Off-resonance three-dimensional elliptical diamond vibration cutting method and device

A vibration cutting and diamond technology, applied in the direction of automatic control devices, feeding devices, auxiliary devices, etc., can solve the problems that affect the processing accuracy, non-adjustable, crosstalk, etc., and achieve the effect of precise control, easy precise control, and precise fine-tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

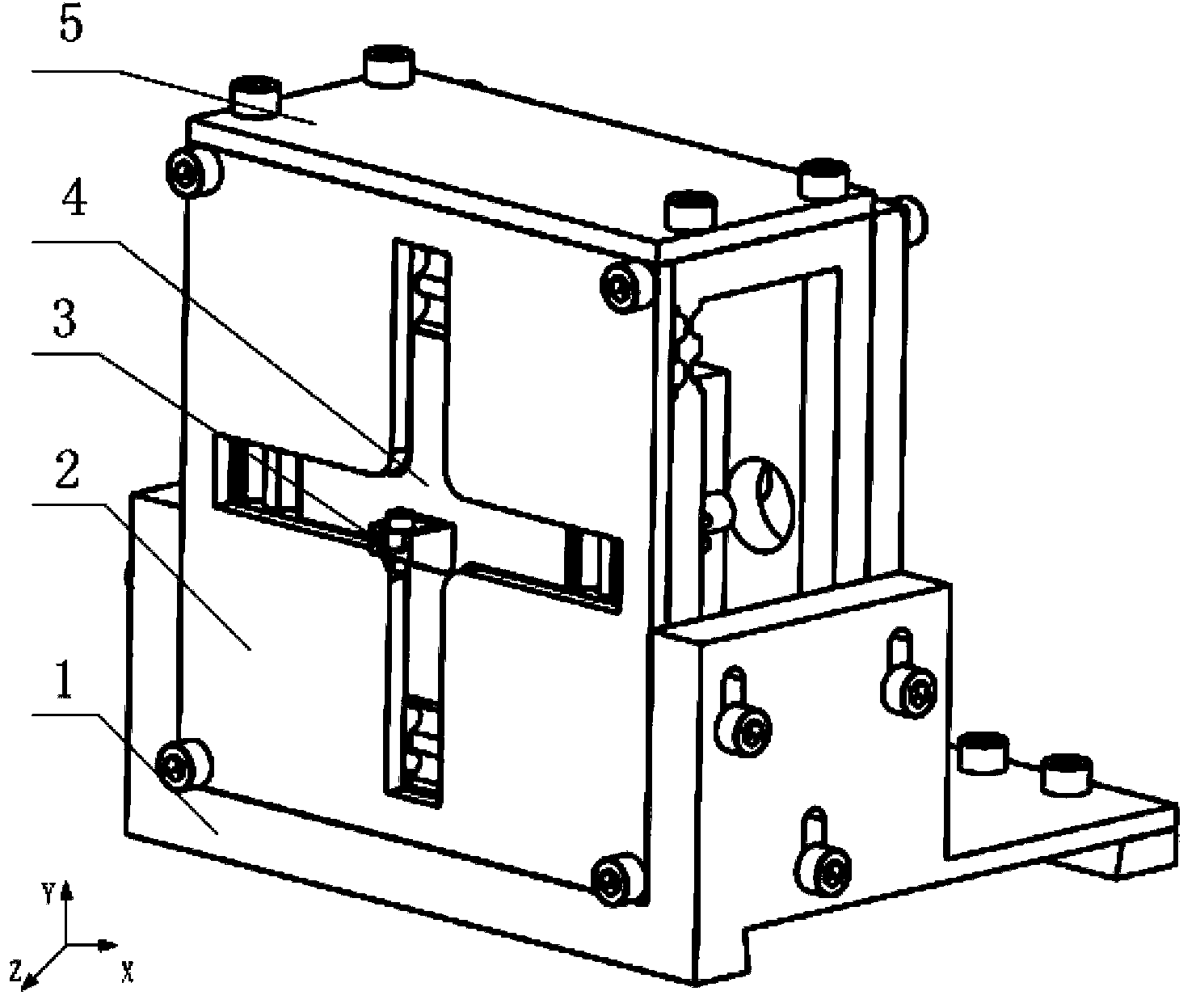

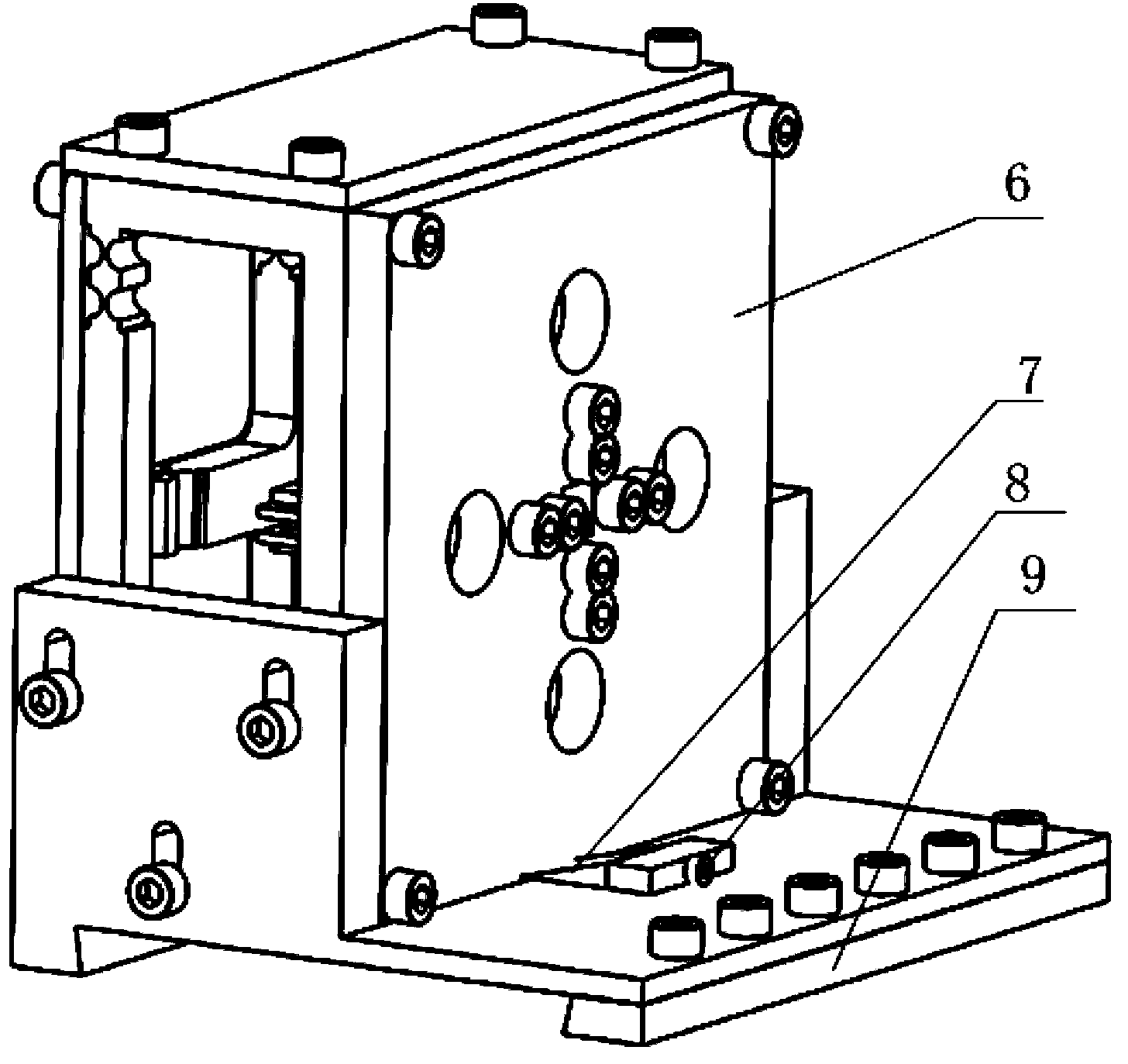

