Table board type silk-screen printing device

A screen printing, desktop technology, applied in the direction of screen printing machines, printing machines, printing machines, etc., can solve the problems of not being able to maintain a stable and reliable working posture, not always maintaining stable printing accuracy, and difficult to meet the requirements of adjustment accuracy, etc. Achieve the effects of firm locking, stable work, and convenient connection and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

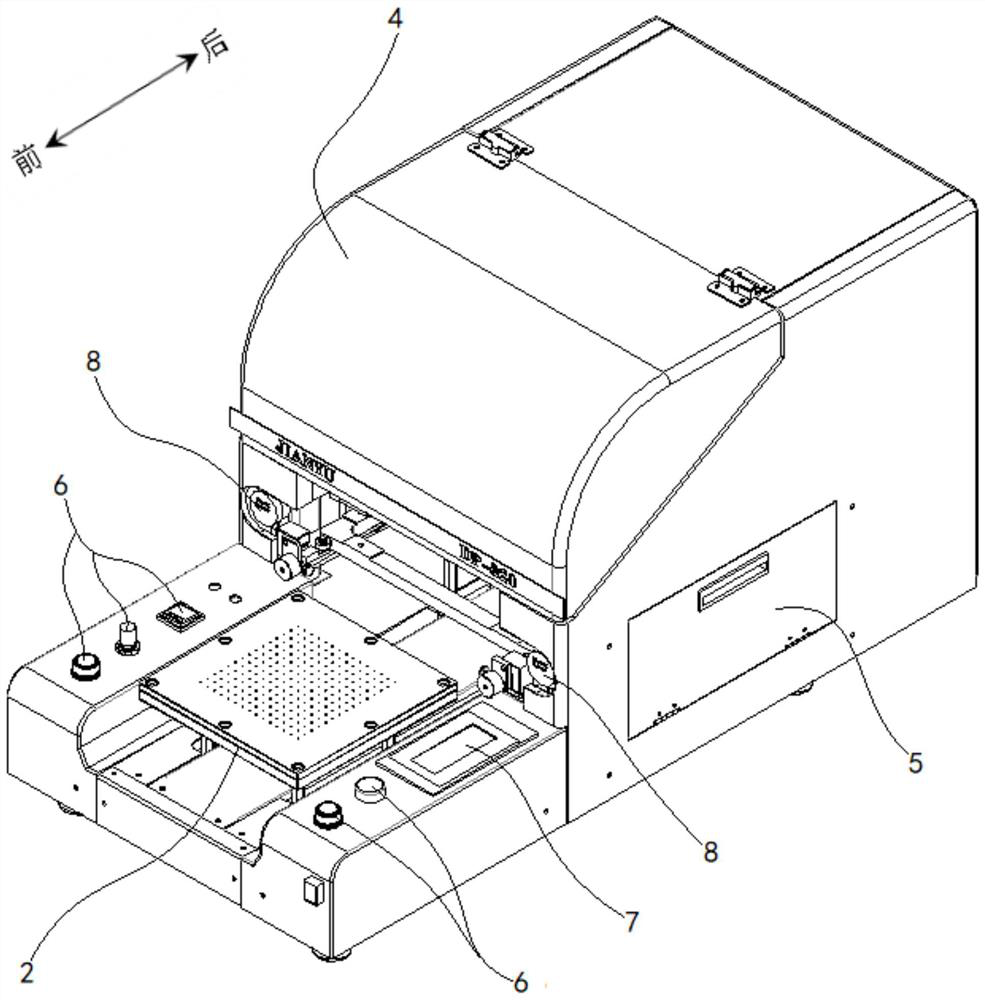

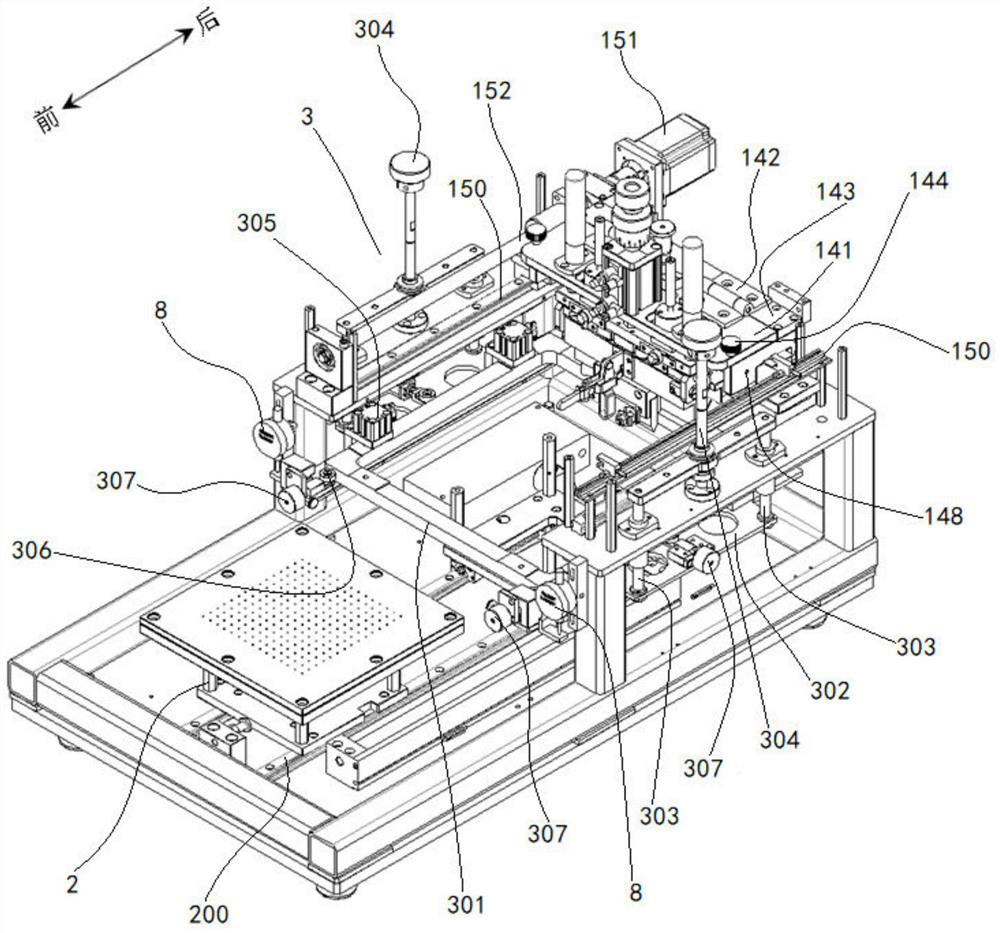

[0034] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the desktop screen printing equipment mainly includes three parts: a printing head 1, a printing table 2, and a screen positioning mechanism 3; The