Roller-bearing preloading adjustment structure and method

A technology for adjusting the structure of roller bearings, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of high manufacturing cost and installation cost, low efficiency, and prolonged operation cycle of parts, and achieve reduction Use, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

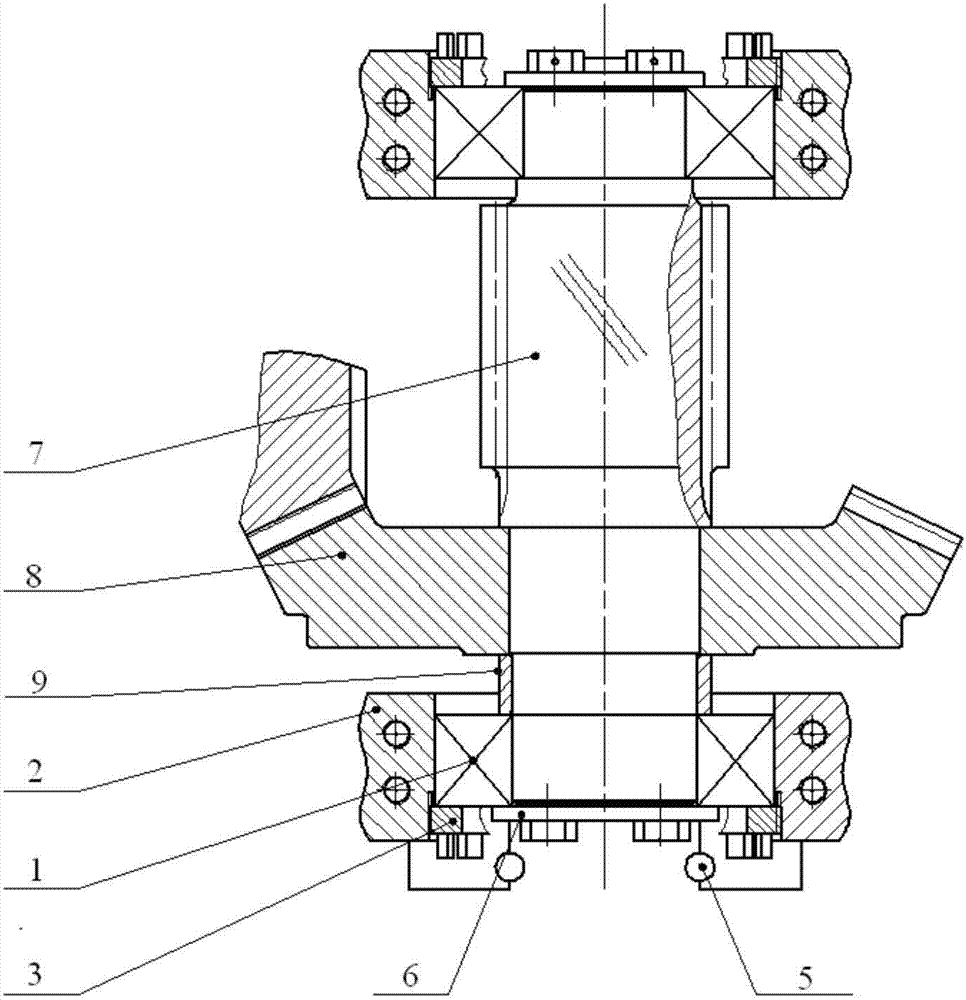

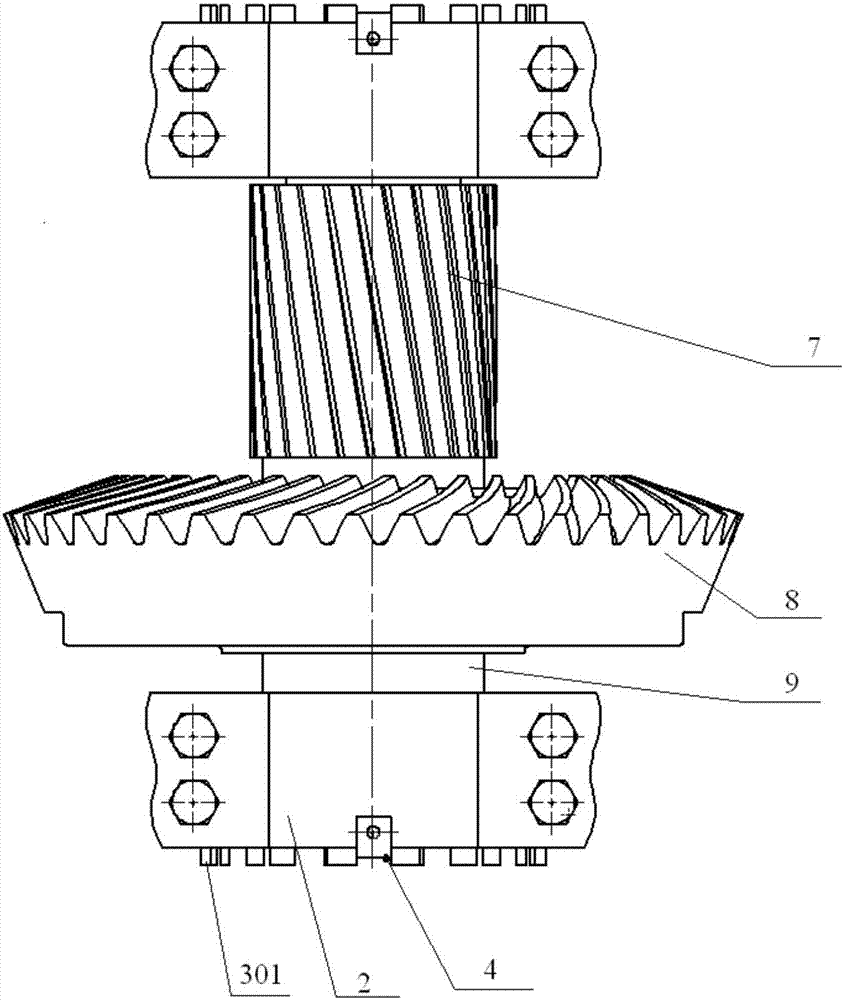

[0048] Such as Figure 1-7 As shown, the present invention discloses a roller bearing preload adjustment structure, which includes a roller bearing 1 , a bearing housing 2 and a bearing lock nut 3 .

[0049] Wherein, the roller bearing 1 can be installed on the transmission shaft, and the transmission shaft can be an input shaft or an output shaft. The roller bearing 1 is supported by the bearing housing 2 , and the outer diameter of the roller bearing 1 is in contact with the inner hole wall of the bearing housing 2 .

[0050] The bearing seat 2 is installed on the casing, and the outer end of the inner ring of the bearing seat 2 has an internal fine thread at a suitable position.

[0051]The bearing lock nut 3 is provided with an outer fine thread that engages with the inner fine thread on the bearing seat 2, and the inner end surface of the bearing lock nut 3 abuts against the outer ring of the roller bearing 1, wherein the bearing is locked The inner end surface of the n...

