Burner controller and adjusting method for a burner controller

a burner controller and burner technology, applied in the direction of combustion regulation, fuel supply regulation, combustion process, etc., can solve the problems of adverse effects on inability to continuously adjust the level of regulating accuracy, and inability to achieve reliable and accurate regulating of the air index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

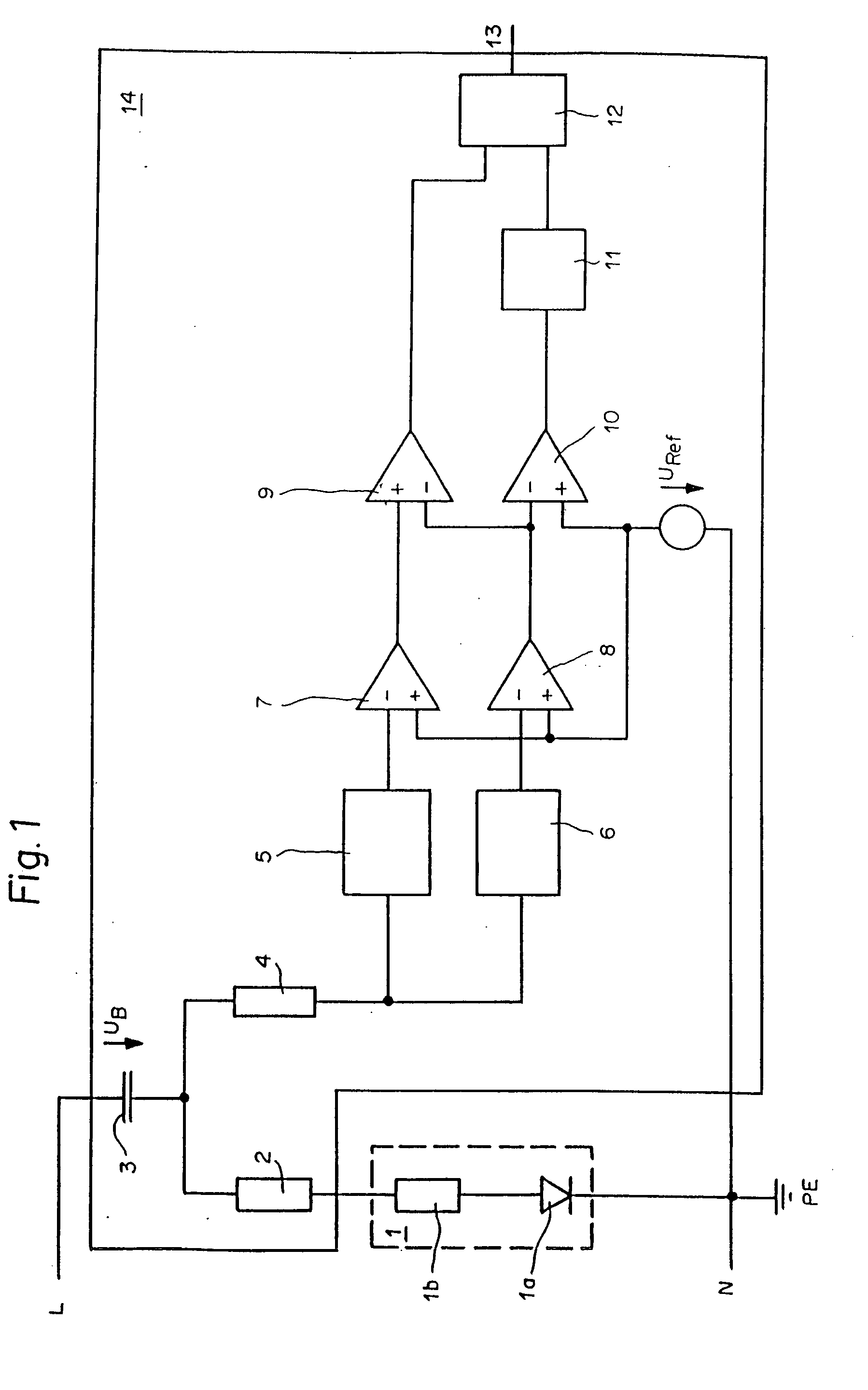

[0023]FIG. 1 diagrammatically shows the operating principle of ionization evaluation device 14 in a burner controller according to the invention. In an equivalent circuit a flame 1 is represented by a diode 1a and a resistor 1b. An ac voltage of for example 230V is applied across L and N. If a flame 1 is present, a greater current flows through a blocking capacitor 3 in the positive half-wave than in the negative half-wave, by virtue of the flame diode 1a. As a result, a positive dc voltage UB is produced at the blocking capacitor 3 between L and a resistor 2 which is provided for the purposes of electric-shock contact protection.

[0024] Therefore a direct current flows through a decoupling resistor 4 from N to the blocking capacitor 3. In that situation the magnitude of the direct current depends on UB and thus directly on the flame resistor 1b. The flame resistor 1b also influences the alternating current through the decoupling resistor 4, but to a differing degree from the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com