Scab grinding machine

A grinding and motor technology, which is applied in the field of medical equipment, can solve problems such as difficult to master, time-consuming and labor-intensive, and achieve precise and controllable grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

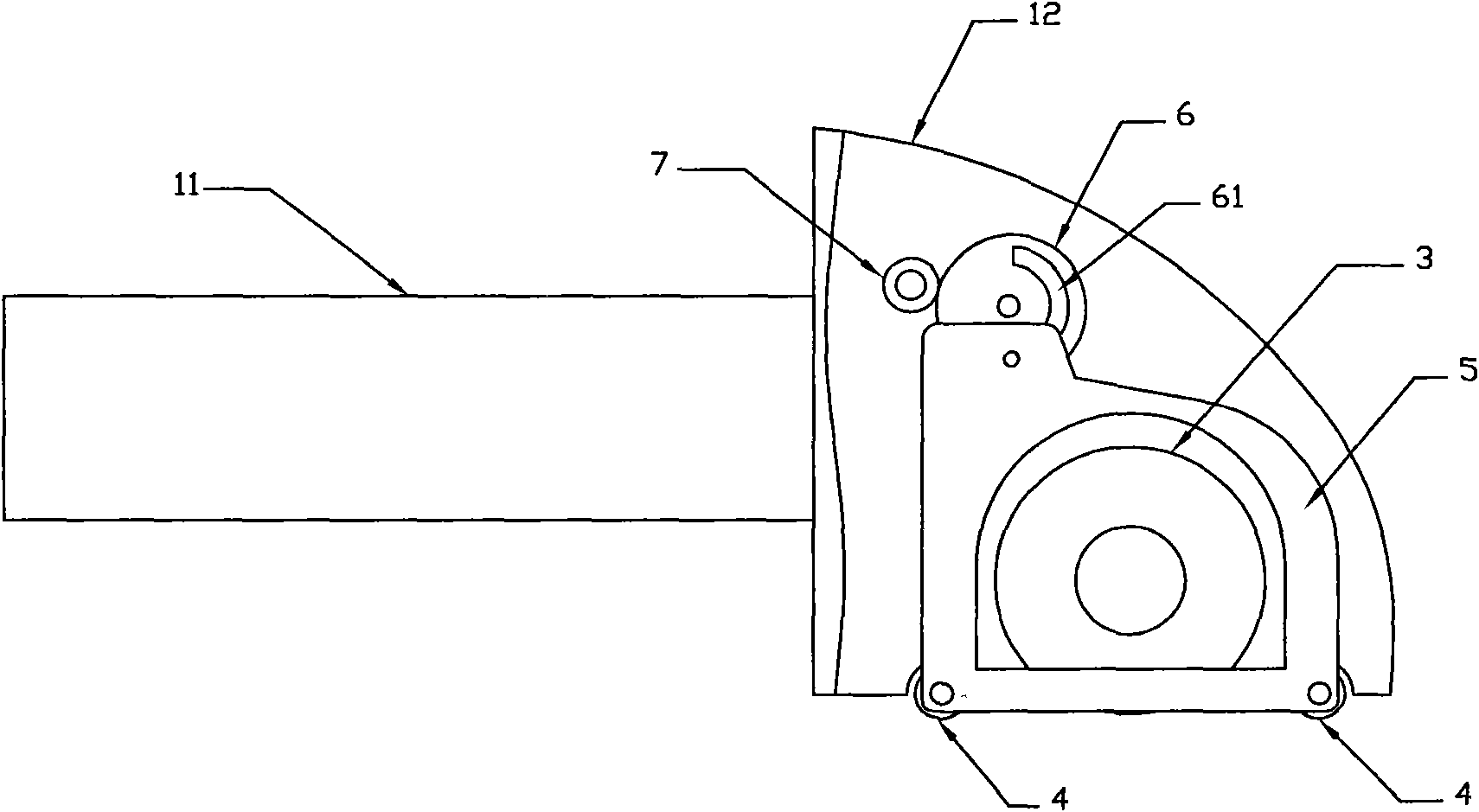

[0037] figure 1 Shown is the scab grinding machine of the present invention, comprising a handle 11, a housing 12 fixedly connected with the handle 11, a housing opening 13 is provided at the lower end of the housing 12; in the housing 12 A motor 2 is provided, a rotary knife 3 connected with the motor 2, and the rotary knife 3 is externally ground through the housing opening 13 (see image 3 shown);

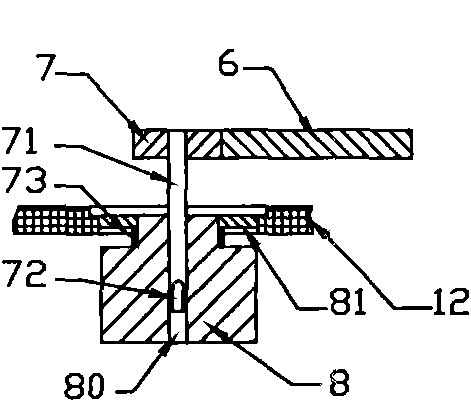

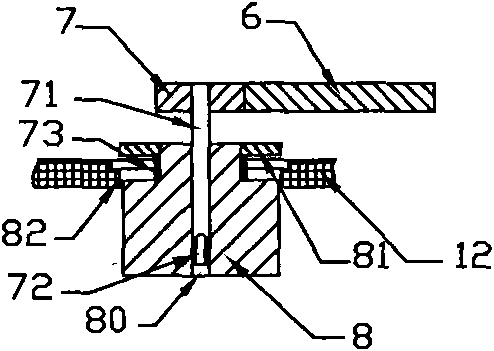

[0038] It also includes an adjustment bracket 5, the adjustment bracket 5 includes rollers 4 respectively arranged on both sides of the housing opening 13 at the lower end of the housing 12, and an adjustment mechanism for adjusting the vertical movement of the rollers 4. In this embodiment Two adjustment plates 51 with pins are set in the example, and the adjustment plates 51 are vertically connected with the center line of the rotating roller 4 and are respectively located at the two ends of the rotating roller 4 (see figure 1 or figure 2 shown), and the bull gear 6 provid...

Embodiment 2

[0042] In this embodiment, on the basis of the above-mentioned embodiments, the adjustment mechanism in the above-mentioned embodiments is replaced by a T-shaped connecting bracket 52 fixedly connected to the rotating roller 4, and the horizontal branch 521 of the T-shaped connecting bracket 52 is horizontally fixed on two Between the rotating rollers 4, one end of the connecting plate 53 is hinged with the vertical branch 522 of the T-shaped connecting bracket 52, and the other end of the connecting plate 53 is hinged on the pin of the cam 54. Bull gear 6, described adjusting device is set as pinion 7 meshing with bull gear 6 in the present embodiment (see Figure 7 shown); in this embodiment, the pinion 7 is set to be connected with a locking device, and the locking device is fixedly connected with the pinion 7 coaxially with a first locking gear 81, and the first locking gear 81 is externally meshed with the second locking gear 82. The central axis of the second locking gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com