Decompression unit

A technology of decompression port and pressure difference, applied in the direction of aircraft floor, aircraft parts, aircraft accessories, etc., can solve the problems of inability to clearly define elasticity, expensive, unable to guarantee rapid trigger time, etc., to achieve high resistance, simple transportation, Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

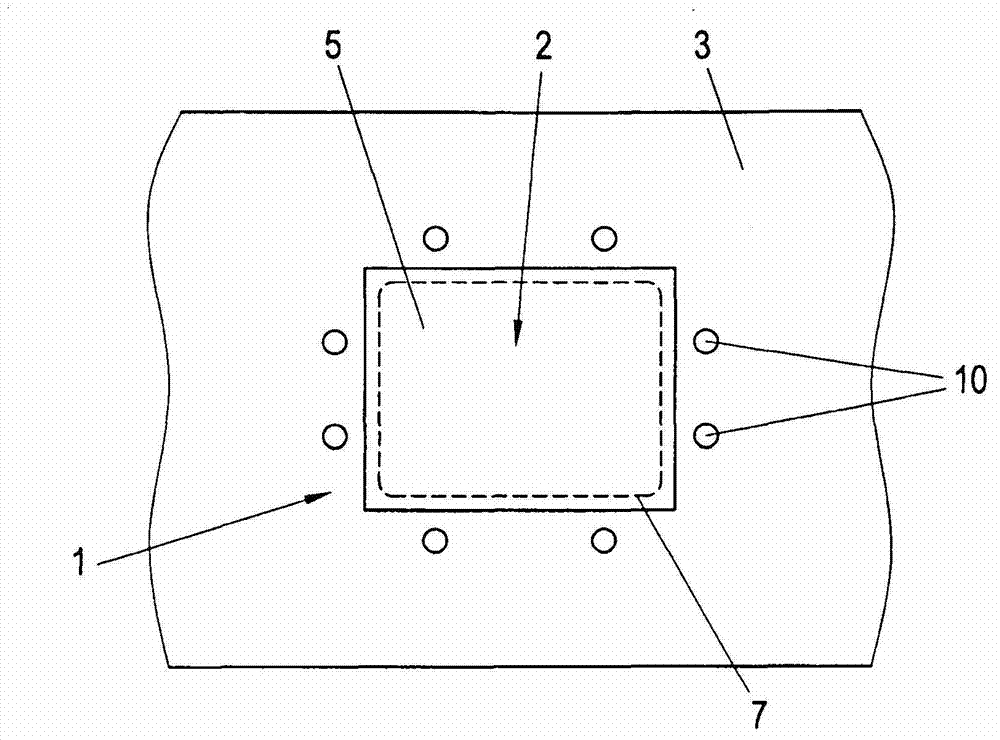

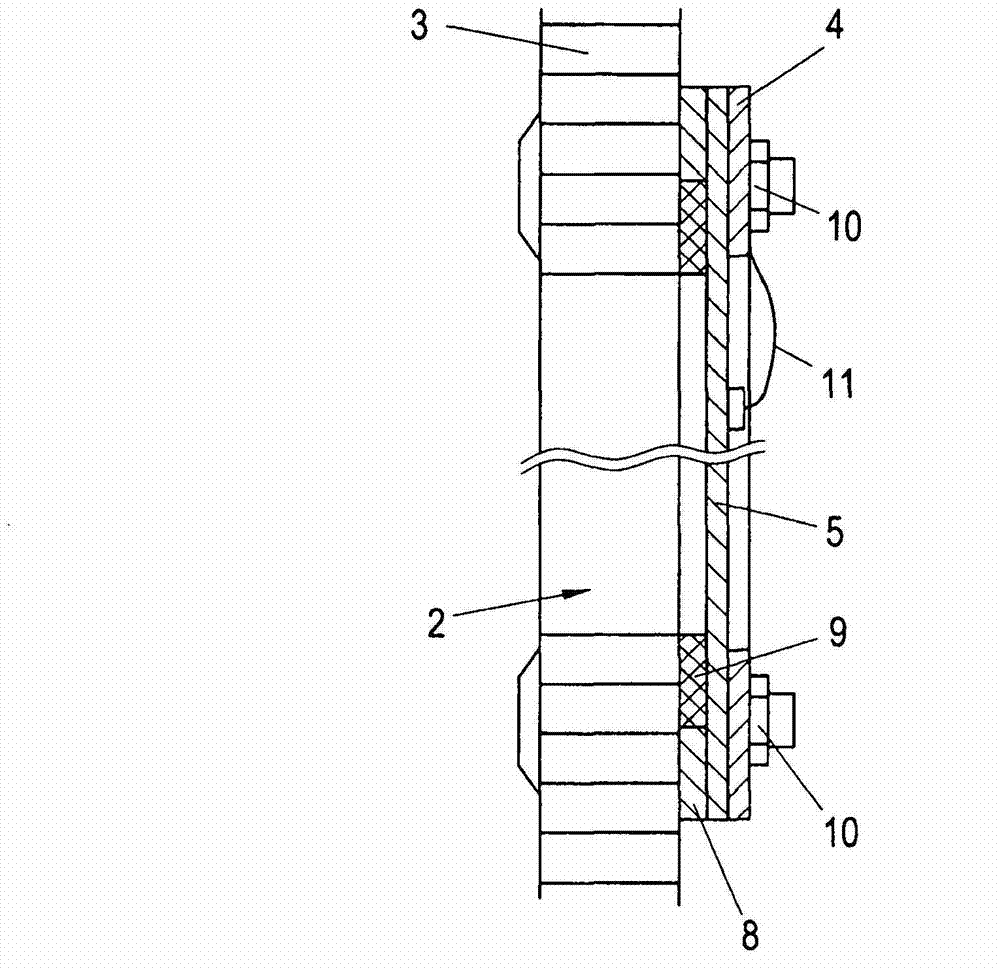

[0026] figure 1 Shown is a view of a decompression unit 1 in a decompression opening 2 of a wall element 3 in an aircraft. Correspondingly, the pressure relief opening 2 in the wall element 3 is covered by a panel 5 formed by at least one hardened prepreg layer 6 having at least one boundary seam 7 