Tire thermocuring flow production line

A thermal curing and production line technology, which is applied to tires, household appliances, and other household appliances, can solve the problems of air pollution in production areas, inability to guarantee product consistency, and heat loss in tanks, so as to ensure thermal curing time and avoid Effect of heat dissipation and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

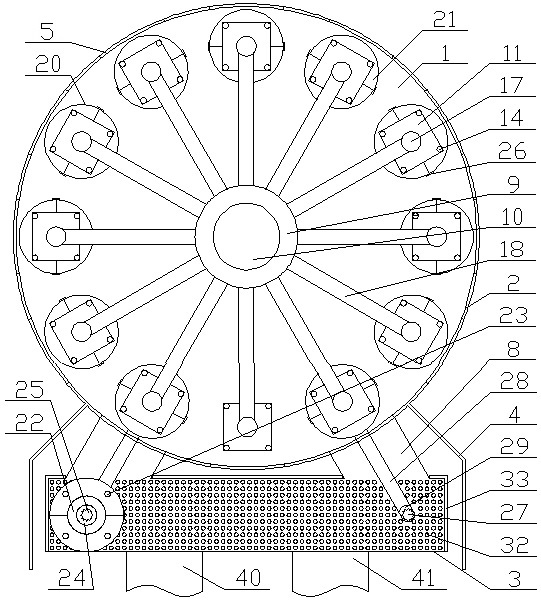

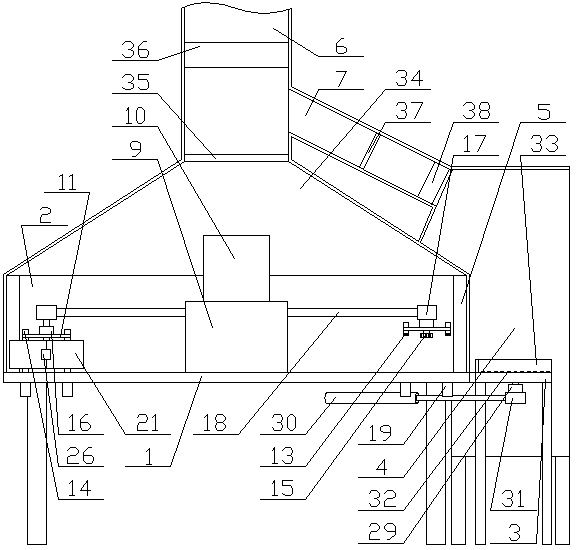

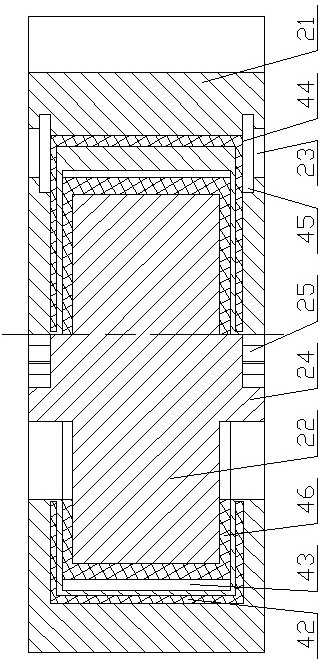

[0035] combine Figure 1~Figure 3 It can be seen that the thermal curing production line for tires includes a work station 1. The center of the top surface of the work station 1 is provided with a vertical shaft. The top of the vertical shaft is fixedly connected with a station rotating motor 10. The output shaft of the rotating motor 10 is fixedly connected with the rotating shaft sleeve 9 which is horizontally rotated around the axis of the vertical shaft and is sleeved on the outer side wall of the vertical shaft. The outer side wall of the rotating shaft sleeve 9 is fixedly connected with a plurality of connecting rods 18. 18 is evenly distributed with the axis of the vertical shaft as the center, one end of the connecting rod 18 away from the rotating shaft sleeve 9 is fixedly connected with a lifting device A17, and the bottom of the lifting device A17 is connected with an epicyclic plate 11 for the epicyclic tire heat curing mold 20 The bottom of the turntable 11 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com