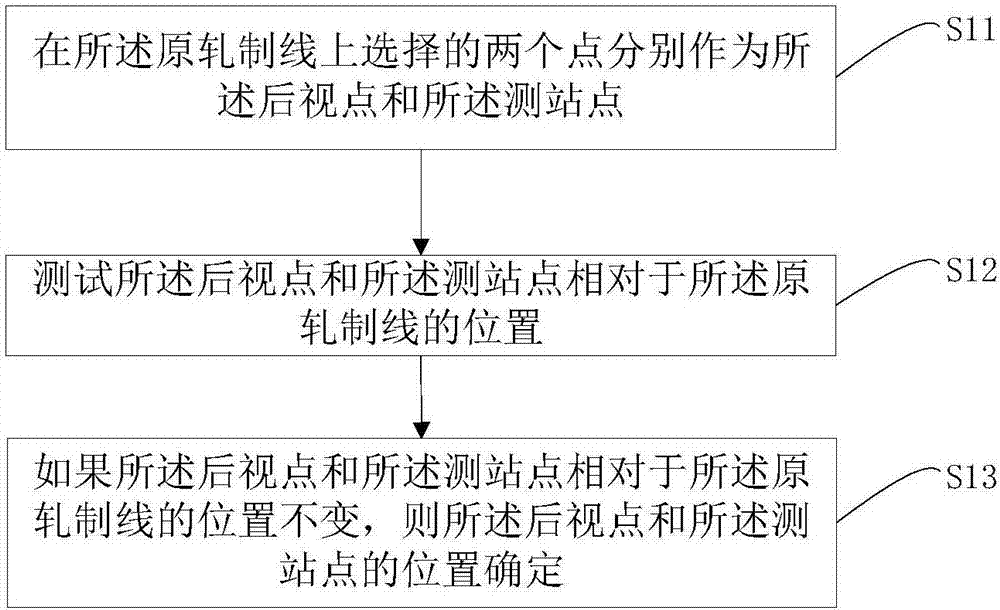

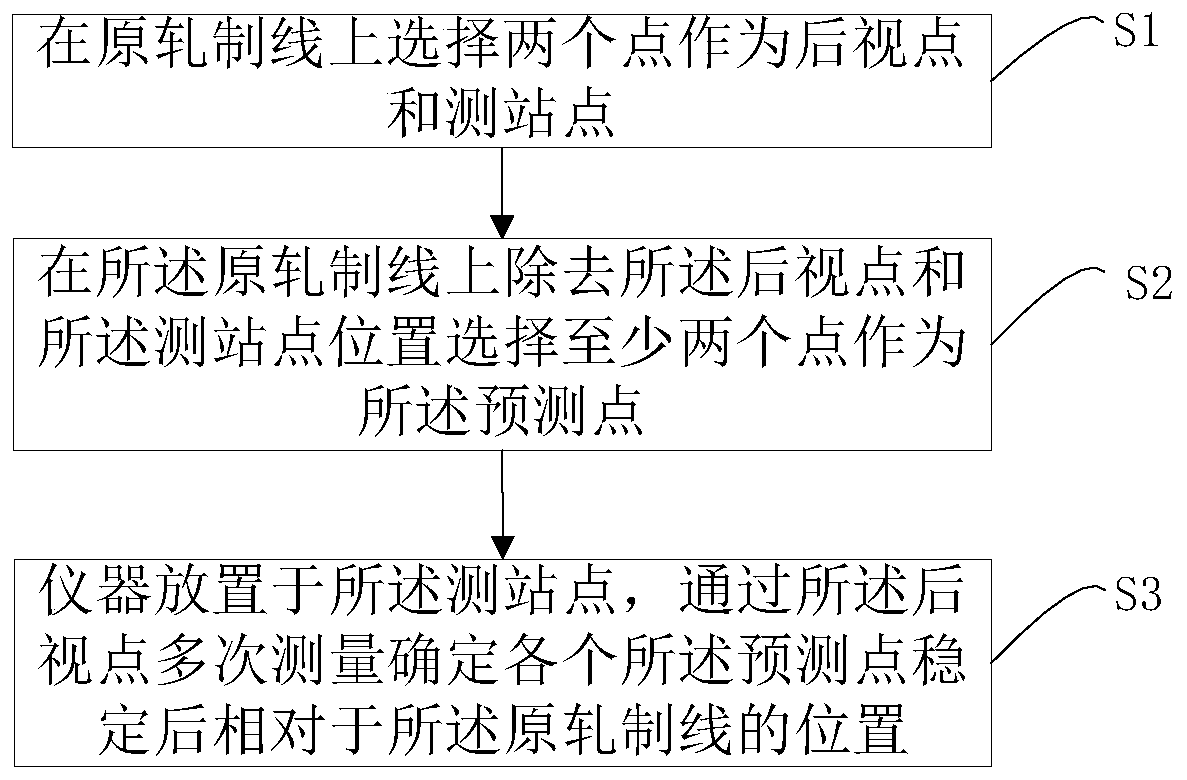

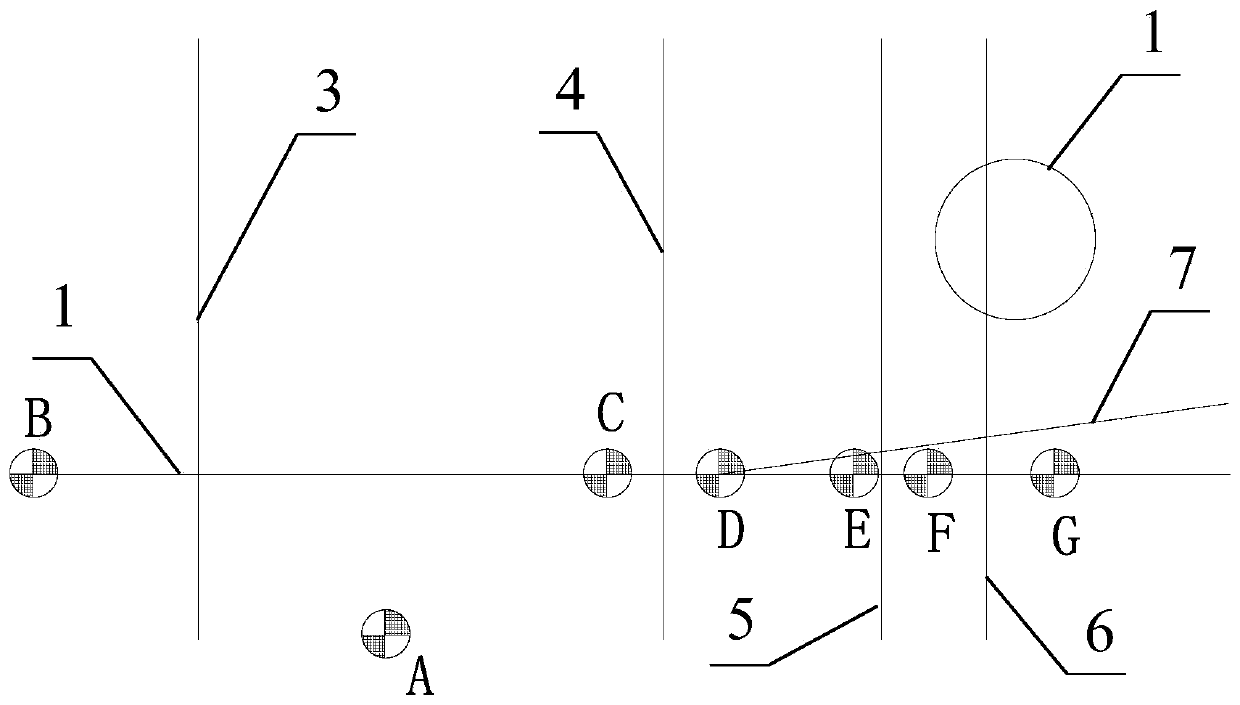

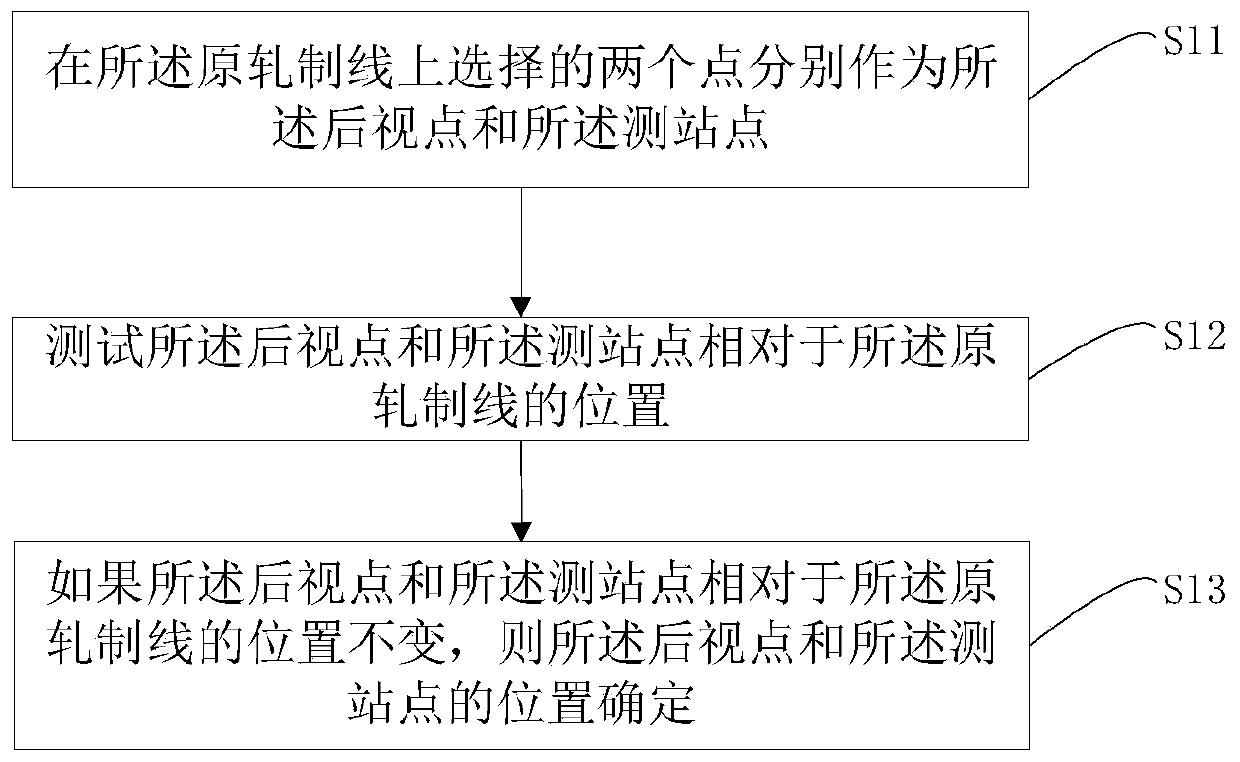

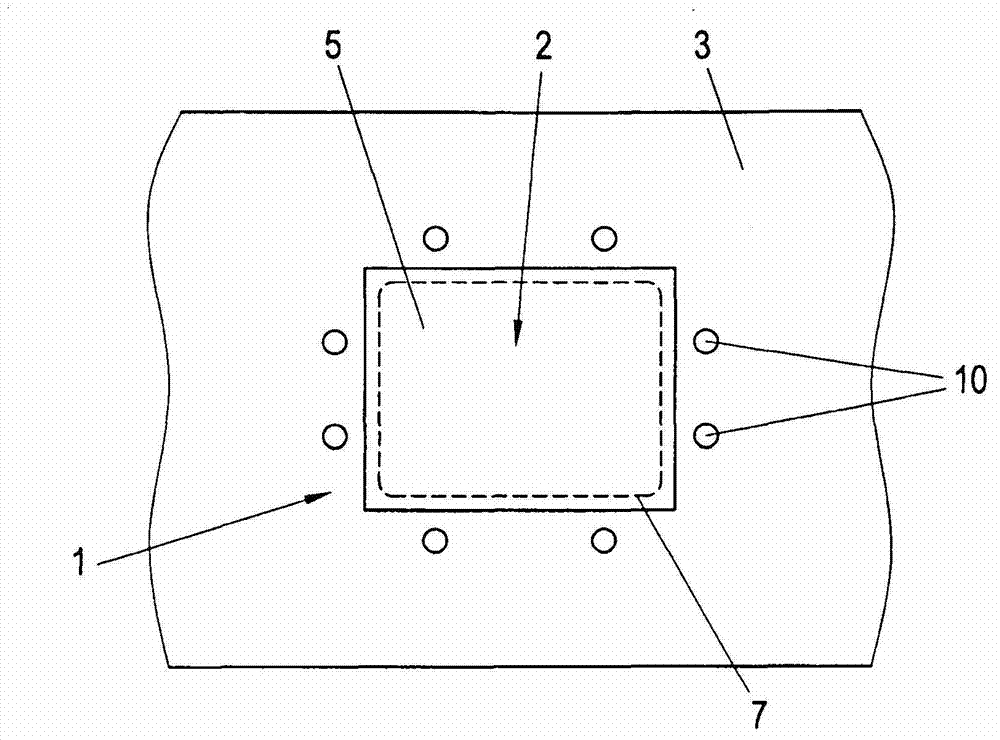

Basic tracking measurement method for rolling line

The invention provides a basic tracking measurement method for rolling lines. The basic tracking measurement method comprises the following steps: selecting two points as a rear view point and a station point on an original rolling line; selecting at least two points except the rear view point and the station point on the original rolling line as prediction points; placing an instrument at the station point, and implementing multiple times of measurement at the rear view point, thereby confirming positions of different prediction points relative to the original rolling line after being stabilized. According to the basic tracking measurement method for rolling lines, the prediction points are directly tested and compared by using the instrument at the station point, then the position of the prediction point relative to the original rolling line is confirmed, basic displacement of the rolling line is tracked