Method and system for spraying and granulating multiple batches of colored mixed liquid in fluidized bed

A liquid compounding and colored technology, applied in the direction of powder suspension granulation, can solve the problems of chromatic aberration content, high granulation efficiency and low cost of granular products, and achieve the effect of reducing mixing time, high granulation efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: as figure 1 As shown, multiple batches of colored mixed liquid are mixed into the fluidized bed granulation method, including:

[0028] Step A: Use the feed pipe connected to the inlet of the mixing tank to transport multiple batches of colored mixed dosing to the mixing tank for mixing, wherein the number of batches of colored mixed dosing is not less than 3 batches, and the colored mixed dosing is in a liquid state The mixed solution that meets the requirements of the proportion range obtained by mixing raw materials and raw material carriers. The mixing tank has the function of stirring and mixing. It is a common device on the market, and no specific introduction is given here;

[0029] Step B: using a discharge pipeline connected to the outlet of the mixing tank to transport the mixed solution to a fluidized bed for spray granulation and drying.

[0030] In this method, all batches of colored mixed liquids are uniformly mixed first, and then the unifo...

Embodiment 2

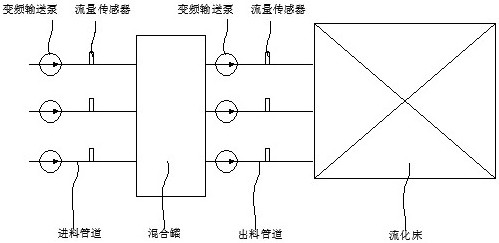

[0032] Embodiment 2: multiple batches of colored mixed liquid into the fluidized bed granulation system, such as figure 2 As shown, it includes a mixing tank connected to a plurality of feeding pipelines for transporting colored mixed liquid and a fluidized bed connected to the mixing tank through a discharge pipeline. The mixing tank is used for stirring and mixing, and the fluidized bed For spray granulation, the feed pipe is connected to the inlet of the mixing tank, and the discharge pipe is connected to the outlet of the mixing tank. In this system, all batches of colored mixed liquids are uniformly mixed, and then the uniformly mixed mixed liquid is transported to the fluidized bed for spray granulation. The color of the obtained particles is consistent, and the content of each substance in the particles is also high Within the deviation range of the target content, the granules can be directly packed into the automatic packaging line as finished products, which solves ...

Embodiment 3

[0034] Embodiment 3: Different from Embodiment 2, the system also includes a liquid level sensor arranged in the mixing tank and electrically connected to the controller, the liquid level sensor can monitor the liquid level of the mixing tank in real time, and send the liquid level signal feedback to the controller. The system also includes an alarm device electrically connected to the controller; the controller judges whether the liquid level reaches a specified limit value according to the liquid level signal, and controls the alarm device to act when the liquid level reaches the specified limit value. When the frequency conversion delivery pump fails and is out of control, the mixing tank is prone to overflow and cause production accidents. An alarm device is installed. When the liquid level reaches the specified limit value, the alarm device will activate to remind workers in time and reduce production. Accidents happen.

[0035] A plurality of the feed pipes form at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com