A kind of production process of fiber-reinforced pvc hose

A fiber reinforcement and production process technology, applied in the production process of PVC hoses, can solve the problems of small diameter, insufficient elasticity of PVC hoses, and insufficient structural strength enhancement effect, achieve high coaxiality, improve elastic force and The effect of structural strength and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

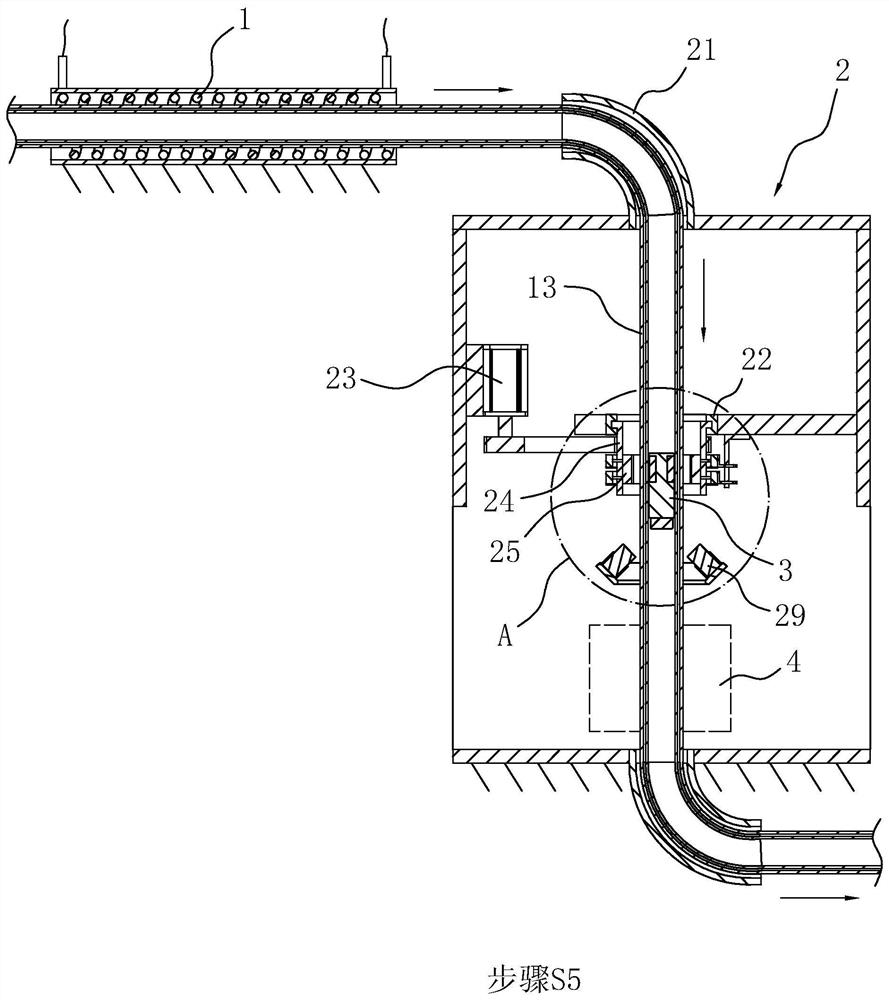

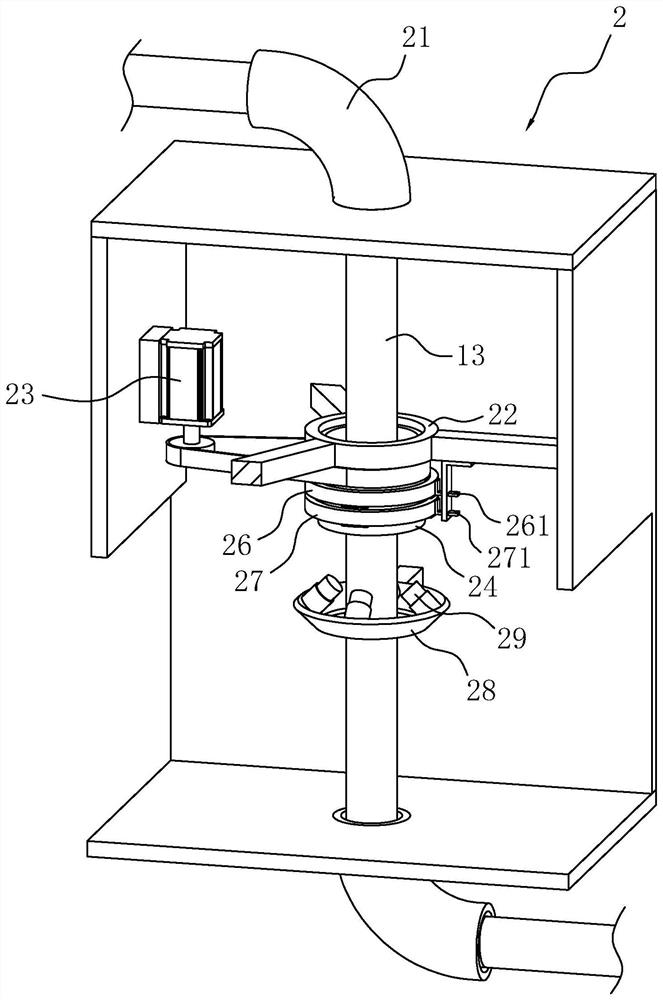

[0042] The invention discloses a production process of a fiber-reinforced PVC hose, which comprises the following steps:

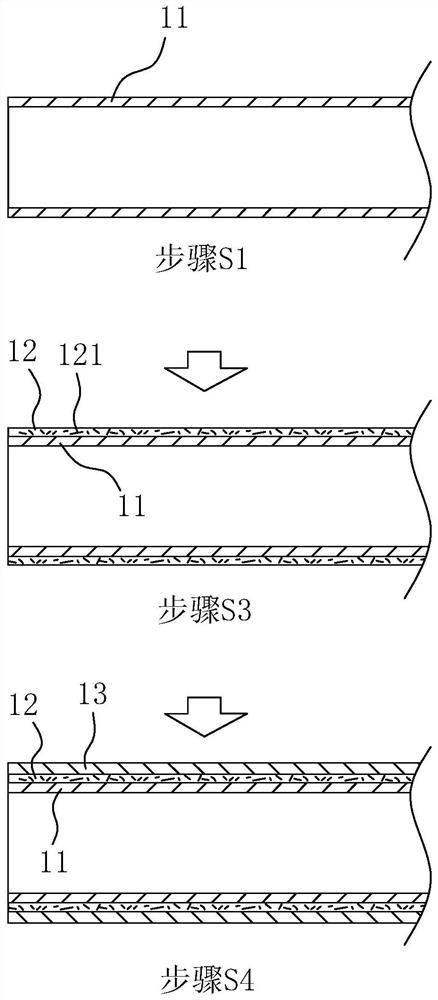

[0043] Step S1: Refer to figure 1 , forming the inner tube 11 by extrusion, and the extrusion is carried out with an extruder.

[0044] Step S2: Take metal fiber 121 made of ferromagnetic material. The metal fiber 121 in this embodiment is iron. Add the metal fiber 121 to hot melt adhesive and stir evenly to form a liquid interlayer material. The mixing process is carried out under heating.

[0045] Step S3: Coating the interlayer material by extrusion molding on the outside of the inner tube 11, the extrusion of the interlayer material is carried out through an extruder, since the metal fiber 121 is very small and can be deformed, the metal fiber 121 will not be stuck in the extruded tube in the extrusion head of the machine. The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com