Wheel nut tightening device

A wheel and nut technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the tightening force of multiple nuts cannot be guaranteed, the tightening degree cannot be monitored, and there is impact in the operation process, etc., so as to improve work efficiency, Enhance the stability and service life, the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

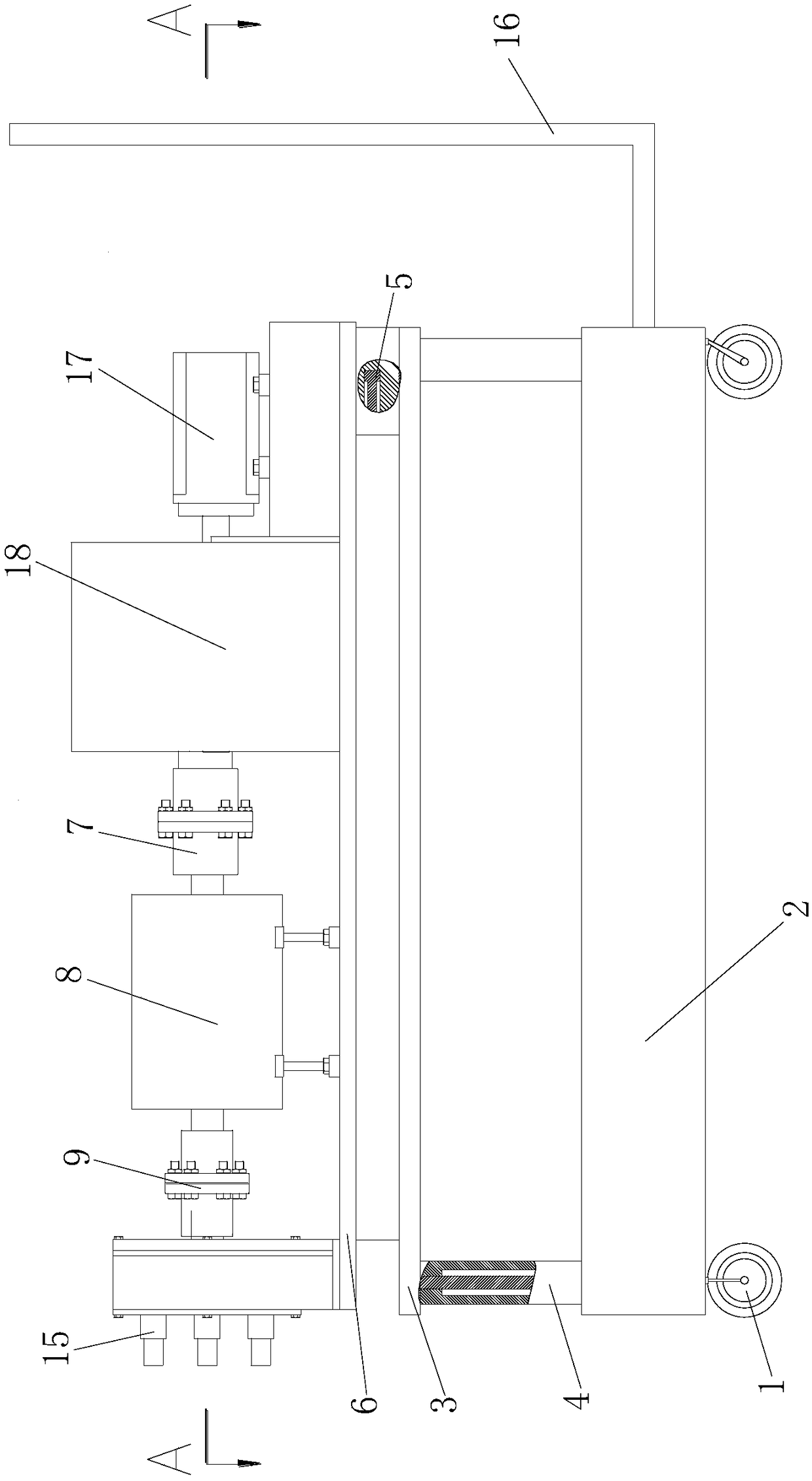

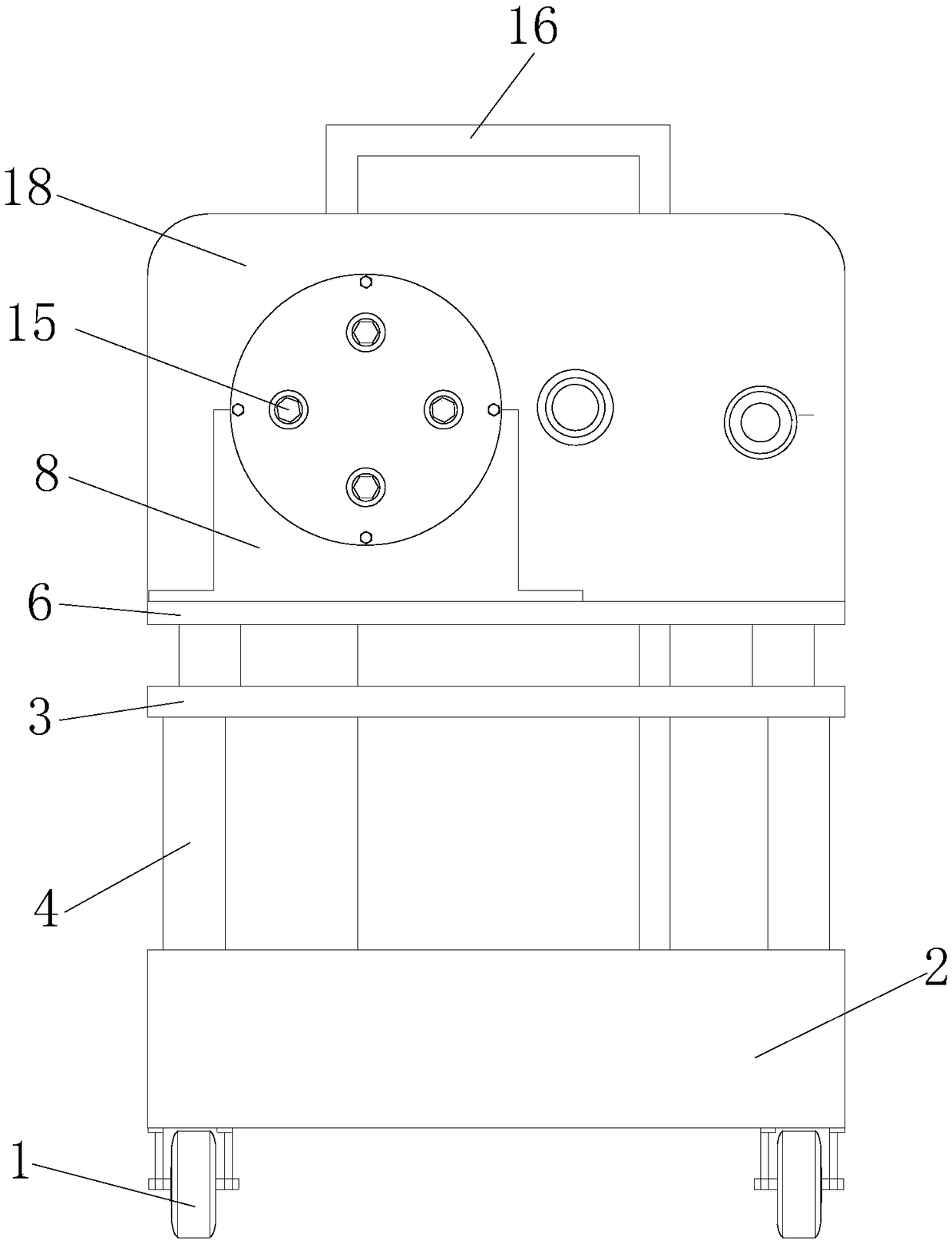

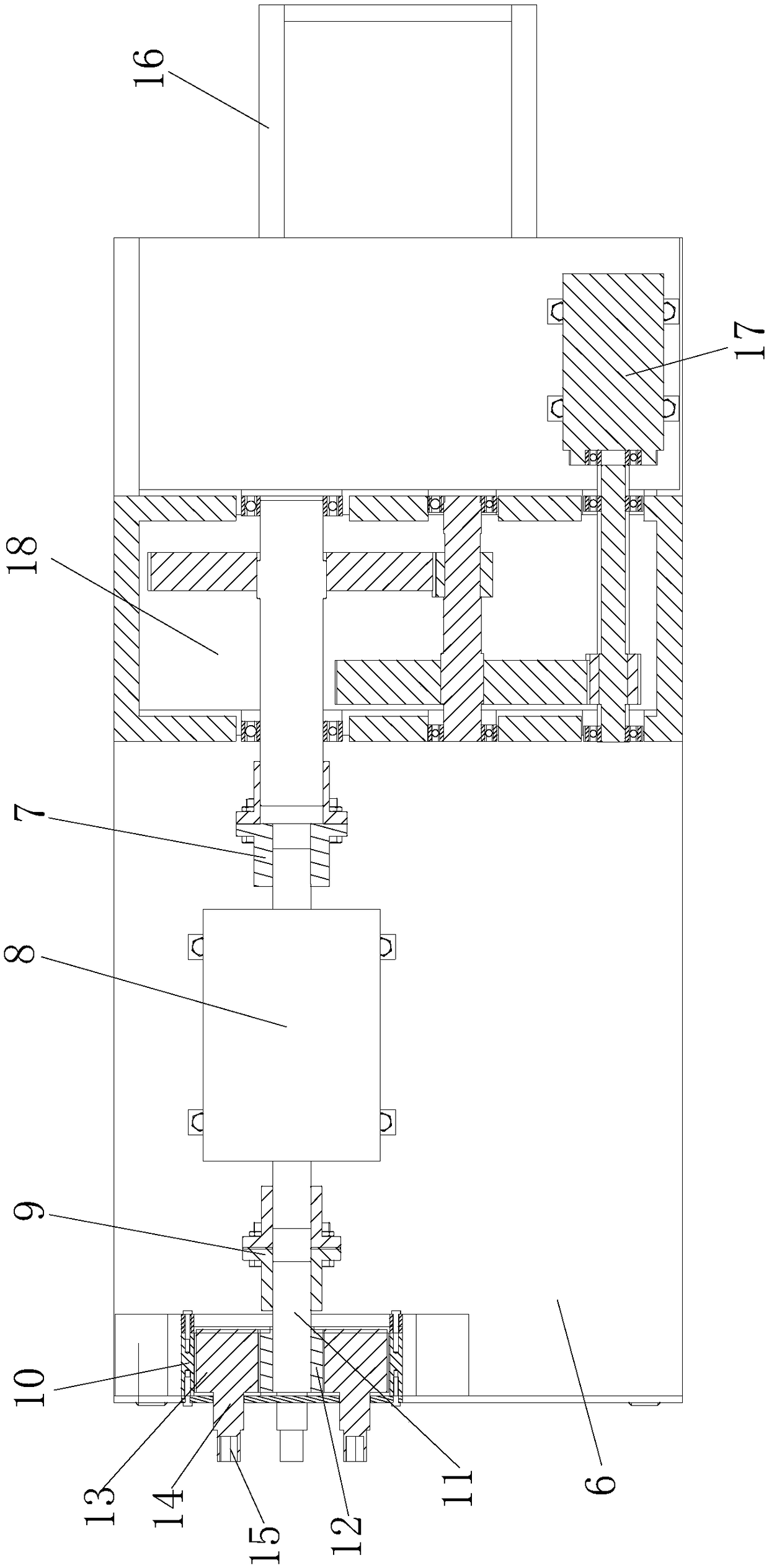

[0030] like Figure 1 to Figure 3 As shown, the present invention includes a mobile platform and an automatic nut tightening device. The mobile platform includes a wheel 1, a vehicle frame 2, a track plate 3, a lifting hydraulic cylinder 4, a propulsion hydraulic cylinder 5 and an installation base plate 6, and the wheel 1 is fixedly installed At the bottom of the vehicle frame 2, the track plate 3 is arranged above the vehicle frame 2, the lifting hydraulic cylinder 4 is arranged between the vehicle frame 2 and the track plate 3, and the lower end of the lifting hydraulic cylinder 4 is connected to the vehicle frame 2. Fixedly connected, the upper end of the lifting hydraulic cylinder 4 is fixedly connected to the track plate 3 and used to adjust the height of the track plate 3 from the frame 2, the installation base plate 6 is arranged above the track plate 3 and can be positioned along the track plate 3 Sliding back and forth, one end of the propulsion hydraulic cylinder 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com