and tested, the testing method is simple, external influence factors in the testing process are reduced, and errors caused by different station points are reduced as the station point of the instrument does not need to be changed for multiple times, and therefore, the method is precise and reliable in adjustment in the adjustment process, and the precision of basic measurement of the rolling line is improved.

Owner:CHINA MCC20 GRP CORP

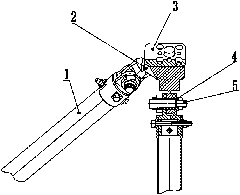

Device for automatically adjusting die lip gap of extrusion die of waterproof plate production line

PendingCN112643994AGuaranteed processing requirementsHigh degree of automationFlat articlesEngineeringManual handling

The invention discloses a device for automatically adjusting a die lip gap of an extrusion die of a waterproof plate production line. The device comprises a guide rail frame, a gap adjusting mechanical arm and a distance measuring device, wherein the guide rail frame comprises two supporting seats arranged on a die, a transmission guide rail arranged between the supporting seats, and a driving mechanism arranged on one supporting seat and used for driving the transmission guide rail to act; the gap adjusting mechanical arm comprises a connecting seat matched with the transmission guide rail, a height adaptive adjusting mechanism arranged on the connecting seat, and a screw rotating adjusting mechanism arranged on the height adaptive adjusting mechanism; and the distance measuring device is arranged on the connecting seat and is used for measuring the die lip gap. According to the device for for automatically adjusting the die lip gap of the extrusion die of the waterproof plate production line provided by the invention, the size of the die head discharge port gap can be automatically adjusted, so that manual operation is not needed, the adjusting efficiency is high, and the production cost can be saved.

Owner:西部铁建工程材料科技有限公司

Combined transshipment glass transport cart with compression device

ActiveCN103693088AImprove stabilityAccurate and reliable adjustmentHand carts with multiple axesCartSteel plates

The invention discloses a combined transshipment glass transport cart with a compression device, which belongs to the technical field of the glass production. The combined transshipment glass transport cart comprises a universal wheel, a fixed support and an assembling support, wherein the assembling support is connected with the fixed support in a sliding manner; the fixed support comprises a soleplate, a supporting plate and guide columns; the assembling support comprises a lead screw support, a lead screw, bushings, a compression device, a base and a back plate, the back plate is made of a rectangular steel plate, and the bottom end of the back plate is hinged with the base; the bottom end of the lead screw is hinged with the back plate; the bushings are connected with the guide columns in a sliding manner; the compression device is fixed on the other end of the base and comprises a U-shaped plate, a pressing plate and a mounting sleeve, and the mounting sleeve is a square steel barrel structure; the pressing plate comprises a rectangular connecting plate and a pressing block. The combined transshipment glass transport cart is ingenious in structural design and low in production cost, the manual binding is not needed, the labor is saved, the device cost is reduced, the working efficiency is improved, simplicity in operation and operation can be realized, and the popularization is favored.

