Environment-friendly casting mold capable of recovering waste heat

A waste heat recovery and casting mold technology, which is applied in the field of casting molds, can solve problems such as unreasonable utilization of resources, polluting the working environment, and waste of solution waste heat, and achieves scientific and reasonable mechanism, improved heat dissipation effect, and increased efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

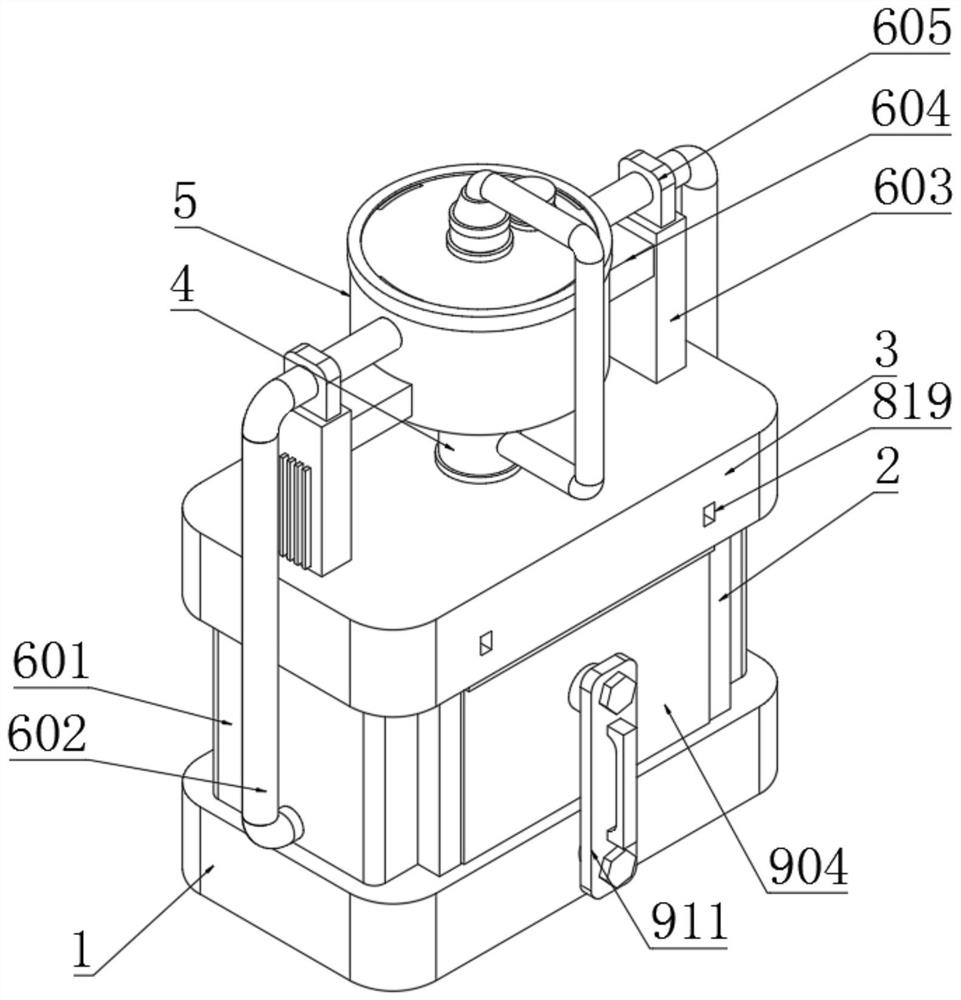

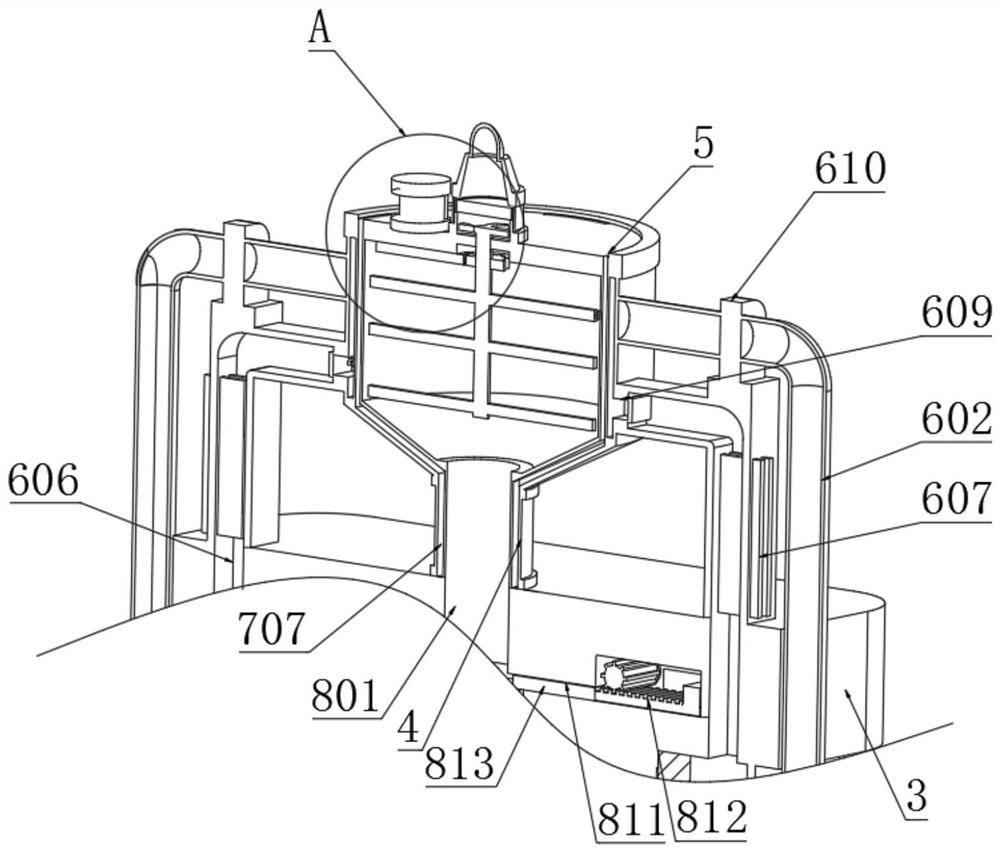

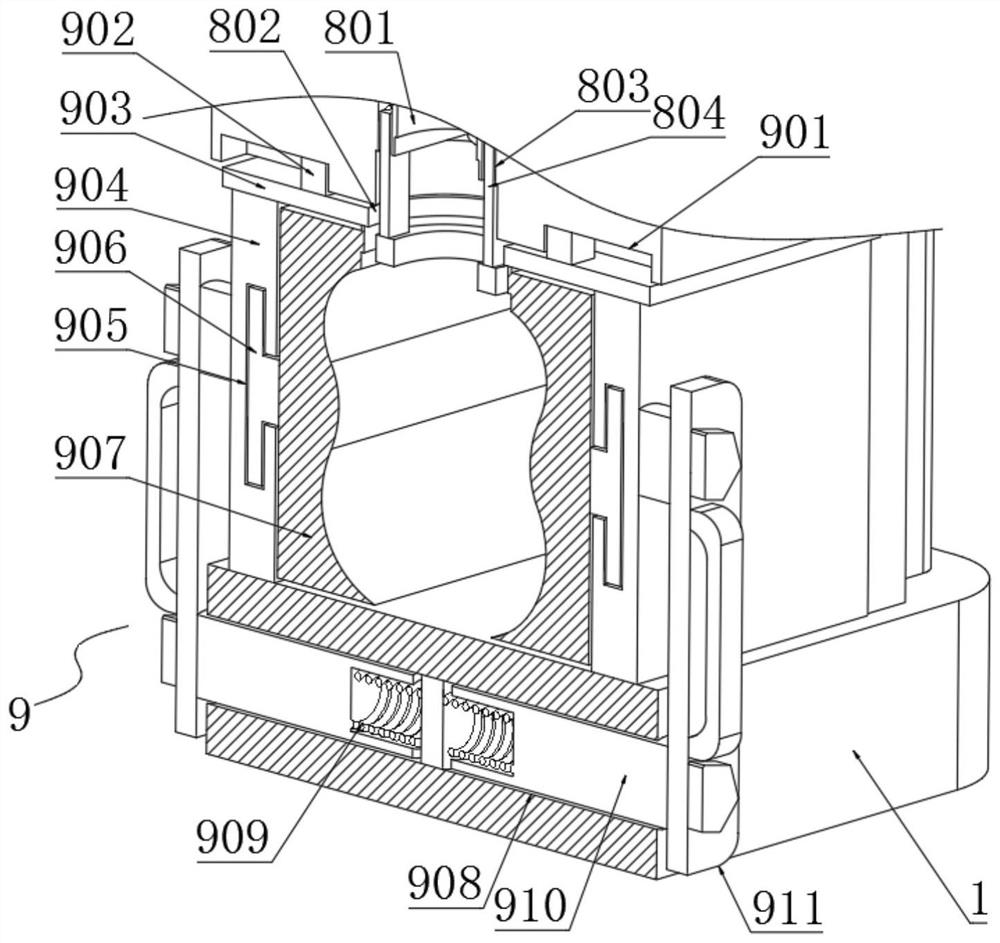

[0035] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, an environmentally friendly casting mold for waste heat recovery, including a lower mold base 1, the top of the lower mold base 1 is symmetrically fixedly connected with a connecting plate 2, and the top of the connecting plate 2 is fixedly connected with an upper mold base 3. An injection tube 4 is fixedly connected to the center of the top of the upper mold base 3, and a heating cylinder 5 is fixedly connected to the top of the injection tube 4;

[0036] The outer end of the heating cylinder 5 is symmetrically and fixedly connected with a cooling and waste heat circulation mechanism 6, the top of the heating cylinder 5 is fixedly connected with an exhaust gas purification and waste heat recovery mechanism 7, the upper mold base 3 is embedded with a solution blocking mechanism 8, and the top of the lower mold base 1 A quick-closing sealing mechanism 9 is installed symmetrically,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com