Mounting process of novel drilling, anchoring and injecting integrated resin anchor rod

An installation process and bolt technology, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of inability to realize high-pressure grouting at the end, complicated installation process, and easy failure, so as to reduce the implementation process and reduce the Effect of labor intensity and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

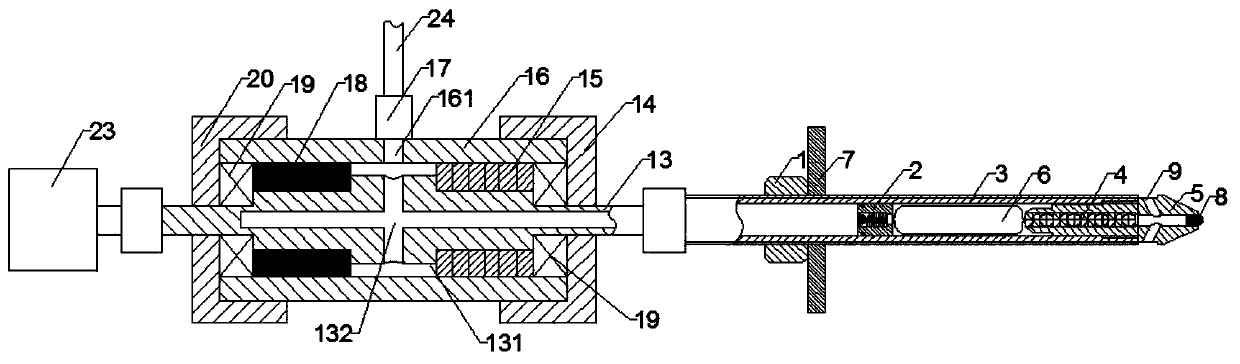

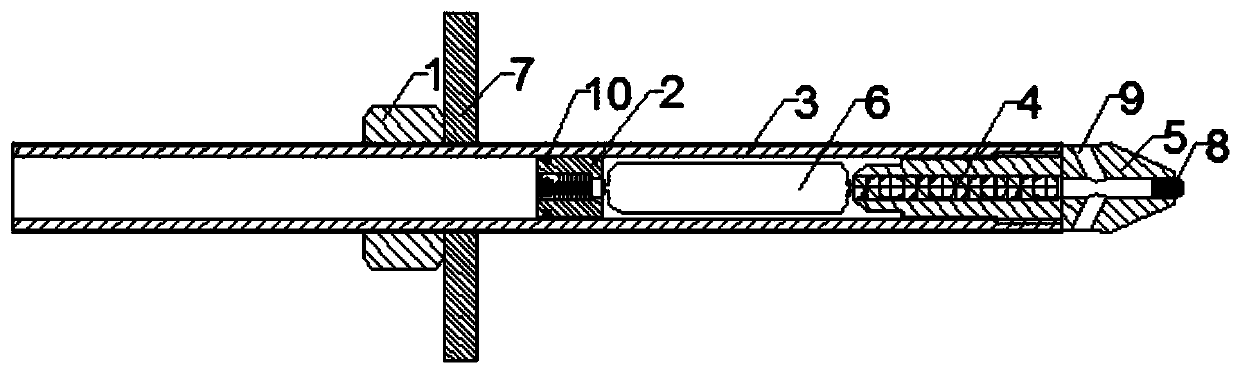

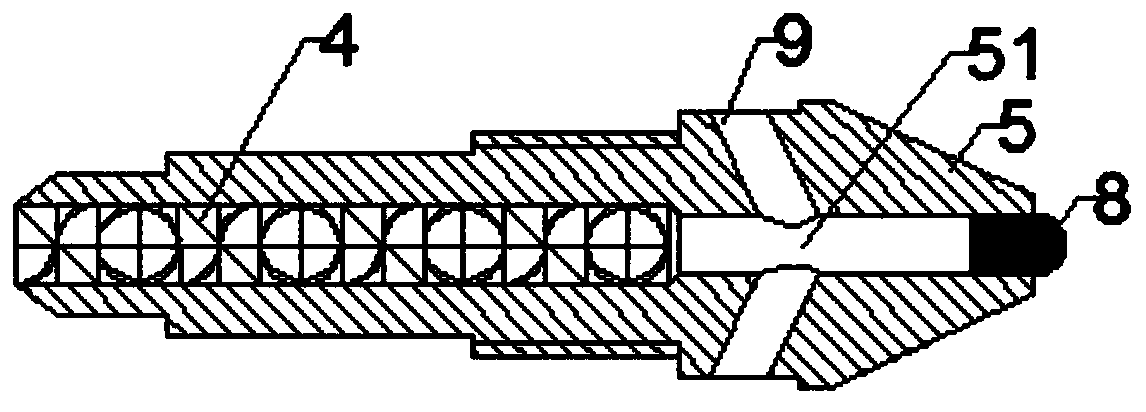

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1 to Figure 5 As shown, the installation process of a new type of drilling, anchoring and injecting integrated resin anchor rod of the present invention includes the following steps:

[0032] a. Select swivel joint and anchor rod,

[0033] A rotary joint, the rotary joint includes a rotating shaft 13, a sleeve 16 and a rotating seal assembly, the rotating shaft 13 and the sleeve 16 are connected in a rotating and sealed manner through the rotating sealing assembly, and the inside of the rotating shaft 13 is provided with a grouting through hole 132, the grouting through hole 132 It includes a connected radial hole and an axial hole. The end of the radial hole away from the axial hole extends out of the outer wall of the rotating shaft 13. The axial hole is a blind hole structure, and one end extends to the end surface of the rotating shaft 13. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com