Full-automatic cooked meat processing equipment for production of meat products

A processing equipment, fully automatic technology, applied in metal processing and other directions, can solve the problems of low efficiency, uneven meat slices, time-consuming and labor-intensive, etc., to prevent slippage, achieve changes, and achieve the effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

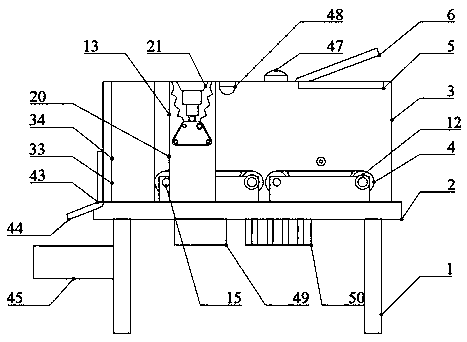

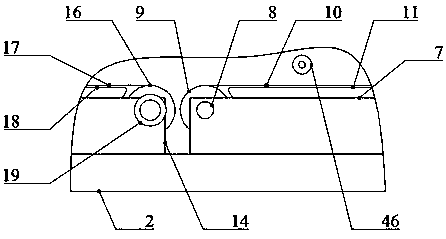

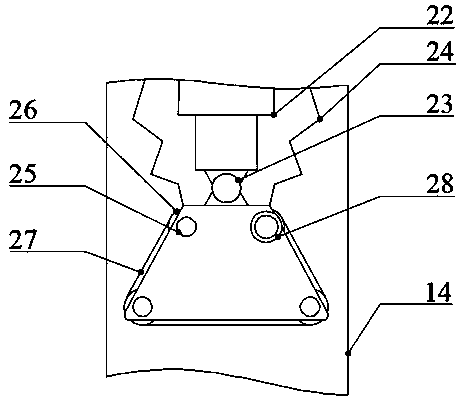

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a fully automatic cooked meat processing equipment in the production of meat products includes an equipment support 1, the equipment support 1 is fixedly installed on the ground, a support plate 2 is arranged above the equipment support 1, and the support plate 2 The top is provided with a protective box 3, and the upper right end of the support plate 2 is provided with a meat feeding device 4, and the meat feeding device 4 consists of a meat opening 5 opened in the middle of the upper surface of the protective box 3, and is located in the protective box. 3 above and a transparent cover 6 that is rotatably connected to the front edge of the meat opening 5 at one end, a support seat 7 that is fixedly connected to the right end of the upper surface of the support plate 2 above the support plate 2, a conveying shaft 8 that is sleeved in the support base 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com