Owner:TONGXIANG HUIFENG ELECTRICAL APPLIANCE DIE CASTING PLANT

Method for Producing a Component and Component for an Electronic Device

ActiveUS20190393376A1Reliable removalAccurate and reliable adjustmentSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringBiomedical engineering

Owner:OSRAM OLED

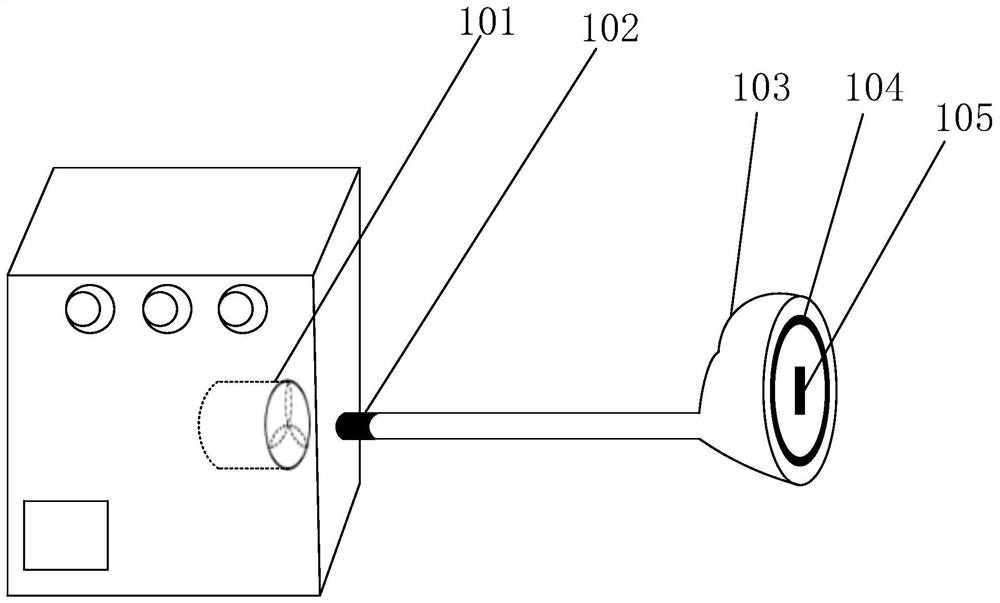

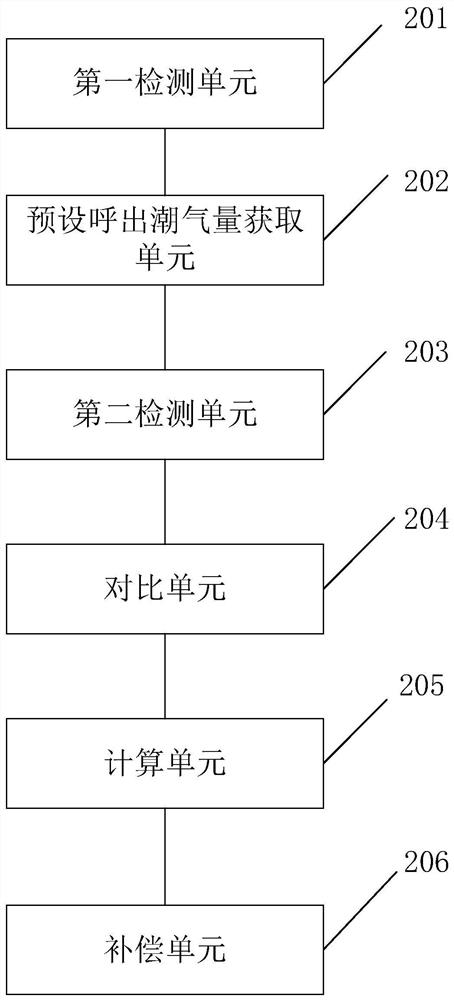

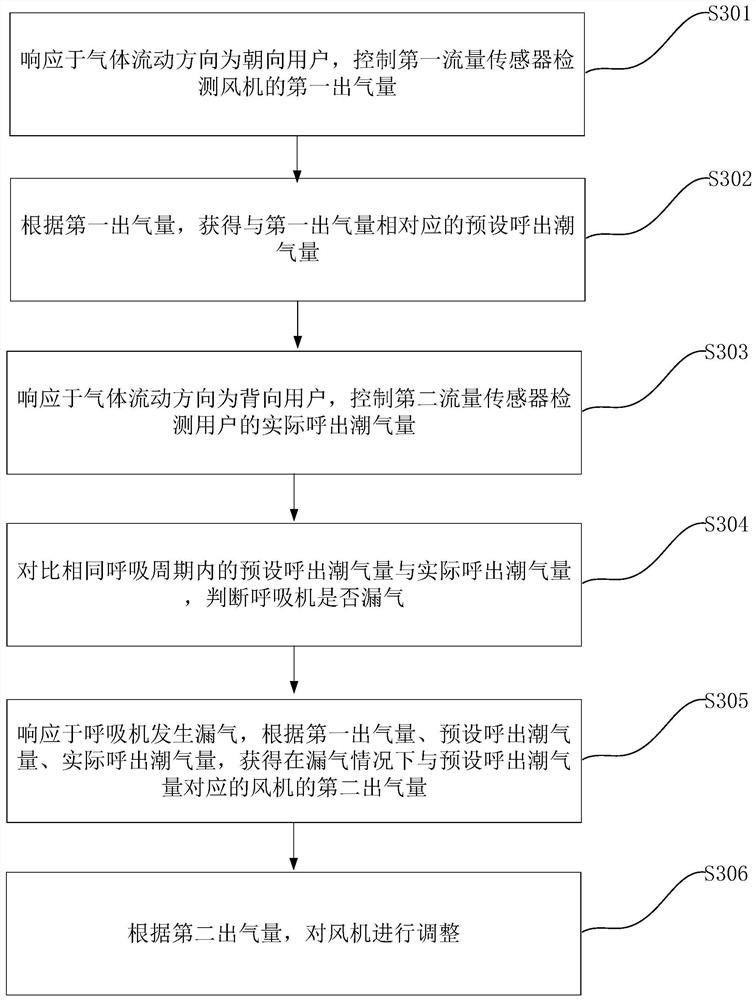

Medical breathing machine for intensive care medicine department

PendingCN113769212ANot susceptible to external influencesImprove accuracyRespiratory masksMedical devicesCritical care medicine specialtyRespiratory mask

The invention discloses a medical breathing machine for the intensive care medicine department. The medical breathing machine comprises a breathing machine body, a first flow sensor, a second flow sensor and a gas flow direction sensor, wherein the breathing machine body at least comprises a draught fan; the first flow sensor is arranged at the air outlet of the draught fan; the draught fan is connected with a breathing mask through a first pipeline; the second flow sensor and the gas flow direction sensor are arranged on the inner side of the breathing mask; the first flow sensor is used for detecting the air output of the draught fan; the second flow sensor is used for detecting the tidal volume exhaled by the user; the gas flow direction sensor is used for detecting a gas flow direction in the breathing mask; and the breathing machine further comprises a main controller, wherein the main controller is used for controlling the first flow sensor to obtain first air output and controlling the second flow sensor to obtain an actual exhaled tidal volume, whether the breathing machine leaks air or not is judged according to the first air output and the actual expired tidal volume, and air leakage compensation is conducted. According to the medical breathing machine for the intensive care medicine department, air leakage detection and compensation can be effectively carried out by aiming at the breathing machine.

Owner:周小平

Rolling Line Foundation Tracking Measurement Method

ActiveCN107084700BHigh precisionReduce mistakesOptical rangefindersControl engineeringMechanical engineering

