Adjustable constant-force screen manufacturing device and application method thereof

A production device and adjustable technology, which can be applied to other home appliances, nets, applications, etc., can solve problems affecting performance, looseness of the screen, insufficient tension, etc., and achieve convenient operation, improved production efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

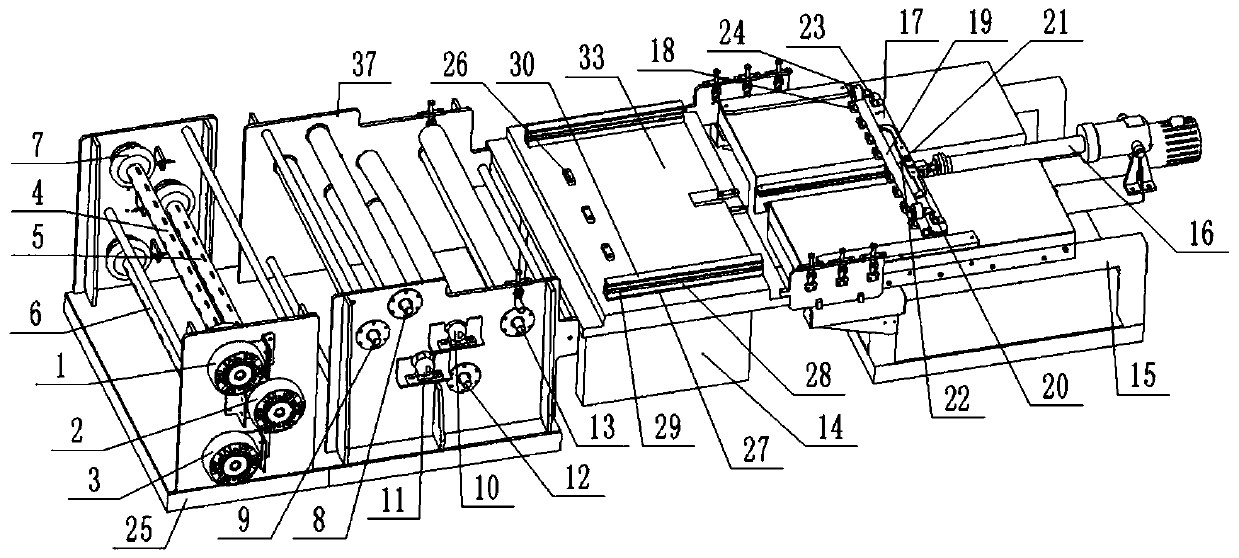

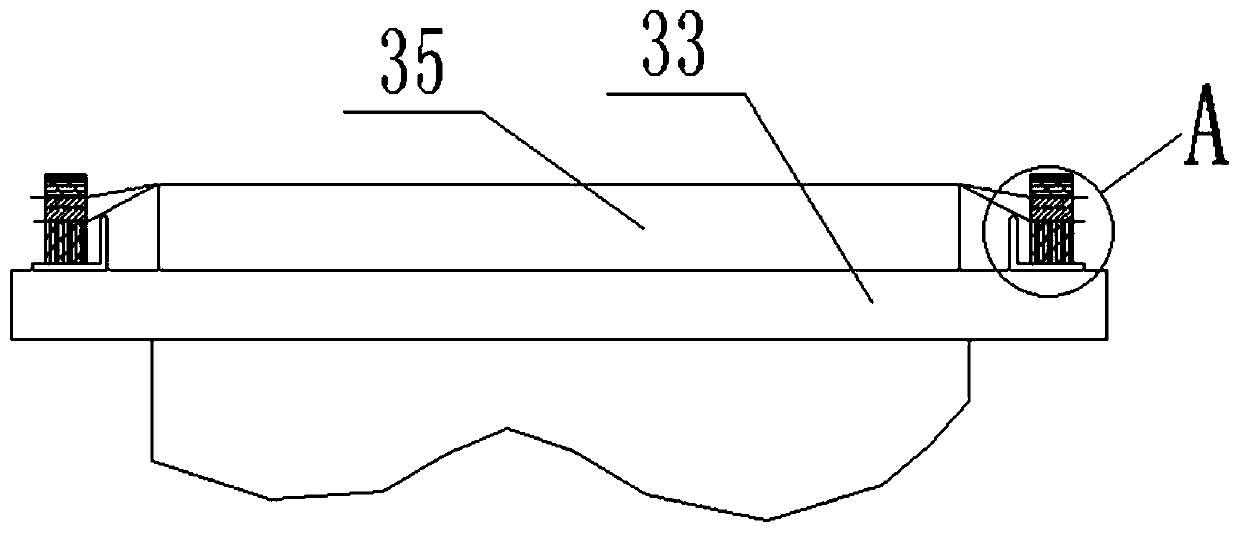

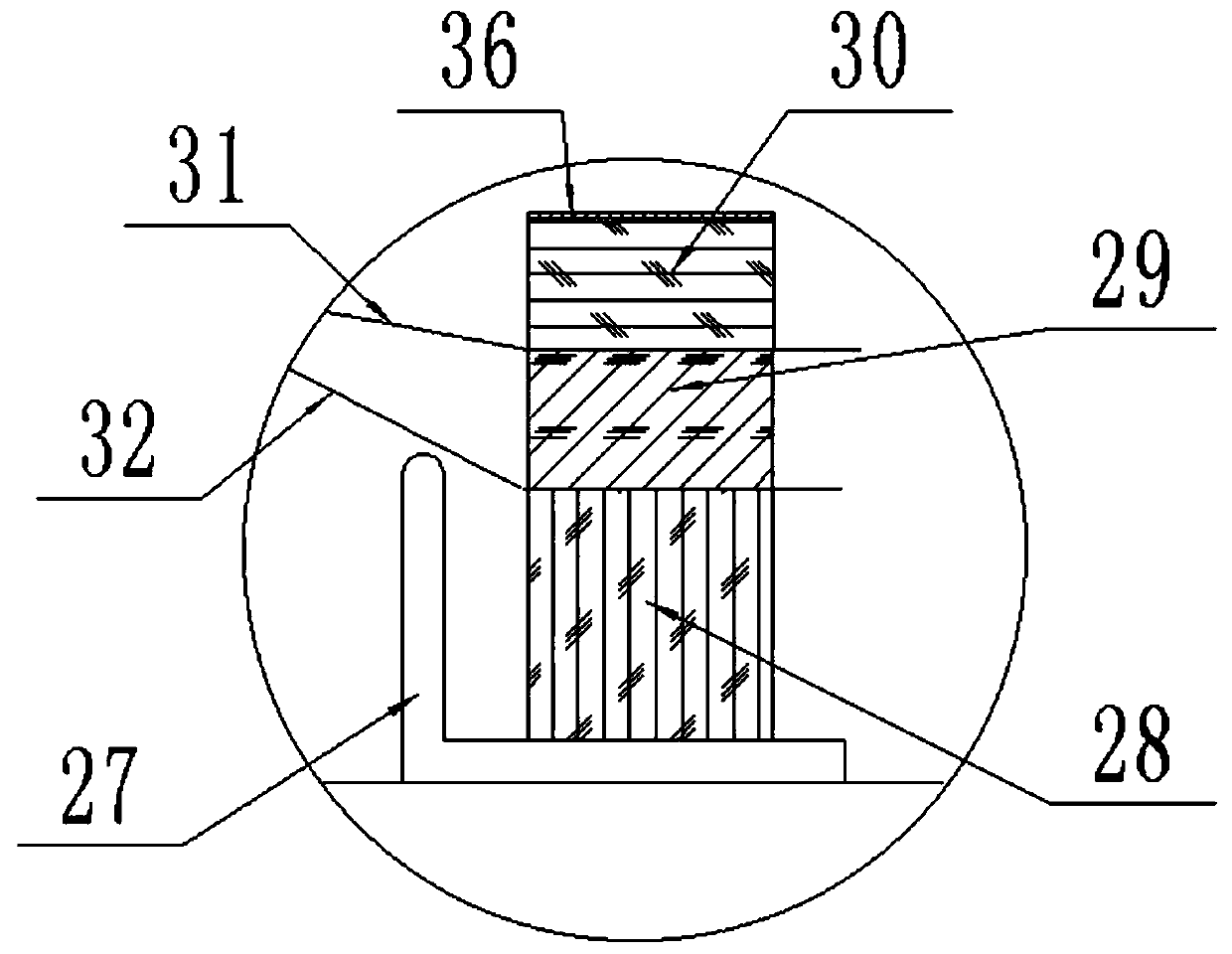

[0018] Such as Figure 1-5 As shown, an adjustable constant force screen making device includes a grid frame 25, and the grid frame 25 is sequentially provided with a first inflatable shaft 4, a second inflatable shaft 5 and a third inflatable shaft 6 from top to bottom, The two ends of the first inflatable shaft 4, the second inflatable shaft 5 and the third inflatable shaft 6 are all connected to the grid 25 through the safety chuck 7, and the grid 25 is equipped with a brake for braking the first inflatable The first magnetic powder brake 1, the second magnetic powder brake 2 and the third magnetic powder brake 3 of the torque of the shaft 4, the second air expansion shaft 5 and the third air expansion shaft 6, the right side of the grid frame 25 is fixed with a guide frame 37, the guide frame 37 The upper hinge is connected with the first upper rubber roller 8 and the second upper rubber roller 9, the first middle rubber roller 10 and the second middle rubber roller 11 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com