Pressure control and feedback system used for adjustable foam support equipment

A feedback system, pressure control technology, applied in the direction of liquid-filled cushions, etc., can solve problems that do not allow users to easily and accurately achieve comfort and support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

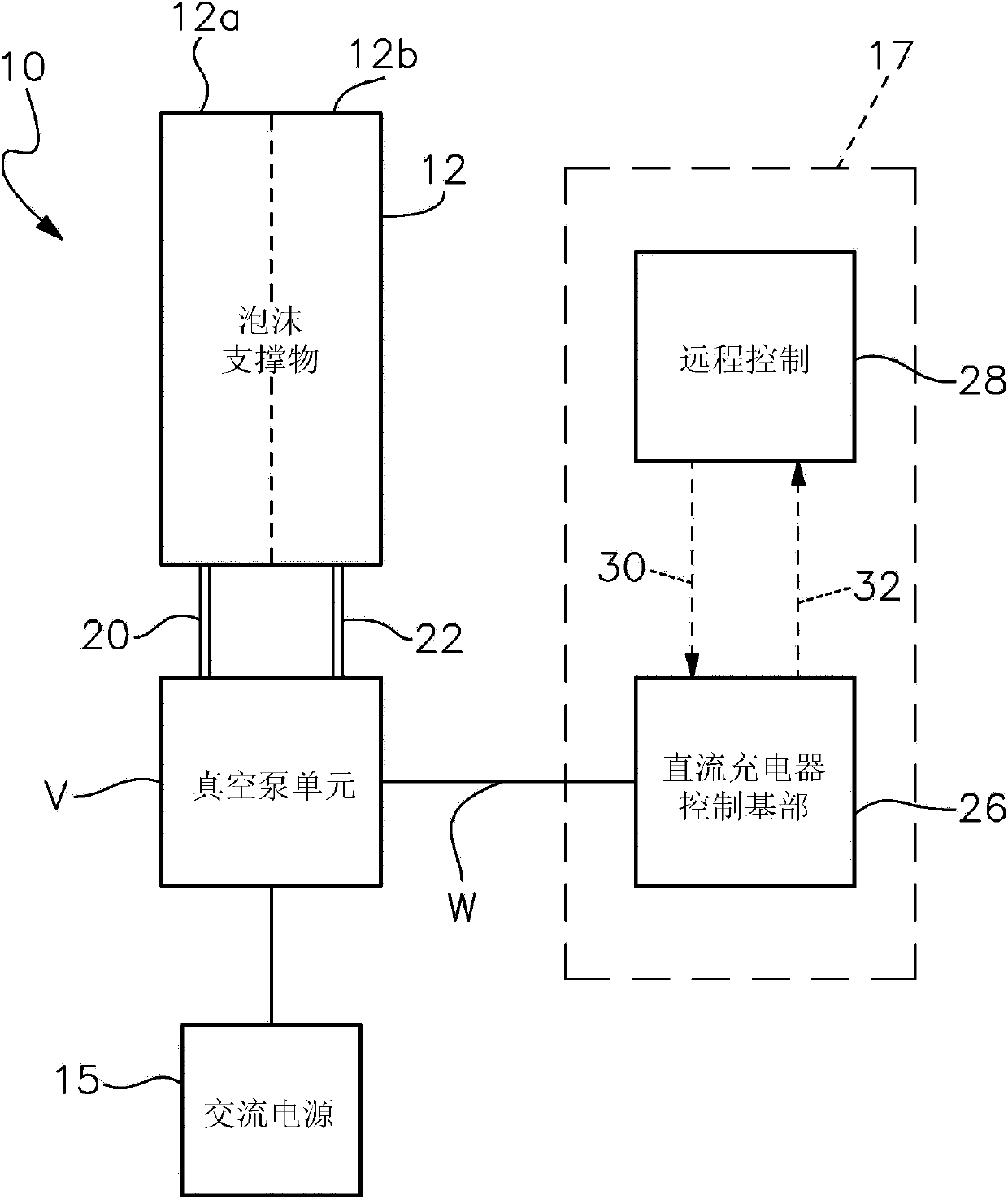

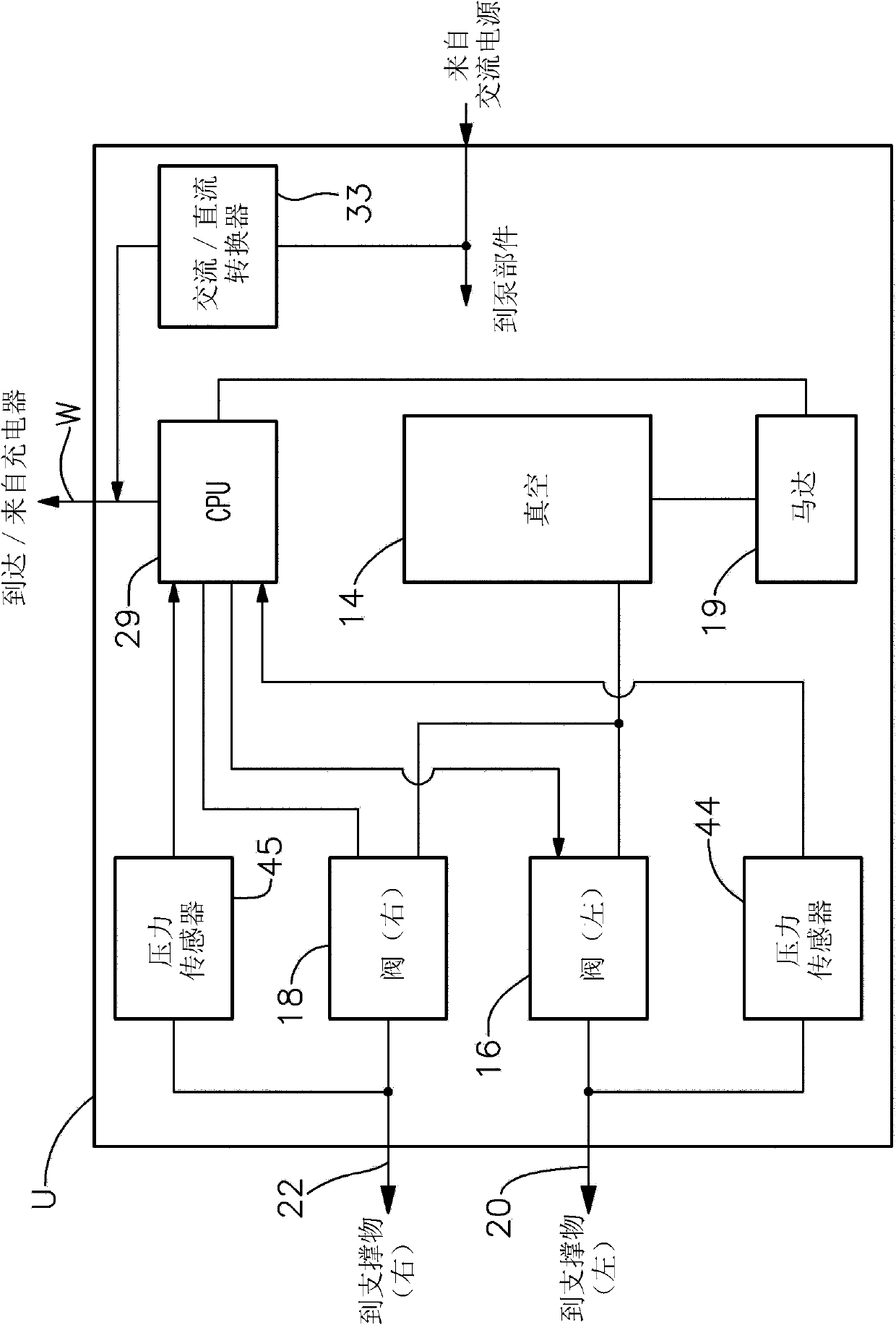

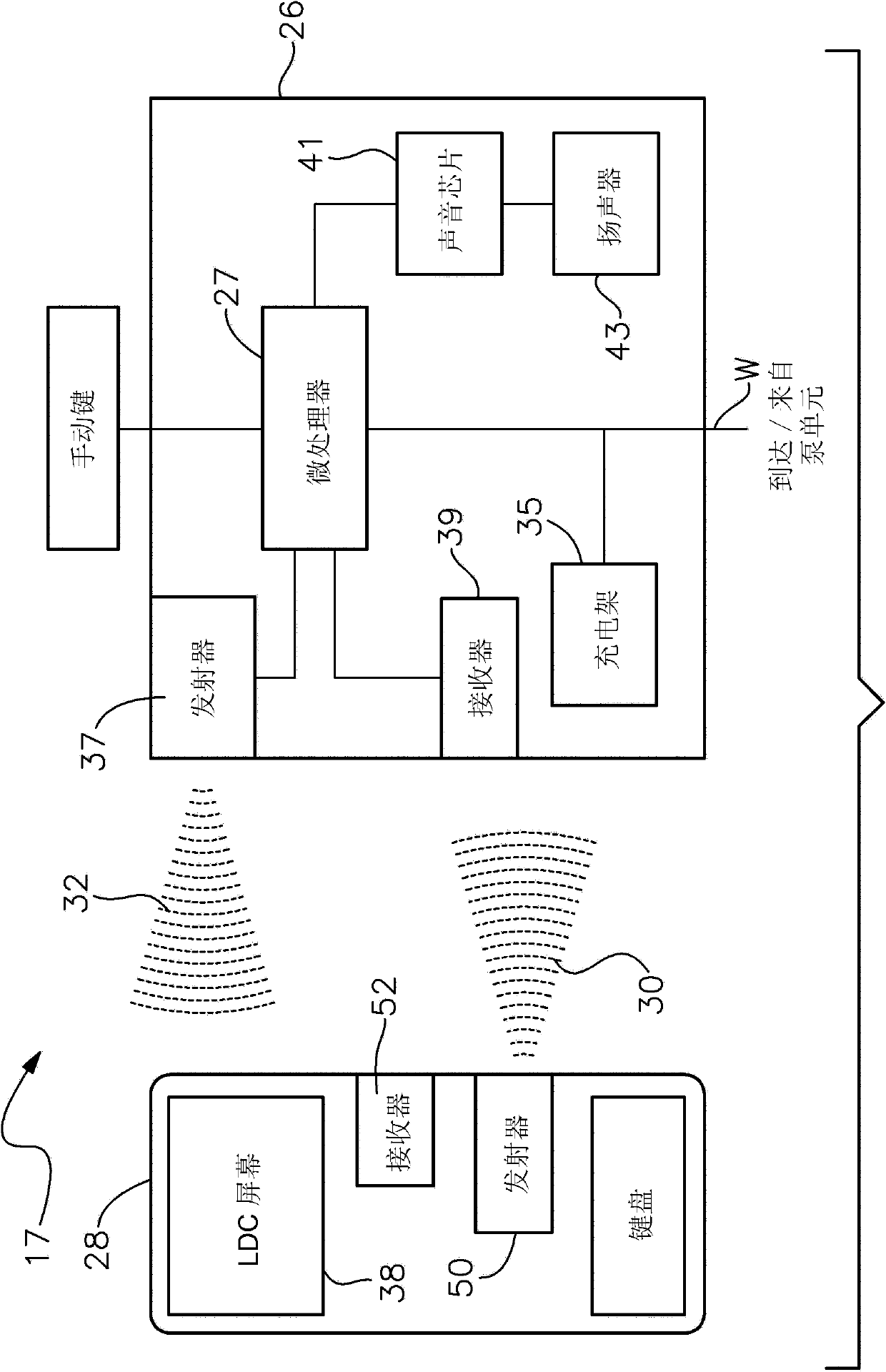

[0019] exist figure 1 A pressure control and feedback system 10 for an adjustable foam support device 12 is shown in . Various supports of this type are disclosed in US Patent Nos. 6,684,433, 6,745,420 and 6,922,863, the disclosures of which are incorporated herein by reference. In particular, adjustable support 12 comprises a sealed self-expanding foam core with incrementally adjustable levels of hardness and softness. Such supports can be used in a wide variety of products including (but not limited to) mattresses, toppers, mats, pads, seat covers, recliners, car seats, etc. . The specific application of the adjustable foam support device is not a limitation of the invention.

[0020] The density and stiffness of device 12 can be incrementally adjusted by removing a selected amount of air from the foam core through the sealing cover. In particular, the vacuum pump unit U is communicable and operatively interconnected with the foam core of the device 12 . In the form des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com