The invention provides a basic tracking measurement method for rolling lines. The basic tracking measurement method comprises the following steps: selecting two points as a rear view point and a station point on an original rolling line; selecting at least two points except the rear view point and the station point on the original rolling line as prediction points; placing an instrument at the station point, and implementing multiple times of measurement at the rear view point, thereby confirming positions of different prediction points relative to the original rolling line after being stabilized. According to the basic tracking measurement method for rolling lines, the prediction points are directly tested and compared by using the instrument at the station point, then the position of the prediction point relative to the original rolling line is confirmed, basic displacement of the rolling line is tracked and tested, the testing method is simple, external influence factors in the testing process are reduced, and errors caused by different station points are reduced as the station point of the instrument does not need to be changed for multiple times, and therefore, the method is precise and reliable in adjustment in the adjustment process, and the precision of basic measurement of the rolling line is improved.

Owner:CHINA MCC20 GRP CORP

Decompression unit

ActiveCN103167984AReliable activationEasy to manufactureFuselage bulkheadsAircraft floorsDifferential pressureMechanical engineering

The invention relates to a decompression unit (1) for use in a decompression opening (2) of a wall element (3) of an aircraft, having a panel (5) which can be mounted via a frame (4) in or over the decompression opening (2) which panel (5) can be moved out of the frame (4) at a predetermined differential pressure (delta p) in order to open the decompression opening (2). In order to form a decompression unit (1) of as simple a design as possible and with an optimum response behaviour, provision is made for the panel (5) to be formed by at least one hardened prepreg layer (6) with at least one separating joint (7) which is filled with cured resin as a weak point, which separating joint (7) breaks when the predetermined differential pressure (delta p) is exceeded.