transparent outer cover 4 that arc turns up, the small door 5 that is used for adjustment is opened on both sides of the equipment, and the control buttons 6, display screen 7 and dial indicator 8 of each cylinder and motor are set on the front low platform.

[0035] The structure of the three parts of the printing head 1, the printing table 2, and the screen positioning mechanism 3 is described as follows:

[0036] Part 1: Printing head

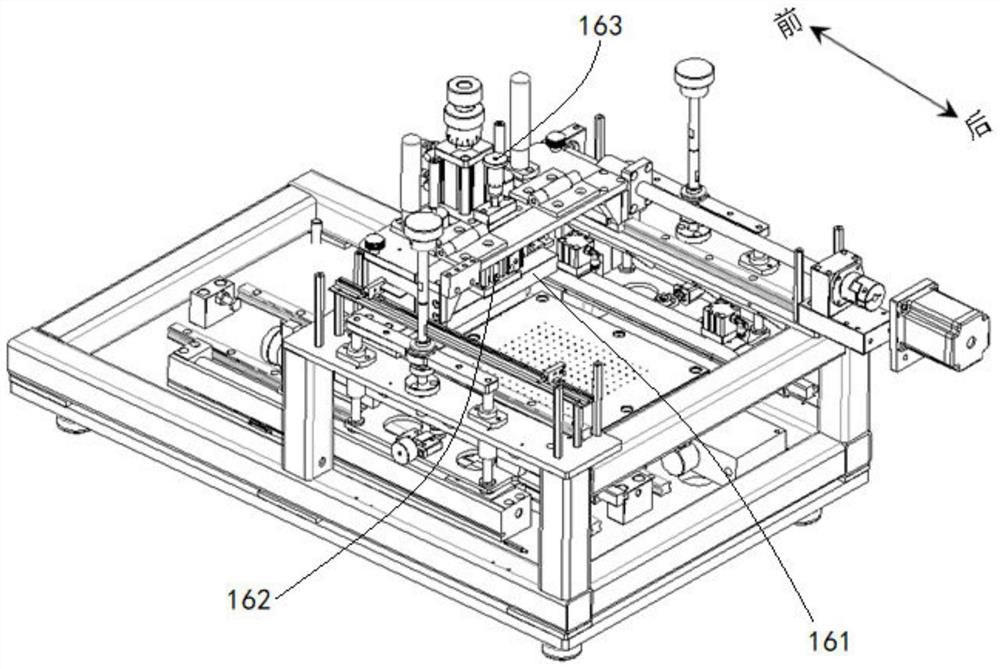

[0037]The printing machine head 1 comprises the scraper seat 101 of the device scraper 100 and the scraper lift cylinder 102 thereof, the ink return knife seat 161 of the device ink return knife 160 and the ink return knife lift cylinder 162 thereof. When the printing machine head moves fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com