Construction method for foundation pit excavation

A construction method and technology of foundation pits, applied in excavation, foundation structure engineering, construction, etc., can solve problems such as difficult accurate calculation and control, lack of direct and effective means for enclosure deformation control, and unsatisfactory deformation control effects, etc., to achieve Accurate and reliable adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments. It can be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for ease of description, the drawings only show parts related to the present invention, but not all.

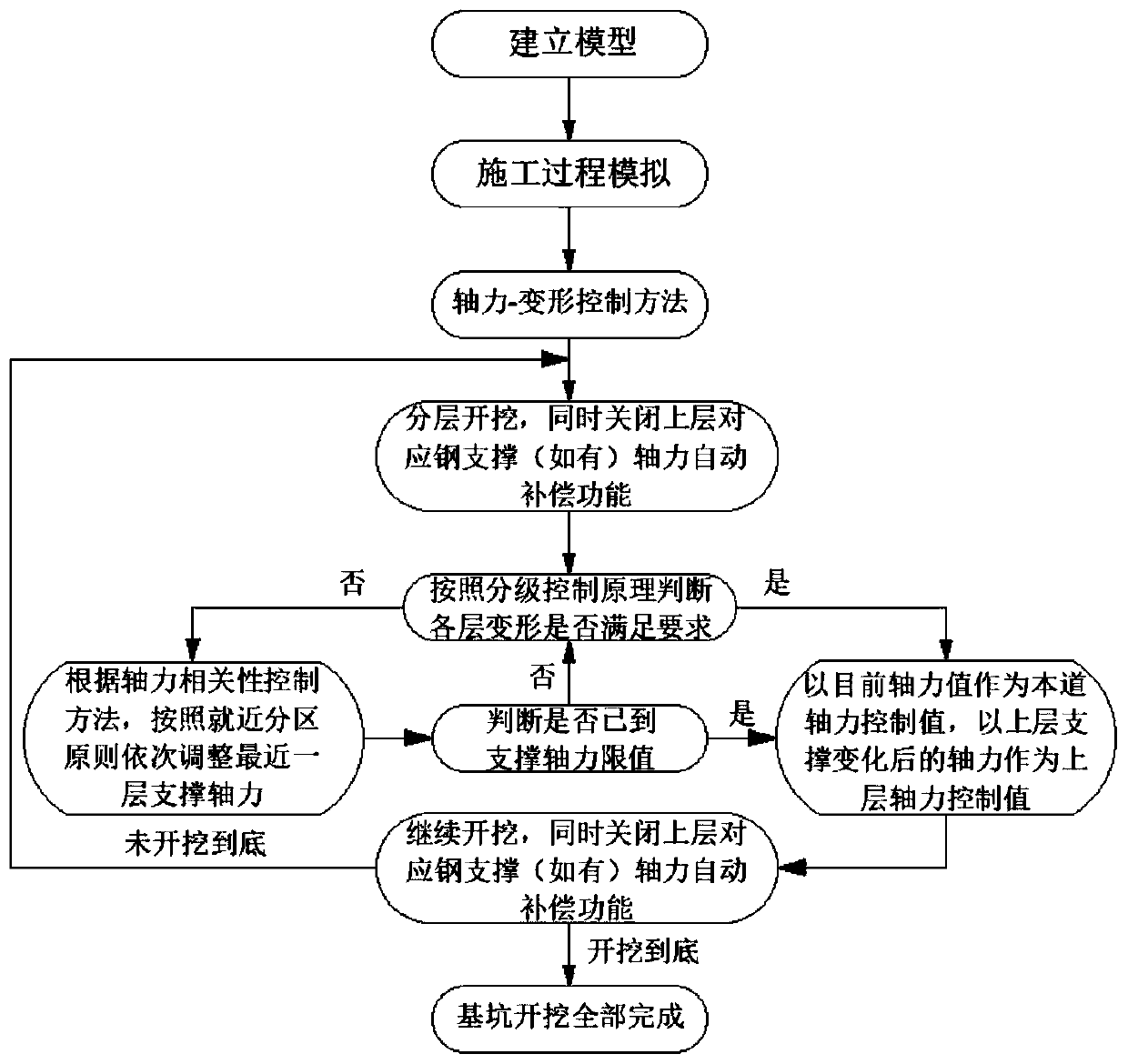

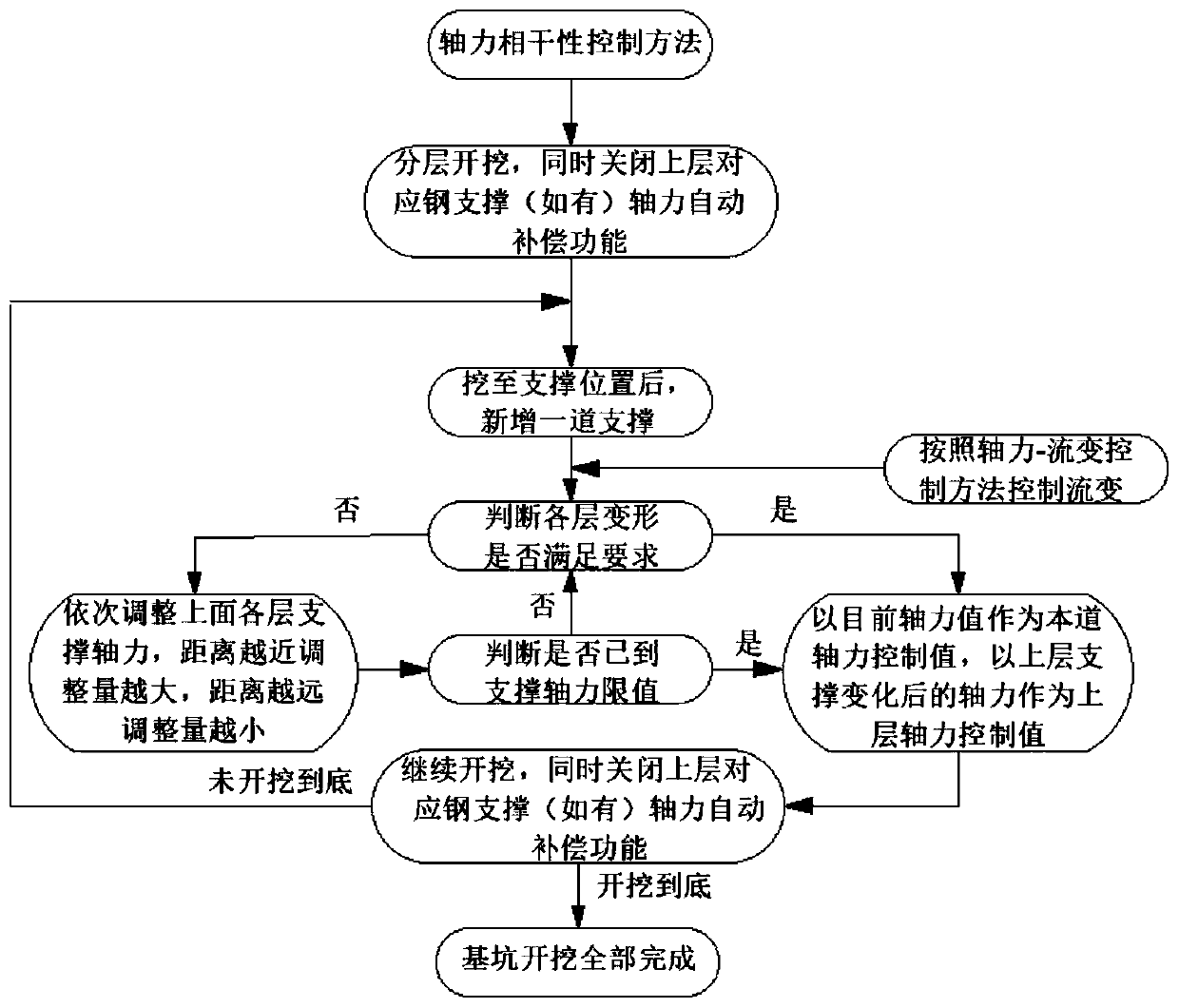

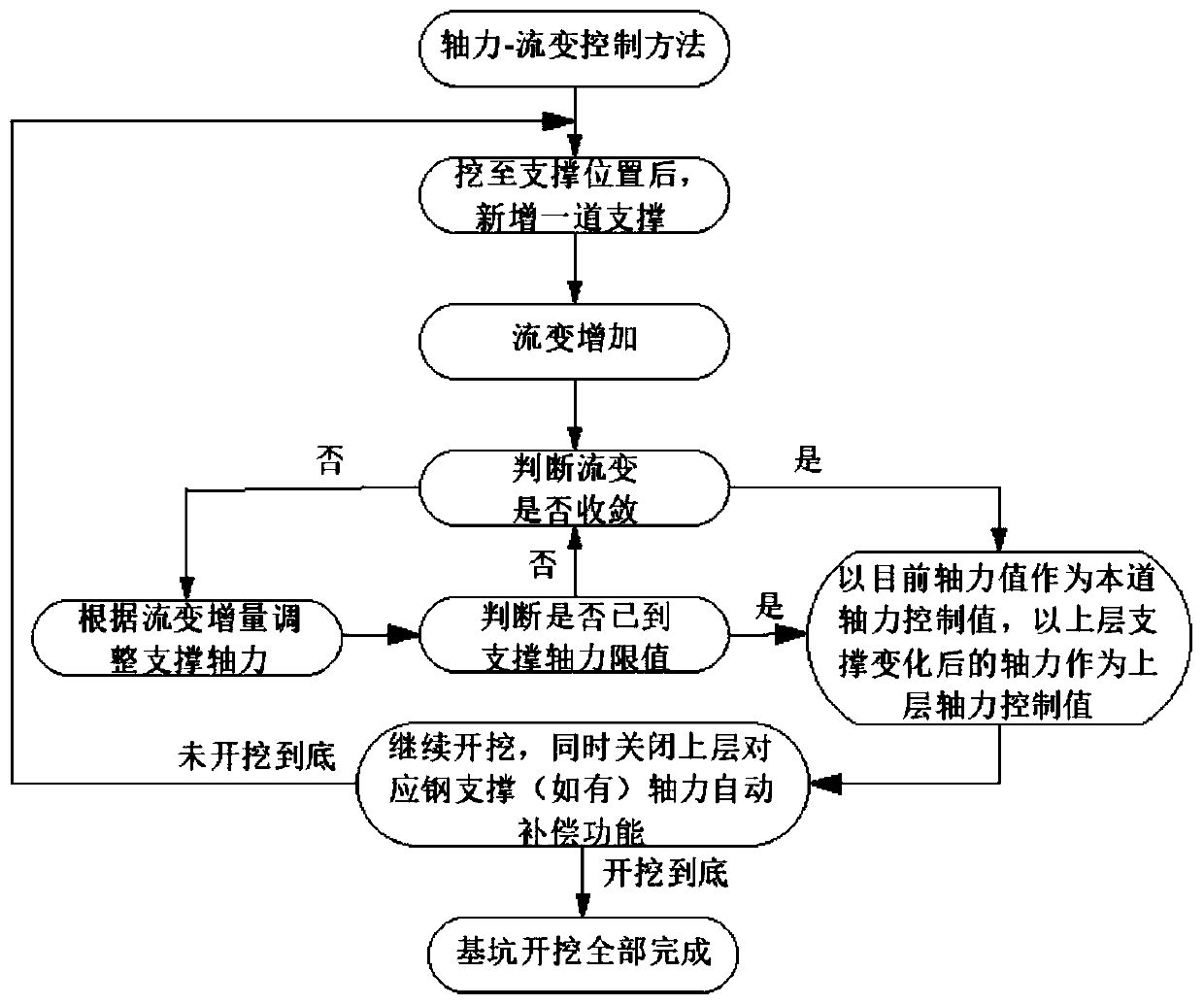

[0067] Such as figure 1 As shown, the present invention provides a foundation pit excavation construction method, and the active control theory of lateral deformation of the foundation pit enclosure in this embodiment is as follows:

[0068] Although the steel support servo control system can adjust the deformation according to the deformation control requirements of the protected object, we should see that there are many factors that affect the deformation of the foundation pit. Axial force is only one of them. Axial force control alone cannot completely so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com