Dry type granulator tabletting pressure control system and method

A dry granulator and pressure control technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of inconstant pressure of the rollers, low yield at one time, uneven density, etc., and achieve uniform density. , Good consistency, accurate and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

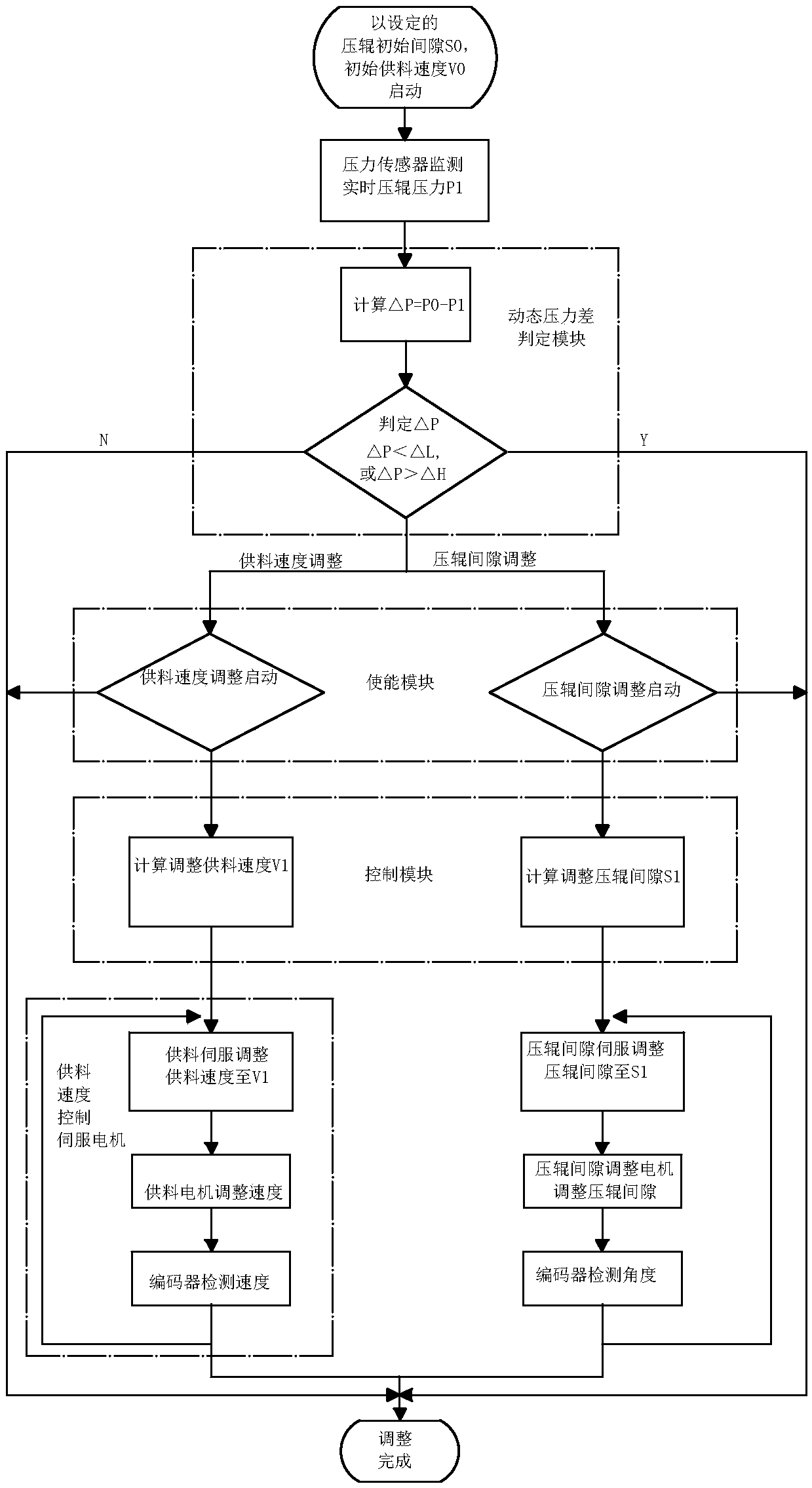

[0030] See attached Figure 1~5 , a tablet pressure control system for a dry granulator disclosed in the present invention, comprising a pressure sensor for real-time measurement of the real-time pressure P1 between the pressure rollers,