Owner:FACC

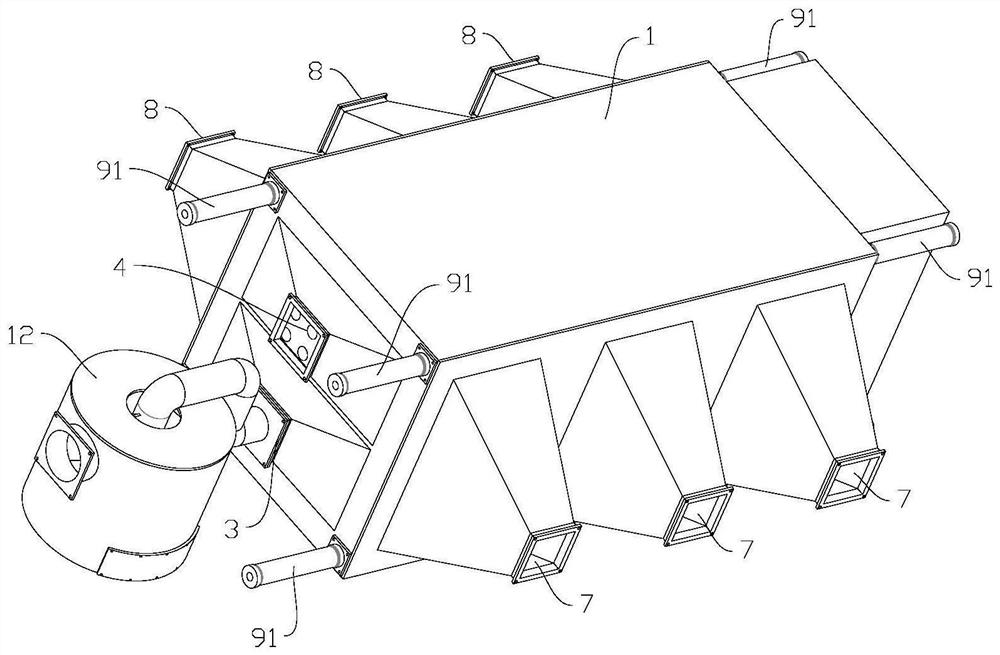

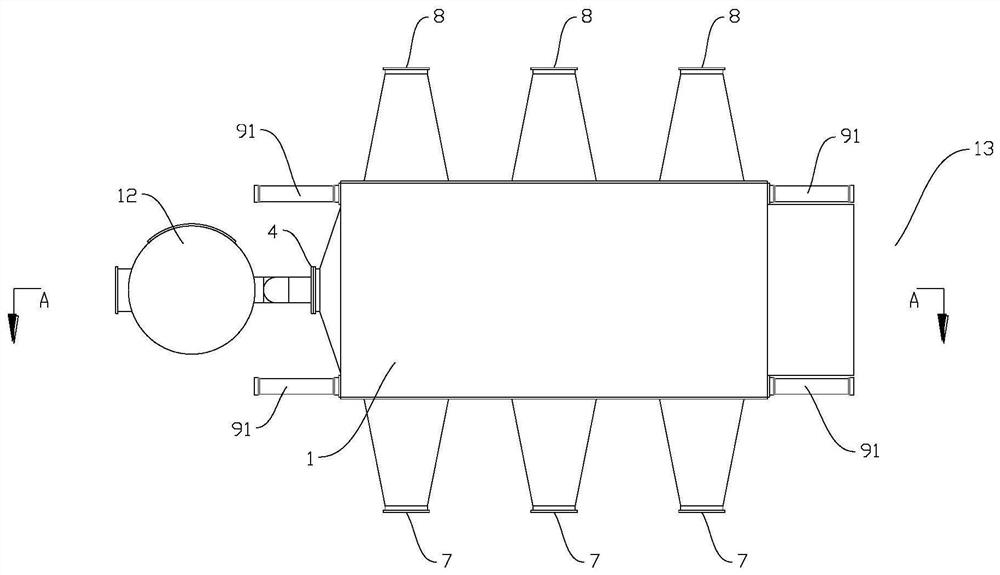

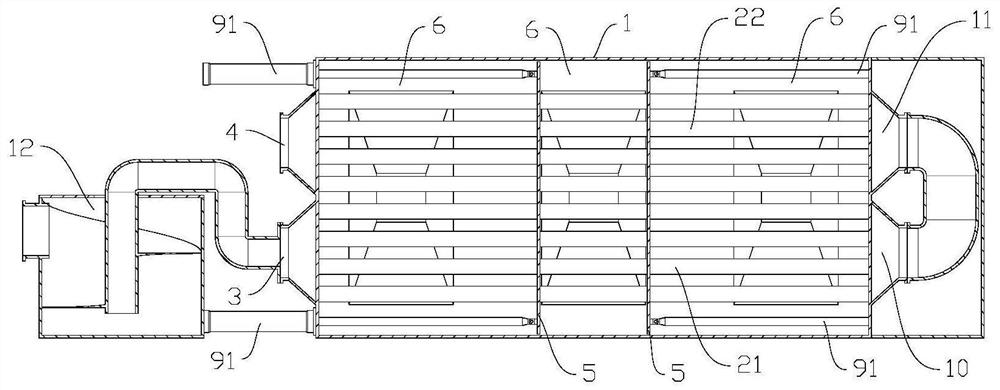

An adjustable tube-bundle heat exchanger, drying tower heat exchange adjustment system and method

ActiveCN111473517BImprove heat transfer effectAdjust heat transfer capacityDrying gas arrangementsAir heatersEngineeringHot blast

The invention discloses an adjustable tube-bundle heat exchanger, which comprises a casing and a tube bundle arranged in the casing along the axial direction, and the outside of the casing is respectively provided with a smoke inlet communicating with the input end of the tube bundle, The smoke outlet communicated with the output end of the tube bundle, and several partitions are arranged in the casing, the tube bundle passes through each partition, and each partition can slide along the axial direction of the casing , several partitions divide the interior of the housing into several heat exchange chambers, each of the two opposite sides of the heat exchange chambers is respectively provided with an air inlet and an air outlet, and the housing is also provided with a useful An adjustment device for driving each partition to slide along the axial direction of the housing. The invention also discloses a drying tower heat exchange adjustment system and method using the adjustable tube bundle heat exchanger. The invention