Nacelle thrust reverser and nacelle equipped with at least one reverser

A thrust reverser, engine nacelle technology, applied in the direction of machines/engines, detachable inspection boards of power units, mechanical equipment, etc., can solve problems such as increasing the weight of the nacelle, increasing the size of the nacelle and related hoods, and complicating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

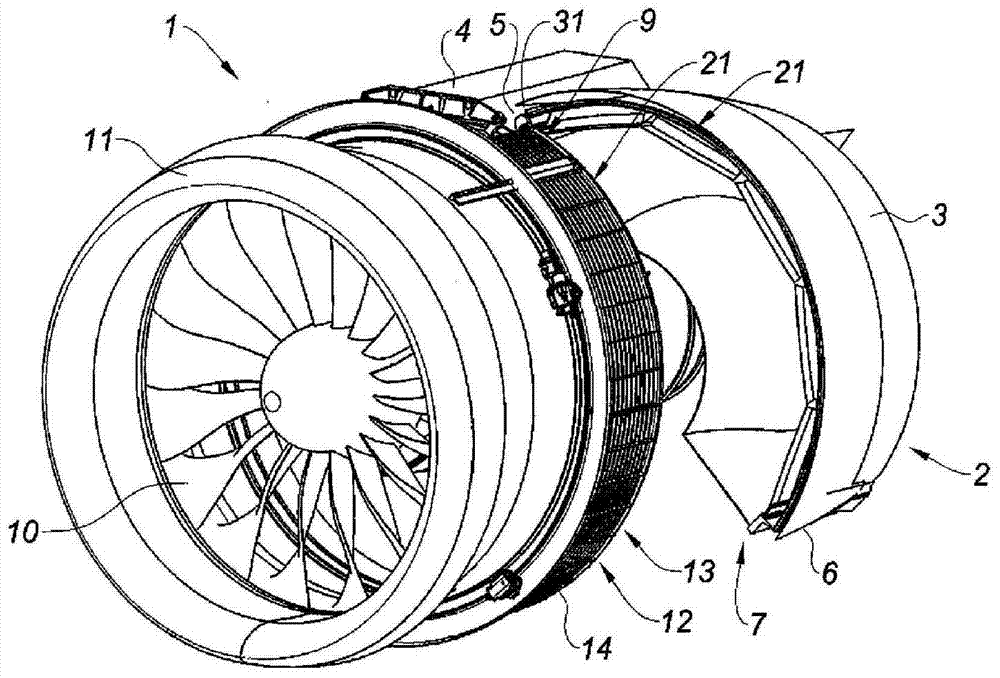

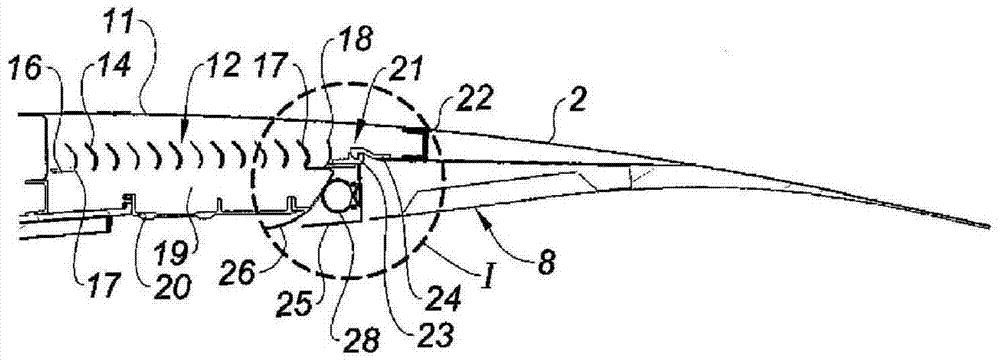

[0041] refer to figure 1 , which represents a nacelle 1 of a turbojet engine (not shown), placed in a maintenance configuration with an outer cowl 2 realized with two half-cowls 3 connected to the upper part 4 of the nacelle, which is not represented in In the accompanying drawings, it is intended to function as a connection interface with the engine pylon.

[0042] In this figure it can be seen that it is in fact a nacelle 1 of D-shaped construction type, thus having two half-cowls 3 hinged on its upper part by means of hinges 5 and comprising at their lower ends 6 for attaching said half-cowls 3 Devices that lock together / unlock.

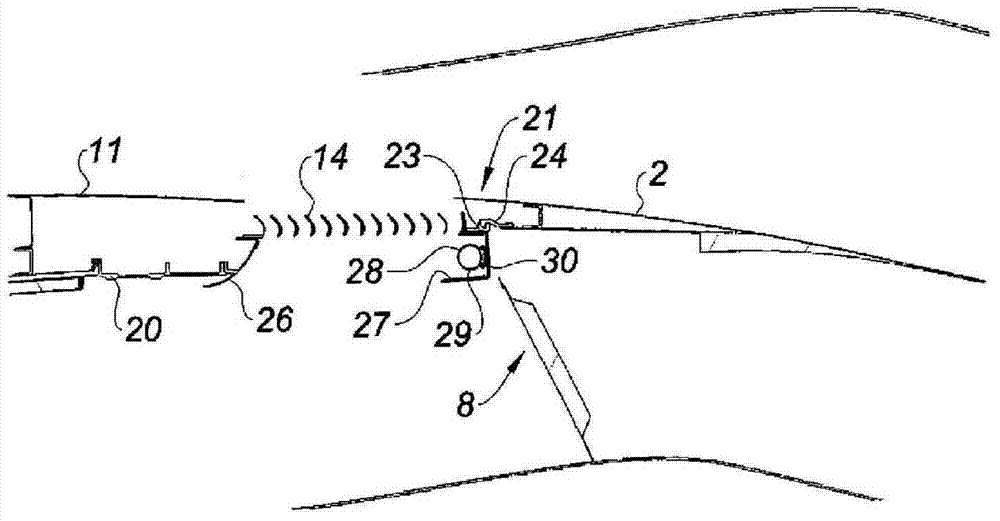

[0043] The downstream frame can perform a translational movement backwards by means of the first drive 8 connected thereto.

[0044] The housing 2 is capable of a rearward translational movement, and also when said housing 2 is unlocked, second drive means 9 enable rotational displacement of each half housing 3 .

[0045] in the figure 1 The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com