A kind of low-temperature flux and preparation method thereof

A flux, low temperature technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as molten droplets, softening and deformation of flexible substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

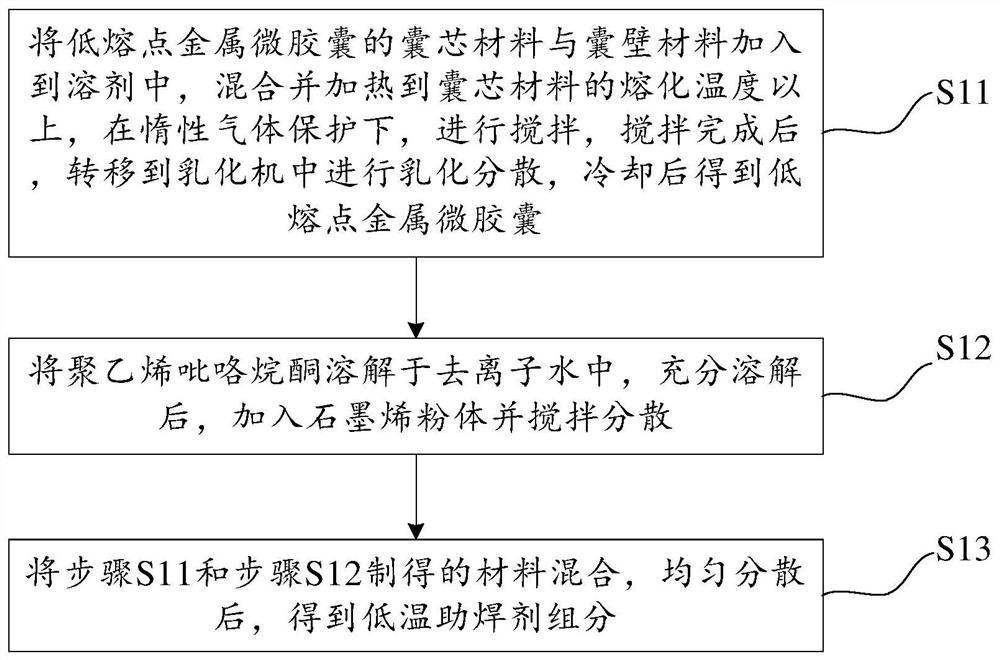

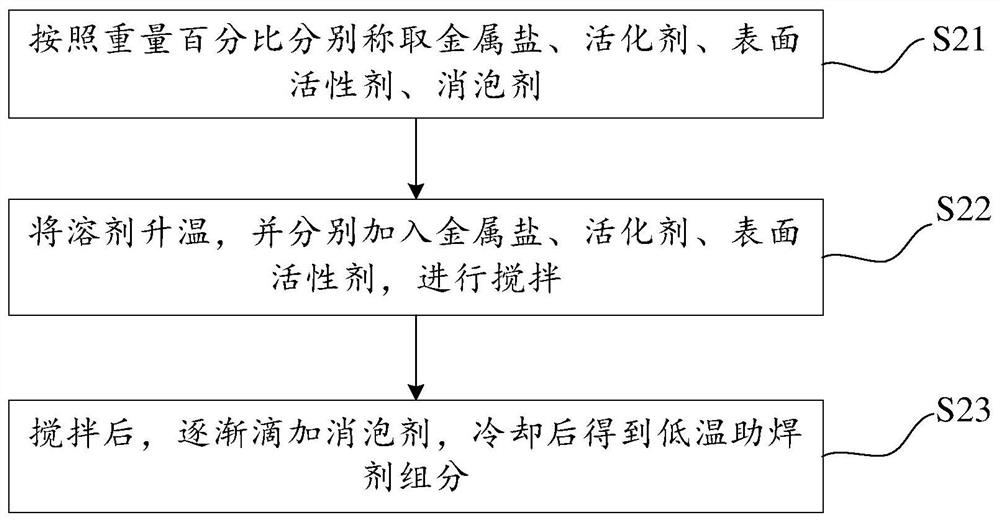

[0059] Exemplarily, as figure 1 as shown, figure 1 The flow chart of the preparation method of the first low-temperature flux component provided by the embodiment of the present invention, the preparation method of the first low-temperature flux component includes:

[0060] Step S11, adding the capsule core material and capsule wall material of the low-melting point metal microcapsules into the solvent, mixing and heating to above the melting temperature of the capsule core material, stirring under the protection of an inert gas, and transferring to emulsification after the stirring is completed Carry out emulsification and dispersion in the machine, and obtain low melting point metal microcapsules after cooling.

[0061] Wherein, the faster the stirring rate and / or the longer the stirring time, the smaller the capsule core particle diameter of the low melting point metal microcapsules, the more serious the oxidation, the faster the emulsification rate and / or the longer the e...

Embodiment 1

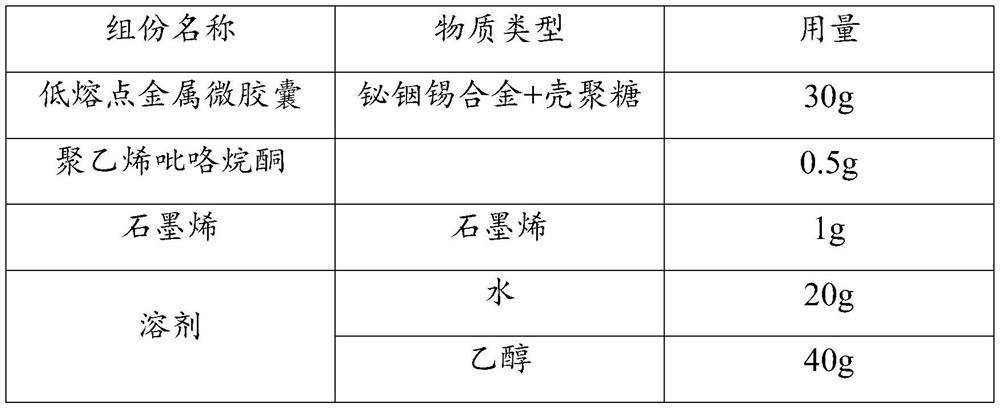

[0086] First Low Temperature Flux Component

[0087]

[0088] Second Low Temperature Flux Component

[0089]

[0090]

Embodiment 2

[0092] First Low Temperature Flux Component

[0093] component name Substance type Dosage Low melting point metal microcapsules Gallium indium tin alloy + polyethylene oxide 23g Polyvinylpyrrolidone 0.65g Graphene Graphene 1.5g solvent Isopropanol 74.85g

[0094] Second Low Temperature Flux Component

[0095] component name Substance type Dosage metal salt Zinc chloride 5g activator lactic acid 5g Surfactant op20 4.5g Defoamer mineral oil defoamer 0.3g solvent Ether 85.2g

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com