Green and environment-friendly white carbon black and caustic soda circulation combined production method

A green and environmental-friendly, joint production technology, applied in the direction of silica, chlorine/hydrogen chloride, electrolysis process, etc., can solve the problems of high production cost, backwardness, large water consumption, etc., and achieve simple production equipment, increase economic value, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

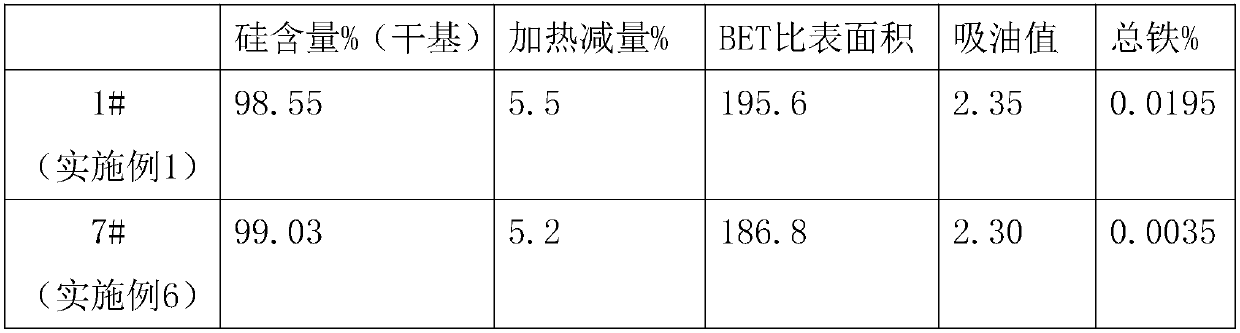

Embodiment 1

[0047] (1) Add 600L to the 1000L reactor with a concentration of 1.21~1.22g / cm 3 , a sodium silicate solution with a modulus of 3.3, heat up to 85°C, stir at a rate of 80 rpm, then add hydrochloric acid with a concentration of 15%, adjust the pH value to 10.5, put in the remaining sodium silicate solution within 60 minutes and continue to add Hydrochloric acid, adjust the pH value to 5.5, heat preservation and aging for 30 minutes to obtain a suspension containing silica precipitation, and the suspension is subjected to solid-liquid separation by a filter press to obtain silica precipitation filter cake and sodium chloride solution;

[0048] (2) the silica precipitated filter cake is washed and pulped, dried, pulverized and packaged to obtain 1# product white carbon black;

[0049] (3) described sodium chloride solution obtains mass concentration as 12% sodium chloride solution and a large amount of pure water through RO membrane treatment twice, and described pure water retur...

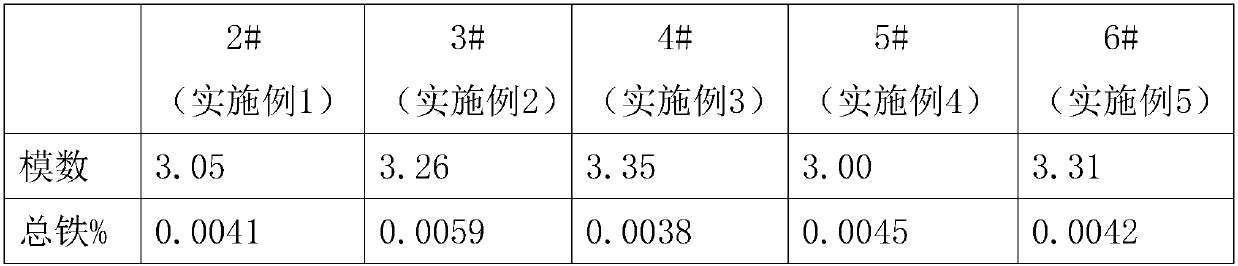

Embodiment 2

[0054] Steps (1)-(5) are the same as above,

[0055] (6) In a 5L pressure vessel, add 1kg of 200-mesh quartz sand, add 0.7kg of sodium hydroxide solution with a mass concentration of 20%, heat up to 143°C, pressurize to 0.4Mpa, and react for three hours to obtain 3# product Sodium silicate solution;

Embodiment 3

[0057] Steps (1)-(5) are the same as above,

[0058] (6) In a 5L pressure vessel, add 1kg of 200 mesh quartz sand, add 0.7kg of sodium hydroxide solution with a mass concentration of 20%, heat up to 143°C, pressurize to 0.4Mpa, react for three hours, and constantly shake the pressure vessel , make 4# product sodium silicate solution;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com