Flat wire automatic unloading forming machine of flat wire hairpin motor of new energy automobile

A new energy vehicle, automatic off-line technology, applied in the field of machinery, can solve problems such as the output power reduction of the card-generating motor and the reduction of the coil cross-sectional area, and achieve the effect of consistent length and shape of the profiling, less damage, and improved processing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be described in detail below through specific embodiments.

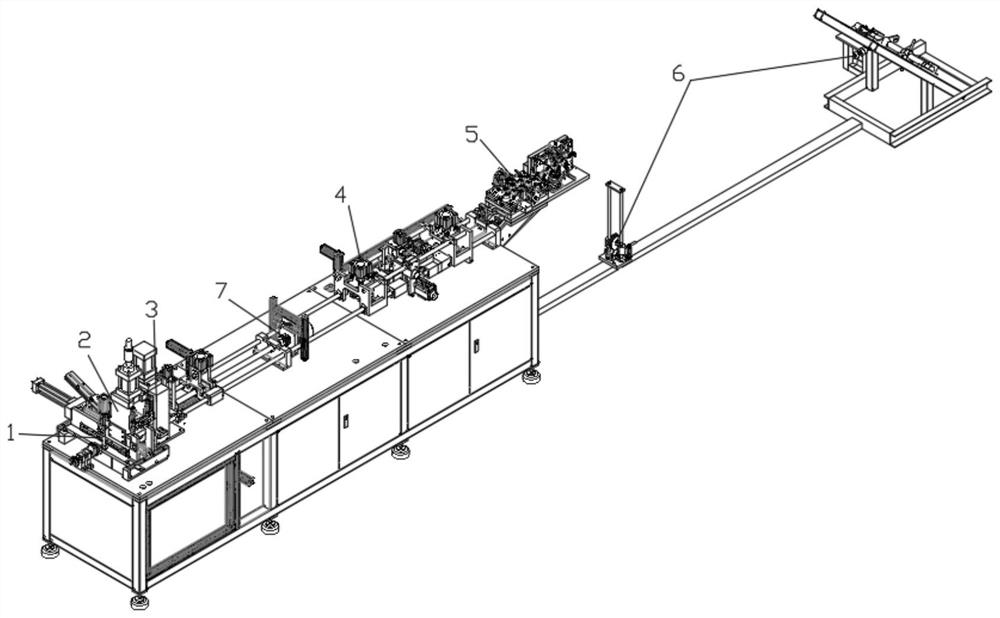

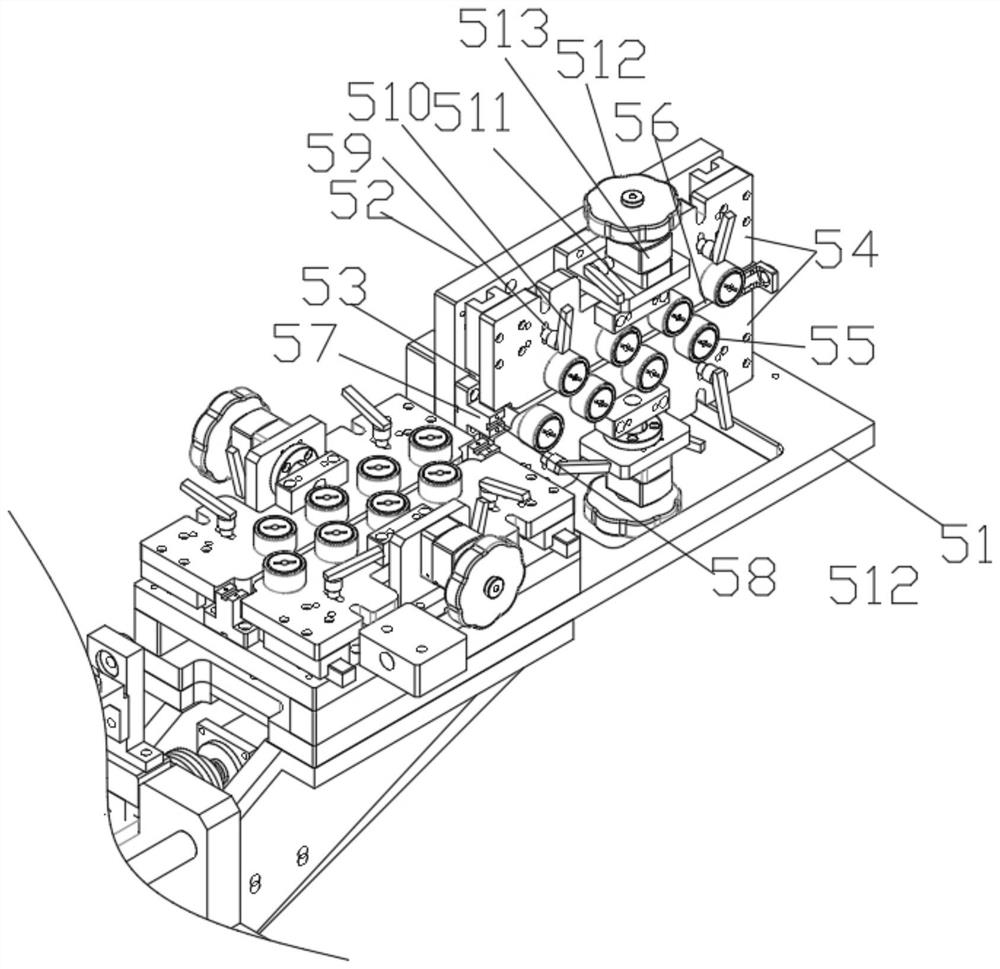

[0046] Such as Figure 1-20 The flat wire automatic off-line forming machine of the new energy automobile flat wire issuing motor shown in the figure is equipped with