Self-adaptive control method and system for oxygen content of garbage incinerator

An adaptive control and waste incineration technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of flue gas index emissions that have a significant impact, are unstable, and cannot be automatically adjusted, so as to reduce excessive pollutant emissions and adjust Accurate, reliable and highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

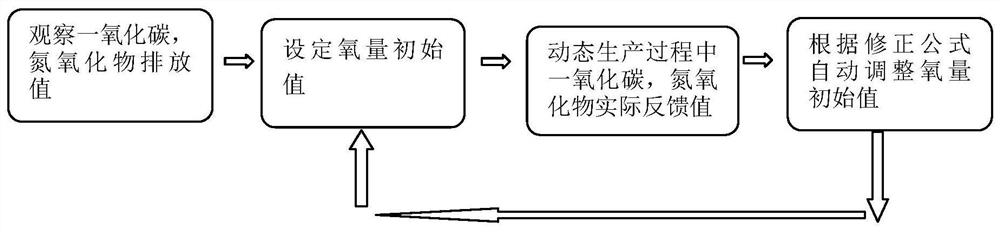

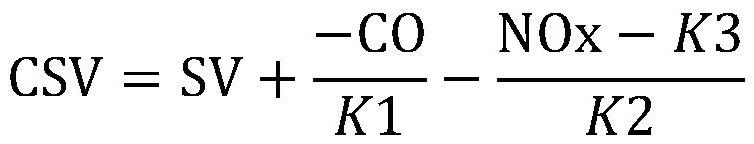

[0026] like figure 1 As shown, the self-adaptive control method for the oxygen content of the waste incinerator according to the embodiment of the present invention, according to the content of carbon monoxide and nitrogen oxides in the flue gas emission index of the waste incinerator in the production process, there is a certain negative correlation (that is, when the carbon monoxide is high, the nitrogen Oxide is low, when nitrogen oxide is high, carbon monoxide is low; and the two values are closely related to the boiler oxygen setting) this characteristic, the oxygen content is adjusted, specifically including the steps:

[0027] S01. Obtain the carbon monoxide and nitrogen oxide contents in the flue gas emitted from the waste incinerator;

[0028] S02. Adjust the oxygen amount of the waste incinerator according to the carbon monoxide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com