Aerodynamic bearing, manufacturing method thereof and mechanical device

The technology of a gas dynamic pressure bearing and its manufacturing method, which is applied in the field of bearings, can solve the problems of reducing the overall bearing capacity of the bearing and not being able to play an effective bearing role, and achieve the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

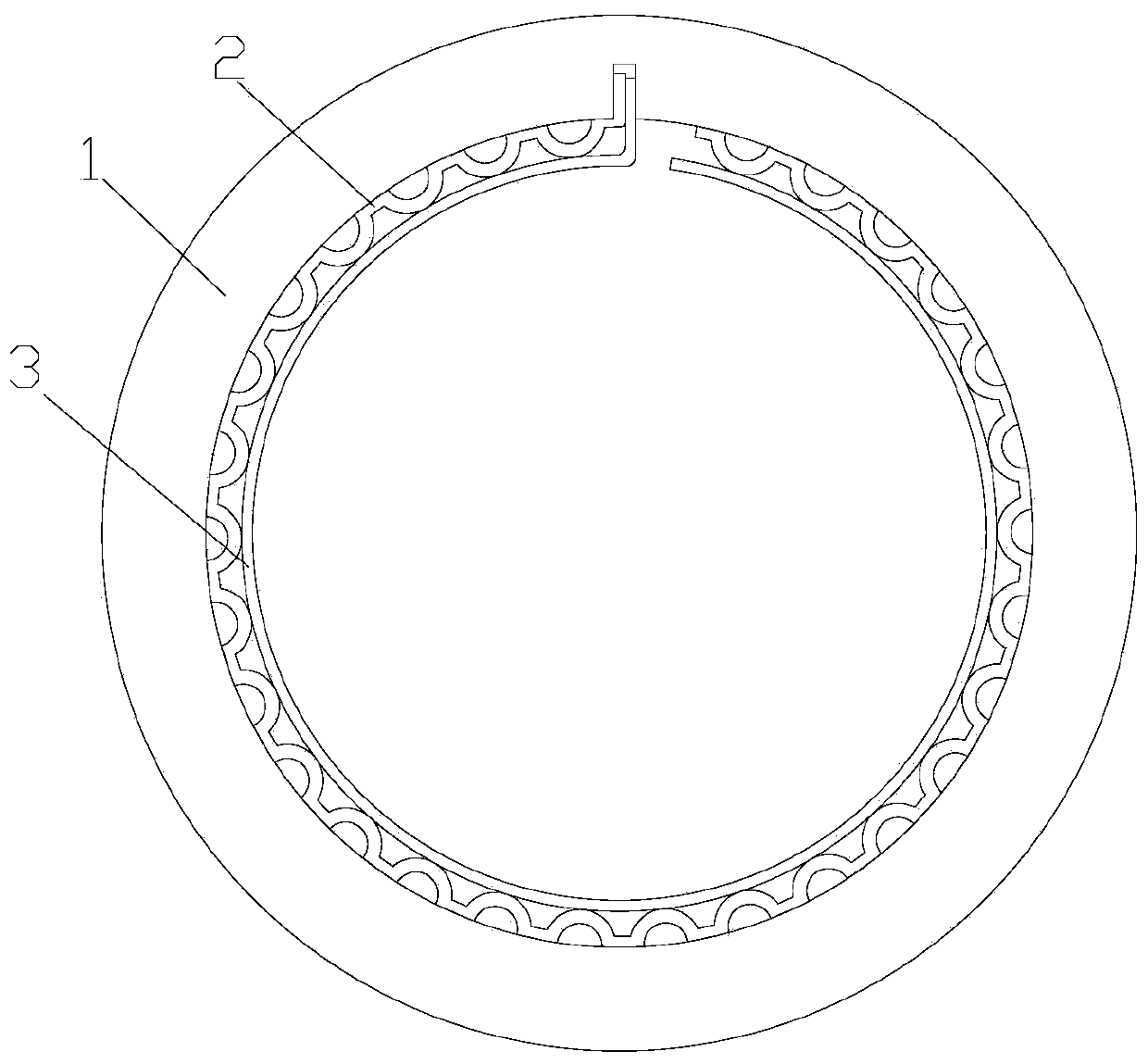

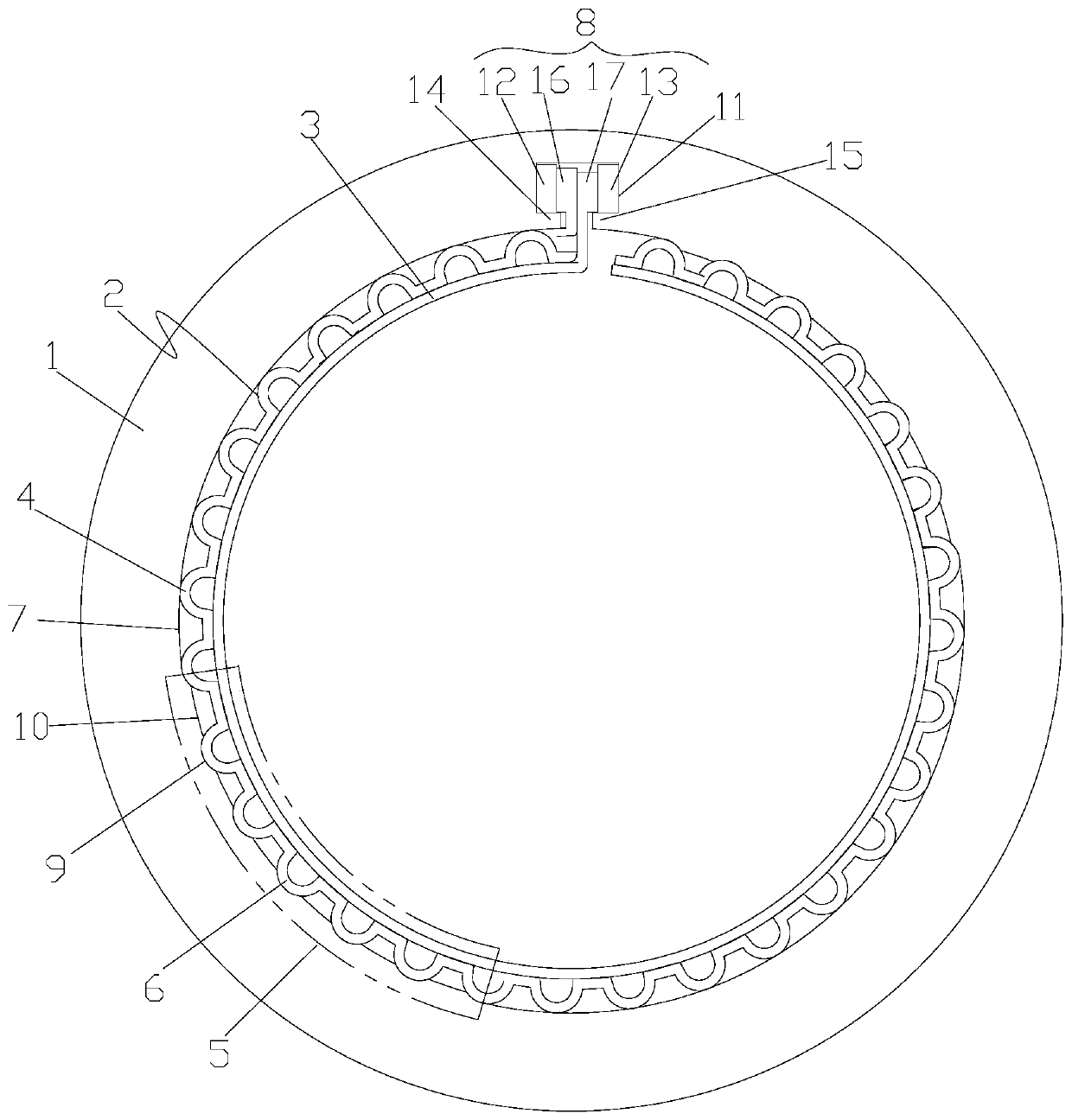

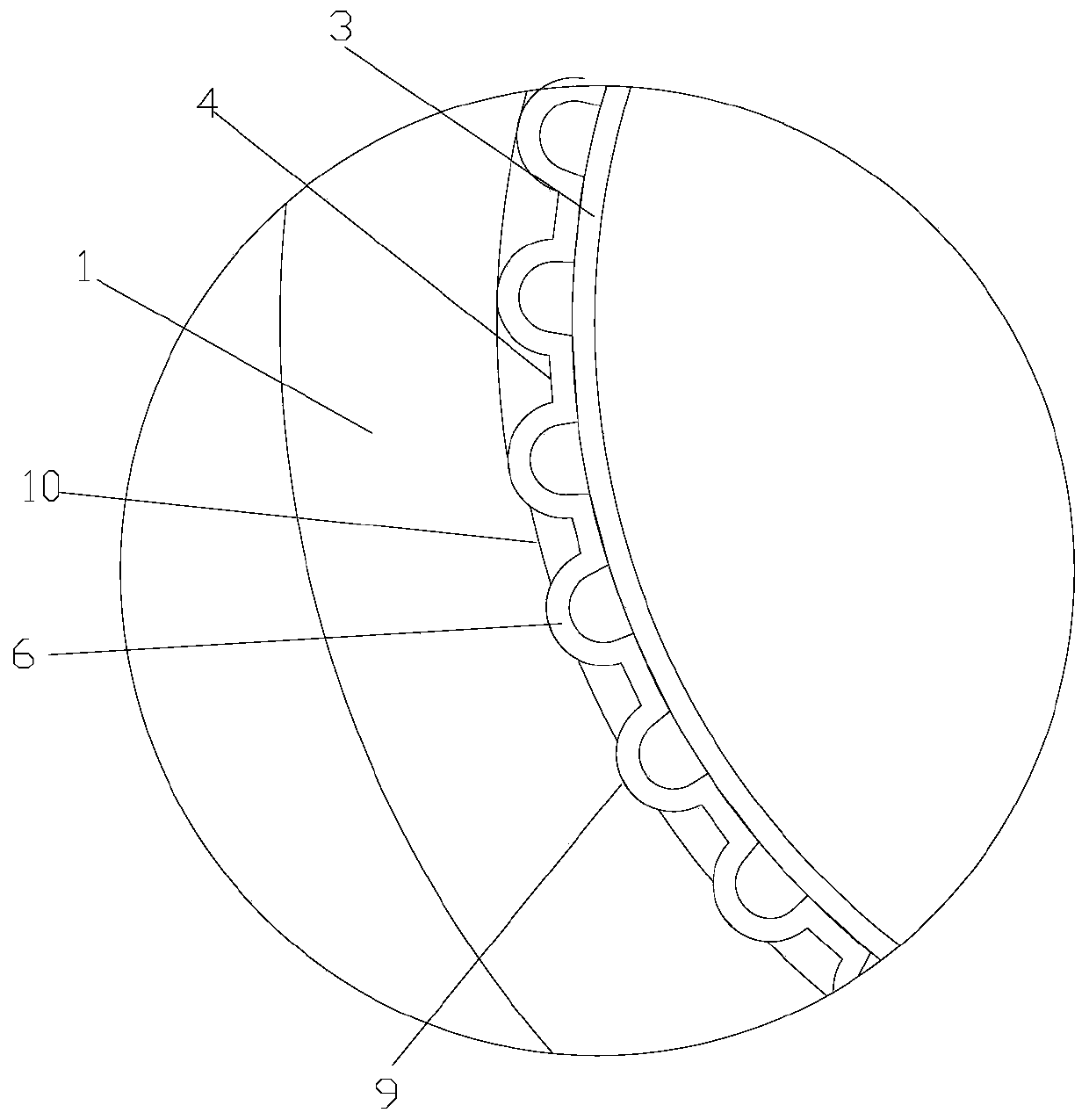

[0055] see in conjunction Figure 2 to Figure 6 As shown, according to the embodiment of the application, the gas dynamic pressure bearing includes a bearing seat 1, an arch foil 2 and a top foil 3, the arch foil 2 is located between the bearing seat 1 and the top foil 3, and the arch foil 2 includes a connecting section 4 and an arch foil Shaped section, connecting section 4 and arched section are arranged in sequence along the circumference of the arch foil 2, the connecting section 4 is connected between the roots of the arched section, the arched section 6 protrudes toward the inner peripheral wall 7 of the bearing seat 1, and the bearing seat The inner peripheral wall 7 of 1 includes a groove 9 corresponding to the arch section 6, and the gas dynamic pressure bearing also includes an adjustment structure 8 for adjusting the circumferential position of the arch foil 2 relative to the bearing seat 1, and the adjustment structure 8 adjusts the arch. The circumferential posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com