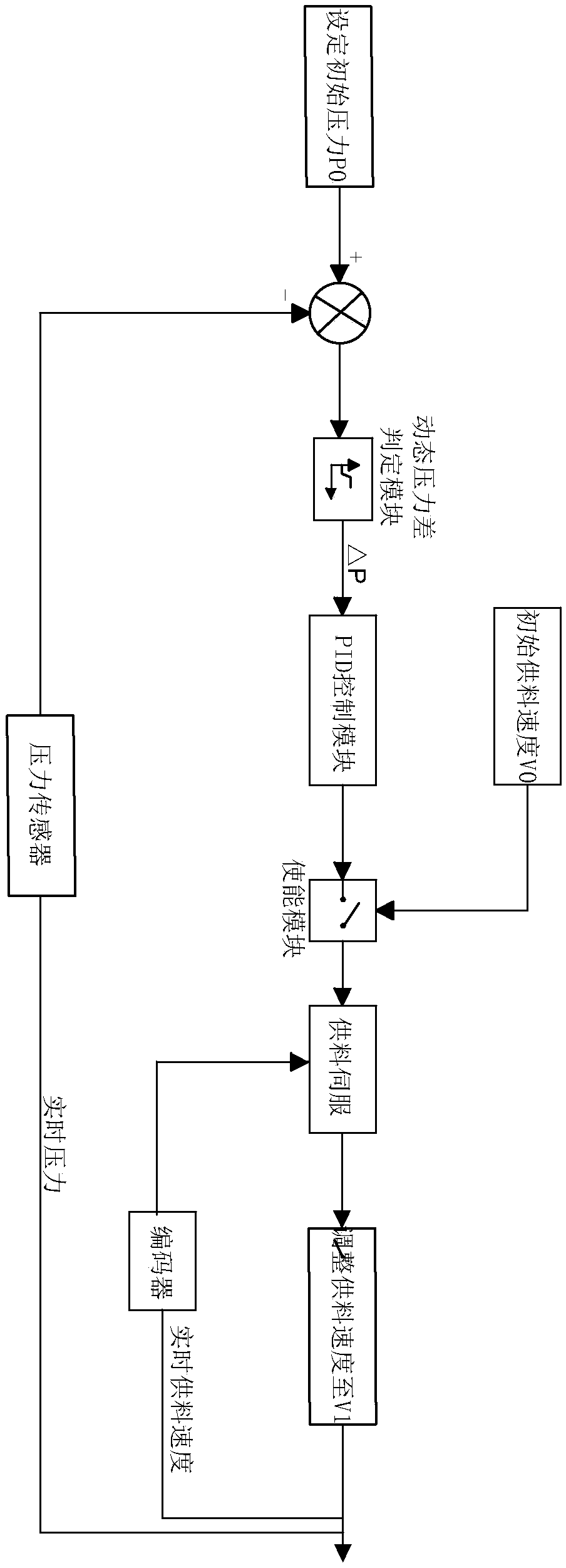

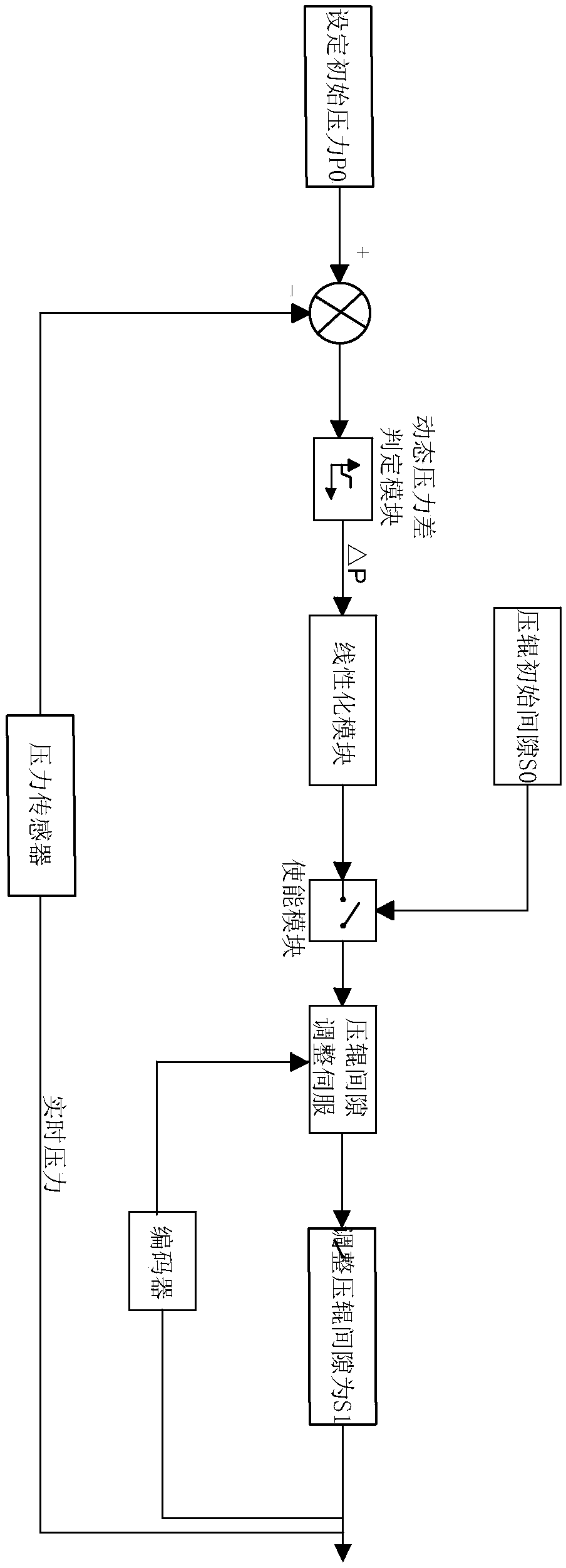

[0031] Pressure roller gap adjustment servo motor, used to adjust the pressure roller gap, and has the pressure roller initial gap S0 that operates when the equipment is initially started, or \ and feed speed control servo motor, used to adjust the supply of materials entering between the pressure rollers Material speed, and run at the initial feeding speed V0 when the equipment is initially started;

[0032] The enabling module drives the pressure roller gap adjustment servo motor to adjust the pressure roller gap or drives the feeding speed control servo motor to adjust the feeding speed;

[0033] Control module, set the initial gap S0 of the pressure roller, set the initial pressure P0, the initial feeding speed V0, the upper limit of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com