Spindle drive

A screw drive, screw technology, applied in the direction of transmission, power control mechanism, door/window accessories, etc., can solve problems such as limiting compactness, and achieve the effect of improving radial compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

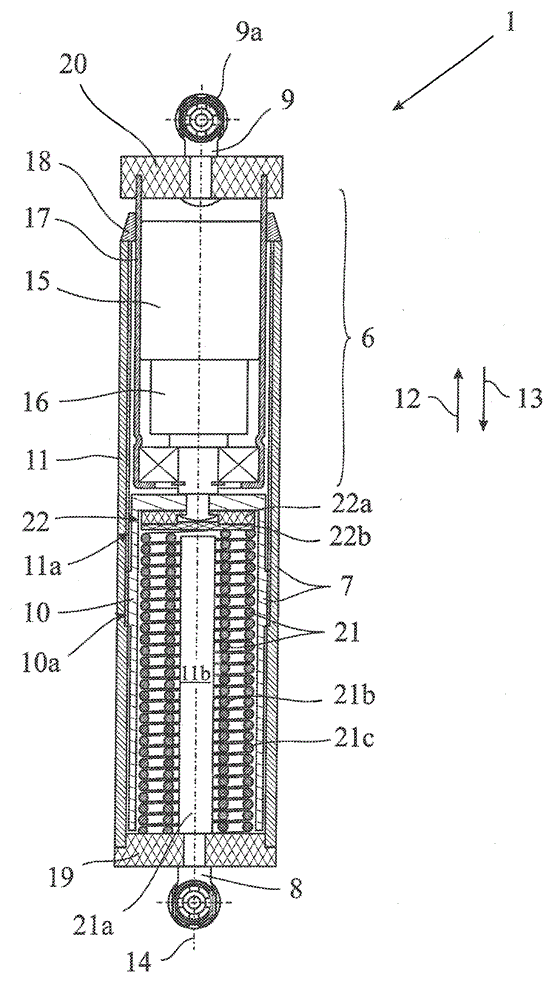

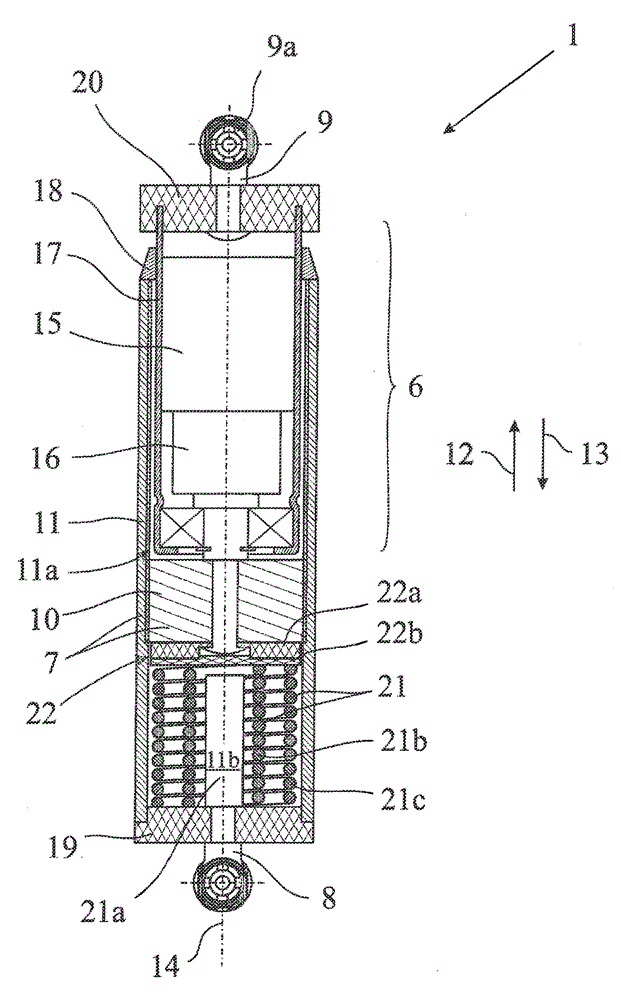

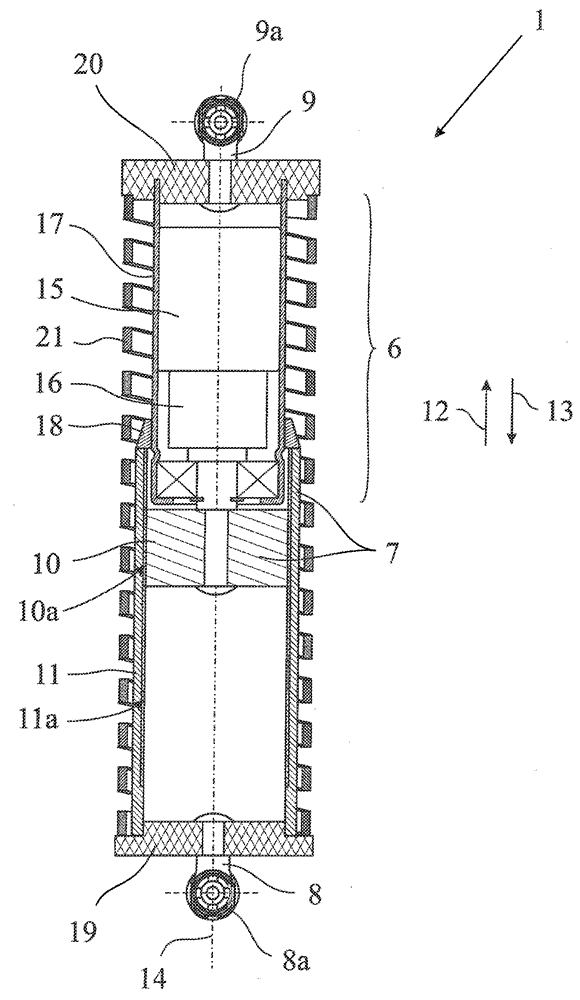

[0020] The screw drive 1 shown in the drawing is used to electrically adjust a motor vehicle flap 2 , which here is formed by the rear lid. Please refer to the description above regarding the term "clamshell".

[0021] Back cover 2 is generally used for closing back cover hole 3, and wherein screw drive device 1 is arranged on the side of back cover hole, preferably is arranged on the inside of rain gutter 4 laying on back cover hole 3 sides here. and figure 1 Only a single screw drive 1 is shown. However, it is preferably provided here that a screw drive 1 is arranged on each side of the rear cover opening 3 . The two screw drives 1 are substantially identical in structure.

[0022] according to figure 1 It can be seen that the screw drive shown there is hinged at one end to the vehicle body 5 and at the other end to the rear cover 2 . The screw drive 1 advantageously has only a slight length, which is given by the proposed construction of the screw drive.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com