Efficient crushing treatment equipment for manufacturing charcoal from carbon powder

A technology of processing equipment and charcoal, applied in grain processing and other directions, can solve the problems of slow crushing, insufficient crushing, poor crushing effect, etc., and achieve uniform crushing, crushing efficiency and high crushing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

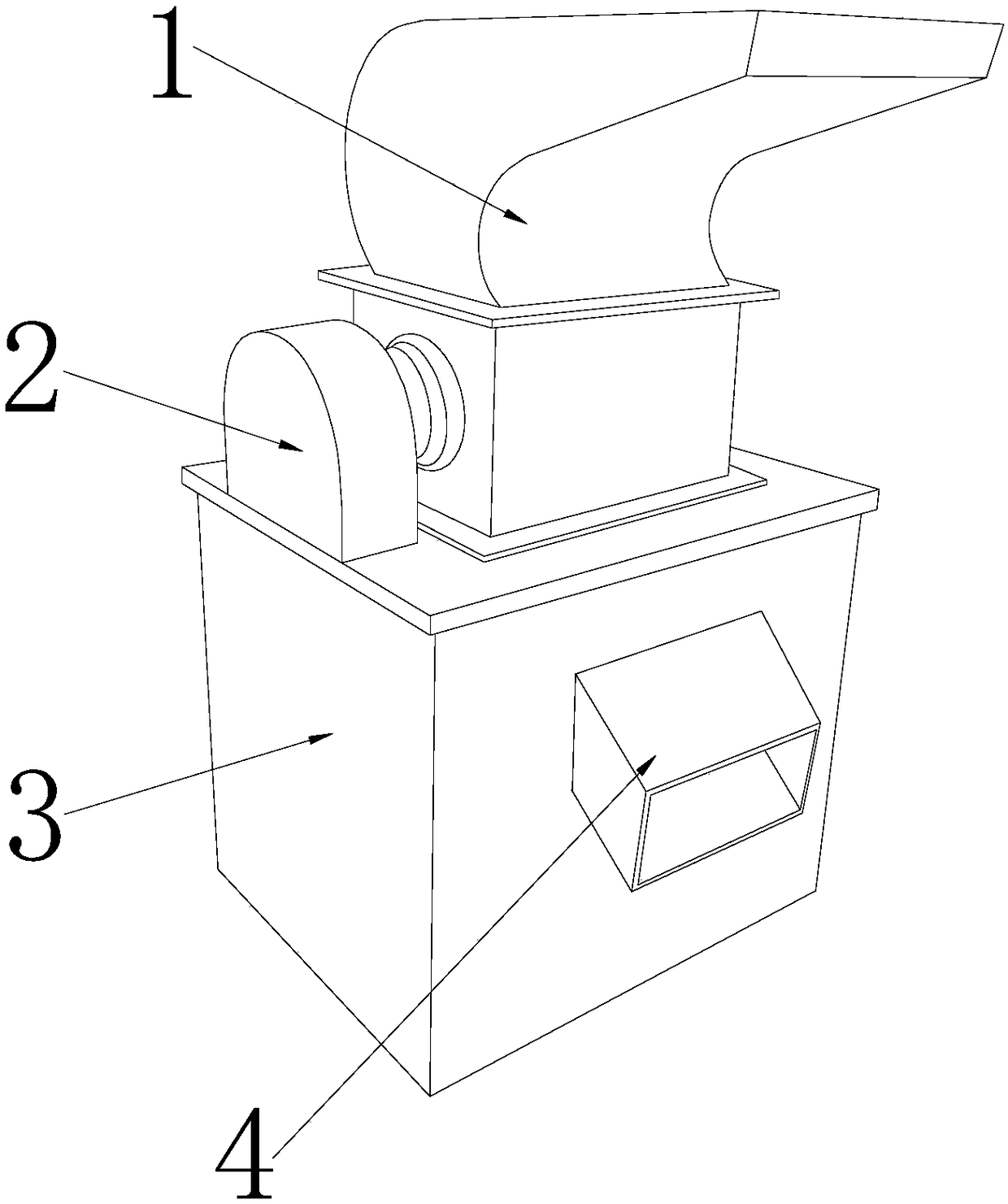

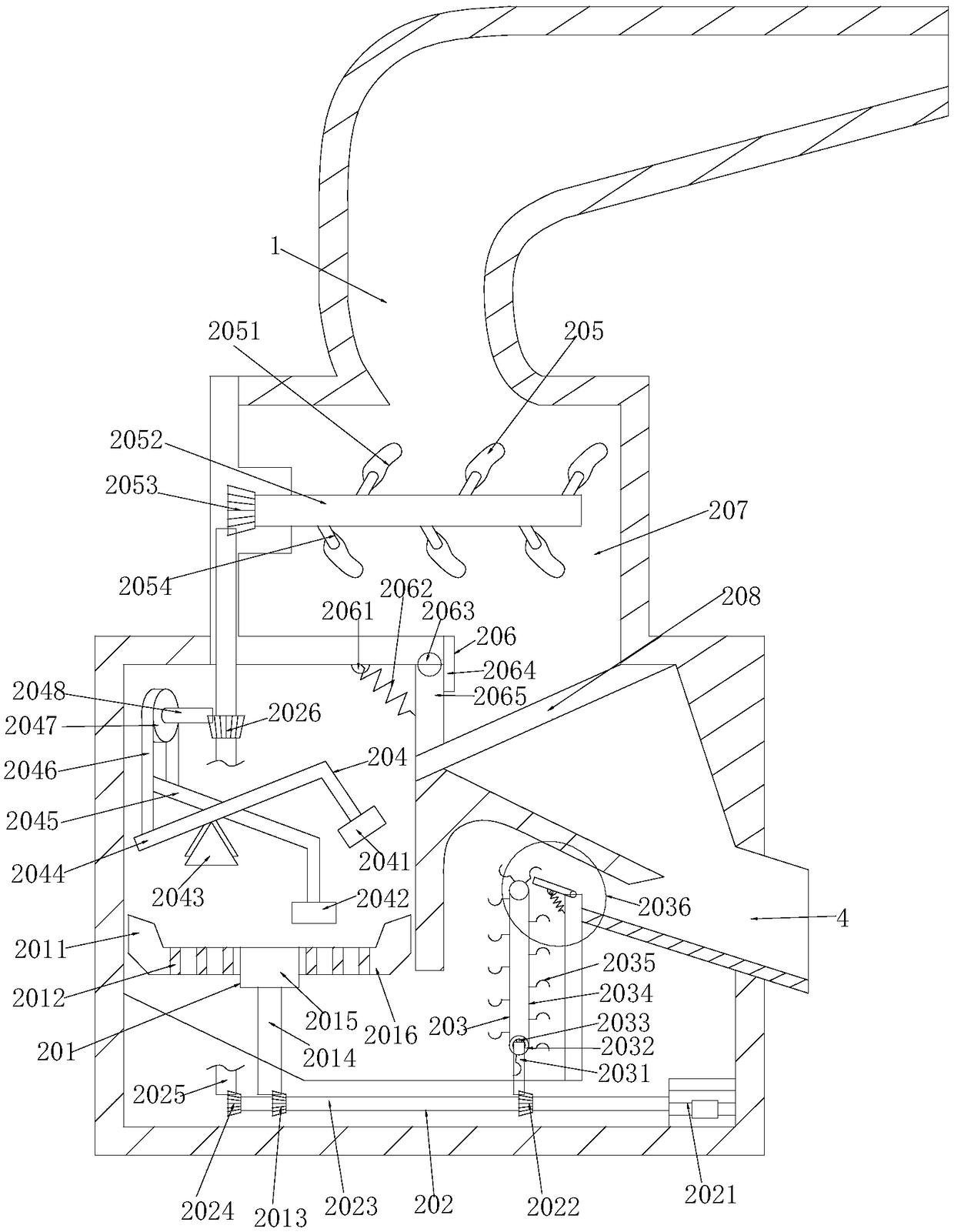

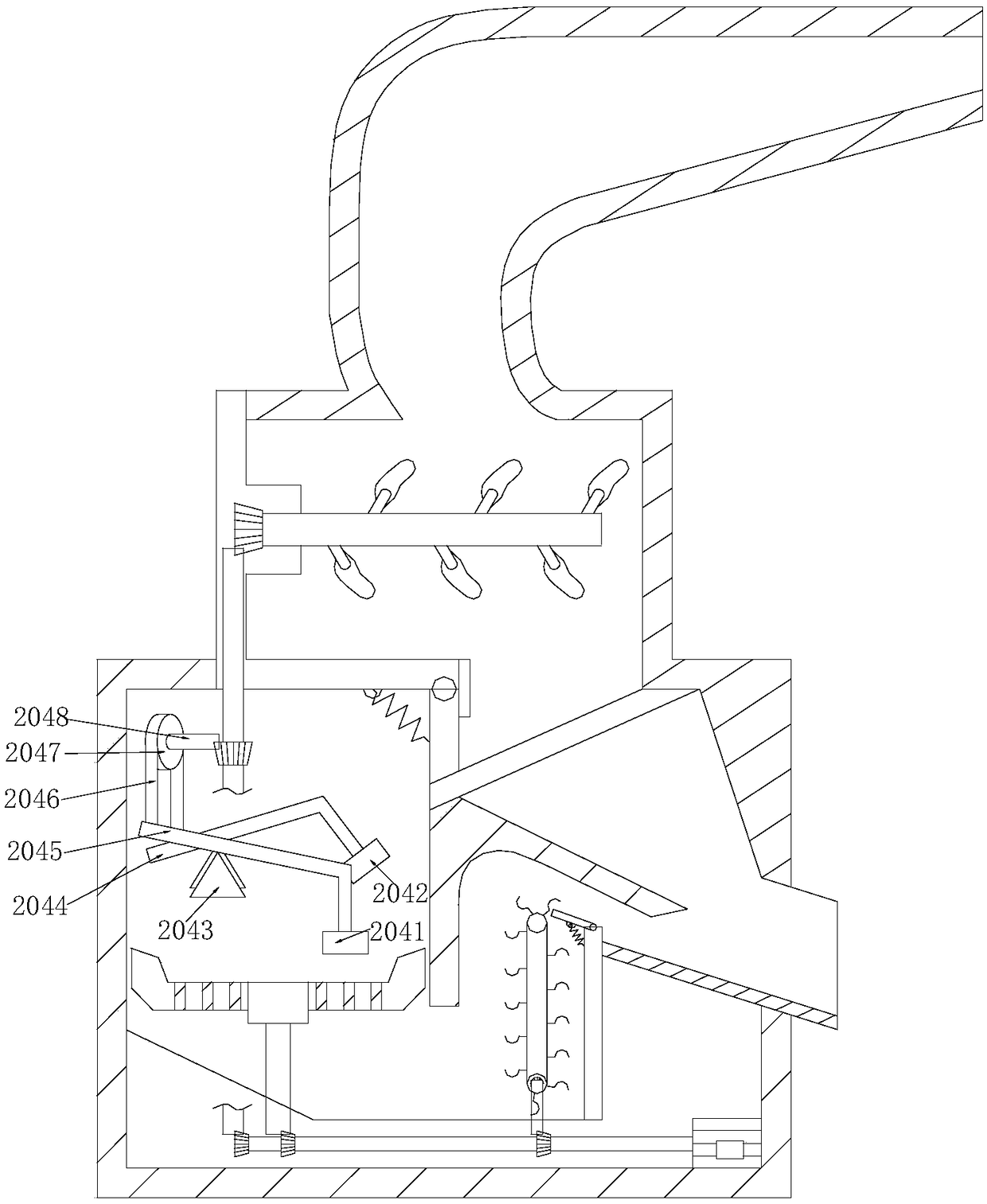

[0027] see Figure 1-Figure 5 , the present invention provides high-efficiency crushing and processing equipment for making charcoal from carbon powder. Its structure includes a feed port 1, a crushing device 2, a shell 3, and a discharge channel 4. The feed port 1 is located on the top of the shell 3 and is connected with the The shell 3 is connected internally, the crushing device 2 is installed in the inner cavity of the shell 3, and the discharge channel 4 is communicated with the shell 3;

[0028] The crushing device 2 is composed of a turntable mechanism 201, a driving mechanism 202, a feeding device 203, a secondary crushing device 204, a primary crushing device 205, a residual particle conveying device 206, a first cavity 207, and a first filter screen 208;

[0029] The secondary crushing device 204 and the turntable mechanism 201 are set up in an up-and-down structure and are mechanically connected. The secondary crushing device 204 is mechanically coordinated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com