A waste heat recovery evaporative crystallization device

A waste heat recovery, evaporation and crystallization technology, applied in the direction of evaporation separation crystallization, spray evaporation, solution crystallization, etc., can solve the problems of secondary separation and purification difficulties, poor thermal convection effect, poor fluidity of solid materials, etc., and achieve high energy utilization efficiency, Large heat flux and excellent heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

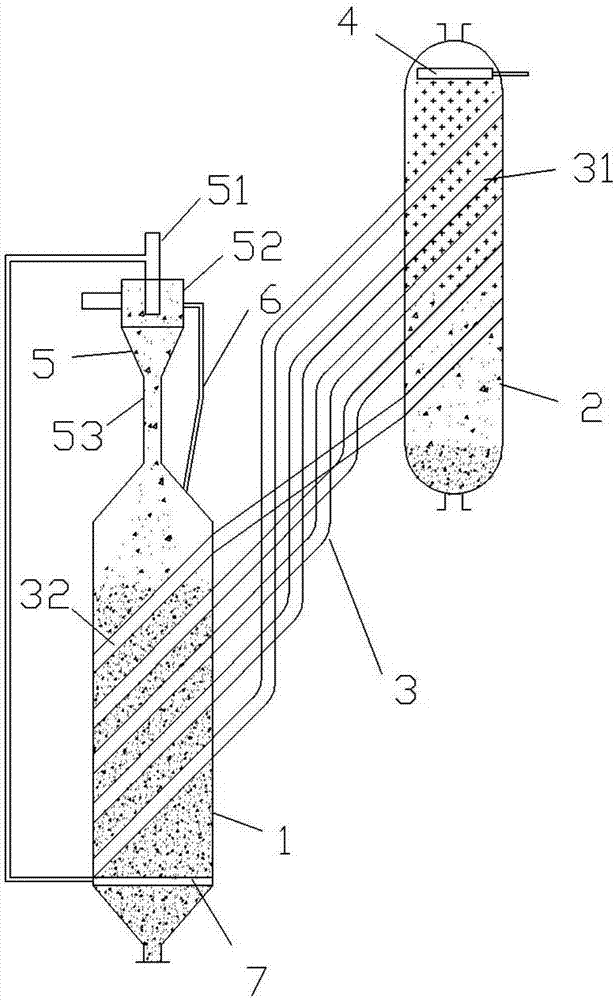

[0013] A waste heat recovery type evaporation and crystallization device, characterized in that it includes an evaporation kettle 2 and a waste heat recovery tower 1, a heat pipe 3 is arranged in the waste heat recovery tower 1, the hot end 32 of the heat pipe 3 is arranged in the waste heat recovery tower 1, and the heat pipe 3 The cold end 31 is set in the evaporator 2, the top of the waste heat recovery tower 1 is provided with a cyclone separator 5, the ash outlet 53 of the cyclone separator 5 is directly connected with the inner cavity of the waste heat recovery tower 1, and the top of the evaporator 2 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com