Device for controlling pivoting blades of a turbine engine

A technology for control devices and turbines, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, engine components, etc., can solve problems such as positioning and centering restrictions, high stress on control devices, and device uncertainty, etc., to achieve Improvement of reliability, improvement of performance, effects that can be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

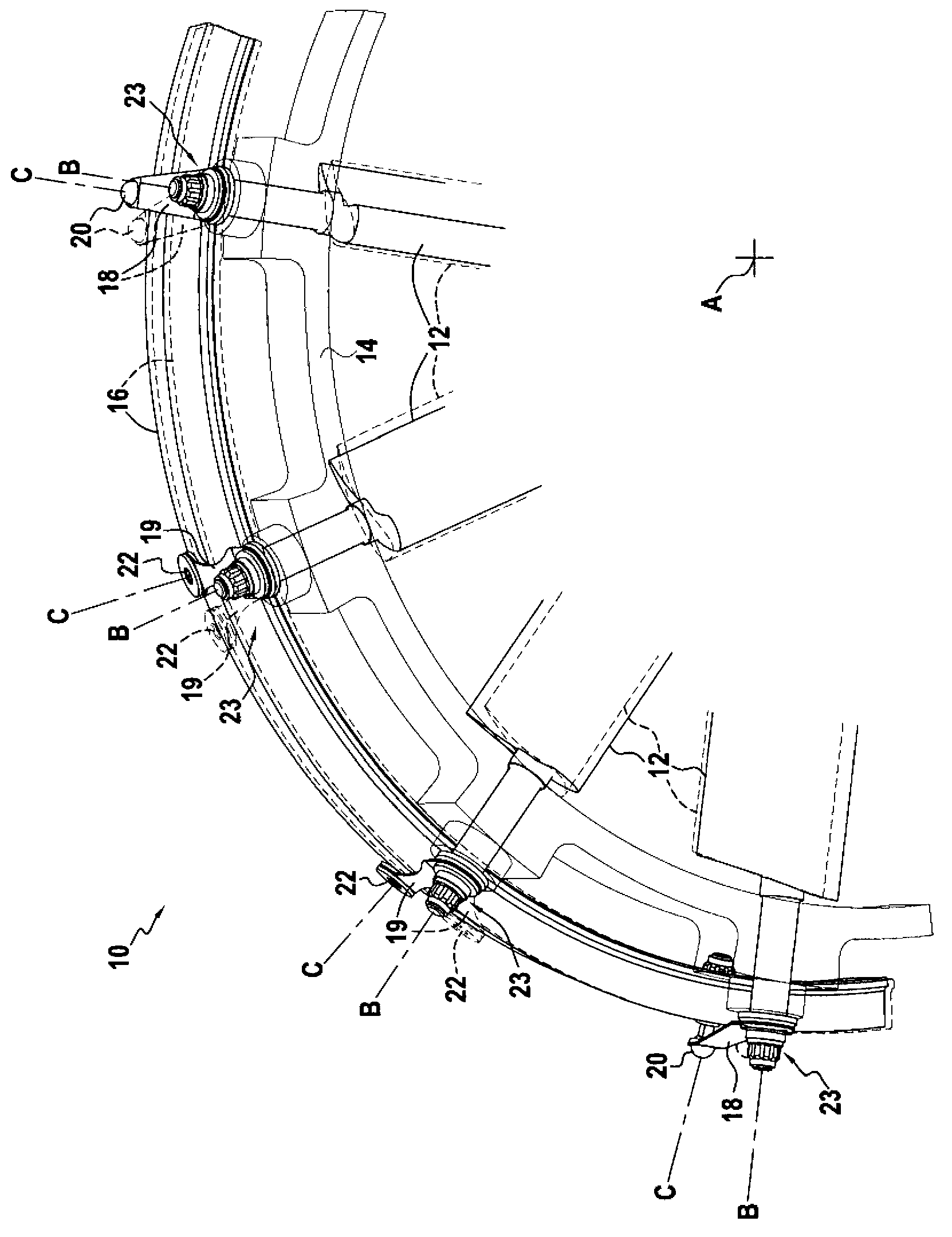

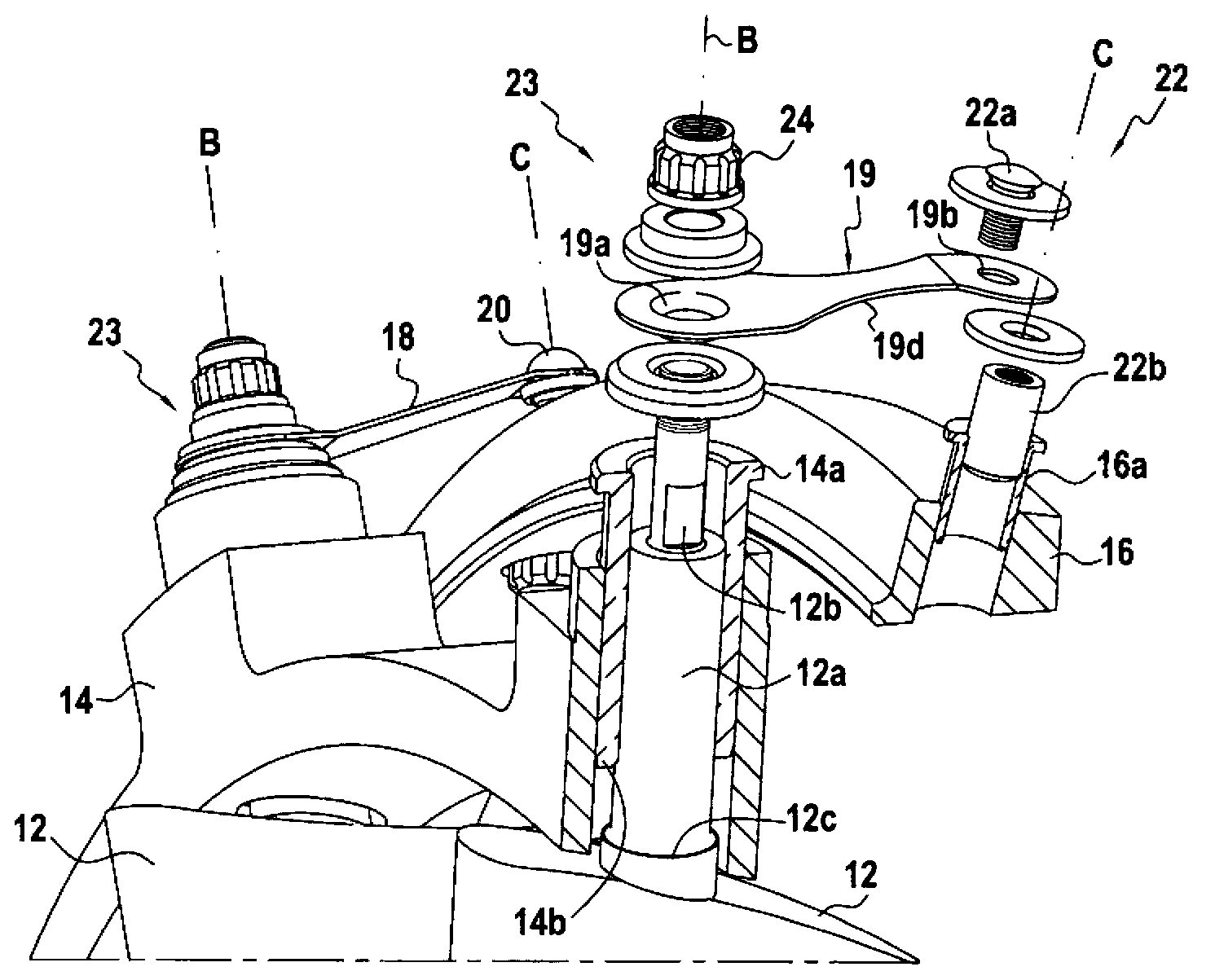

