Automatic hot press sintering system and method for diamond tool bits

A technology of diamond cutter head and hot pressing sintering, which is applied in the direction of metal processing equipment, grinding equipment, grinding/polishing equipment, etc., can solve the problems of production process and production efficiency, and the inability to realize synergistic and effective work, and achieve improvement Production efficiency, avoiding loose and falling phenomena, and the effect of accurate grasping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

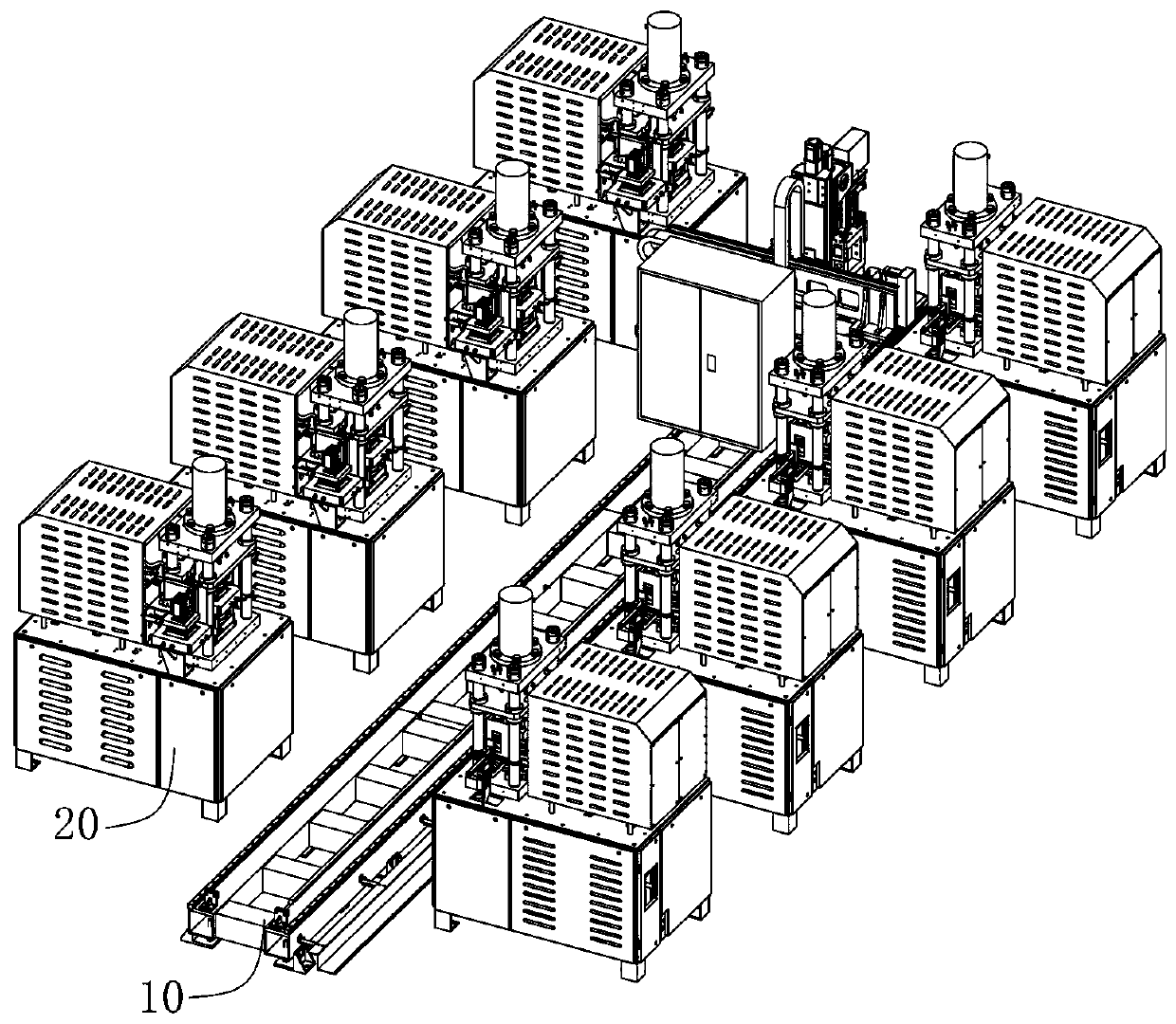

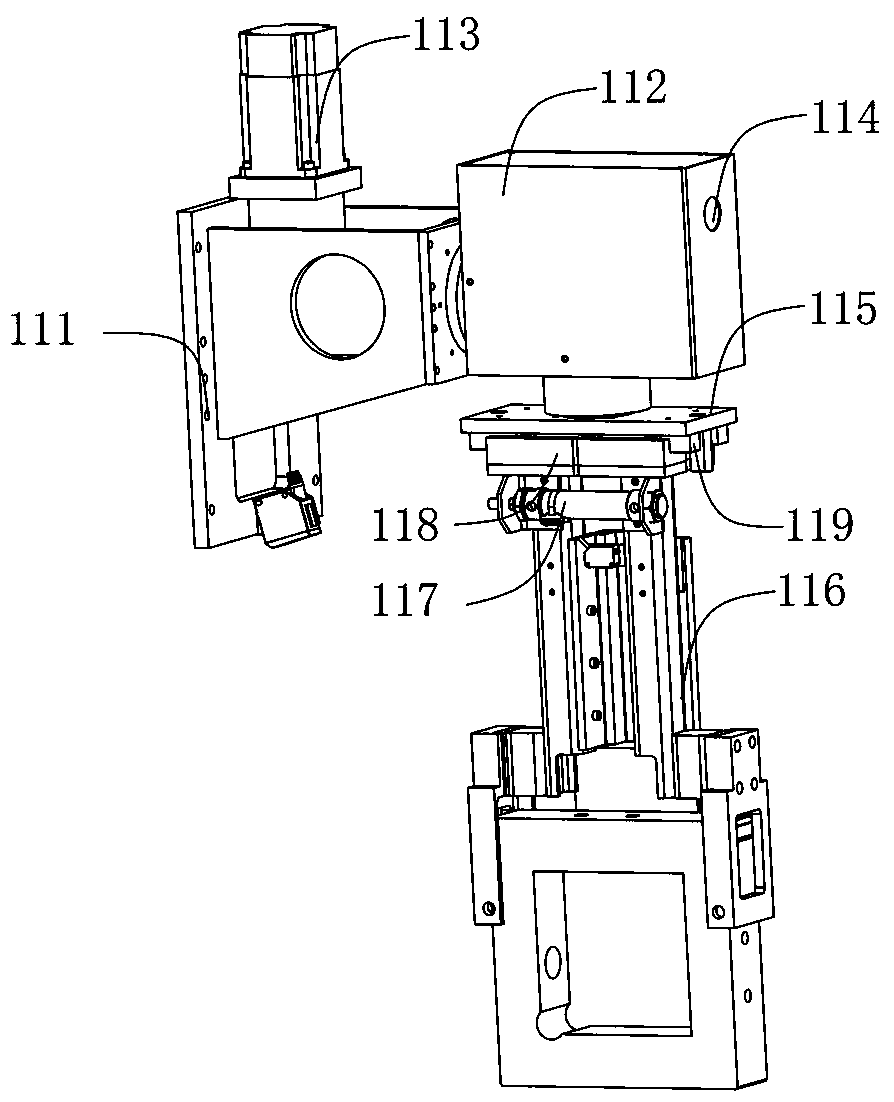

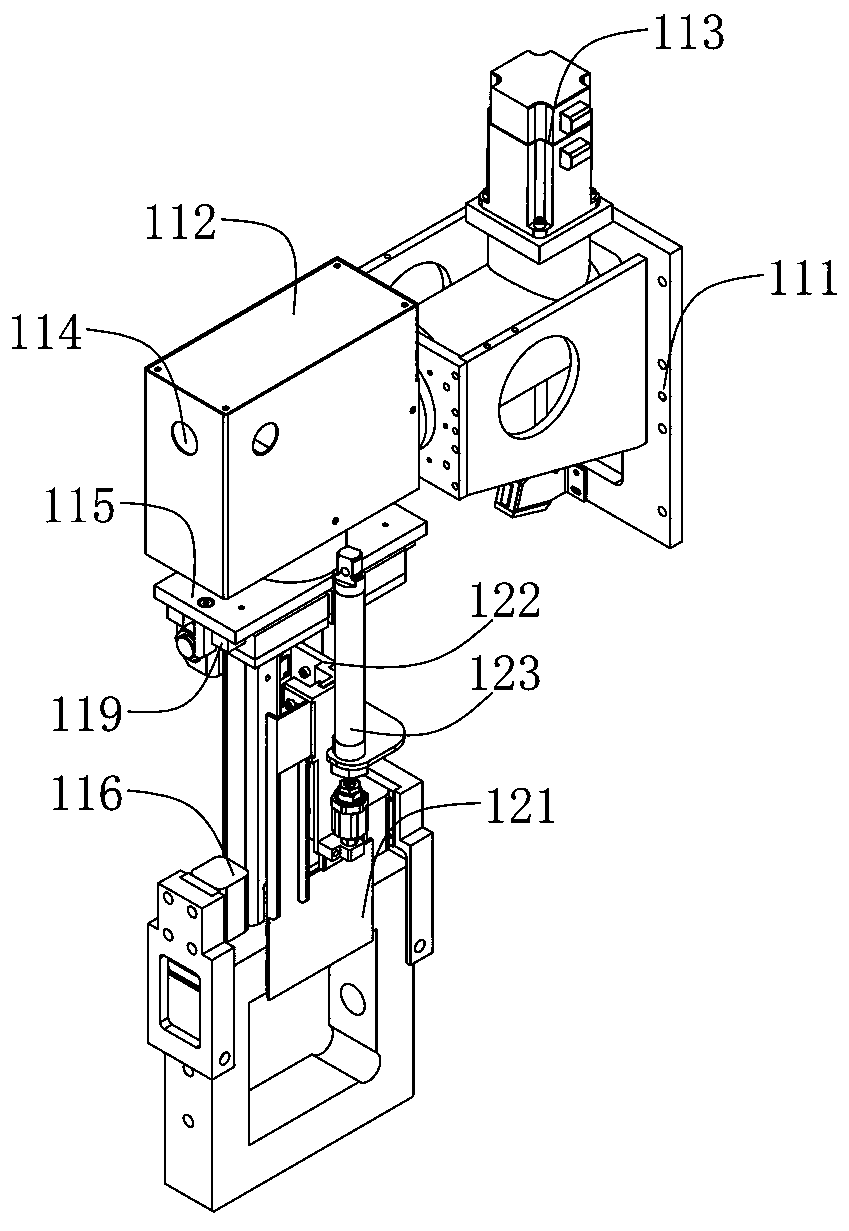

[0042] An automatic hot-press sintering system for a diamond cutter head of the present invention comprises a mold frame grasping manipulator, a hot-press sintering machine and a control system, and the hot-press sintering machines are multiple, and are respectively arranged at the ends of the mold frame grabbing manipulator One side or both sides; wherein, the mold frame grabbing manipulator includes: a walking ground rail; a base, the base is matched with the walking ground rail, and reciprocates along the walking ground rail; a transmission truss, the The transmission truss is a three-dimensional truss, which includes an X-axis truss, a Y-axis truss, and a Z-axis truss; The frame grabbing device moves in the directions of X, Y, and Z axes; and the mold frame tray, the mold frame tray is matched and placed on the base, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com