adjusts the temperature of the output hot air by adjusting the size of each heat exchange chamber, and achieves the purpose of adjusting the temperature and humidity of the grain in each drying section of the drying tower.

Owner:吉林市安瑞克能源科技开发有限公司 +1

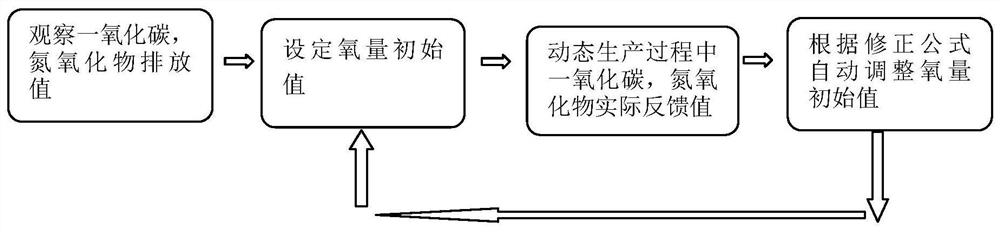

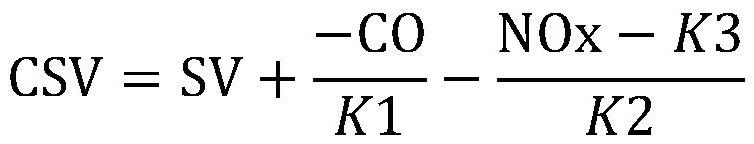

Self-adaptive control method and system for oxygen content of garbage incinerator

PendingCN114198759AReduce Exceeding EmissionsHigh degree of automationIncinerator apparatusNitrogen oxidesFlue gas

The invention discloses a self-adaptive control method and system for the oxygen content of a garbage incinerator, belongs to the technical field of garbage incinerators, and is used for solving the technical problems that the oxygen content of an existing garbage incinerator is not accurately adjusted, and the like. The method comprises the steps that S01, the content of carbon monoxide and the content of nitric oxide in flue gas discharged by the garbage incinerator are obtained; and S02, the oxygen content of the garbage incinerator is adjusted according to the content of the carbon monoxide and the content of the nitric oxide so as to adapt to different fuel working conditions. The device has the advantages of high automation degree, high oxygen amount adjusting precision and the like.

Owner:浦湘生物能源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com