Safety air bag used in helmet

A technology for airbags and helmets, applied in helmets, helmet covers, applications, etc., can solve problems such as limited protective effect, and achieve the effects of low manufacturing cost, reasonable design and head protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

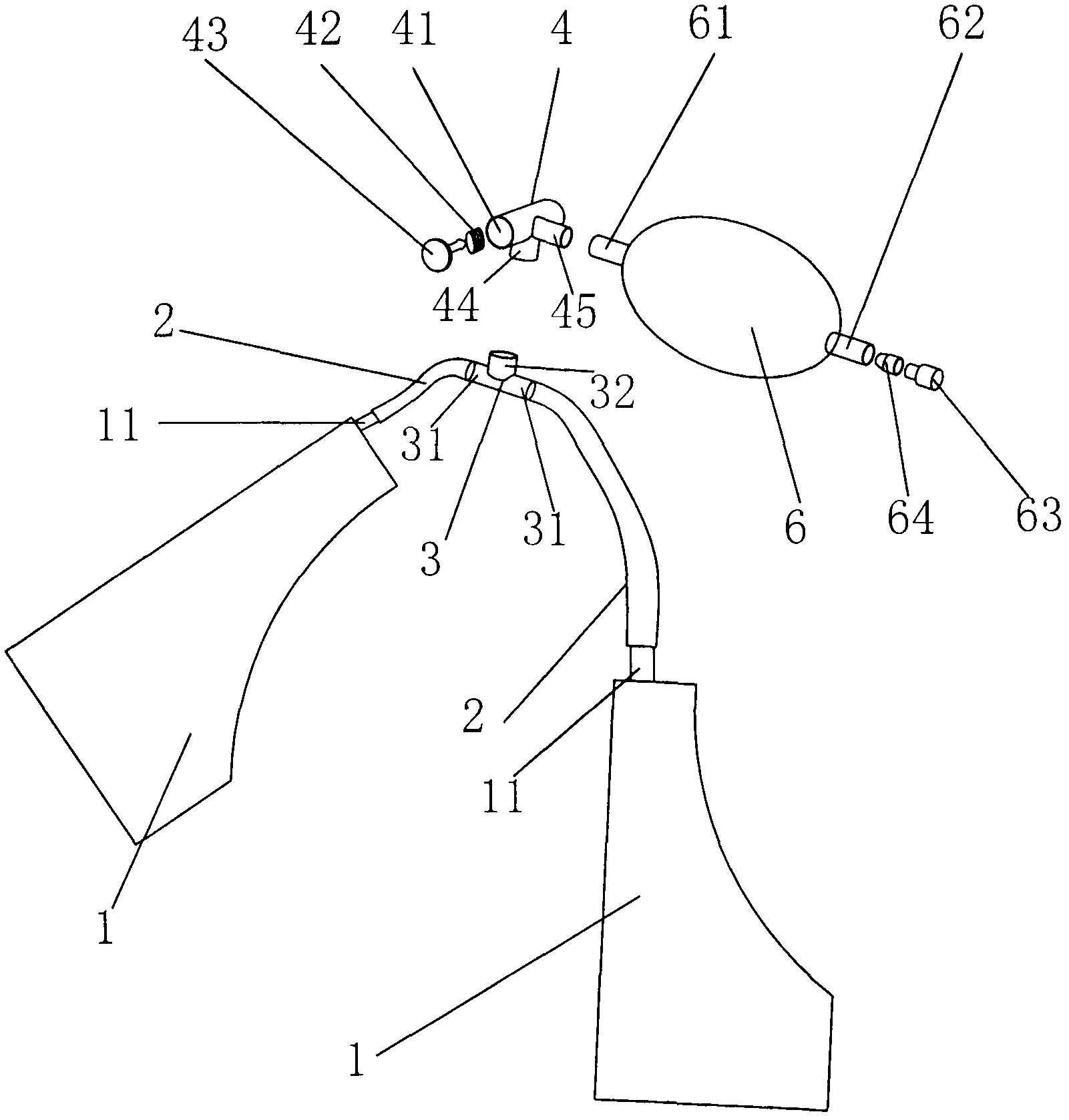

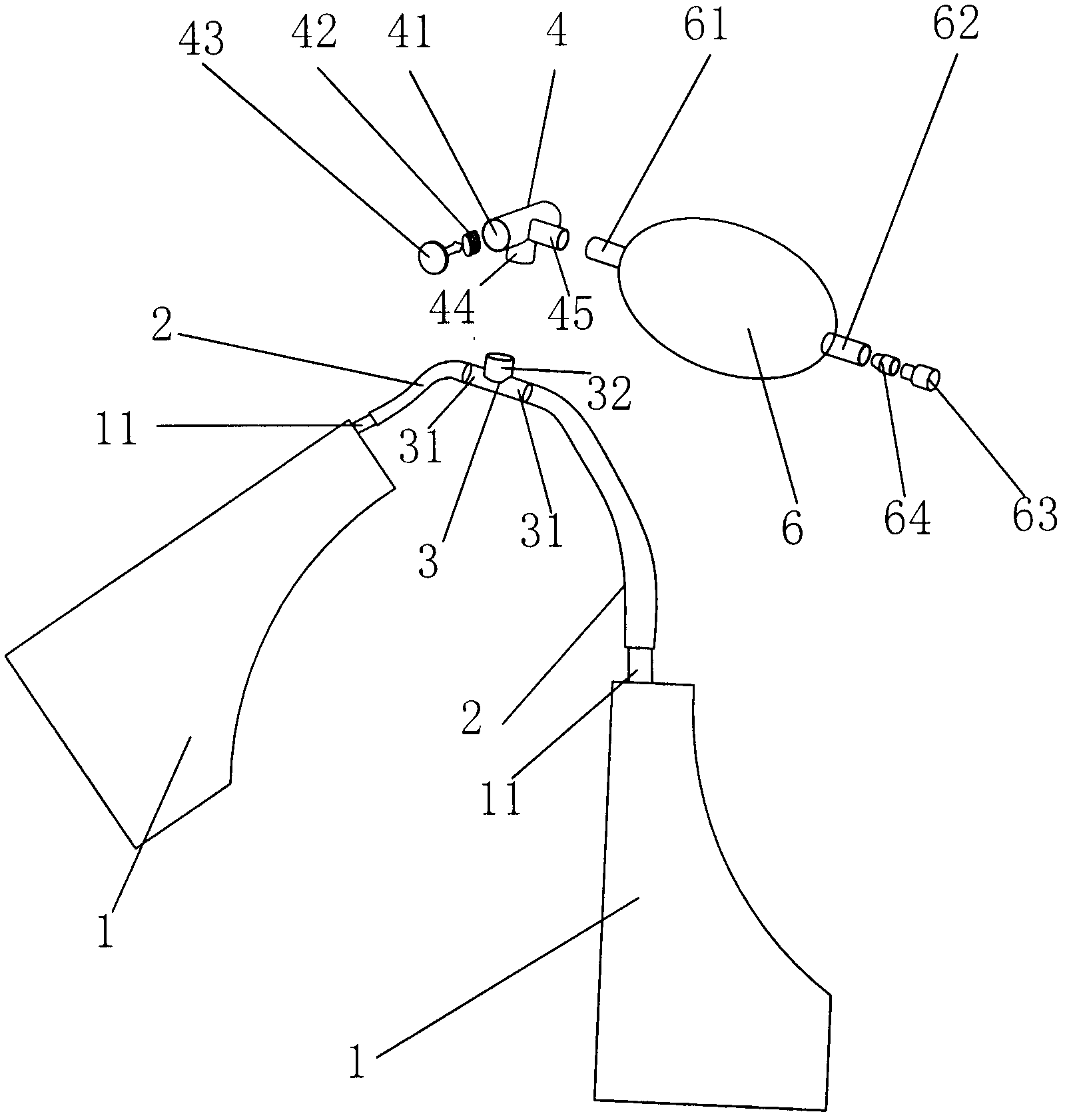

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, a safety airbag used in a helmet according to the present invention includes an air bag 1, a connecting pipe 3, a valve body 4 and an inflating ball 6, and the above-mentioned components constitute the main structure of the present invention.

[0023] The inflatable ball 6 is provided with a ball exhaust hole 61 and a ball suction hole 62, and the ball suction hole 62 has a built-in air suction device, wherein the air suction device includes a valve core 63 and a valve core bushing 64, The valve core bushing 64 is arranged between the valve core 63 and the ball suction hole 62 . The valve core bushing 64 is mainly used to fix the valve core 63 to prevent it from falling off during the suction process.

[0024] The valve body 4 is provided with a valve air intake hole 45, a valve air outlet hole 44 and a valve air release hole 41, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com