System and method for producing C5-C19 alkyl ketones

A technology of C5-C19 and alkanones, which is applied in the system field of producing C5-C19 alkanones, can solve the problems of not being effectively utilized, not, and the energy density is only gasoline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of the pervaporation membrane described in the following examples is: drying ZSM-5 at 80°C for 24 hours; pressing the gel forming agent base liquid and curing agent in the polydimethylsiloxane (PDMS) kit Mix with a weight ratio of 10:1 to obtain PDMS membrane-forming liquid; mix ZSM-5 which accounts for 80% of the weight of PDMS with PDMS membrane-forming liquid, suspend ZSM-5 in the PDMS membrane-forming liquid with a stirrer, and centrifuge at 8000r / min After 5 minutes, vacuumize to remove bubbles, then stir to make the ZSM-5 particles uniformly dispersed in PDMS, evenly spread on the glass plate, and dry at 100°C for 3 hours to obtain a pervaporation membrane.

[0064] The catalyst Pd / C described in the following examples was purchased from China Evonik.

[0065] The chemical catalysis method described in the following examples is: combining 5wt% of Pd / C with 12.8gK 3 PO 4 After mixing, it was put into a fixed bed reactor, and 5 mL of toluene was in...

Embodiment 1

[0067] A kind of using glucose medium to produce C 5 -C 19 System and method of alkanone:

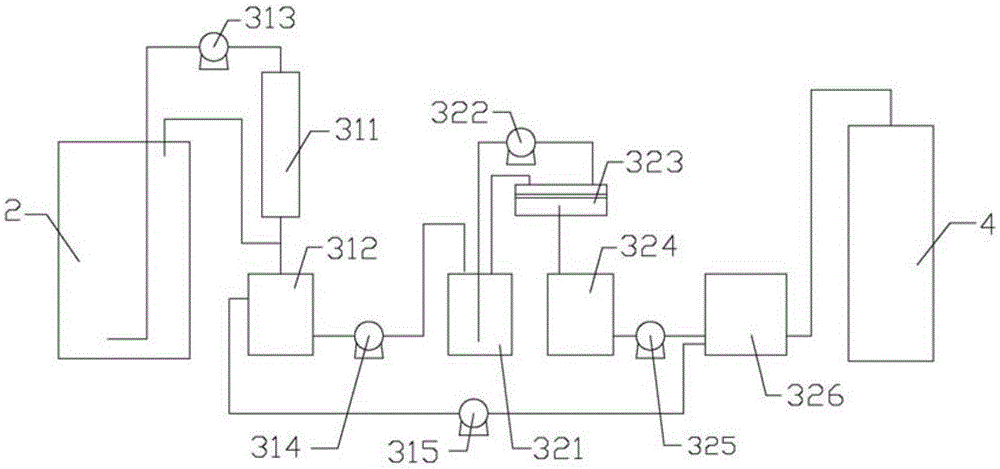

[0068] Such as figure 1 As shown, the system includes a fermentation device 2, a gas stripping purification device, a pervaporation membrane purification device, and a chemical catalytic device 4;

[0069] The gas stripping purification device includes a condenser tube 311, a storage tank I312, a pump I313, a pump II314, and a pump III315;

[0070] The pervaporation membrane purification device includes a heater 321, a pump IV 322, a separation tank 323, a storage tank II 324, a pump V 325, and a storage tank III 326;

[0071] The bottom outlet of the condenser tube 311 is connected with the top inlet of the storage tank I312, the top outlet of the fermentation device 2 is connected between the condenser tube 311 and the connecting pipeline of the storage tank I312, and the top outlet of the condenser tube 311 is connected by a pump I313 is connected to the fermentation device 2. The lower out...

Embodiment 2

[0078] A kind of using glucose medium to produce C 5 -C 19 System and method of alkanone:

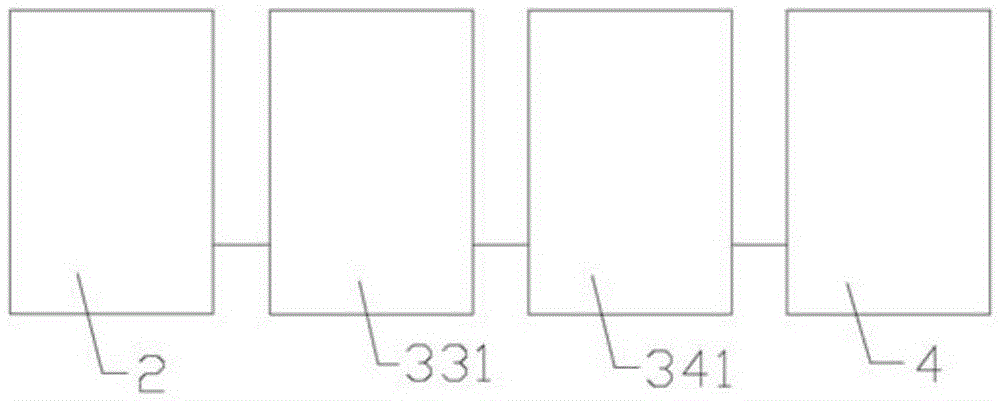

[0079] Such as figure 2 As shown, the system includes a fermentation device 2, a centrifugal device 331, a distillation purification device 341, and a chemical catalytic device 4;

[0080] The fermentation device 2 is connected to the chemical catalyst device 4 through a centrifugal device 331 and a distillation purification device 341 in sequence.

[0081] The method includes the following steps:

[0082] The culture and fermentation of the acetone butanol producing bacteria are carried out according to the above method. After the fermentation is completed, the bacterial cells in the fermentation broth are removed by the centrifugal device 331, and then the butanol, acetone and ethanol in the fermentation broth are purified by the distillation purification device 341 to make Its water content is less than 10%. The product after rectification and purification is mixed with toluene and used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com