Frequency and amplitude adjustable mud sample vibration device

A technology of frequency amplitude and vibration device, which is applied in the field of geological disaster model tests, can solve problems such as the inability to take into account amplitude modulation, frequency modulation and vibration frequency control functions, high requirements for mechanical structure and circuit precision, and few vibration devices for landslide physical models. The amplitude modulation operation is convenient and fast, the control is accurate and reliable, and the effect of ensuring the operation safety and noise isolation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

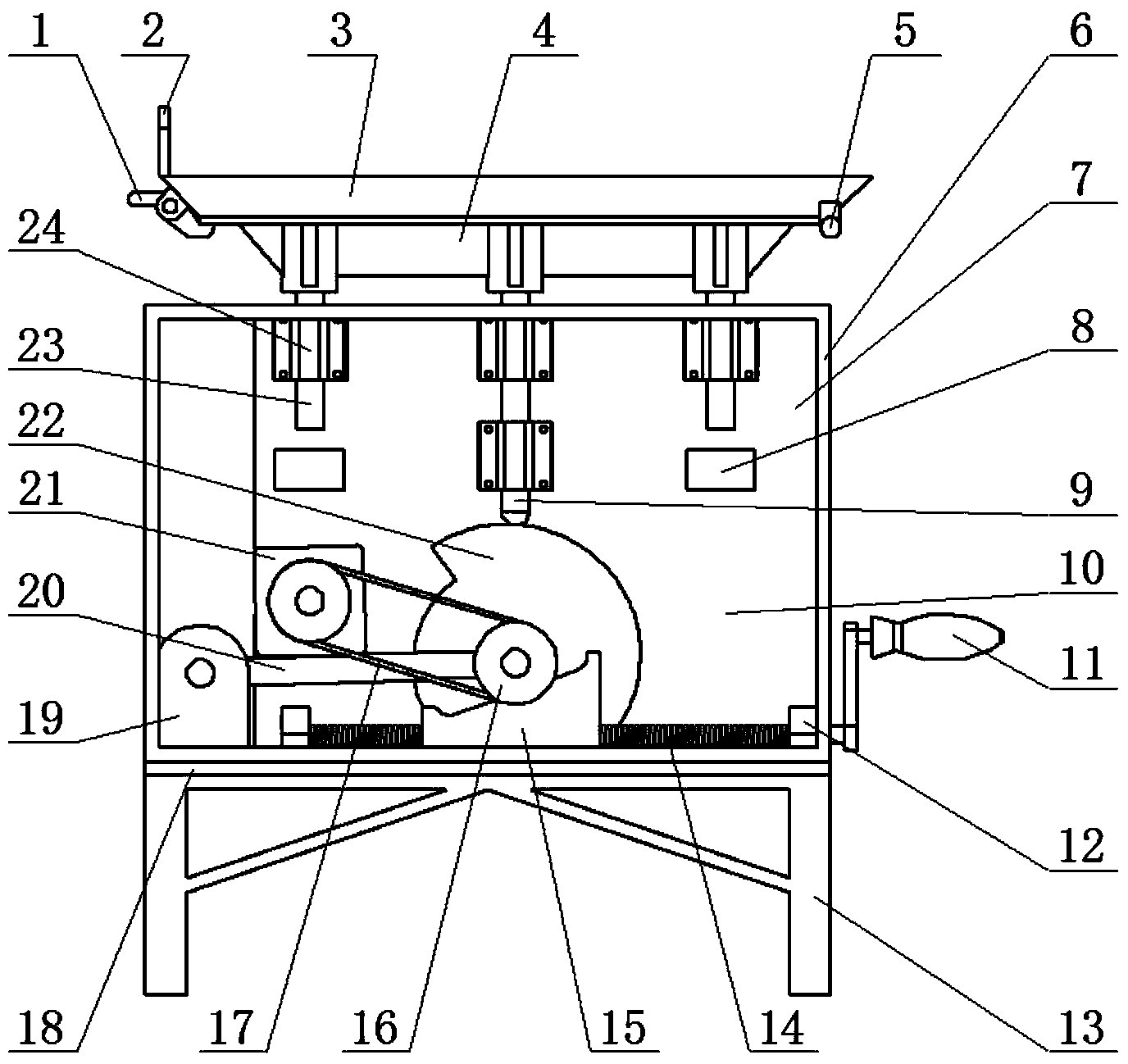

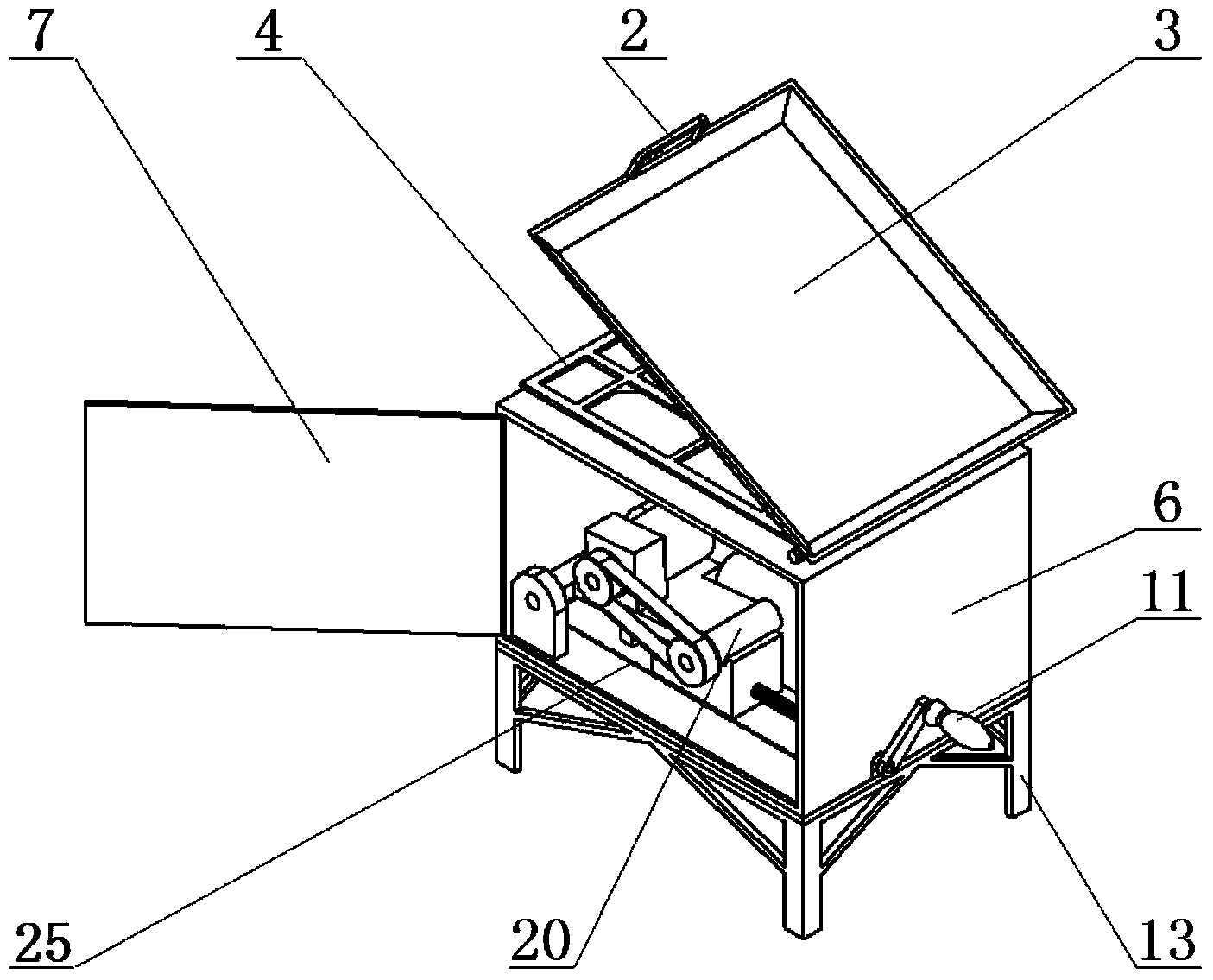

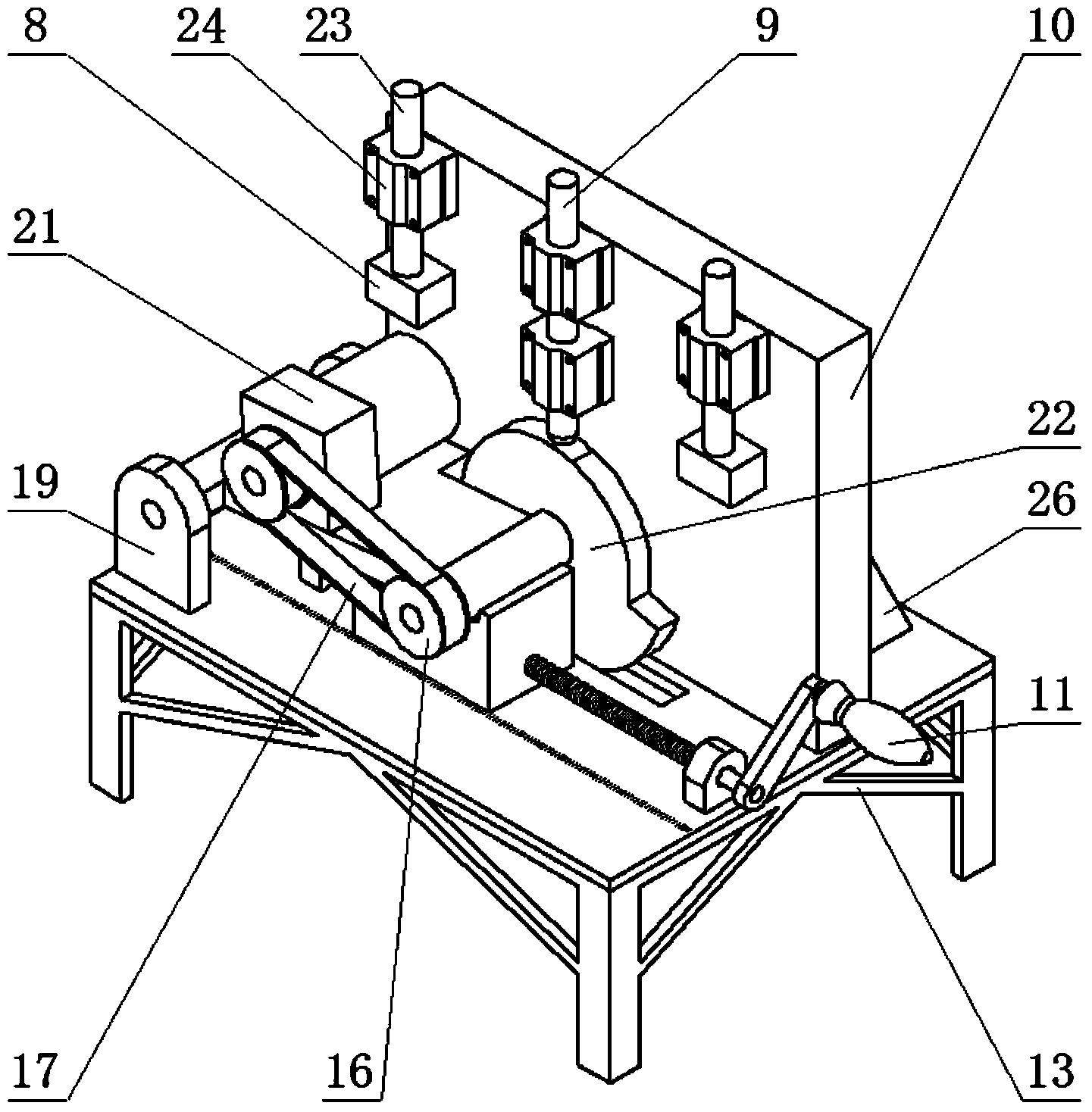

[0026] Such as Figure 1 to Figure 4 As shown, the present invention includes a vibration mechanism and a material loading and unloading mechanism, and is characterized in that: it also includes an amplitude modulation mechanism and a frequency modulation unit; Seat 12, amplitude modulation support 19 and amplitude modulation scale 25; frequency modulation unit is a stepping motor 21 for frequency modulation, and stepping motor 21 is installed on the amplitude modulation pendulum plate 20; vibrating mechanism includes belt 17, pulley 16, start vibration cam 22 , ejector rod 9, impact rod 23 and impact block 8, belt pulley 16 and start-up vibration cam 22 coaxial, belt pulley 16 and stepper motor 21 link to each other by belt 17, belt pulley 16 is embedded in the sleeve end of amplitude modulation pendulum plate 20 right sides, The middle part of the sleeve rests on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com