Rotor bearing for a laboratory centrifuge

A laboratory centrifuge, rotor support technology, applied in the field of rotor support devices, can solve problems such as danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

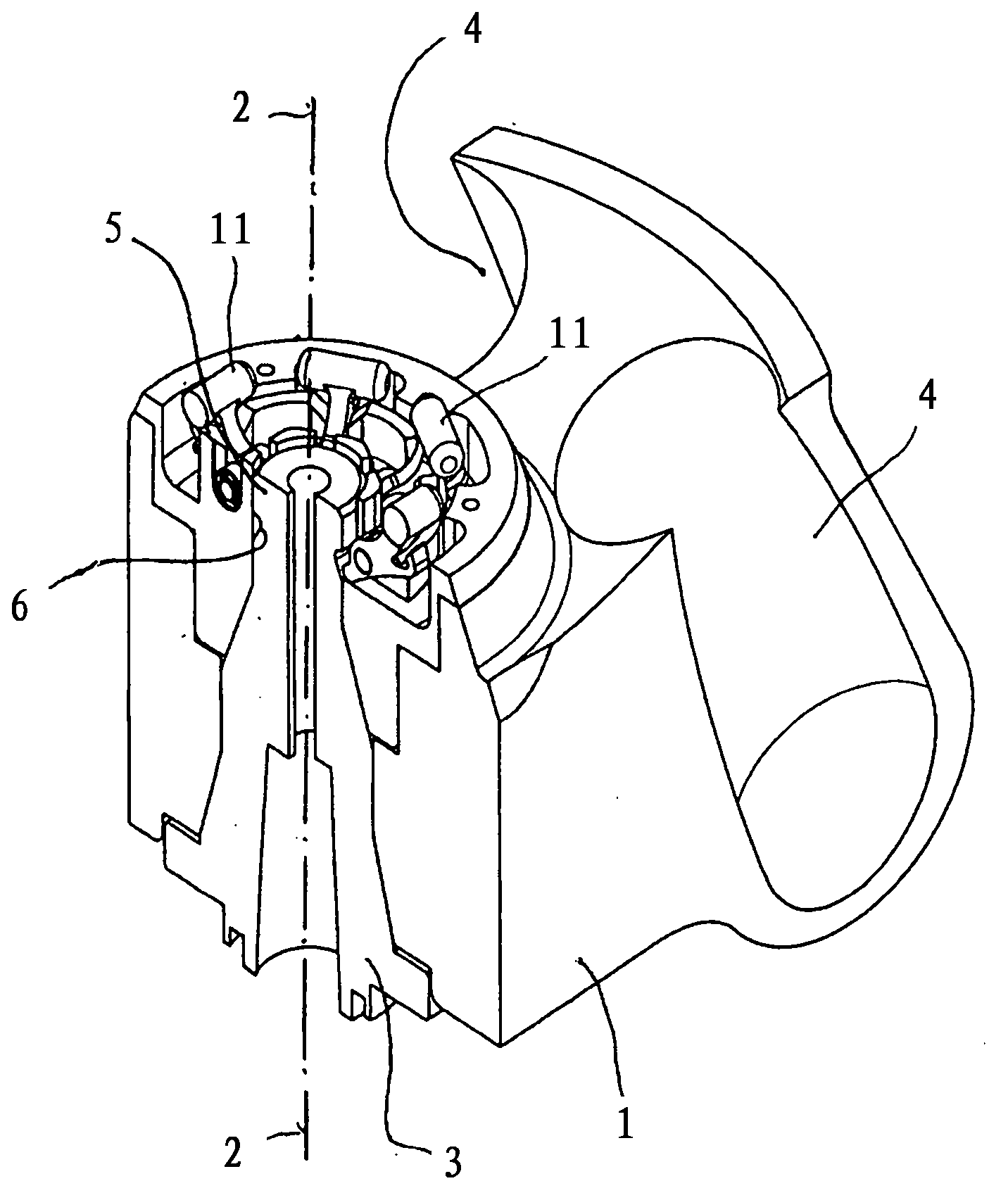

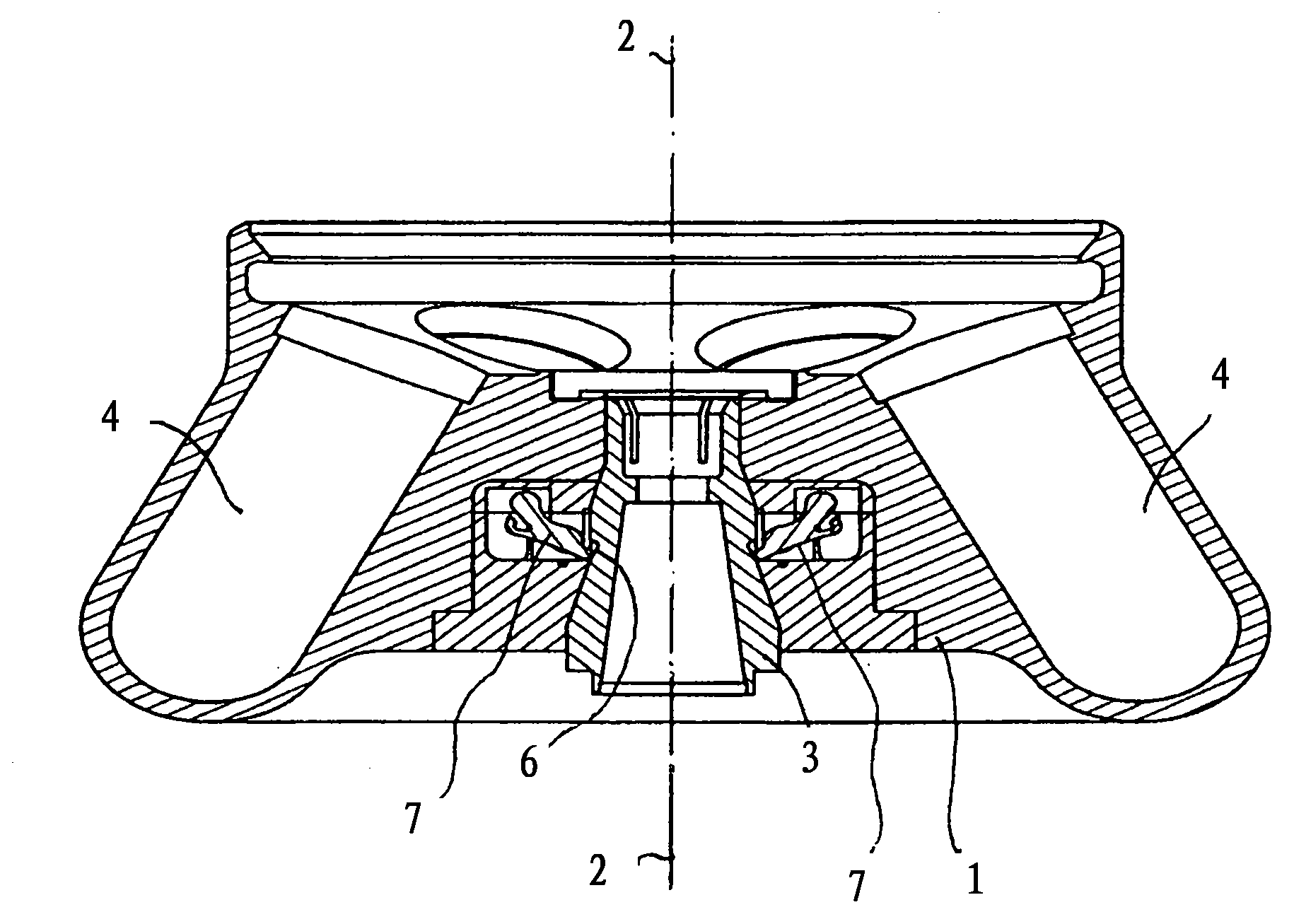

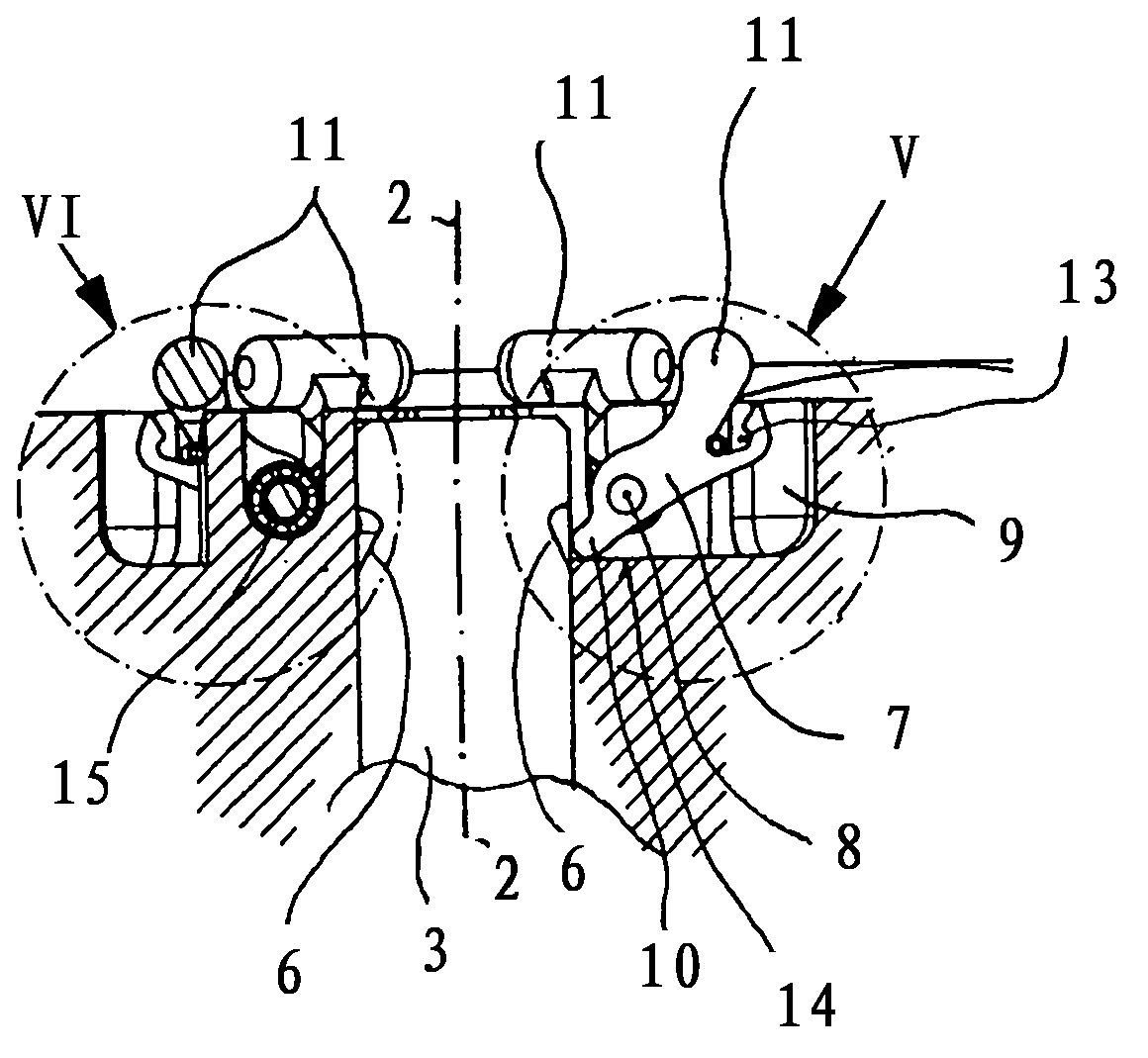

[0028] figure 1 and 2 In each case a rotor 1 of a laboratory centrifuge is shown, which can be slipped onto the upper end of a shaft 3 mounted rotatably about an axis 2 . The shaft 3 is connected to the drive in a manner not shown in the figures.

[0029] In a known manner, the rotor 1 is provided in the peripheral region with recesses 4 , which extend upward at an angle in the direction of the axis 2 and are respectively intended to receive containers for the mixture to be centrifuged.

[0030] The shaft 3 has, on its upper end 5 for fitting the rotor 1 , a plurality of sections that enlarge conically in the axial direction from top to bottom, wherein the inner contour of the rotor 1 has sections adapted to the aforementioned sections. In particular, the outer contour of the shaft 3 has an annular groove 6 intended to cooperate with a locking system, which will also be described below, for ensuring a fixed fit of the rotor 1 in the socketed position, and Especially during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com