Embodiment 2

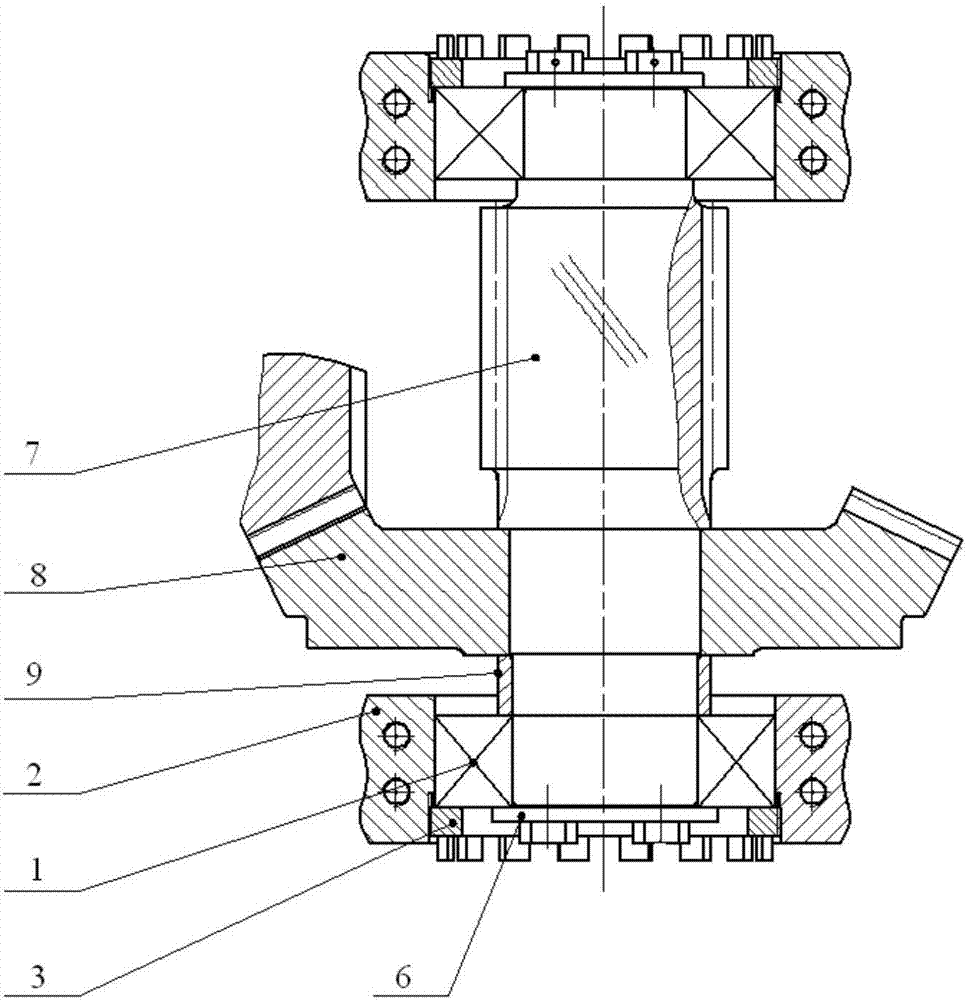

[0057] In the second embodiment provided by the present invention, the roller bearing preload adjustment structure in this embodiment is similar to the roller bearing preload adjustment structure in Embodiment 1, and the similarities will not be repeated here. Only the differences are presented.

[0058] In this embodiment, it is specifically disclosed that the roller bearing preload adjustment structure also includes a stop washer 4 detachably installed on the bearing seat 2, the stop washer 4 can lock the bearing lock nut 3, and the stop washer 4 The setting further strengthens the connection firmness between the bearing lock nut 3 and the bearing housing 2, and prevents the bearing lock nut 3 from loosening due to vibration and the like.

[0059] Further, the present invention specifically discloses a specific connection structure between the stop washer 4 and the bearing seat 2: a plurality of bosses 301 are evenly distributed on the end surface of the bearing lock nut 3, ...

Embodiment 3

[0074] In the third embodiment provided by the present invention, the roller bearing preload adjustment structure in this embodiment is similar to the roller bearing preload adjustment structure in Embodiment 2, and the similarities will not be repeated here. Only the differences are presented.

[0075] In this embodiment, it is specifically disclosed that in the roller bearing preload adjustment structure, the end surface of the bearing lock nut 3 is uniformly provided with a plurality of grooves. The stop washer 4 includes a third plate, a fourth plate and a fifth plate, the third plate is vertically connected to the fourth plate, the fifth plate is vertically connected to the fourth plate, and the third plate and the fifth plate are arranged symmetrically, that is, The movable washer 4 is a U-shaped plate with a vertical bottom. A second threaded hole is opened on the third plate, a third threaded hole is opened on the fifth plate, both the third plate and the fifth plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com