Abrasion compensation device of driving disc brake and self-compensation method of abrasion compensation device

A disc brake and wear compensation technology, applied in brake actuators, slack adjusters, gear shifting mechanisms, etc., can solve the problems of being easily disturbed by the external environment, high maintenance and operation costs, low automation level, etc. Maintenance time, small overall size, stable and continuous effect of piston return force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

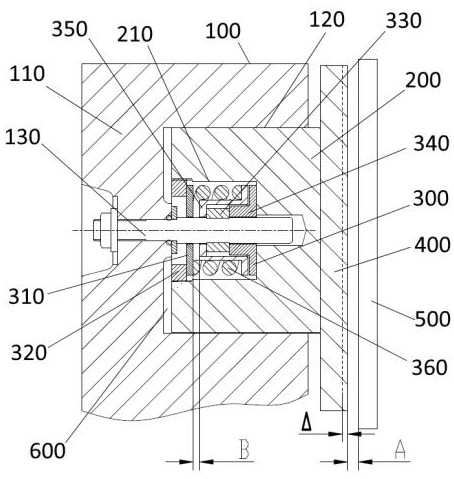

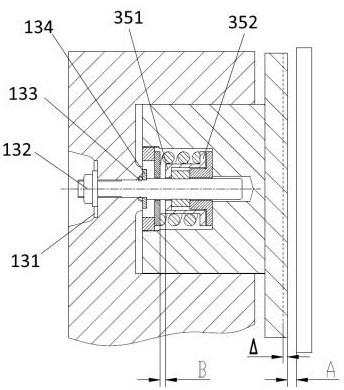

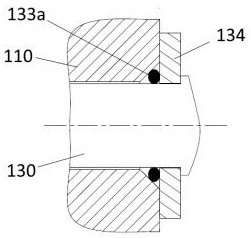

[0045] See attached Figures 1 to 7 , a wear compensation device for a driving disc brake, wherein the brake includes: a caliper body 100, a body portion 110, a first installation space 120, a fixing rod 130, a lock washer 131, a mounting nut 132, a sealing ring 133, Seal pressing plate 134, corner seal 133a, piston 200, second installation space 210, compensation device 300, spring pressing plate 310, fixing nut 320, adjusting expansion sleeve 330, adjusting bushing 340, spring guide sleeve 350, external thread 321, installation groove 322, iron wire 323, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com