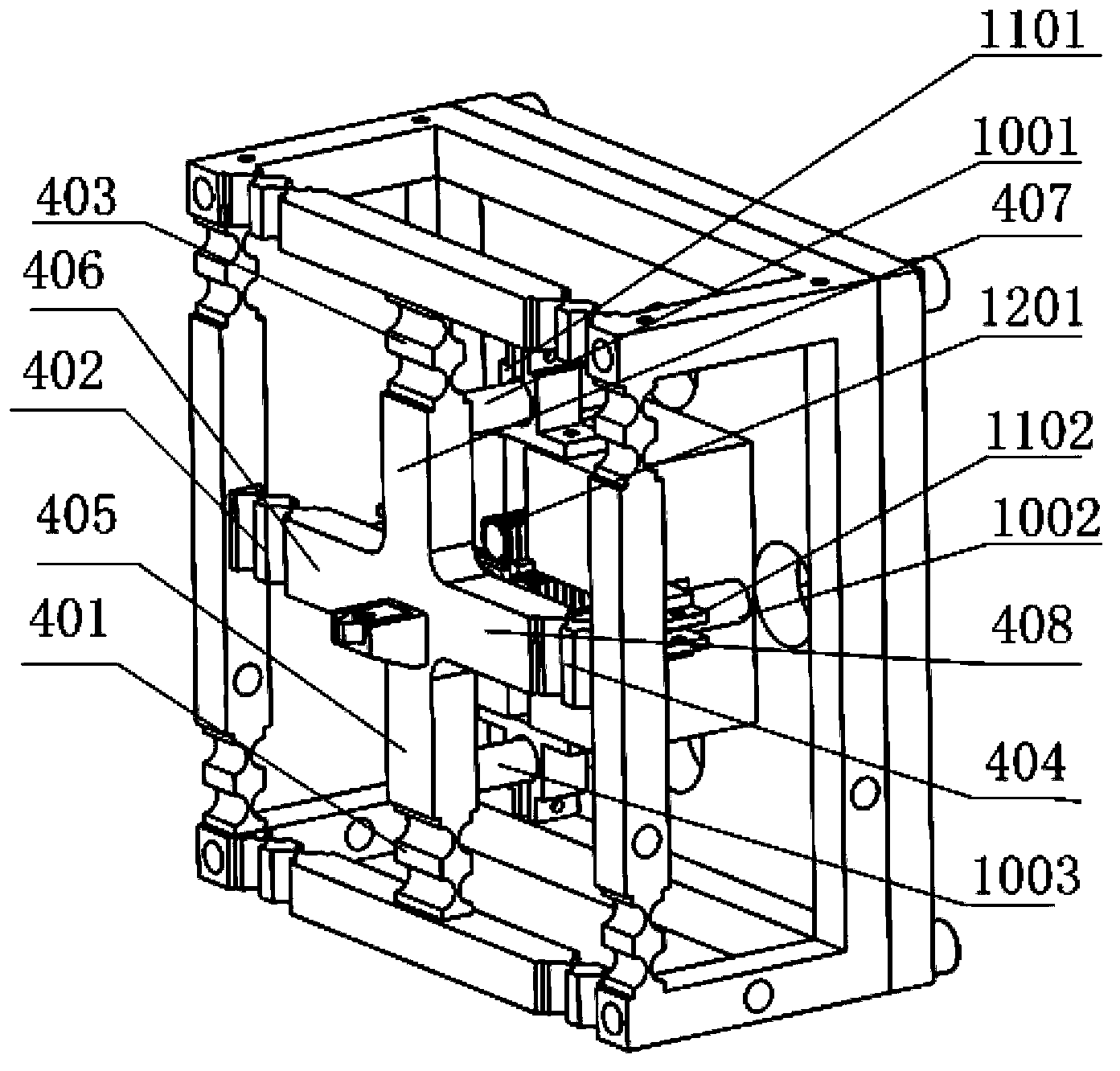

[0033] A non-resonant three-dimensional elliptical diamond vibration cutting method is as follows:

[0034] The four parallel piezoelectric stacks 1 1201, 2 piezoelectric stack 1202, 3 piezoelectric stack 1203, and 4 piezoelectric stack 1204 are respectively driven by the input driving signal, and the driving signal is: The four piezoelectric stacks respectively push the first push surface 405, the second push surface 406, the third push surface 407, and the fourth push surface 408 on the hinge base 4 of the knife seat, so that the hinge one 401, the hinge two 402, the hinge three 403, the hinge 404 generates micro-displacement for guidance, and when there is a phase difference between the phase angles of the four piezoelectric stack drive signals, an adjustable three-dimensional elliptical motion trajectory of the diamond tool tip point of the diamond tool 3 is obtained. The trajectory can be actively adjusted through the frequency, amplitude, and phase difference of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com