filled with hardened resin as Rated breaking point (refer to Figure 4a and 4b ). The parting seam 7 in the panel 5 ensures that the fibers of the prepreg layer, in particular the glass fibers, are broken and thus form a desired breaking point which is only filled with the cured resin. When a predetermined differential pressure Δp is exceeded, the brittle resin in the parting seam 7 breaks and the panel 5 moves out of the pressure relief opening 2 , so that a pressure compensation between the two sides of the wall element 3 can take place.

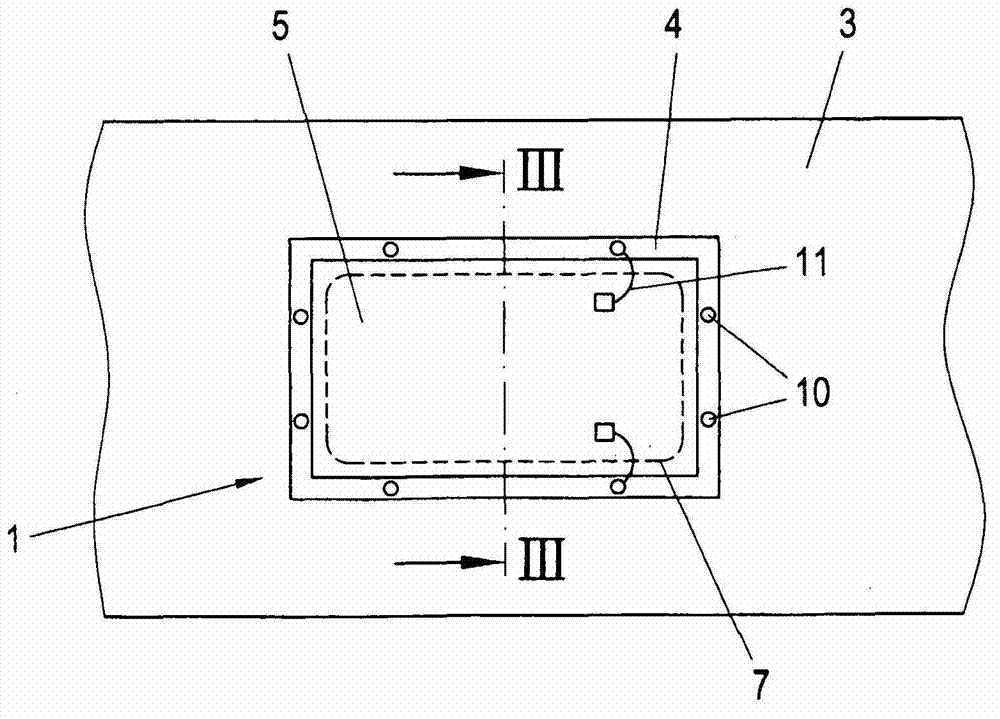

[0027] figure 2 shown based on figure 1 Rear view of the decompression unit 1. Here, the panel 5 is connected to the wall element 3 via...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com