New method for preparation of plant oil fatty acid ethyl ester

A technology of fatty acid ethyl ester and vegetable oil, applied in the direction of fatty acid esterification, etc., can solve the problems affecting industrialization, large-scale process, reaction speed influence, reaction rate decrease, etc., to achieve excellent strengthening reaction effect, reduce energy consumption, reduce reaction effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

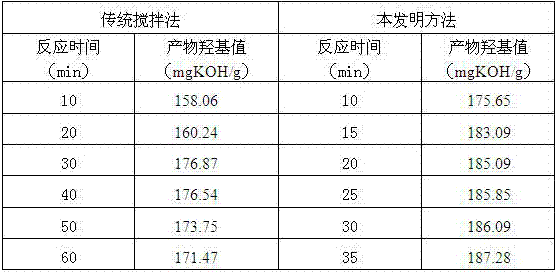

Image

Examples

Embodiment 1

[0014] Embodiment 1: a kind of novel method preparing vegetable oil fatty acid ethyl ester, comprises the following steps:

[0015] (1) Take 50g of cottonseed oil and preheat it to 70°C in a constant temperature water bath.

[0016] (2) Weigh a certain amount of KOH (1.25% of the weight of cottonseed oil) into a certain amount of anhydrous ethanol (the molar ratio of anhydrous ethanol to cottonseed oil is 10:1), and use ultrasonic treatment for 4min to 6min The KOH is completely dissolved in ethanol, and the power of the ultrasonic wave is 200W.

[0017] (3) Pour the preheated cottonseed oil, KOH and absolute ethanol dissolved by ultrasonic waves into a 250ml three-neck flask at the same time, and then connect the hydrodynamic cavitation device to circulate and react at 70°C for 15min.

[0018] (4) After the reaction, 0.5 mol / L dilute hydrochloric acid was added dropwise to adjust the pH value of the product to neutral, and rotary steamed at 70°C for 30 minutes to obtain vege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com