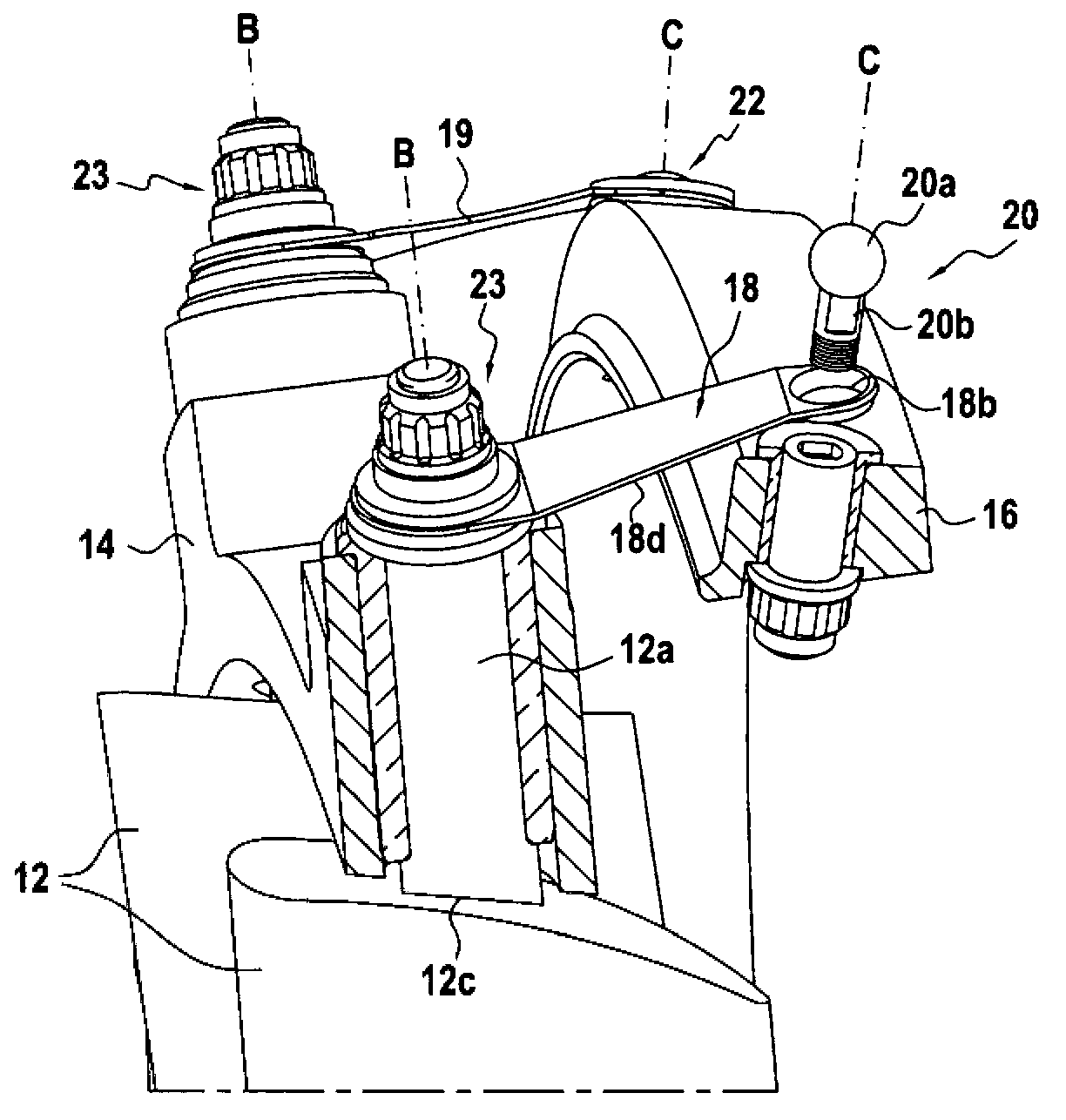

[0038] figure 1 An embodiment of the control device of the invention for controlling pivoting blades of a turbomachine is shown. In this embodiment, the blades are oriented radially with respect to the turbine axis. The schematic diagram shown is a partial one, the whole arrangement extending 360° around the axis A of the turbine (not shown). This axis A forms the longitudinal direction. The radial and azimuthal directions are determined with respect to the axis A.

[0039] The control unit 10 includes a plurality of vanes 12 pivotally mounted on a stator 14 . The pivot axis B of each blade 12 is oriented in a radial direction. Each blade 12 is mounted on the stator 14 by a pivot-only connection 23 (ie pivot connection) in which the only movement (or degree of freedom) allowed is a rotational movement about the axis B.

[0040] Each blade 12 is connected to a control ring 16 by a connecting rod. Each rigid link 18 connects the blade 12 to the control ring 16 by a ball jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com