Combined transshipment glass transport cart with compression device

The technology of a glass transport vehicle and a pressing device is applied in the directions of transportation and packaging, handcarts, motor vehicles, etc., which can solve the problems of single transportation mode, decreased production and transportation efficiency, single design function, etc., so as to improve work efficiency and reduce equipment. cost, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments.

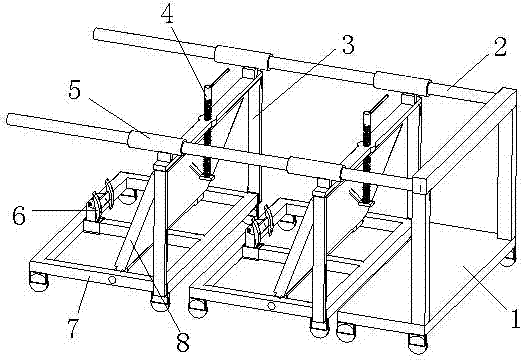

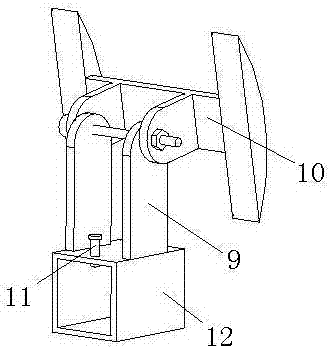

[0016] Such as figure 1 , figure 2 As shown, a combined transfer glass transport vehicle with a pressing device includes universal wheels, a fixed bracket 1 and an assembly bracket, and the assembly bracket and the fixed bracket 1 are slidably connected; the fixed bracket 1 includes a bottom plate, a support plate and a guide Column 2, the bottom plate is made of rectangular steel plate, the support plate is a "Xi" type structure, which is fixed vertically at one end of the bottom plate; there are two guide columns 2, which are respectively horizontally and vertically fixed on the upper end of the support plate; the assembly bracket includes a screw bracket 3. The screw rod 4, the sleeve 5, the pressing device 6, the base 7 and the back plate 8, the base 7 is a rectangular frame structure, the back plate 8 is made of a rectangular steel plate, and its bottom is hinged wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com