an automatic pre-feeding mechanism 6, a flat wire straightening mechanism 5, and a profiling tool non-destructive paint peeling mechanism 4 in sequence along the flat wire traveling direction , flat wire feeding mechanism 7, flat wire chamfering and initial cutting mechanism 3, hairpin imitation length equal positioning rotary wire breaking mechanism 1 and hairpin imitation forming and automatic blanking mechanism 2.

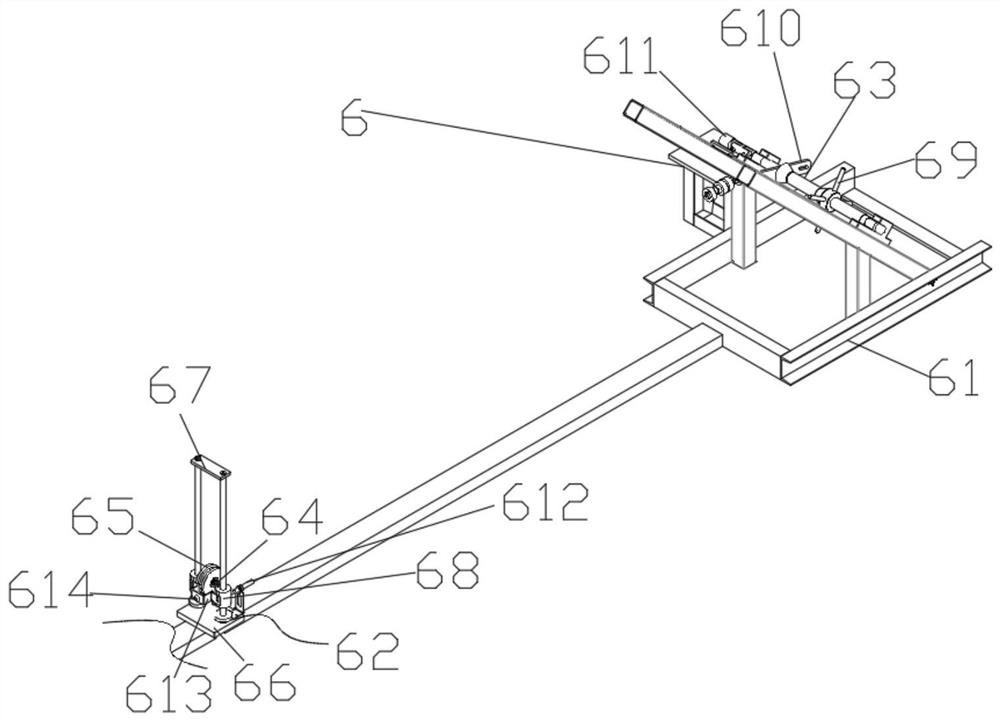

[0047] The automatic pre-feeding mechanism 6 includes a first support 61 and a second support 62, the first support 61 is axially connected with a flat wire winding shaft 63, and the flat wire winding shaft 63 is connected with a pay-off motor 611; A rotating shaft 64 is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com