Perlite insulation board pressing machine

A perlite insulation board and plate pressing machine technology, applied in the direction of ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of inability to produce insulation boards, inability to transport materials, etc., to achieve orderly stacking and reduce workload , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-8 The application is described in further detail.

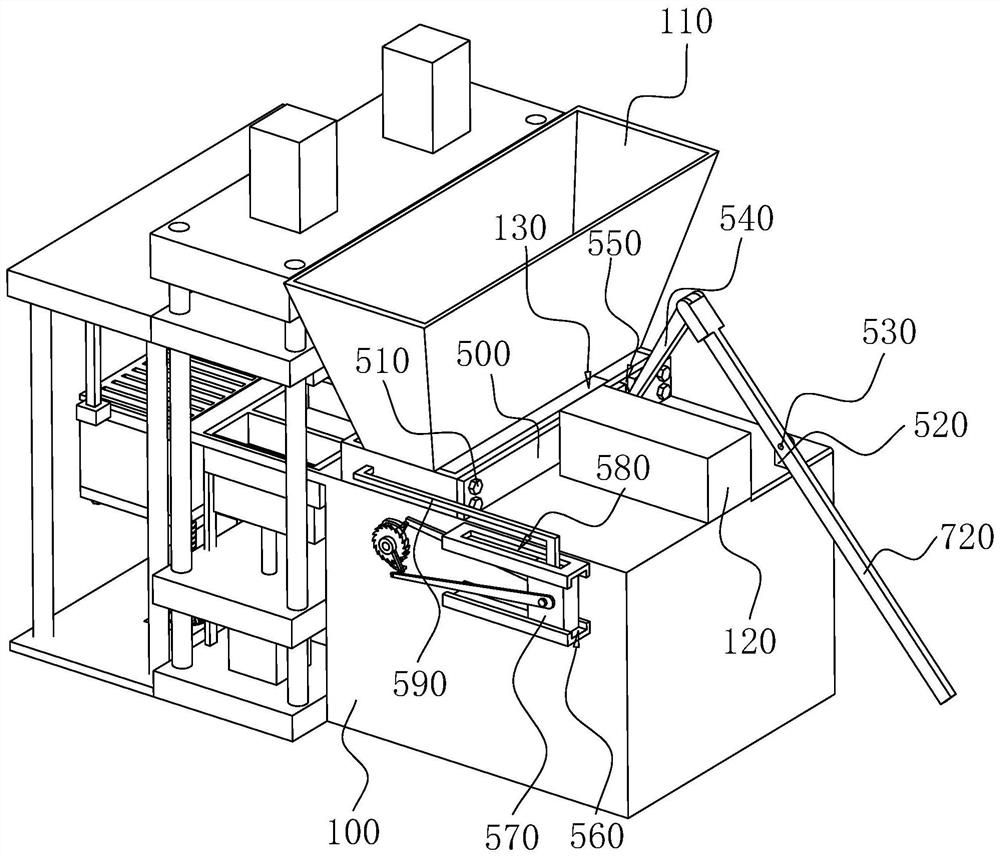

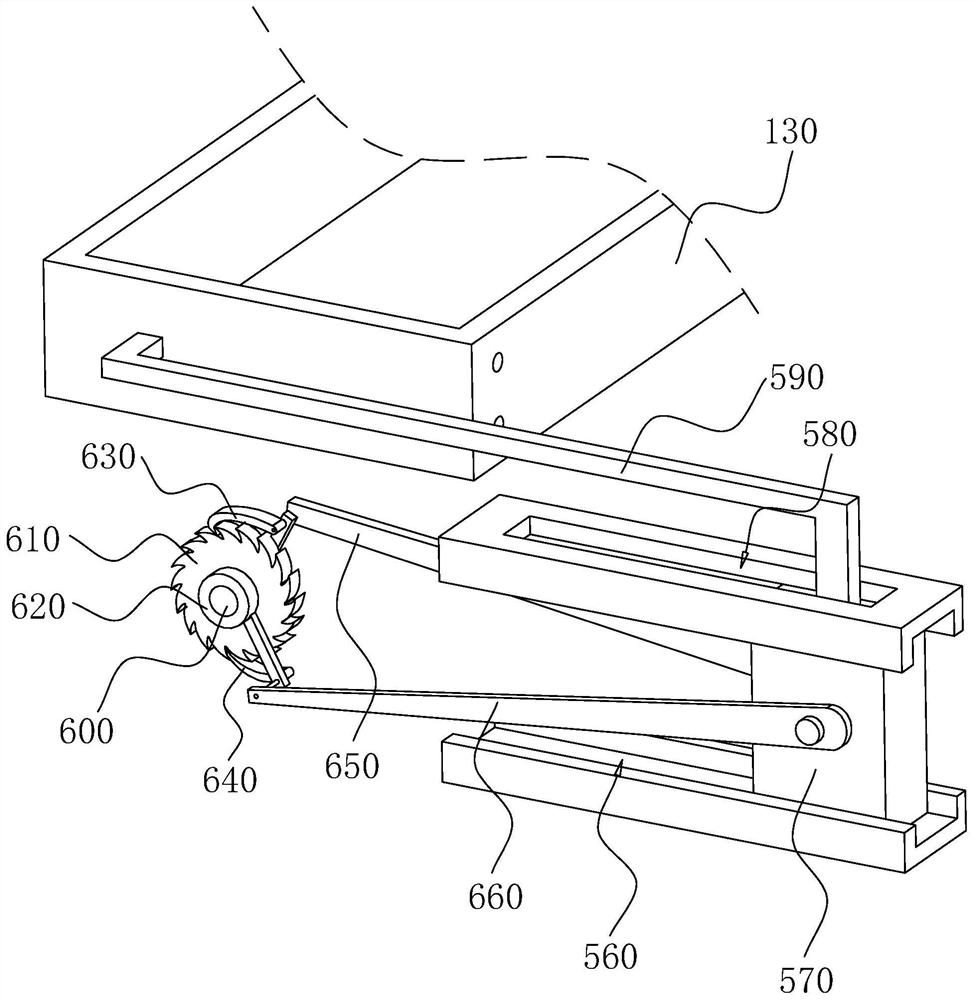

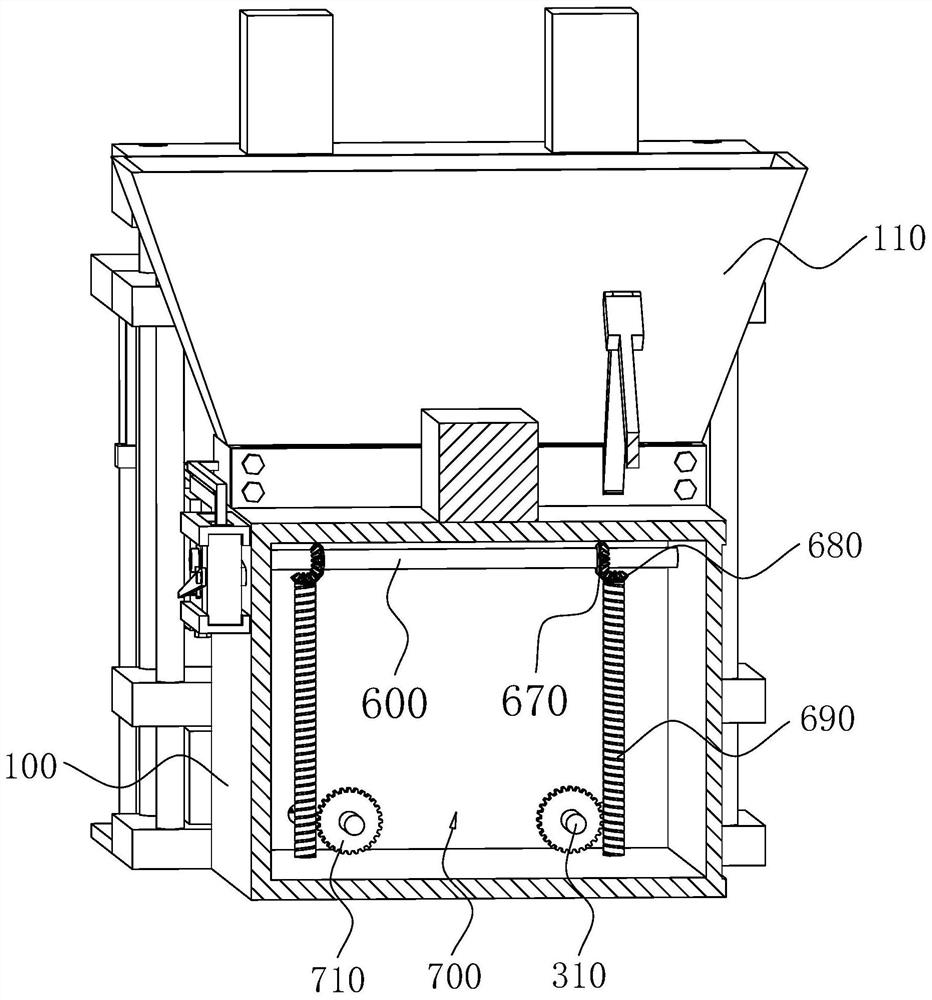

[0047] The embodiment of the present application discloses a perlite insulation board pressing machine. refer to figure 1 , the press machine includes a workbench 100, a feed device installed on the workbench 100 and a discharge device installed on one side of the workbench 100, the feed device includes a feed hopper 110, and the feed hopper 110 is fixedly connected to the workbench 100 superior. The feeding device further includes a third hydraulic cylinder 120 fixedly connected to the top surface of the workbench 100 , and the third hydraulic cylinder 120 is located at one side of the feeding hopper 110 . The feeding device further includes a feeding frame 130 slidably connected to the top surface of the workbench 100 , and a first connecting member is provided between the feeding frame 130 and the third hydraulic cylinder 120 .

[0048] refer to figure 1 , the first connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com